Professional Documents

Culture Documents

Msa mm01

Uploaded by

amitvohraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Msa mm01

Uploaded by

amitvohraCopyright:

Available Formats

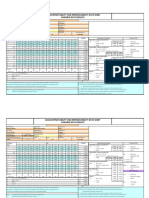

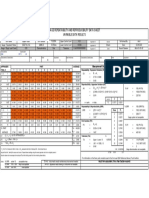

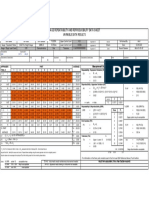

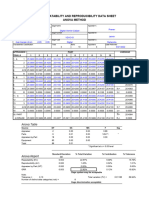

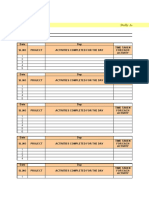

GAGE REPEATABILITY AND REPRODUCIBILITY DATA SHEET

VARIABLE DATA RESULTS

Part Name Support Gear Part Number P210514 Upper Control Limit 42.1 Appraiser A Gaurav Performed By Amit

Gauge / Equipment Name DIGITAL micrometer DMM-01 25-50mm Lower Control Limit 41.938 Appraiser B Bheem Date 13.04.2021

Gauge / Equip. Least Count 0.01 Characteristics Dim Tolerance 0.161999999999999 Appraiser C Sahil Record Number MSA-13-21-02

Characteristic Specification

DIM 41.938 42.1

Characteristic Classification Trials Parts Appraisers Date Performed Characteristic Classification Trials Parts Appraisers

3 10 3 3 10 3

APPRAISER/ PART AVERAGE Measurement Unit Analysis % Tolerance (Tol)

TRIAL # 1 2 3 4 5 6 7 8 9 10 Repeatability - Equipment Variation (EV)

1. A 1 41.946 41.939 41.999 41.956 41.965 41.964 41.989 41.986 41.985 41.993 41.972 EV = R x K1 Trials K1 % EV = 100 (EV/Tol)

2 2 41.948 41.940 41.998 41.955 41.961 41.965 41.984 41.990 41.988 41.994 41.972 = 0.004 x 0.5908 2 0.8862 = 100(0.002/0.027)

3 3 41.944 41.941 41.997 41.951 41.963 41.959 41.986 41.991 41.984 41.990 41.971 = 0.002 3 0.5908 = 8.39

4 AVE 41.95 41.94 42.00 41.95 41.96 41.96 41.99 41.99 41.99 41.99 xa= 41.972 Reproducibility - Appraiser Variation (AV)

5 R 0.00 0.00 0.00 0.01 0.00 0.01 0.00 0.01 0.00 0.00 ra= 0.004 AV = {(xDIFF x K2)2 - (EV2/nr)}1/2 % AV = 100 (AV/Tol)

6. B 1 41.940 41.943 41.995 41.956 41.965 41.964 41.989 41.992 41.985 41.993 41.972 = {(0.000 x 0.5231)^2 - (0.002 ^2/(10 x 3))}^1/2 = 100(0.003/0.027)

7 2 41.945 41.938 41.996 41.956 41.961 41.964 41.984 41.990 41.988 41.994 41.972 = 0.003 = 11.08

8 3 41.942 41.941 41.997 41.956 41.963 41.962 41.986 41.991 41.984 41.990 41.971 Appraisers 2 3

9 AVE 41.94 41.94 42.00 41.96 41.96 41.96 41.99 41.99 41.99 41.99 xb= 41.972 n = parts r = trials K2 0.7071 0.5231

10 R 0.01 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 rb= 0.003 Repeatability & Reproducibility (GRR) % GRR = 100 (GRR/Tol)

11. C 1 41.946 41.939 41.999 41.956 41.965 41.964 41.989 41.986 41.985 41.993 41.972 GRR = {(EV2 + AV2)}1/2 Parts K3 = 100(0.004/0.027)

12 2 41.948 41.940 41.998 41.955 41.961 41.965 41.984 41.990 41.988 41.994 41.972 = {(0.002^2 + 0.003^2)}^1/2 2 0.7071 = 13.90

13 3 41.944 41.941 41.997 41.951 41.963 41.959 41.986 41.991 41.984 41.990 41.971 = 0.004 3 0.5231 Gage system may be acceptable

