Professional Documents

Culture Documents

POSORJA TERMINAL INSPECTION TEST REPORT

Uploaded by

hz135874Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

POSORJA TERMINAL INSPECTION TEST REPORT

Uploaded by

hz135874Copyright:

Available Formats

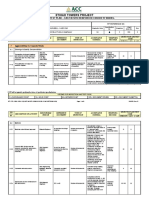

POSORJA MULTIPURPOSE TERMINAL

TERMINAL WORKS

CONTRACTOR ENGINEER

CHINA HARBOUR CULLEN GRUMMITT & ROE

INSPECTION TEST REPORT

CEMENT BOUND GRANULAR MIXTURE (CBGM)

CEMENT STABILIZED CRUSHED STONE (CSCS)

Doc No.

PMPT-ITP-016-03

REVISIONS RECORD

Rev. No. Date Issued by Approved by Description

01 03/07/2018 Sebastian Shi Tianhua Inspection Test Plan

Gonzalez

02 07/08/2018 Sebastian Shi Tianhua Inspection Test Plan

Gonzalez

Pedro

03 20/09/2018 Lezama Shi Tianhua Inspection Test Plan

Doc. No.: PMPT-ITP-016-03

POSORJA MULTIPURPOSE TERMINAL WORKS

REV. 3

INSPECTION TEST REPORT Date: 20/09/2018

CEMENT BOUND GRANULAR MIXTURE Page: 2 of 3

CEMENT STABILIZED CRUSHED STONE

CEMENT STABILIZED CRUSHED STONE

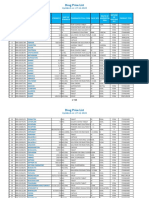

PERFORMANCE & INSPECTION TYPE OF INSPECTION/

SL NO ACTIVITY DESCRIPTION REFERENCE ACCEPTANCE CRITERIA FRECUENCY FUNCTION SURVEILLANCE RECORD

PERFORMER CHECKER CHEC CGR FUNCTION

DOCUMENT

CHEC CHEC

In accordance with Before start Planning Construction Method

Method Statement Employer´s Employer´s Requirements works engineering Manager H R Statement

1 Requirements

A.10.11

In accordance with Before start Environmental Construction Environmental

Environmental Permit Employer´s Employer´s Requirements works Engineer Manager H R Permit Certificate

2 Requirements

A.11.2.1

In accordance with Before start Environmental Construction Access Permit

Access Permit Employer´s Employer´s Requirements works Engineer Manager H R Certificate

3 Requirements

A.10.5.1

In accordance with Before start Safety In charge Construction Job Safety

Job Safety Analysis Employer´s Employer´s Requirements works Manager H R Analysis

4 Requirements

A.10.11.1

5 CSCS (CBGM) MAS

BS EN 14227-1 Maximum Particle size 31.5

BS EN 13242:2002 mm. Site Engineer / QA/QC Test report /

5.1 Sieve Analysis 10000 m3 H H

ES-132.003-301-24-001 (Section 4.2.1 – Table 3.1 Lab Assistant Engineer PMPT-MAS

and 4.2)

