Professional Documents

Culture Documents

Aditya Patel: Professional Experience

Uploaded by

Alissa Esther Gonzalez0 ratings0% found this document useful (0 votes)

21 views1 pageOriginal Title

a29c991bd2262c29c026d21c12faac0d

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views1 pageAditya Patel: Professional Experience

Uploaded by

Alissa Esther GonzalezCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Aditya Patel

6573195610 ● Fullerton, CA ● adityapatel113@gmail.com

Insightful strategic leader experienced in developing and implementing solutions to complex business problems with a focus on

approaches that improve the customer experience. Skillful communicator with experience liaising between senior management,

engaging government entities and gaining an in-depth understanding of organizational objectives.

PROFESSIONAL EXPERIENCE

Controls Engineer Aug. 2015 - May 2018

Reliance Industries LTD | Gujarat, GJ

• Remediation hardware include Allen Bradley PLC, Siemens PLC, SCADAPack PLC, Power Meters, power relays, Rockwell OIT

(operator interface terminal), Wonderware HMI and Applications (LOWIS, RSlogix, RSview, InTouch, ArchestrA, Proworks,

panelbuilder, Etc.) but not limited to these devices.

• Program PLC (ControlLogix), DCS (Yokogawa, DeltaV), and HMI (InTouch/ArchestrA) and Various Field devices.

• Knowledge of Lean, Six Sigma, Shop floor Layout, BOM, TQM, PPM, ISO, GD&T, SAP, Solidworks, ProE, MATLAB,

Yokogawa DCS, other programs for equipment selection and design.

• New system Development, Run and Maintain SCADA SYSTEM.

• Establish manufacturing and assembly procedures for new products, including Selection of materials, design of assembly tooling,

design and selection of jigs and fixture, creation of assembly instructions, making layouts, heat treatment processes, perform load

and force calculations, establishment of inspection methods Surface preparation like sand blasting and priming and paint coating

etc.

• Make Complex Program for various PLCs (ControlLogix, PLC5, SLC and Modicon), and HMI Visualize graphic (Rockwell,

Wonderware InTouch, and Wonderware ArchestrA).

• Conduct Safety training on regular time interval.

• Investigate ways to reduce the cost of maintenance or improvement projects

• Works closely with Design Engineering, Quality, Production, and Process Sustaining teams to take the components from initial

design through prototype development and into full production.

• Review trends, analyze data, and monitor equipment/systems to identify trends and ensure they are running within specifications

• Developed new automation concepts and techniques to maximize production effectiveness.

• Document potential workplace hazards and measures taken to eliminate them

Automation Engineer Jul. 2018 - Jun. 2019

D’Autremount-Helms & Associates Inc. | Los Angeles, CA

• Troubleshoot PLC control systems to ensure sensors are functioning correctly

• Architect, write, and debug PLC ladder logic with an emphasis on generating code that is organized, structured, documented,

maintainable and reusable. PLC code will interact with subsystems such as conveyors, robots, Manufacturing Execution System

(MES), and 3rd party equipment.

• Provide Engineering support to the Manufacturing and Maintenance groups to troubleshoot, and improve/maximize the

performance of equipment and processes

• Responsible for controller programming using advanced techniques and their HMI interfaces

• Investigate equipment failures or difficulties to diagnose faulty operation, recommend remedies

EDUCATION

Master of Science in Electrical and Electronics Engineering | College of Engineering DEC 2021

Bachelor of Engineering in Electrical | Narnarayan Shastri Institute of Technology 2014

SKILLS & LANGUAGES

Skills: PLC Programming | SCADA | AutoCAD | HMI | VFD | Python | MS Office | Robotics | MES | FANUC |Yokogawa Fieldmate

(DCS) | Lean Six Sigma

Languages: English (fluent) | Hindi (fluent) | Gujarati (fluent) | Spanish (beginner)

You might also like

- A PMP Resume SampleDocument4 pagesA PMP Resume SampleJahirul QuaimNo ratings yet

- DOM CDCR Operations ManualDocument188 pagesDOM CDCR Operations ManualElisha Mc BrideNo ratings yet

- Beginners Guide To Learning ItalianDocument50 pagesBeginners Guide To Learning Italianannie.nikol75% (4)

- Senior Information Technology Business Analyst in Chicago IL Resume Daniel TownsendDocument2 pagesSenior Information Technology Business Analyst in Chicago IL Resume Daniel TownsendDanielTownsend100% (1)

- Post-War Reconstruction in Liberia: The Governance and Economic Management Assistance ProgramDocument16 pagesPost-War Reconstruction in Liberia: The Governance and Economic Management Assistance ProgramrkrechwbNo ratings yet