14 AVE 41.95 41.94 42.00 41.95 41.96 41.96 41.99 41.99 41.99 41.99 x c= 41.972 Part Variation (PV) 4 0.4467

15 R 0.00 0.00 0.00 0.01 0.00 0.01 0.00 0.01 0.00 0.00 rc= 0.004 PV = RP x K3 5 0.4030 % PV = 100 (PV/Tol)

16. PART X= 41.972 = 0.057 x 0.3146 6 0.3742 = 100(0.018/0.027)

AVERAGE 41.94 41.94 42.00 41.95 41.96 41.96 41.99 41.99 41.99 41.99 Rp= 0.057 = 0.018 7 0.3534 = 66.55

17 (ra + rb + rc) / (# OF APPRAISERS) = R= 0.004 Tolerance (Tol) tv 8 0.3375

18 xDIFF = (Max x - Min x) = xDIFF 0.000 Tol = Upper - Lower / 6 0.018355 9 0.3249 ndc = 1.41(PV/GRR)

19 * UCLR = R x D4 UCL 0.010 = ( 42.1 - 41.938 ) / 6 10 0.3146 = 1.41(0.018/0.004)

= 0.027 = 6

* D4 =3.27 for 2 trials and 2.58 for 3 trials. UCLR represents the limit of individual R's. Circle those that are 1.41 0.361538 Gage discrimination acceptable

beyond this limit. Identify the cause and correct. Repeat these readings using the same appraiser and unit as originally used or 0.156 0.04 3.9

discard values and re-average and recompute R and the limiting value from the remaining observations.

For information on the theory and constants used in the form see MSA Reference Manual, Fourth edition.

Notes: % GRR under 10 acceptable msa EV>AV : instruments needs maintenance,improvement needed ndc≥5 then acceptable ( if less than 5 action required)

% GRR 10% - 30% May be acceptable AV>EV : Appraiser needs training or instrument not readable

% GRR over 30% unacceptable

You might also like

- Cubuilt Cepl VC 02 MsaDocument1 pageCubuilt Cepl VC 02 MsaCu Built Engineers Pvt. Ltd.No ratings yet

- Pre Test Civil ServiceDocument17 pagesPre Test Civil ServiceIsaac NewtonNo ratings yet

- La Ex CSAT PYQ SolvedDocument254 pagesLa Ex CSAT PYQ SolvedSiddharth WorkNo ratings yet

- DTMF GenDocument22 pagesDTMF GenMohammad R AssafNo ratings yet

- Gauge Repeatability and Reproducibility Data Sheet Variable Data ResultsDocument5 pagesGauge Repeatability and Reproducibility Data Sheet Variable Data ResultsSharif KhanNo ratings yet

- GR&R Variable October 2019 Check - As FoundDocument5 pagesGR&R Variable October 2019 Check - As FoundxharpreetxNo ratings yet

- CalculationReport PDFDocument10 pagesCalculationReport PDFFikret DavudovNo ratings yet

- Design of Davit Arm & SupportDocument4 pagesDesign of Davit Arm & Supportorode franklynNo ratings yet

- Msa VV401Document1 pageMsa VV401amitvohraNo ratings yet

- Gage Repeatability and Reproducibility Data Sheet Variable Data ResultsDocument1 pageGage Repeatability and Reproducibility Data Sheet Variable Data ResultsamitvohraNo ratings yet

- GR&R (9.50)Document1 pageGR&R (9.50)Quality VenusNo ratings yet

- MSA of Sealing Plate DC-12Document2 pagesMSA of Sealing Plate DC-12RahulNo ratings yet

- Contoh Perhitungan Uji Triaxial: Vertical Dial (Div) Vertical Dial (CM) Vertical Dial (Div)Document26 pagesContoh Perhitungan Uji Triaxial: Vertical Dial (Div) Vertical Dial (CM) Vertical Dial (Div)Yoga PriyantNo ratings yet

- 410-SOL AR: Handheld ReflectometerDocument4 pages410-SOL AR: Handheld ReflectometerBazingaNo ratings yet

- Averages (X Bar Chart) : Gage R AnalysisDocument1 pageAverages (X Bar Chart) : Gage R AnalysisFernando BeltránNo ratings yet

- Alinamiento Antenas SRT IfDocument5 pagesAlinamiento Antenas SRT IfJoseMiguelBlancoAlvarezNo ratings yet

- Wind Energy 004Document17 pagesWind Energy 004Ankam VinodNo ratings yet

- Marin E: 124 DescriptionDocument1 pageMarin E: 124 Descriptionshaikh junaidNo ratings yet