Water content of aggregate or Site Engineer / QA/QC H H Test report /

5.2 BS 800 Table 8/14 N/A (Only Report) 3 per 1000 m2

soil sources on site Lab Assistant Engineer PMPT-MAS

Vibration Hammer Compaction Site Engineer / QA/QC H H Test report /

5.4 BS EN13286-4 Wet density >95% 10000 m3

Test Lab Assistant Enginee PMPT-MAS

5.5 Batching records for ‘mix-in-plant’ BS 800 Table 8/14 Report Continuously

Site Engineer / r

Plant

H H

Test report /

method of construction using Lab Assistant Engineer PMPT-MAS

Compressive Strength of CBGM

batching by mass Site Engineer / QA/QC Test report /

5.6 EN 13286-41 A minimum of Rcc = 10 N/ 5 specimens H H

cylinder mm2 for cubes and RC= 8 N/ every1000 m2 Lab Assistant Engineer PMPT-MAS

mm2 for Cylinders after 28

days

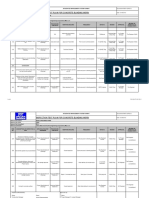

Doc. No.: PMPT-ITP-016-03

POSORJA MULTIPURPOSE TERMINAL WORKS

REV. 3

INSPECTION TEST REPORT Date: 20/09/2018

CEMENT BOUND GRANULAR MIXTURE Page: 3 of 3

CEMENT STABILIZED CRUSHED STONE

Design level Survey

Surveying and setting out Before start Site & survey QA/QC

6 ES-132.003-301-24-001 -15/+20 mm REP-CL01-2

SUBGRADE (GBS) works Engineer Engineer H H

Surface Clean and / Report

Compacted 98%

CBGM placing Multi lift layers of at leastWhen work Site Engineer / QA/QC Test report /

7 ES-132.003-301-24-001 H H

150mm up to 260mm begins Lab Assistant Engineer PMPT-MAS

ASTM 1557 Compaction ≥ 95% 5 density per Laboratory

8 Rolling Compaction Test BS EN 13286-50 1000 m2 Site Engineer / QA/QC H H report nuclear

From average of 5 measures not

and Water Content BS EN 13286-2 Lab Assistant Engineer instrument

one with less than 92% Not less than 3

BS 800 Table 8/14 compaction

Optimum water content +/-1% measures per day REP-CL01-1

CBGM Design Level:: After works Site & survey QA/QC Survey

9 Surveying and leveling ES-132.003-301-24-001 finish

-15/+20 mm Engineer Engineer H H REP-CL01-2

AT CBGM TOP

BS 800 Clause 818 Submitted in CAD to Eng.

10 Longitudinal Joints ES-132.003-301-24-001 Straight Lines Prior Works Site & survey QA/QC H H Report /

Full Thickness Cut / Engineer Engineer Visual Inspection

At Works

Not Allowed on wheel tracks

BS 800 Clause 818 Straight Lines, perpendicular Report /

10 Transversal Joints ES-132.003-301-24-001 to longitudinal joints. End of Site & survey QA/QC H H Visual

Full Thickness Cut at least Works Engineer Engineer Inspection

1.5 times thickness

Design Spacing +/- 150mm Report /

11 Induced Cracking Joints BS 800 Clause 818 Filled PEN50 Bitumen Every 100m Site & survey QA/QC H H Visual

ES-132.003-301-24-001 After initial Compaction / Prior linear Engineer Engineer Inspection

Final Compaction placing

12 Curing BS 800 End of

Surface Covered with Works

Site Engineer Site Engineer W W Visual

ES-132.003-301-24-001 Moist Geotextile Inspection

7 days

13 Coring BS 800 Monolithic, no cold As requested Site Engineer / QA/QC H H Test report

joints between lifts by Engineer Lab Assistant Engineer

Note:

1) Strictly adhere with HSE plan for safe work environment.

2) Materials which are not included in this ITP and need arise to use at site and same shall be added in ITP in later stage.

3) All items in which cement is used shall be cured for minimum seven days.

LEGEND H = Hold Point W = Witness Inspection R = Review of Document S = Surveillance

You might also like

- Itp & Material Inspection For MasonryDocument3 pagesItp & Material Inspection For MasonryImho TepNo ratings yet

- Inspection and Test Plan for Fuel Oil Piping SystemDocument2 pagesInspection and Test Plan for Fuel Oil Piping Systemachusanachu100% (1)

- Well Testing Project Management: Onshore and Offshore OperationsFrom EverandWell Testing Project Management: Onshore and Offshore OperationsNo ratings yet

- 01 Work Repair Procedure PDFDocument17 pages01 Work Repair Procedure PDFZul HafizNo ratings yet

- Marriot Grand Ballroom Project Inspection and Test PlanDocument3 pagesMarriot Grand Ballroom Project Inspection and Test PlanImho Tep75% (4)

- Bed 2381 Q Itp XX 000 00 PDFDocument1 pageBed 2381 Q Itp XX 000 00 PDFKareem GhazyNo ratings yet

- Itp For Piping Fabrication and Erection CorrectionDocument4 pagesItp For Piping Fabrication and Erection CorrectionAnand Ramachandran67% (3)

