Professional Documents

Culture Documents

API 610 Centrifugal Pump Data Sheet

Uploaded by

jojaguca0 ratings0% found this document useful (0 votes)

67 views2 pagesOriginal Title

38781_mec-001

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

67 views2 pagesAPI 610 Centrifugal Pump Data Sheet

Uploaded by

jojagucaCopyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 2

API 610, 8TH EDITION PAGE 1 OF 2 .

CENTRIFUGAL PUMP DATA SHEET JOB No. ITEM No. .

SI UNITS / ISO STANDARDS REQ / SPEC No. / .

US UNITS / US STANDARDS PURCH ORDER No DATE .

(Short version by Ecopetrol - VIT, ago-97) INQUIRY No. BY .

REVISION DATE .

APPLICABLE TO: ¡ PROPOSAL ¡ PURCHASE ² AS BUILT

FOR . UNIT .

SITE . SERVICE .

No REQ . PUMP SIZE . TYPE . No STAGES .

MANUFACTURER MODEL

. . SERIAL No .

NOTE: ¡ INDICATES INFORMATION COMPLETED BY PURCHASER o BY MANUFACTURER ² BY MANUFACTURER OR PURCHASER

¡ GENERAL (3.1.1)

Pumps to operate in (parallel)(series) with . Gear Data Sheet No .

Pump item No . Motor item No .

Gear item No . Motor provided by .

Gear provided by . Motor mounted by .

Gear mounted by . Motor Data Sheet No .

OPERATING CONDITIONS PERFORMANCE (CONT)

¡ CAPACITY, NORMAL (m3/h)(gpm) RATED (m3/h)(gpm) ¨ SUCTION SPECIFIC SPEED 12,000 max. (2.1.9)

¡ SUCTION PRESSURE MAX/RATED / (kPa)(psig) Ä MAX SOUND PRESS. LEVEL 85 max. (dBA)(2.1.14)

¡ DISCHARGE PRESSURE (kPa)(psig) REMARKS See paragraphs 2.1.11.a, 2.1.11.b and 2.1.27 of standard VIT-MEC-001..

¡ DIFFERENTIAL PRESSURE (kPa)(psig) CONSTRUCTION

¡ DIFFERENTIAL HEAD (m)(ft) NPSHA (m)(ft) APPLICABLE STANDARD:

SITE AND UTILITY DATA Ä API 610 8TH EDITION

LOCATION (2.1.29) PUMP TYPE: (1.1.2)

¡ INDOOR Ä OUTDOOR ¡ UNDER ROOF ² BB1 ² BB4 ² VS3

¡ ELECTRICAL AREA CLASSIFICATION (2.1.22 / 3.1.5) ² BB2 ² VS1 ² VS4

CL I GR D DIV . ² BB3 ² VS2 ² OTHER

Ä TROPICALIZATION REQ'D o NOZZLE CONECTIONS: (2.3.2)

SITE DATA (2.1.29) SIZE RATING FACING POSITION

¡ ALTITUDE (m)(ft) BAROMETER (kPa abs)(psia) SUCTION

¡ RANGE OF AMBIENT TEMPS MIN/MAX / (°C)(°F) DISCHARGE

¡ RELATIVE HUMIDITY MIN/MAX / (%) PRESSURE CASING CONNECTIONS: (2.3.3)

LIQUID No SIZE TYPE

¡ Type/name of liquid . o DRAIN

¡ PUMPING TEMPERATURE: o VENT

Normal (°C)(°F) max (°C)(°F) min (°C)(°F) o PRESSURE GAUGE

¡ VAPOR PRESSURE (kPa abs)(psia) @ (°C)(°F) o TEMP GAUGE

¡ RELATIVE DENSITY (SPECIFIC GRAVITY): o BALANCE / LEAK-OFF

NORMAL MAX MIN ¡ CYLINDRICAL THREADS REQUIRED (2.3.3)

¡ VISCOSITY (cP) @ (°C)(°F) CASE PRESSURE RATING:

¡ MAX VISCOSITY (cP) o MAX ALLOWABLE WORKING PRESSURE (kPa)(psig)

¡ CORROSIVE/EROSIVE AGENT (2.11.1.8) @ (°C)(°F)

PERFORMANCE o HYDRO TEST PRESSURE (kPa)(psig)