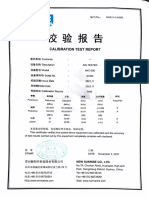

- Camera Calibration ReportDocument5 pagesCamera Calibration ReportadintNo ratings yet

- Msa hg01Document1 pageMsa hg01amitvohraNo ratings yet

- GR&R Data Sheet GR&R Data Sheet: Variable Data Results - Total Variation Variable Data Results - Total VariationDocument4 pagesGR&R Data Sheet GR&R Data Sheet: Variable Data Results - Total Variation Variable Data Results - Total VariationRahulNo ratings yet

- 3300 Series Single Column ModelsDocument2 pages3300 Series Single Column ModelsGerald AndersonNo ratings yet

- Interpretation of Core Test Results (Grade M 40 at FG Yard) : Patch 01 & 02Document2 pagesInterpretation of Core Test Results (Grade M 40 at FG Yard) : Patch 01 & 02Sasanka SekharNo ratings yet

- Cerato (LD) Advanced Alpha Automatic TransaxleDocument73 pagesCerato (LD) Advanced Alpha Automatic TransaxleM aliNo ratings yet

- ADAPT TN294 RC DFLTN Crack Ex 12Document7 pagesADAPT TN294 RC DFLTN Crack Ex 12CarsonBakerNo ratings yet

- Assessment FactorDocument11 pagesAssessment FactorMurtaza IoBMNo ratings yet

- Transverse Vibrations of A BeamDocument10 pagesTransverse Vibrations of A Beammazen ashaNo ratings yet

- Reliability: NotesDocument37 pagesReliability: NotesRahul PaulNo ratings yet

- OLAH DATA - Humam Juzaili Afif - J3E116060Document13 pagesOLAH DATA - Humam Juzaili Afif - J3E116060Humam Juzaili AfifNo ratings yet

- Unit Test 2Document2 pagesUnit Test 2Patricia Angelee GoggsNo ratings yet

- Reliability: NotesDocument37 pagesReliability: NotesryntubbNo ratings yet

- Msa (25.40)Document1 pageMsa (25.40)Quality VenusNo ratings yet

- Factor Analysis: NotesDocument6 pagesFactor Analysis: NotesInthiyaz KothapalleNo ratings yet

- Single Cell Functional Test Report: Circle-Up EastDocument11 pagesSingle Cell Functional Test Report: Circle-Up EastAshish JaiswalNo ratings yet

- Lumax Quality System: Gauge TypeDocument4 pagesLumax Quality System: Gauge TypeHarkesh KumarNo ratings yet

- Appendix - 4BDocument12 pagesAppendix - 4Bmoumita mukherjeeNo ratings yet

- Reccomendation & Oss Data List: SectorDocument10 pagesReccomendation & Oss Data List: SectorAbdul FatahNo ratings yet

- Aiwa XR Em50 XR Em51Document73 pagesAiwa XR Em50 XR Em51max baldero ferrandizNo ratings yet

- 518kHz Navtex ReceptionDocument18 pages518kHz Navtex ReceptionJose Antonio López FernándezNo ratings yet

- Factor Analysis: NotesDocument13 pagesFactor Analysis: NotesShankeyNo ratings yet

- Chapter 10Document5 pagesChapter 10Richelle DandoNo ratings yet

- Tool Test Summary SheetDocument3 pagesTool Test Summary SheetabbraNo ratings yet

- Lab Fl14a086cDocument5 pagesLab Fl14a086czyassNo ratings yet

- Aircraft Design Project Ii: Infant Jesus College of EngineeringDocument25 pagesAircraft Design Project Ii: Infant Jesus College of Engineeringmaridurai mathanGNo ratings yet

- 250kW VDFDocument3 pages250kW VDFalex.burgosNo ratings yet

- APAGA5Document32 pagesAPAGA5Produção PelotasNo ratings yet

- Solenoid Key Release Unit - SRUE: Installation InstructionsDocument2 pagesSolenoid Key Release Unit - SRUE: Installation InstructionsEva SuárezNo ratings yet

- Dial Indicators: Comparison Measuring Instruments Which Ensure High Quality, High Accuracy and ReliabilityDocument1 pageDial Indicators: Comparison Measuring Instruments Which Ensure High Quality, High Accuracy and Reliabilitysomkiat kongprasiatNo ratings yet