- ITP For False Ceiling Works of BuildingsDocument4 pagesITP For False Ceiling Works of BuildingsYay B. Gico0% (1)

- QAP FinalDocument6 pagesQAP FinalANSHUMAN KUMARNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksDocument8 pagesEtihad Towers Project: Inspection & Test Plan - Cast in Situ Reinforced Concrete WorksjiniNo ratings yet

- Fiberglass and Foster - Inspection Test Plan - ITPDocument4 pagesFiberglass and Foster - Inspection Test Plan - ITPAlaa Ali100% (1)

- ITP-00010 Pavement Road WorksDocument3 pagesITP-00010 Pavement Road WorksIsmail MydeenNo ratings yet

- ITP PipelineDocument5 pagesITP PipelineFerhat Aral GürbüzdalNo ratings yet

- Drainage Work - Inspection Test Plan - ITPDocument4 pagesDrainage Work - Inspection Test Plan - ITPAlaa Ali67% (3)

- Etihad Towers Project: Inspection & Test Plan - Hollow Core SlabsDocument2 pagesEtihad Towers Project: Inspection & Test Plan - Hollow Core SlabsjiniNo ratings yet

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Document2 pagesET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- Awwa-C302 (1995)Document28 pagesAwwa-C302 (1995)masoudNo ratings yet

- Application Format For Child CustodyDocument2 pagesApplication Format For Child CustodyDHUP CHAND JAISWAL100% (3)

- 01 Work Repair ProcedureDocument17 pages01 Work Repair ProcedureAnonymous sQ1toMHD100% (2)

- ITP - Distribution TransformerDocument6 pagesITP - Distribution TransformerOsman AbdoutNo ratings yet

- Spectralis Touch Panel Upgrade GuideDocument10 pagesSpectralis Touch Panel Upgrade GuideMohamed AbdulaalNo ratings yet

- Inspection and Test Plan: Tile WorksDocument2 pagesInspection and Test Plan: Tile WorksAlvene Tagoc100% (2)

- Schedule Comments AttachmentDocument4 pagesSchedule Comments Attachmenthz135874100% (1)

- 01 Itp-380kv Gis - PlanDocument9 pages01 Itp-380kv Gis - PlanYahya SamaraNo ratings yet

- PMPT Itp 010Document3 pagesPMPT Itp 010hz135874No ratings yet

- ITP & Checklist FOR Excavation & Backfilling and CompactionDocument7 pagesITP & Checklist FOR Excavation & Backfilling and CompactionAmran Hossain100% (4)

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- FINAL-ITP For Concreting Work Rev.2 25-Oct-2014Document12 pagesFINAL-ITP For Concreting Work Rev.2 25-Oct-2014Mohammed MujahidNo ratings yet

- ItpDocument15 pagesItpsubhash kumarNo ratings yet

- Pembekalan Tenaga Supervisi: Dalam Rangka Persiapan Pengawasan Diproyek-Proyek Umk VDocument10 pagesPembekalan Tenaga Supervisi: Dalam Rangka Persiapan Pengawasan Diproyek-Proyek Umk Vfuad ahmadNo ratings yet

- Company Logo Project Name / No.: Inspection & Test PlanDocument3 pagesCompany Logo Project Name / No.: Inspection & Test PlanAmr HamedNo ratings yet

- Tie in Procedure Rev. BDocument8 pagesTie in Procedure Rev. BgenjiNo ratings yet

- Beta Analytic Presentation at NNFCC Conference - Linking Bio-Based Materials To Renewable Energy ProductionDocument25 pagesBeta Analytic Presentation at NNFCC Conference - Linking Bio-Based Materials To Renewable Energy ProductionBeta AnalyticNo ratings yet

- Iocl Section 1 - Process SpecficationDocument73 pagesIocl Section 1 - Process SpecficationYogi173No ratings yet

- Posorja Multipurpose Terminal Terminal Works: Contractor EngineerDocument7 pagesPosorja Multipurpose Terminal Terminal Works: Contractor Engineerhz135874No ratings yet

- Posorja Multipurpose Terminal Terminal Works: Pump House ConstructionDocument9 pagesPosorja Multipurpose Terminal Terminal Works: Pump House Constructionhz135874No ratings yet