PROPOSAL CURVE No o RPM . Ä SUCTION PRESS. REGIONS MUST BE DESIGNED FOR MAWP (2.2.4)

o IMPELLER DIA RATED MAX MIN (mm)(in) ROTATION: (VIEWED FROM COUPLING END)

o RATED POWER (BHP)(kW) EFFICIENCY (%) o CW o CCW

o MINIMUM CONTINUOUS FLOW: Ä IMPELLERS INDIVIDUALLY SECURED (5.2.2.2)

THERMAL (m3/h)(gpm) STABLE (m3/h)(gpm) REMARKS: .

o MAX HEAD @ RATED IMPELLER (m)(ft) SHAFT:

o MAX POWER @ RATED IMPELLER (kW)(BHP) o SHAFT DIAMETER AT COUPLING (mm)(in)

o NPSH REQUIRED AT RATED CAP (m)(ft) (2.1.8) o SHAFT DIAMETER BETWEEN BEARINGS (mm)(in)

API 610, 8TH EDITION PAGE 2 OF 2 .

CENTRIFUGAL PUMP DATA SHEET JOB No. ITEM No. .

SI UNITS / ISO STANDARDS REQ / SPEC No. / .

US UNITS / US STANDARDS PURCH ORDER No DATE .

(Short version by Ecopetrol - VIT, ago-97) INQUIRY No. BY .

REVISION DATE .

CONSTRUCTION (CONT) INSTRUMENTATION

REMARKS . VIBRATION:

COUPLINGS: (3.2.2) DRIVER-PUMP REMARKS See 2.9.2 and 3.4.3.4 of VIT-MEC-001.

¡ MAKE . TEMPERATURE AND PRESSURE:

¨ MODEL (Flexible; see 3.2 of VIT-MEC-001). ¨ RADIAL BRG METAL TEMP Ä THRUST BRG METAL TEMP

o RATING (CPLG kW/100 RPM)(HP/100) . ¡ TEMP GAUGES (WITH THERMOWELLS) (3.4.1.3)

DRIVER HALF COUPLING MOUNTED BY: OTHER .

¡ PUMP MFR. ¡ DRIVER MFR. ¡ PURCHASER Ä PRESSURE GAUGE TYPE (3.4.2.2) See 3.4.2 of VIT-MEC-001.

BASEPLATES: LOCATION .

Ä NON-GROUT CONSTRUCTION: (3.3.13/5.3.8.3.5) REMARKS See 3.4.3 of VIT-MEC-001..

REMARKS See 3.3 of VIT-MEC-001.. .

MATERIAL SPARE PARTS

Ä APPENDIX H CLASS S-6 . ¡ START-UP ¡ NORMAL MAINTENANCE

o BARREL/CASE IMPELLER . ¡ SPECIFY .

o CASE/IMPELLERS WEAR RINGS . MOTOR DRIVE (3.1.5)

o SHAFT . REMARKS See 3.1of VIT-MEC-001.

o DIFFUSERS . o WEIGHTS

o COUPLING SPACERS/HUBS . MOTOR DRIVEN:

o COUPLING DIAPHRAGMS (DISKS) . WEIGHT OF PUMP (kg)(lb) .

REMARKS . WEIGHT OF BASEPLATE (kg)(lb) .

BEARINGS AND LUBRICATION WEIGHT OF MOTOR (kg)(lb) .

BEARING (TYPE NUMBER) (See 2.9.1.1 of VIT-MEC-001): WEIGHT OF GEAR (kg)(lb) .

o RADIAL / . TOTAL WEIGHT (kg)(lb) .

o THRUST / . REMARKS .

LUBRICATION: (2.10) OTHER PURCHASER REQUIREMENTS

² GREASE ² FLOOD ² RING OIL Ä TORSIONAL ANALYSIS REPORT (See 2.8.2.6 of VIT-MEC-001.)

² FLINGER ¡ PURGE OIL MIST ¡ PURE OIL MIST REMARKS .

Ä CONSTANT LEVEL OILER PREFERENCE (SEE REMARKS) (2.9.2.2) QA INSPECTION AND TEST

REMARKS See 2.9.1.1of VIT-MEC-001. TEST NON-WIT WIT OBSERVE

MECHANICAL SEAL OR PACKING HYDROSTATIC (4.3.2)

SEAL DATA: (2.7.3) PERFORMANCE (4.3.3)

² SEAL MANUFACTURER . NPSH (4.3.4.1)

² SIZE AND TYPE / . COMPLETE UNIT TEST (4.3.4.)

² MANUFACTURER CODE . REMARKS See Section 4 of VIT-MEC-001.

REMARKS See 2.7.3.17, 2.7.3.19 and 2.7.3.21 of VIT-MEC-001. GENERAL REMARKS

STEAM AND COOLING WATER PIPING REMARK 1: For reference, see corresponding paragraphs of standard VIT-MEC-001.

