Professional Documents

Culture Documents

Msa hg01

Uploaded by

amitvohraOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Msa hg01

Uploaded by

amitvohraCopyright:

Available Formats

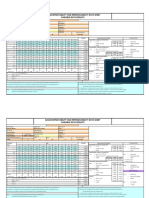

GAGE REPEATABILITY AND REPRODUCIBILITY DATA SHEET

VARIABLE DATA RESULTS

Part Name left boss Part Number P210514 Upper Control Limit 42.1 Appraiser A Gaurav Performed By Amit

Gauge / Equipment Name DIGITAL Height Gauge DMM-01 25-50mm Lower Control Limit 41.938 Appraiser B Bheem Date 13.04.2021

Gauge / Equip. Least Count 0.01 Characteristics Dim Tolerance 0.161999999999999 Appraiser C Sahil Record Number MSA-13-21-02

Characteristic Specification

DIM 24.75 25.25

Characteristic Classification Trials Parts Appraisers Date Performed Characteristic Classification Trials Parts Appraisers

3 10 3 3 10 3

APPRAISER/ PART AVERAGE Measurement Unit Analysis % Tolerance (Tol)

TRIAL # 1 2 3 4 5 6 7 8 9 10 Repeatability - Equipment Variation (EV)

1. A 1 25.120 25.182 24.860 24.960 25.065 25.120 25.182 24.860 24.960 25.065 25.037 EV = R x K1 Trials K1 % EV = 100 (EV/Tol)

2 2 25.080 25.184 24.850 24.940 25.071 25.080 25.185 24.850 24.940 25.071 25.025 = 0.023 x 0.5908 2 0.8862 = 100(0.013/0.083)

3 3 25.090 25.190 24.890 24.950 25.068 25.090 25.190 24.890 24.950 25.068 25.038 = 0.013 3 0.5908 = 16.16

4 AVE 25.10 25.19 24.87 24.95 25.07 25.10 25.19 24.87 24.95 25.07 xa= 25.033 Reproducibility - Appraiser Variation (AV)

5 R 0.04 0.01 0.04 0.02 0.01 0.04 0.01 0.04 0.02 0.01 ra= 0.023 AV = {(xDIFF x K2)2 - (EV2/nr)}1/2 % AV = 100 (AV/Tol)

6. B 1 25.120 25.182 24.860 24.960 25.065 25.120 25.182 24.860 24.960 25.065 25.037 = {(0.000 x 0.5231)^2 - (0.013 ^2/(10 x 3))}^1/2 = 100(0.002/0.083)

7 2 25.080 25.184 24.850 24.940 25.071 25.080 25.184 24.850 24.940 25.071 25.025 = 0.002 = 2.10

8 3 25.090 25.190 24.890 24.950 25.068 25.090 25.190 24.890 24.950 25.068 25.038 Appraisers 2 3

9 AVE 25.10 25.19 24.87 24.95 25.07 25.10 25.19 24.87 24.95 25.07 xb= 25.033 n = parts r = trials K2 0.7071 0.5231

10 R 0.04 0.01 0.04 0.02 0.01 0.04 0.01 0.04 0.02 0.01 rb= 0.023 Repeatability & Reproducibility (GRR) % GRR = 100 (GRR/Tol)

11. C 1 25.120 25.182 24.860 24.960 25.065 25.120 25.182 24.860 24.960 25.065 25.037 GRR = {(EV2 + AV2)}1/2 Parts K3 = 100(0.014/0.083)

12 2 25.080 25.184 24.850 24.940 25.071 25.080 25.184 24.850 24.940 25.071 25.025 = {(0.013^2 + 0.002^2)}^1/2 2 0.7071 = 16.30

13 3 25.090 25.190 24.890 24.950 25.068 25.090 25.190 24.890 24.950 25.068 25.038 = 0.014 3 0.5231 Gage system may be acceptable