- Posorja Multipurpose Terminal Terminal Works: Contractor EngineerDocument5 pagesPosorja Multipurpose Terminal Terminal Works: Contractor Engineerhz135874No ratings yet

- Posorja Multipurpose Terminal Terminal Works: High-Mast and CCTV Poles InstallationDocument5 pagesPosorja Multipurpose Terminal Terminal Works: High-Mast and CCTV Poles Installationhz135874No ratings yet

- Inspection and Test Plan For Cpno5 Installation of Conduits and Boxes For All BuildingDocument1 pageInspection and Test Plan For Cpno5 Installation of Conduits and Boxes For All BuildingJoyce GordonioNo ratings yet

- Concrete Blinding ITPDocument2 pagesConcrete Blinding ITPDan SarmientoNo ratings yet

- Staircases & HandrailsDocument2 pagesStaircases & HandrailsPavul RajNo ratings yet

- Itp Repair Works 79Document2 pagesItp Repair Works 79Mohamed GamalNo ratings yet

- ITP EXCAVATION BACKFILLDocument1 pageITP EXCAVATION BACKFILLDan SarmientoNo ratings yet

- Itp-Internals R2Document2 pagesItp-Internals R2Delta akathehuskyNo ratings yet

- Inspection & Test Plan: Ramsis Job No: 20BG1251 Item No: Bapco Gas Product LineDocument2 pagesInspection & Test Plan: Ramsis Job No: 20BG1251 Item No: Bapco Gas Product LineSanjit TiwariNo ratings yet

- PIPING R04 101022 DraftDocument2 pagesPIPING R04 101022 DraftPavul RajNo ratings yet

- Inspection Test FormDocument3 pagesInspection Test FormsreejeshNo ratings yet

- ITP For Construction of CurbsDocument4 pagesITP For Construction of CurbsYay B. GicoNo ratings yet

- ESACPC-3K661-AB (Tie Rod Boot Spec)Document14 pagesESACPC-3K661-AB (Tie Rod Boot Spec)Francesco VignaliNo ratings yet

- AozayDocument11 pagesAozayheryfiononanapierrette01No ratings yet

- EPOXY RESIN FLLORINGDocument5 pagesEPOXY RESIN FLLORINGparesh.ahirNo ratings yet

- 4.1i Inspection &test PlanDocument8 pages4.1i Inspection &test PlanISAACNo ratings yet

- ITP for Protection of Existing ServicesDocument16 pagesITP for Protection of Existing ServicesCesar DuriasNo ratings yet

- China National Machinery Imp. & Exp. Corp. DCM Pile Inspection PlanDocument6 pagesChina National Machinery Imp. & Exp. Corp. DCM Pile Inspection Plandimuthu lasinthaNo ratings yet

- Technical Specification and PQR - 2022 05 04 11 00 54Document9 pagesTechnical Specification and PQR - 2022 05 04 11 00 54isepcontrolNo ratings yet

- ITP-3041 For PipeDocument8 pagesITP-3041 For PipeSkinhead TvNo ratings yet

- UntitledDocument1 pageUntitledMuhammad Jamil KhanNo ratings yet

- Qap6648 0000 5 Qa Qap 0002Document10 pagesQap6648 0000 5 Qa Qap 0002KHALEDNo ratings yet

- Asitp P 001 02Document2 pagesAsitp P 001 02MosabAhmedNo ratings yet

- 4172-GENON-1-25-0019_Rev 1Document16 pages4172-GENON-1-25-0019_Rev 1Rajesh SinghNo ratings yet

- Commissioning TestDocument30 pagesCommissioning TestErlen PolancoNo ratings yet

- ENMAS EPC Quality Assurance Plan for Piping ComponentDocument2 pagesENMAS EPC Quality Assurance Plan for Piping ComponentPavul RajNo ratings yet

- Condensate Collection Tank Qap 290722Document3 pagesCondensate Collection Tank Qap 290722Pavul RajNo ratings yet

- 109-RR-AMT-ITP-02-Fall Arrest SystemDocument1 page109-RR-AMT-ITP-02-Fall Arrest SystemSher DilNo ratings yet