- Tabla de Impedancia Cables Media TensionDocument7 pagesTabla de Impedancia Cables Media Tensionvcontrerasj72No ratings yet

- Oneway: Oneway DV by Cell /statistics Descriptives Homogeneity /missing Analysis /posthoc Bonferroni GH Alpha (0.05)Document6 pagesOneway: Oneway DV by Cell /statistics Descriptives Homogeneity /missing Analysis /posthoc Bonferroni GH Alpha (0.05)selvi annisaNo ratings yet

- SPC CompactibilityDocument2 pagesSPC CompactibilityDhananjay PatilNo ratings yet

- Experiment 4 Pump CharacteristicsDocument7 pagesExperiment 4 Pump CharacteristicsJam JoNo ratings yet

- 2S-3 / 3S-3 (Both End Continuous)Document4 pages2S-3 / 3S-3 (Both End Continuous)Denver PiliNo ratings yet

- 1N4001 - 1N4007 General-Purpose Rectifiers: FeaturesDocument5 pages1N4001 - 1N4007 General-Purpose Rectifiers: FeaturesAdenilton L de AndradeNo ratings yet

- EN 3-2005 Example 003Document5 pagesEN 3-2005 Example 003dar.elhalNo ratings yet

- Mu PT 2018 RodDocument5 pagesMu PT 2018 RodammyNo ratings yet

- Arka Series WSMD-420-455 Wel-E&pd-420-455-144-Mp-Hc-Cmz118-00-02.07.2021Document2 pagesArka Series WSMD-420-455 Wel-E&pd-420-455-144-Mp-Hc-Cmz118-00-02.07.2021arjun kNo ratings yet

- Store 1: Minimum Thickness of Slab:: Dead Loads 1.58 Kpa 0.48 Kpa 1.19 Kpa 2.61kpa 5.86 KpaDocument7 pagesStore 1: Minimum Thickness of Slab:: Dead Loads 1.58 Kpa 0.48 Kpa 1.19 Kpa 2.61kpa 5.86 Kpadiego lopezNo ratings yet

- Direct Shear Test: Soil Engineering LabDocument13 pagesDirect Shear Test: Soil Engineering LabAbhinav KumarNo ratings yet

- Soil Test Report Summary - Existing Carriageway Nothern Access RoadDocument2 pagesSoil Test Report Summary - Existing Carriageway Nothern Access RoadAmila SampathNo ratings yet

- Trial EmbankmentDocument3 pagesTrial EmbankmentAhmad Rifqi syauqieNo ratings yet

- Unrestrained Beam Design: General Data Selected Section Section of PropertiesDocument1 pageUnrestrained Beam Design: General Data Selected Section Section of Propertiesamar aimanNo ratings yet

- Callibration & Validation For Instruments in Kapotech IndustriesDocument5 pagesCallibration & Validation For Instruments in Kapotech IndustriesamitvohraNo ratings yet

- Inspection Report For Grey PrimerDocument1 pageInspection Report For Grey PrimeramitvohraNo ratings yet

- Tape Test Inspection Report: S.M.B, Brake Pedal, Rocker Link, Toe HookDocument2 pagesTape Test Inspection Report: S.M.B, Brake Pedal, Rocker Link, Toe HookamitvohraNo ratings yet

- P10004382A - (AQP) Clutch PedalDocument7 pagesP10004382A - (AQP) Clutch PedalamitvohraNo ratings yet

- Daily Report SheetDocument18 pagesDaily Report SheetamitvohraNo ratings yet

- Berger Paints India LimitedDocument4 pagesBerger Paints India LimitedamitvohraNo ratings yet

- Statistical Process Control Study: Process Is Good But Still Improvement Is RequiredDocument1 pageStatistical Process Control Study: Process Is Good But Still Improvement Is RequiredamitvohraNo ratings yet

- Kaizen Sheet (F16)Document1 pageKaizen Sheet (F16)amitvohraNo ratings yet

- Msa hg01Document1 pageMsa hg01amitvohraNo ratings yet

- Optimal Kinematic Design of A 2-DOF Planar Parallel ManipulatorDocument7 pagesOptimal Kinematic Design of A 2-DOF Planar Parallel Manipulatorinventor_bkNo ratings yet

- Codigos de Funcion y Direccion MODBUSDocument19 pagesCodigos de Funcion y Direccion MODBUSRuben Mondejar MaciánNo ratings yet