14 AVE 25.10 25.19 24.87 24.95 25.07 25.10 25.19 24.87 24.95 25.07 x c= 25.033 Part Variation (PV) 4 0.4467

15 R 0.04 0.01 0.04 0.02 0.01 0.04 0.01 0.04 0.02 0.01 rc= 0.023 PV = RP x K3 5 0.4030 % PV = 100 (PV/Tol)

16. PART X= 25.033 = 0.319 x 0.3146 6 0.3742 = 100(0.100/0.083)

AVERAGE 25.10 25.19 24.87 24.95 25.07 25.10 25.19 24.87 24.95 25.07 Rp= 0.319 = 0.100 7 0.3534 = 120.34

17 (ra + rb + rc) / (# OF APPRAISERS) = R= 0.023 Tolerance (Tol) tv 8 0.3375

18 xDIFF = (Max x - Min x) = xDIFF 0.000 Tol = Upper - Lower / 6 0.101203 9 0.3249 ndc = 1.41(PV/GRR)

19 * UCLR = R x D4 UCL 0.059 = ( 42.1 - 41.938 ) / 6 10 0.3146 = 1.41(0.100/0.014)

= 0.083 = 10

* D4 =3.27 for 2 trials and 2.58 for 3 trials. UCLR represents the limit of individual R's. Circle those that are 1.41 0.361538 Gage discrimination acceptable

beyond this limit. Identify the cause and correct. Repeat these readings using the same appraiser and unit as originally used or 0.156 0.04 3.9

discard values and re-average and recompute R and the limiting value from the remaining observations.

For information on the theory and constants used in the form see MSA Reference Manual, Fourth edition.

Notes: % GRR under 10 acceptable msa EV>AV : instruments needs maintenance,improvement needed ndc≥5 then acceptable ( if less than 5 action required)

% GRR 10% - 30% May be acceptable AV>EV : Appraiser needs training or instrument not readable

% GRR over 30% unacceptable

You might also like

- Seducing Women Manual - Dating Book For Men, Seduction, Attraction, Daygame & How To Talk To GirlsDocument121 pagesSeducing Women Manual - Dating Book For Men, Seduction, Attraction, Daygame & How To Talk To GirlsJoe Edwards0% (1)

- Gauge Repeatability and Reproducibility Data Sheet Variable Data ResultsDocument5 pagesGauge Repeatability and Reproducibility Data Sheet Variable Data ResultsSharif KhanNo ratings yet

- Lab Report 2 - Indeterminate FrameDocument14 pagesLab Report 2 - Indeterminate FrameNurshahadah Shahrunnizam100% (1)

- Msa (25.40)Document1 pageMsa (25.40)Quality VenusNo ratings yet

- GR&R Data Sheet GR&R Data Sheet: Variable Data Results - Total Variation Variable Data Results - Total VariationDocument4 pagesGR&R Data Sheet GR&R Data Sheet: Variable Data Results - Total Variation Variable Data Results - Total VariationRahulNo ratings yet

- Lumax Quality System: Gauge TypeDocument4 pagesLumax Quality System: Gauge TypeHarkesh KumarNo ratings yet

- MSA of Sealing Plate DC-12Document2 pagesMSA of Sealing Plate DC-12RahulNo ratings yet

- Gage Repeatability and Reproducibility Data Collection SheetDocument12 pagesGage Repeatability and Reproducibility Data Collection SheetkkdilliNo ratings yet

- MSA FormatDocument4 pagesMSA FormatSaurabh PhandNo ratings yet

- Measurement System Analysis (R & R Study) DAP: ResultDocument2 pagesMeasurement System Analysis (R & R Study) DAP: Resultconversionbu2No ratings yet

- Control Valve #11Document6 pagesControl Valve #11Dimas Maulana HasbyNo ratings yet

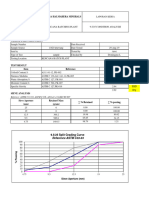

- Insitu California Bearing Ratio (CBR) Test With Dynamic Cone Penetrometer (DCP)Document1 pageInsitu California Bearing Ratio (CBR) Test With Dynamic Cone Penetrometer (DCP)salman al-fariziNo ratings yet

- GRADING OF SPLIT 10-20MM 29 Agust 2019Document2 pagesGRADING OF SPLIT 10-20MM 29 Agust 2019Zulhan90No ratings yet

- Linear Potentiometer: Precision Potentiometric Output Ranges: 0-3 To 0-30 Inches (0-75 To 0-750 MM) 5K - 10K Ohms IP65Document2 pagesLinear Potentiometer: Precision Potentiometric Output Ranges: 0-3 To 0-30 Inches (0-75 To 0-750 MM) 5K - 10K Ohms IP65Pepe BiondiNo ratings yet