REMARKS See paragraph 2.1.17 of standard VIT-MEC-001. REMARK 2: See additional requirements in standard VIT-MEC-001.

You might also like

- Soul Contracts & Forecasts: 3 CommentsDocument3 pagesSoul Contracts & Forecasts: 3 Commentswoojer100% (1)

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

- Engine Brake Service Information SummaryDocument10 pagesEngine Brake Service Information SummaryHamilton MirandaNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

- DatasheetDocument71 pagesDatasheetRhadityo Shakti BudimanNo ratings yet

- Belt Conveyor. Technical Data SheetDocument1 pageBelt Conveyor. Technical Data SheetCarmen FloresNo ratings yet

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Document5 pagesSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz Aydin100% (1)

- Daily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDocument1 pageDaily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDeniz AydinNo ratings yet

- Detroit Motor Katalog Rez DelovaDocument544 pagesDetroit Motor Katalog Rez DelovaStefan BabicNo ratings yet

- SIMS ReportDocument2 pagesSIMS Reportr_i_k_yNo ratings yet

- Pm-Clinic Service Inspection Sheet For GD825A-2 #12001 and Up Base InformationDocument10 pagesPm-Clinic Service Inspection Sheet For GD825A-2 #12001 and Up Base InformationLucio Valderrama100% (1)

- Contoh Sims ReportDocument4 pagesContoh Sims ReportAditya Ramadhanch AjNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- SEO-Optimized Title for API 685 Centrifugal Pump Data SheetDocument5 pagesSEO-Optimized Title for API 685 Centrifugal Pump Data SheetaltipatlarNo ratings yet

- 1vce014869t0201 PDFDocument39 pages1vce014869t0201 PDFkienNo ratings yet

- Standard Forms: IndexDocument8 pagesStandard Forms: IndexjojagucaNo ratings yet

- Project data sheet for rotary pumpDocument3 pagesProject data sheet for rotary pumpeduinNo ratings yet

- PharmacognosyDocument1 pagePharmacognosyBea Tan100% (1)

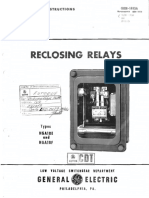

- GE Reclosing Relay HGA18E HGA18F ManualDocument8 pagesGE Reclosing Relay HGA18E HGA18F ManualMauricio100% (1)

- SA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02Document5 pagesSA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02altipatlarNo ratings yet

- SEO-OPTIMIZED TITLEDocument3 pagesSEO-OPTIMIZED TITLEwado11No ratings yet

- Painampuram, Muthukurmandal, S.P.S.R. Nellore District, A.PDocument22 pagesPainampuram, Muthukurmandal, S.P.S.R. Nellore District, A.Pkkumar_717405No ratings yet

- GRP Drainage Piping System FabricationDocument5 pagesGRP Drainage Piping System FabricationkahootNo ratings yet

- SRU Presentation For NewDocument47 pagesSRU Presentation For Newviettanct100% (3)

- SEO-OPTIMIZED TITLEDocument5 pagesSEO-OPTIMIZED TITLEaltipatlarNo ratings yet

- Ansi C84.1Document24 pagesAnsi C84.1jojagucaNo ratings yet

- Manual de Serviço DL200Document697 pagesManual de Serviço DL200Marcelo Lana100% (1)

- API STD 610 (1995) - Data Sheets ExampleDocument6 pagesAPI STD 610 (1995) - Data Sheets ExampleRickNo ratings yet

- IPS-C-PM-215-Equipment record cardDocument1 pageIPS-C-PM-215-Equipment record cardseguridadyambiente641No ratings yet

- Contract specifications centrifugal pumpDocument4 pagesContract specifications centrifugal pumpDiego RuanoNo ratings yet

- 30001-Technical Specification Sheet (Datasheet)Document6 pages30001-Technical Specification Sheet (Datasheet)ali valatabar100% (1)

- 03 30 00-14, Concrete Mix Design (34.5 Mpa, WC Ratio 0.38)Document120 pages03 30 00-14, Concrete Mix Design (34.5 Mpa, WC Ratio 0.38)anju vimalNo ratings yet

- TSR Info Unit Accident PTSBM Site Muara Lawa (1) 230921 144623Document5 pagesTSR Info Unit Accident PTSBM Site Muara Lawa (1) 230921 144623Ifan saputroNo ratings yet