- Company Profile: National Diploma in Engineering SciencesDocument74 pagesCompany Profile: National Diploma in Engineering SciencesNiranjan Swarnasiri BandaraNo ratings yet

- Rubric For Research PresentationDocument1 pageRubric For Research Presentationjoseph082281100% (3)

- Intellectual Property Code Edited RFBTDocument135 pagesIntellectual Property Code Edited RFBTRobelyn Asuna LegaraNo ratings yet

- SR - Manual Tester Resume Profile, Atlanta - Hire IT People - We Get IT DoneDocument5 pagesSR - Manual Tester Resume Profile, Atlanta - Hire IT People - We Get IT DoneRavikumar MulagapatiNo ratings yet

- Music: First Quarter - Module2 Differentiates Aurally Among 2/4, 3/4, 4/4 and 6/8 Time SignaturesDocument22 pagesMusic: First Quarter - Module2 Differentiates Aurally Among 2/4, 3/4, 4/4 and 6/8 Time Signaturesjodzmary86100% (3)

- Advenginuse3 Ank Wbspa 16129Document32 pagesAdvenginuse3 Ank Wbspa 16129JMJPILOT75% (4)

- Resume Pedro Diaz Hernandez - Full Stack Developer Detailed - 2022 OK - AMZ USADocument19 pagesResume Pedro Diaz Hernandez - Full Stack Developer Detailed - 2022 OK - AMZ USAGuillermo EsquivelNo ratings yet

- Engineering Manager Senior Project Manager in Marietta Atlanta GA Resume Jeremy RichardDocument2 pagesEngineering Manager Senior Project Manager in Marietta Atlanta GA Resume Jeremy RichardJeremyRichardNo ratings yet

- Detail MarchApril 2017 PDFDocument108 pagesDetail MarchApril 2017 PDFInma Franco100% (1)

- Ople Vs TorresDocument4 pagesOple Vs TorresJon Joshua FalconeNo ratings yet

- Viraj Kansara ResumeDocument5 pagesViraj Kansara ResumeViraj Kansara100% (1)

- JD 11515Document5 pagesJD 11515Kamal MeenaNo ratings yet

- Quality Assurance ToolsDocument2 pagesQuality Assurance ToolszhanjeNo ratings yet

- Arun Shivaprasanna: SummaryDocument2 pagesArun Shivaprasanna: SummaryDivya NinaweNo ratings yet

- Ample Automation Engineer ResumeDocument3 pagesAmple Automation Engineer ResumedeeprocksNo ratings yet

- Job Description: Title: Automation Engineer - PLC ExperienceDocument2 pagesJob Description: Title: Automation Engineer - PLC ExperienceArdhiNo ratings yet

- ShinojDocument4 pagesShinojArish BallanaNo ratings yet

- Quality Systems Engineer: DescriptionDocument3 pagesQuality Systems Engineer: DescriptionRaghavendra KalyanNo ratings yet

- Vedaant Rajoo ResumeDocument2 pagesVedaant Rajoo ResumeVeDaant RajuNo ratings yet

- Ramya Jallygama-PLM Business AnalystDocument6 pagesRamya Jallygama-PLM Business Analystdurga prasad ravvaNo ratings yet

- Cory T. Murdock - ResumeDocument2 pagesCory T. Murdock - ResumeShanavaz ShahulNo ratings yet

- Rultz Raymond: Work Experience Resident Maintenance Engineer TGW Systems - Mcdonough, Ga - May 2017 To PresentDocument8 pagesRultz Raymond: Work Experience Resident Maintenance Engineer TGW Systems - Mcdonough, Ga - May 2017 To PresentFirdaus PanthakyNo ratings yet

- Ranjani ResumeDocument4 pagesRanjani ResumeganapathyramasubramaNo ratings yet

- RCM (Instrument) Engineer IMS One World - Jubail: Required SkillsDocument4 pagesRCM (Instrument) Engineer IMS One World - Jubail: Required SkillsadibNo ratings yet

- Client CV - Software Engineer:Software DeveloperDocument2 pagesClient CV - Software Engineer:Software DeveloperascelinetanNo ratings yet

- Radha Priyanka ResumeDocument4 pagesRadha Priyanka ResumepneelgundNo ratings yet

- Bhanu PDF TPMDocument3 pagesBhanu PDF TPMAshmita BhattacharyaNo ratings yet

- Shravya Sharma: Phone: 9008366227Document4 pagesShravya Sharma: Phone: 9008366227Lavanya SharmaNo ratings yet