- Omnia 08206 - Datasheet SampleDocument8 pagesOmnia 08206 - Datasheet Samplepatra.thomiNo ratings yet

- Salessparesservicetesting Calibration ModernizationDocument1 pageSalessparesservicetesting Calibration ModernizationVipul SharmaNo ratings yet

- Insitu California Bearing Ratio (CBR) Test With Dynamic Cone Penetrometer (DCP)Document1 pageInsitu California Bearing Ratio (CBR) Test With Dynamic Cone Penetrometer (DCP)salman al-fariziNo ratings yet

- Msa VV401Document1 pageMsa VV401amitvohraNo ratings yet

- Gage Repeatability and Reproducibility Data Sheet Variable Data ResultsDocument1 pageGage Repeatability and Reproducibility Data Sheet Variable Data ResultsamitvohraNo ratings yet

- 300t Mexican Calibrations June 2023Document4 pages300t Mexican Calibrations June 2023marco chavezNo ratings yet

- 1M Lookahead ScheduleDocument29 pages1M Lookahead ScheduleErickson MalicsiNo ratings yet

- Crescent Foundry Company Pvt. LTDDocument4 pagesCrescent Foundry Company Pvt. LTDsuraj kumarNo ratings yet

- M.D. K V Cosø I Diseño TG I NominalDocument7 pagesM.D. K V Cosø I Diseño TG I Nominalelmer ramirez floresNo ratings yet

- GR&R (9.50)Document1 pageGR&R (9.50)Quality VenusNo ratings yet

- Insitu California Bearing Ratio (CBR) Test With Dynamic Cone Penetrometer (DCP)Document1 pageInsitu California Bearing Ratio (CBR) Test With Dynamic Cone Penetrometer (DCP)salman al-fariziNo ratings yet

- Omnia 08257 - Datasheet SampleDocument8 pagesOmnia 08257 - Datasheet Samplepatra.thomiNo ratings yet

- Duct Pressure DropDocument1 pageDuct Pressure DropRufus D SNo ratings yet

- Omnia 08256 - Datasheet SampleDocument8 pagesOmnia 08256 - Datasheet Samplepatra.thomiNo ratings yet

- Omnia 08207 - Datasheet SampleDocument8 pagesOmnia 08207 - Datasheet Samplepatra.thomiNo ratings yet

- Dokumen - Tips - Toyota BT C3e150r Forklift Service Repair Manual 1623177478Document22 pagesDokumen - Tips - Toyota BT C3e150r Forklift Service Repair Manual 1623177478npNo ratings yet

- Updated SummaryDocument16 pagesUpdated SummaryErickson MalicsiNo ratings yet

- Asset ManagementDocument4 pagesAsset Managementmanasisalvi08No ratings yet

- GRRreport RFDocument690 pagesGRRreport RFLiam HoangNo ratings yet

- Buton, Joshua C.-Part2-ComputationDocument29 pagesButon, Joshua C.-Part2-ComputationJoel Rodello B DugeniaNo ratings yet

- Demo Rockwell Certificate ASTMDocument7 pagesDemo Rockwell Certificate ASTMYAMA ENGINEERSNo ratings yet

- Chapter 3 Regression Analysis Section 3.2 Simple Regression With Data Analysis Example 3.2 Honda Civic (II)Document4 pagesChapter 3 Regression Analysis Section 3.2 Simple Regression With Data Analysis Example 3.2 Honda Civic (II)Harsey Joy Punzalan100% (1)

- Inversión INCIAL (S/.) Inversión Anualizada (S/.)Document2 pagesInversión INCIAL (S/.) Inversión Anualizada (S/.)LioAldair Madden MirandaNo ratings yet

- G R&RDocument12 pagesG R&Rpradeep kumarNo ratings yet

- An924 Rev. 14Document8 pagesAn924 Rev. 14David WongNo ratings yet

- Load Schedule and ComputationDocument2 pagesLoad Schedule and Computationzandro padillaNo ratings yet

- Chapter24 Electrical PowerDocument66 pagesChapter24 Electrical PowerIman GhNo ratings yet

- Test Report AngulosDocument2 pagesTest Report Angulosdeportesaldia2014No ratings yet

- 400t Mexican Calibrations June 2023Document5 pages400t Mexican Calibrations June 2023marco chavezNo ratings yet