- Dissertation Report of Vikas SudanDocument73 pagesDissertation Report of Vikas Sudanapi-3759085100% (1)

- Chapter 4 Rock MassDocument26 pagesChapter 4 Rock MassAzreenoor AtieqahNo ratings yet

- Comprehensive Method For Transient Modeling of Single Phase InductionDocument15 pagesComprehensive Method For Transient Modeling of Single Phase InductionvalentinmullerNo ratings yet

- Clusters and Semistable Models of Hyperelliptic Curves in The Wild CaseDocument84 pagesClusters and Semistable Models of Hyperelliptic Curves in The Wild CasenagiNo ratings yet

- Interpretation of The Point-Biserial Correlation Coe Cient in The Context of A School ExaminationDocument11 pagesInterpretation of The Point-Biserial Correlation Coe Cient in The Context of A School Examinationsmitha singhNo ratings yet

- 1.1 Integers: Math and Science DivisionDocument23 pages1.1 Integers: Math and Science DivisionBobby BannerjeeNo ratings yet

- Implementation of RSA Algorithm With Chinese Remainder Theorem For Modulus N 1024 Bit and 4096 BitDocument9 pagesImplementation of RSA Algorithm With Chinese Remainder Theorem For Modulus N 1024 Bit and 4096 BitAI Coordinator - CSC JournalsNo ratings yet

- Toy Car Investigation: PurposeDocument4 pagesToy Car Investigation: PurposeOscar HerreraNo ratings yet

- MTS Iit AdvancedDocument1 pageMTS Iit AdvancedNaman Shankar UpadhyayNo ratings yet

- Fixed Length and Horizontal Compositing Options in MinesightDocument7 pagesFixed Length and Horizontal Compositing Options in MinesightJosé R. CastroNo ratings yet

- Measurement of Conducted Supraharmonic Emissions: Quasi-Peak Detection and Filter BandwidthDocument19 pagesMeasurement of Conducted Supraharmonic Emissions: Quasi-Peak Detection and Filter BandwidthPrakash Madhur DevadasuNo ratings yet

- P1 Chapter 6::: CirclesDocument29 pagesP1 Chapter 6::: CirclesPrince YugNo ratings yet

- Gen Physics 1 Wk3Document10 pagesGen Physics 1 Wk3Hannah Bianca RegullanoNo ratings yet

- XFDTD Reference Manual PDFDocument440 pagesXFDTD Reference Manual PDFELPICHUENo ratings yet

- Determinant Sheet by OM SirDocument7 pagesDeterminant Sheet by OM SirAbhiNo ratings yet

- Introduction To MATLAB: Ashraf Al-Rimawi Matlab 12-12-2008Document32 pagesIntroduction To MATLAB: Ashraf Al-Rimawi Matlab 12-12-2008Sura DaraghmehNo ratings yet

- Final Oopm Lab Manual - 17-18Document45 pagesFinal Oopm Lab Manual - 17-18Nikita SakpalNo ratings yet

- Mathcad - Postfilter-Feedback-Halfbridge-Single-Supply-170VDocument6 pagesMathcad - Postfilter-Feedback-Halfbridge-Single-Supply-170Vfarid.mmdNo ratings yet

- Comparative Study of Effectiveness of Different Var Compensation Devices in Large-Scale Power NetworksDocument9 pagesComparative Study of Effectiveness of Different Var Compensation Devices in Large-Scale Power NetworksRamkumarNo ratings yet

- 2CB Questions - Data and DecisionDocument2 pages2CB Questions - Data and DecisionShivam GargNo ratings yet

- Dse 1 Unit 3Document10 pagesDse 1 Unit 3kkant872002No ratings yet

- The Most Common Methods of Measuring The Resistance of An Earth Electrode - EEP-001Document7 pagesThe Most Common Methods of Measuring The Resistance of An Earth Electrode - EEP-001Abdul Mohid SheikhNo ratings yet

- Distillation Column Design 2014Document4 pagesDistillation Column Design 2014John PortlandNo ratings yet

- Ortho PDFDocument1 pageOrtho PDFAlex OliveiraNo ratings yet

- Lesson 39 Multiplies Decimals Up To 2 Decimal Places by 1 To 2 Digit Whole Numbers.Document23 pagesLesson 39 Multiplies Decimals Up To 2 Decimal Places by 1 To 2 Digit Whole Numbers.Rugenie DomingoNo ratings yet