- Sample MGRDocument3 pagesSample MGRMottu2003No ratings yet

- Control Systems Engineer Resume SampleDocument7 pagesControl Systems Engineer Resume Sampleafmgouewajkkdu100% (1)

- Arman KanooniDocument5 pagesArman Kanooniprabu2125No ratings yet

- "JR" H T, J ., PMP, Pmi-Rmp: Omer Hompson RDocument3 pages"JR" H T, J ., PMP, Pmi-Rmp: Omer Hompson RAman PradhanNo ratings yet

- Chintan Maru: ObjectiveDocument3 pagesChintan Maru: ObjectiveAkashNo ratings yet

- Resume For TrainerDocument5 pagesResume For Trainerapi-17589726No ratings yet

- Techncial Support Engineer - Danfoss Indonesia (Job Description)Document2 pagesTechncial Support Engineer - Danfoss Indonesia (Job Description)jeri saputraNo ratings yet

- Naukri AlbertRaj (14y 9m)Document2 pagesNaukri AlbertRaj (14y 9m)Khushi GuptaNo ratings yet

- Ahmed MohdDocument12 pagesAhmed MohdHARSHANo ratings yet

- Oracle Consultant 0008Document6 pagesOracle Consultant 0008Cendien ConsultingNo ratings yet

- Process Designer - JDDocument9 pagesProcess Designer - JDMoataz BelkhairNo ratings yet

- JD For QA AutomationDocument2 pagesJD For QA Automationchirag suresh chiruNo ratings yet

- Srilakshmi CVDocument2 pagesSrilakshmi CVSrilakshmi MNo ratings yet

- Associate SDET Analyst - DotNetDocument2 pagesAssociate SDET Analyst - DotNetsandipmisal2000No ratings yet

- Kadechur Banashankar - Latest - UpdatedDocument4 pagesKadechur Banashankar - Latest - UpdatedVenky VenkyNo ratings yet

- D MurtyDocument3 pagesD Murtydineshtej7768No ratings yet

- Prince AugDocument3 pagesPrince AugFalkan77 ;xNo ratings yet

- Soujanya: Professional SummaryDocument3 pagesSoujanya: Professional Summarymunna thoNo ratings yet

- Chief Technology OfficerDocument2 pagesChief Technology OfficerChen YooNo ratings yet

- Satyajeet Raj2Document1 pageSatyajeet Raj2satyajeet rajNo ratings yet

- PLC Automation EngineerDocument2 pagesPLC Automation EngineerAsad KhanNo ratings yet

- Suggested KeywordsDocument6 pagesSuggested KeywordsHomer Texido FrangioniNo ratings yet

- Vacancies 11th of March PDFDocument104 pagesVacancies 11th of March PDFMariaBufneaNo ratings yet

- Robotics Engineering ProfileDocument5 pagesRobotics Engineering ProfileBps PSNo ratings yet

- Dan Craciun - CurriculumDocument3 pagesDan Craciun - CurriculumdkxNo ratings yet

- Sasanka ResumeDocument3 pagesSasanka ResumeSasanka PanchamukhiNo ratings yet

- Arshad+Sayed BSADocument5 pagesArshad+Sayed BSAEmiNo ratings yet

- Himanshu Kumar 21Document5 pagesHimanshu Kumar 21Lavanya SharmaNo ratings yet

- Himanshu Kumar: Functional TestingDocument5 pagesHimanshu Kumar: Functional TestingLavanya SharmaNo ratings yet

- Design Engineer Jobs Description: Requirement & SkillsDocument6 pagesDesign Engineer Jobs Description: Requirement & SkillsfathinainNo ratings yet

- Drona: 902-441-4686 - Halifax, NS, CanadaDocument2 pagesDrona: 902-441-4686 - Halifax, NS, CanadaBhuvana AnalapudiNo ratings yet

- AbhishekChopra CV 2023Document4 pagesAbhishekChopra CV 2023Abhishek ChopraNo ratings yet

- Amol Khedkar - Senior IT Manager & ArchitectDocument5 pagesAmol Khedkar - Senior IT Manager & Architectashish ojhaNo ratings yet

- Resume May09Document3 pagesResume May09sganesh69100% (1)

- Naukri Balajisrinivasn (8y 0m)Document1 pageNaukri Balajisrinivasn (8y 0m)saurabhrai85No ratings yet

- Moral Decision Making Frameworks For Artificial IntelligenceDocument5 pagesMoral Decision Making Frameworks For Artificial IntelligenceAlissa Esther GonzalezNo ratings yet