- 22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecDocument48 pages22-DS-R-004 Rev 0 P-2230 Diesel Fuel Transfer Pump ElecChike NwachukwuNo ratings yet

- D8R Abk D802Document6 pagesD8R Abk D802SMKN 6 SAMARINDA PANGESTUNo ratings yet

- DBGFC 431-?'dif$: ModelDocument2 pagesDBGFC 431-?'dif$: Modeljohnny sabinNo ratings yet

- 22-DS-R-006 Rev 0 P-4110 A-B Firewater PumpDocument3 pages22-DS-R-006 Rev 0 P-4110 A-B Firewater PumpChike NwachukwuNo ratings yet

- Verifical Turbine Pump PDFDocument1 pageVerifical Turbine Pump PDFnecio77No ratings yet

- Pump Data Sheet For Circulating Water PumpDocument2 pagesPump Data Sheet For Circulating Water PumpSherwin SabandoNo ratings yet

- Machine Condition D85ESS - 2: GroupDocument1 pageMachine Condition D85ESS - 2: GrouplilikNo ratings yet

- 22-DS-R-010 Rev 0 P-2440 Fire Water Feed PumpDocument3 pages22-DS-R-010 Rev 0 P-2440 Fire Water Feed PumpChike NwachukwuNo ratings yet

- Weld Log PDFDocument1 pageWeld Log PDFDeniz AydinNo ratings yet

- Daily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDocument1 pageDaily Welding Inspection Report (Weld Log) : Cargill Balikesir Ammonia ProjectDeniz AydinNo ratings yet

- Bill of Quantity Electrical WorksDocument1 pageBill of Quantity Electrical WorksXtra BabeNo ratings yet

- Al-Amara 4x125MW Gas Turbines Spare Parts ListDocument8 pagesAl-Amara 4x125MW Gas Turbines Spare Parts ListElias Abu FakherNo ratings yet

- Pulsation Damper Specification FormDocument1 pagePulsation Damper Specification FormsanthoshkumarplNo ratings yet

- Rotary Pump (Api 676-3Rd) Data Sheet: U.S. CustomaryDocument3 pagesRotary Pump (Api 676-3Rd) Data Sheet: U.S. CustomaryEduin MorenoNo ratings yet

- Sahyog Engineering production and quality reportDocument3 pagesSahyog Engineering production and quality reportPrakash kumarTripathiNo ratings yet

- Camera Replacement ReportDocument4 pagesCamera Replacement Reportdwi supraptoNo ratings yet

- Sims Report c18 PT Dendymarker Indah Lestari So 8600445523Document1 pageSims Report c18 PT Dendymarker Indah Lestari So 8600445523Teguh Prabowo CenaNo ratings yet

- CCR 980NG AbkDocument13 pagesCCR 980NG AbkSMKN 6 SAMARINDA PANGESTUNo ratings yet

- Power House: Schedule of EquipmentDocument1 pagePower House: Schedule of EquipmentBilly Joe BreakfastNo ratings yet

- DBGFC 431-z DB: ModelDocument2 pagesDBGFC 431-z DB: Modeljohnny sabinNo ratings yet

- Diesel Transfer Hand Pump Tgp-p-620-2002 CDocument2 pagesDiesel Transfer Hand Pump Tgp-p-620-2002 Cgharsallah mounaNo ratings yet

- l5 Dza FMT 068 Rev 01 Rapport CND UtDocument2 pagesl5 Dza FMT 068 Rev 01 Rapport CND Utzakaria khaledNo ratings yet

- Ac Oqa 2014Document1 pageAc Oqa 2014pm9286vNo ratings yet

- DcrerweDocument1 pageDcrerwesri9987No ratings yet

- WA-6007416 - Test ReportDocument1 pageWA-6007416 - Test ReportGunarsyahNo ratings yet

- AE-QA-08 - Non-Confirmity RecordDocument3 pagesAE-QA-08 - Non-Confirmity RecordKarthi ThiyagarajanNo ratings yet

- Form MCR PC2000-8Document2 pagesForm MCR PC2000-8Dwi IswantoNo ratings yet

- Sample Utpa Report Latest For L3Document1 pageSample Utpa Report Latest For L3prabuNo ratings yet

- Compound & Chemical Change Trial ReportDocument1 pageCompound & Chemical Change Trial ReportRS MANIKANDANNo ratings yet

- SIMS ContohDocument1 pageSIMS ContohDanNo ratings yet

- Data Sheet: EnpplDocument2 pagesData Sheet: EnpplMo ZeroNo ratings yet

- Sign: Assistant: Sign: Assistant: SignDocument1 pageSign: Assistant: Sign: Assistant: SignSalim BakhshNo ratings yet