- AN924Document8 pagesAN924David WongNo ratings yet

- Img 20231129 0013Document1 pageImg 20231129 0013VikashNo ratings yet

- Data Sheet California Bearing Ratio (CBR) (TEST METHOD BS 1377: PART 9: 1990)Document3 pagesData Sheet California Bearing Ratio (CBR) (TEST METHOD BS 1377: PART 9: 1990)Dis ConnectNo ratings yet

- California Bearing Ratio (Insitu) : Bsa Lab EngineeringDocument1 pageCalifornia Bearing Ratio (Insitu) : Bsa Lab Engineeringsyahmi adliNo ratings yet

- Simply Supported Beam Design (Singly Reinforcement)Document3 pagesSimply Supported Beam Design (Singly Reinforcement)Farah WahidaNo ratings yet

- Recommended CAT 8CM32C - SparepartsDocument27 pagesRecommended CAT 8CM32C - SparepartsFergiKalesaranNo ratings yet

- 7302Document23 pages7302Qichiix KiciNo ratings yet

- All BlendDocument1 pageAll Blendusman ali usman aliNo ratings yet

- QEL-C6-22-004 Programme Testing Unit WARTISILLA EADocument2 pagesQEL-C6-22-004 Programme Testing Unit WARTISILLA EAjoshuaNo ratings yet

- PB04Document2 pagesPB04Jagadesh PNo ratings yet

- Location and Layout Models 1111Document40 pagesLocation and Layout Models 1111ravi alwaysNo ratings yet

- Load Vs Penetration: CBR VALUE at 2.5 MMDocument6 pagesLoad Vs Penetration: CBR VALUE at 2.5 MMBhargavi ChowdaryNo ratings yet

- Blower Double Impeller bl520002 Technical Data Sheet en v3Document2 pagesBlower Double Impeller bl520002 Technical Data Sheet en v3Docu CenterNo ratings yet

- Esp CalculationDocument3 pagesEsp CalculationprinceNo ratings yet

- Soil 2-12-2023Document2 pagesSoil 2-12-2023mido_20067581No ratings yet

- Reinforcement Sec 1 FlangeDocument1 pageReinforcement Sec 1 Flangeflawedbot123No ratings yet

- Nehemiah Wall-Section 5Document3 pagesNehemiah Wall-Section 5Hazim AffendiNo ratings yet

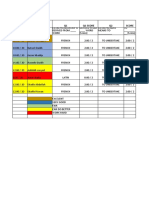

- Callibration & Validation For Instruments in Kapotech IndustriesDocument5 pagesCallibration & Validation For Instruments in Kapotech IndustriesamitvohraNo ratings yet

- Inspection Report For Grey PrimerDocument1 pageInspection Report For Grey PrimeramitvohraNo ratings yet

- Tape Test Inspection Report: S.M.B, Brake Pedal, Rocker Link, Toe HookDocument2 pagesTape Test Inspection Report: S.M.B, Brake Pedal, Rocker Link, Toe HookamitvohraNo ratings yet

- P10004382A - (AQP) Clutch PedalDocument7 pagesP10004382A - (AQP) Clutch PedalamitvohraNo ratings yet

- Daily Report SheetDocument18 pagesDaily Report SheetamitvohraNo ratings yet

- Berger Paints India LimitedDocument4 pagesBerger Paints India LimitedamitvohraNo ratings yet

- Statistical Process Control Study: Process Is Good But Still Improvement Is RequiredDocument1 pageStatistical Process Control Study: Process Is Good But Still Improvement Is RequiredamitvohraNo ratings yet

- Msa VV401Document1 pageMsa VV401amitvohraNo ratings yet

- Kaizen Sheet (F16)Document1 pageKaizen Sheet (F16)amitvohraNo ratings yet

- Msa mm01Document1 pageMsa mm01amitvohraNo ratings yet

- Gage Repeatability and Reproducibility Data Sheet Variable Data ResultsDocument1 pageGage Repeatability and Reproducibility Data Sheet Variable Data ResultsamitvohraNo ratings yet

- GCSE Mathematics 1MA1 Problem-Solving Questions 1: Higher TierDocument21 pagesGCSE Mathematics 1MA1 Problem-Solving Questions 1: Higher TierMorena PotenzaNo ratings yet