- 4802 - Sp2020 4-23-20Document2 pages4802 - Sp2020 4-23-20Alissa Esther GonzalezNo ratings yet

- 10-323-19F Review Solutions For MT-1 - 2Document16 pages10-323-19F Review Solutions For MT-1 - 2Alissa Esther GonzalezNo ratings yet

- 05-Lesson 323 Sec 1.5 Com Example Item HDocument1 page05-Lesson 323 Sec 1.5 Com Example Item HAlissa Esther GonzalezNo ratings yet

- 03 Lesson OUTLINE 323 Sec 1.4a Joint-Condional ProbDocument6 pages03 Lesson OUTLINE 323 Sec 1.4a Joint-Condional ProbAlissa Esther GonzalezNo ratings yet

- 05-Lesson OUTLINE 323 Sec 1.5 Independent EventsDocument4 pages05-Lesson OUTLINE 323 Sec 1.5 Independent EventsAlissa Esther GonzalezNo ratings yet

- Air India Air Transport Services LimitedDocument5 pagesAir India Air Transport Services LimitedSumit KumarNo ratings yet

- Understanding Culture, Society and Politics (Grade 12) Mrs. Ana Lyn D. de Leon Subject TeacherDocument5 pagesUnderstanding Culture, Society and Politics (Grade 12) Mrs. Ana Lyn D. de Leon Subject TeacherSelvin A Crisostomo100% (1)

- CSTP 3 April 9.22.20 3.6Document1 pageCSTP 3 April 9.22.20 3.6Kaitlyn AprilNo ratings yet

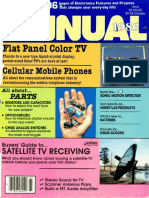

- Radio Electronics Annual 1986 PDFDocument98 pagesRadio Electronics Annual 1986 PDFhfalanizNo ratings yet

- The International Journal of Advanced Manufacturing Technology - Submission GuidelinesDocument21 pagesThe International Journal of Advanced Manufacturing Technology - Submission GuidelinesJohn AngelopoulosNo ratings yet

- Accenture 5G Municipalities Become Smart CitiesDocument20 pagesAccenture 5G Municipalities Become Smart CitiesEkastrielNo ratings yet

- InterPals Compliance Guide For Law EnforcementDocument19 pagesInterPals Compliance Guide For Law Enforcementll6equj5No ratings yet

- LLB New Course ContentsDocument22 pagesLLB New Course Contentssalarzai12No ratings yet

- Rolemaster Character Record Rolemaster Character Record Rolemaster Character Record Rolemaster Character Record Rolemaster Character RecordDocument2 pagesRolemaster Character Record Rolemaster Character Record Rolemaster Character Record Rolemaster Character Record Rolemaster Character RecordKarl MaxNo ratings yet

- 10 Ruhi Economics Chapter 4Document27 pages10 Ruhi Economics Chapter 4NidhiNo ratings yet

- BergeracDocument2 pagesBergeracspam0% (1)

- Assignment of PragmaticsDocument8 pagesAssignment of PragmaticsFatima QadeerNo ratings yet

- A Roadmap Towards The Implementation of An Efficient Online Voting System in BangladeshDocument5 pagesA Roadmap Towards The Implementation of An Efficient Online Voting System in BangladeshNirajan BasnetNo ratings yet

- Assignment - II HS/2014/1166 Naveen Devinda Walimuni ENGL 32654: Diversity Politics Ms. Sabreena NilesDocument6 pagesAssignment - II HS/2014/1166 Naveen Devinda Walimuni ENGL 32654: Diversity Politics Ms. Sabreena NilesRustic VenuNo ratings yet

- Biochemistry Rubric PresentationDocument1 pageBiochemistry Rubric PresentationEmiliano Z. Sison Jr.No ratings yet

- DTI Department Administrative Order No. 004-14, December 15, 2014Document2 pagesDTI Department Administrative Order No. 004-14, December 15, 2014Mak FranciscoNo ratings yet

- BFHI GuidelineDocument876 pagesBFHI GuidelinenopiyaniNo ratings yet

- 8 Millennium Development GoalsDocument2 pages8 Millennium Development GoalschenlyNo ratings yet

- January 2019 1546422160 241kanagaDocument3 pagesJanuary 2019 1546422160 241kanagaArtem ZenNo ratings yet

- Eaap ReviewerDocument3 pagesEaap ReviewerCamille SalvadoraNo ratings yet

- Employee Green BehaviorDocument13 pagesEmployee Green BehaviorDeep KhatiNo ratings yet