- Sundyne Pump Specification Sheet for PEMEX Condensate PumpsDocument3 pagesSundyne Pump Specification Sheet for PEMEX Condensate Pumpsaldoacss_148400122No ratings yet

- SG1572FD-3U02-41-131-0001Document1 pageSG1572FD-3U02-41-131-0001mNo ratings yet

- The Use of Si Quantities and Units: ManualDocument7 pagesThe Use of Si Quantities and Units: ManualjojagucaNo ratings yet

- Standard Drawings IndexDocument27 pagesStandard Drawings IndexjojagucaNo ratings yet

- How To Run A Lathe SB 1of2 PDFDocument32 pagesHow To Run A Lathe SB 1of2 PDFjojagucaNo ratings yet

- Quantum Mechanics - DescriptionDocument2 pagesQuantum Mechanics - DescriptionRafael Nascimento100% (1)

- 3MXM-M - EEDEN16 - Data Books - English PDFDocument43 pages3MXM-M - EEDEN16 - Data Books - English PDFMilan Miladinovic0% (1)

- Hsmi Hudco TrainingDocument20 pagesHsmi Hudco TrainingThomas PeguNo ratings yet

- Catalogo Perma-CoolDocument24 pagesCatalogo Perma-CoolrotnegerNo ratings yet

- Essential equipment maintenance checklistDocument3 pagesEssential equipment maintenance checklistYonas AyeleNo ratings yet

- ATLAS Controller: Brushless DC Variable Speed Controller Technical Data SheetDocument4 pagesATLAS Controller: Brushless DC Variable Speed Controller Technical Data Sheetraza239No ratings yet

- Medical Application For LASERDocument3 pagesMedical Application For LASERAnonymous xzi9LiT100% (1)

- Next Generation High Performance Walls: Construction GuideDocument52 pagesNext Generation High Performance Walls: Construction GuideРостислав ГатевNo ratings yet

- Essential Terms and Condition of Dyeing Part 1Document7 pagesEssential Terms and Condition of Dyeing Part 1Mohammed Atiqul Hoque ChowdhuryNo ratings yet

- OFR 2013-12 Maps of Fresh Groundwater Chemistry, Edmonton-Calgary Corridor, Alberta: VI - Belly River AquiferDocument23 pagesOFR 2013-12 Maps of Fresh Groundwater Chemistry, Edmonton-Calgary Corridor, Alberta: VI - Belly River AquiferAlberta Geological SurveyNo ratings yet

- System4700geneobrochure 4700700 RehauDocument16 pagesSystem4700geneobrochure 4700700 RehauraduteopNo ratings yet

- The Thermophilic Anaerobic Digestion ProcessDocument15 pagesThe Thermophilic Anaerobic Digestion ProcessoccbuziNo ratings yet

- Comprehensive Overview On Diesel Additives To Reduce Emissions, Enhance Fuel Properties and Improve Engine PerformanceDocument3 pagesComprehensive Overview On Diesel Additives To Reduce Emissions, Enhance Fuel Properties and Improve Engine PerformanceEduard DinuNo ratings yet

- 09 Rotating Equipment - InddDocument12 pages09 Rotating Equipment - InddAnonymous q9eCZHMuSNo ratings yet

- Thermal Power Plants Lecure 1 Online 2020Document52 pagesThermal Power Plants Lecure 1 Online 2020Bassam RiachiNo ratings yet

- Study Guide for SLK POM/PCE TestDocument20 pagesStudy Guide for SLK POM/PCE TestAlex Trujillo GutiérrezNo ratings yet

- Alarm and Fault FindingDocument40 pagesAlarm and Fault FindingDima KlipaNo ratings yet

- 5 Subsea ArchitectureDocument39 pages5 Subsea Architectureahmezo100% (1)

- Manual Monitoring Relay SIRIUS Monitoring DevicesDocument392 pagesManual Monitoring Relay SIRIUS Monitoring DevicesDebye101No ratings yet

- SwitchesDocument8 pagesSwitchesvaidehi vakilNo ratings yet

- Diesel Quality Certificate for MT TORM GUNHILDDocument1 pageDiesel Quality Certificate for MT TORM GUNHILDMarcones SáNo ratings yet

- Statement 1 Is Not Correct: Article 161 of The Constitution of India DescribesDocument13 pagesStatement 1 Is Not Correct: Article 161 of The Constitution of India Describesamol maliNo ratings yet