- Comparison of MPPT Algorithms For PV Systems Based DC-DC ConverterDocument11 pagesComparison of MPPT Algorithms For PV Systems Based DC-DC ConverterLeandro SouzaNo ratings yet

- Legislation Register - ExampleDocument10 pagesLegislation Register - ExampleKingsley AhanonuNo ratings yet

- CCPR Question BankDocument5 pagesCCPR Question BankEthan FernandesNo ratings yet

- Balance Chemical Equation - Online BalancerDocument2 pagesBalance Chemical Equation - Online BalancershoyebNo ratings yet

- Teaching StandardsDocument21 pagesTeaching Standardsapi-557400513No ratings yet

- CMC Chapter 03Document59 pagesCMC Chapter 03api-294176229No ratings yet

- Entrepreneurship Development Test 2 Assessment SheetDocument7 pagesEntrepreneurship Development Test 2 Assessment SheetHaseeb ShaikhNo ratings yet

- National Institute of Technology, DelhiDocument2 pagesNational Institute of Technology, DelhiAdhiraj choudharyNo ratings yet

- Appendix A. Code Generators For BCH CodesDocument28 pagesAppendix A. Code Generators For BCH CodesBereket TarikuNo ratings yet

- Translating Isaac Bashevis SingerDocument4 pagesTranslating Isaac Bashevis SingerDavid StrombergNo ratings yet

- A-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportDocument4 pagesA-Star Testing & Inspection (S) Pte LTD: Magnetic Particle Testing ReportHari KarthickNo ratings yet

- High-Quality Performance: Envg-B Enhanced Night Vision Goggle-BinocularDocument2 pagesHigh-Quality Performance: Envg-B Enhanced Night Vision Goggle-BinocularKyle YangNo ratings yet

- Me8781 MCTDocument2 pagesMe8781 MCTSiva RamanNo ratings yet

- Lab 06: Arrays & Functions Objective(s) :: ExercisesDocument4 pagesLab 06: Arrays & Functions Objective(s) :: ExercisesAhsan Ali GopangNo ratings yet

- Topic, Purpose, and Research QuestionsDocument16 pagesTopic, Purpose, and Research QuestionsVellardo AlbayNo ratings yet

- FS2 Le18Document1 pageFS2 Le18Jorebell W. QuiminoNo ratings yet

- Conclusion HDFCDocument2 pagesConclusion HDFCSudeep MallNo ratings yet

- Impromptu Quote PromptsDocument2 pagesImpromptu Quote PromptsWei Ning100% (1)

- IT-101 - Module 1 - Introduction To Infomation Technology SlidesDocument30 pagesIT-101 - Module 1 - Introduction To Infomation Technology SlidesIyesusgetanew100% (1)

- Copy Math9 Q4 Mod6 ProblemsInvolvingRightTriangles v3Document20 pagesCopy Math9 Q4 Mod6 ProblemsInvolvingRightTriangles v3txbi nariiNo ratings yet

- Dynamic Child 1st Edition Manis Solutions Manual 1Document20 pagesDynamic Child 1st Edition Manis Solutions Manual 1lois100% (36)

- What Is History: E. Kent RogersDocument27 pagesWhat Is History: E. Kent RogersAnnalyn EndrinalNo ratings yet

- Azrak Pipe ScheduleDocument1 pageAzrak Pipe ScheduleErcan YilmazNo ratings yet

- Springer Reassessing European Impressions of Indian AstronomyDocument7 pagesSpringer Reassessing European Impressions of Indian AstronomyAnkur KakkarNo ratings yet

- Unit 35 Explanatory Texts. Structure and CharacteristicsDocument9 pagesUnit 35 Explanatory Texts. Structure and CharacteristicsMiriam Reinoso SánchezNo ratings yet

- Office of The Mayor: Republic of The Philippines Province of La Union Municipality of Caba Tel. # (072) 607-03-12Document3 pagesOffice of The Mayor: Republic of The Philippines Province of La Union Municipality of Caba Tel. # (072) 607-03-12Sunshine MaglayaNo ratings yet

- Preview: ProfileDocument12 pagesPreview: ProfileBEN marketingNo ratings yet

- T-Test For Correlated Samples: Sherry V. Mecida, LPT, MATCCDocument6 pagesT-Test For Correlated Samples: Sherry V. Mecida, LPT, MATCCReno PhillipNo ratings yet