- CARPET LAYINGDocument7 pagesCARPET LAYINGparesh.ahirNo ratings yet

- Procedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectionDocument10 pagesProcedure No. L&T/ Kkro / Mech / WP 05: Procedure For Ag Piping Fabrication & ErectiondiptiNo ratings yet

- Blown Asphalt EN1Document1 pageBlown Asphalt EN1hz135874No ratings yet

- Dubai Arrivals Quarantine Procedure Declaration FormDocument1 pageDubai Arrivals Quarantine Procedure Declaration FormRajendraNo ratings yet

- Checklist ITP-CL06Document1 pageChecklist ITP-CL06hz135874No ratings yet

- Concrete Works Receiving RecordDocument1 pageConcrete Works Receiving Recordhz135874No ratings yet

- Hse Manager / Safety Advisor / Safety Specialist: SummaryDocument4 pagesHse Manager / Safety Advisor / Safety Specialist: Summaryhz135874No ratings yet

- ITP-CL05-3Document1 pageITP-CL05-3hz135874No ratings yet

- Steel Bar Inspection Report for Posorja Multipurpose TerminalDocument1 pageSteel Bar Inspection Report for Posorja Multipurpose Terminalhz135874No ratings yet

- Inspection of I Steel Casing Welding Construction Site: Posorja Multipurpose Terminal-Terminal works-Part/Lot No.: Section of Specs.: Drawing No.Document1 pageInspection of I Steel Casing Welding Construction Site: Posorja Multipurpose Terminal-Terminal works-Part/Lot No.: Section of Specs.: Drawing No.hz135874No ratings yet

- Khalid Missaoui - EnglishDocument3 pagesKhalid Missaoui - Englishhz135874No ratings yet

- BAKHAT SohaibDocument1 pageBAKHAT Sohaibhz135874No ratings yet

- S.Anwar EN 2022Document2 pagesS.Anwar EN 2022hz135874No ratings yet

- Tabsi MeryemDocument4 pagesTabsi Meryemhz135874No ratings yet

- Senior Quantity Surveyor with 13+ years experienceDocument3 pagesSenior Quantity Surveyor with 13+ years experiencehz135874No ratings yet

- Siham KAMEL HSEE OfficerDocument1 pageSiham KAMEL HSEE Officerhz135874No ratings yet

- Anc Awc Nac NR: Material Approval (Map)Document1 pageAnc Awc Nac NR: Material Approval (Map)hz135874No ratings yet

- APMT TANGIER EXPANSION PQL SUBMISSIONDocument1 pageAPMT TANGIER EXPANSION PQL SUBMISSIONhz135874No ratings yet

- CV ELMEKRAZI Ilyas EnglishDocument3 pagesCV ELMEKRAZI Ilyas Englishhz135874No ratings yet

- Hse Manager / Safety Advisor / Safety Specialist: SummaryDocument4 pagesHse Manager / Safety Advisor / Safety Specialist: Summaryhz135874No ratings yet

- Ma PTM 0202 Itp Gen C01 WGM 00002 01Document1 pageMa PTM 0202 Itp Gen C01 WGM 00002 01hz135874No ratings yet

- Civil Engineer QC Inspector ResumeDocument2 pagesCivil Engineer QC Inspector Resumehz135874No ratings yet

- HSSE Engineer - Abdessamad MERZAKDocument2 pagesHSSE Engineer - Abdessamad MERZAKhz135874No ratings yet

- Hafsa - Bensghir French PrimeveraDocument3 pagesHafsa - Bensghir French Primeverahz135874No ratings yet

- AMIDA Walven SilalahiDocument7 pagesAMIDA Walven Silalahihz135874No ratings yet

- 12 HSSE Lifesaving RulesDocument14 pages12 HSSE Lifesaving Ruleshz135874No ratings yet

- Grundfosliterature 743129Document7 pagesGrundfosliterature 743129Ted Andrew AbalosNo ratings yet

- HPLC Determination of Caffeine in Coffee BeverageDocument7 pagesHPLC Determination of Caffeine in Coffee Beveragemuhammad ihklasulNo ratings yet

- Sect 5Document25 pagesSect 5PuneetNo ratings yet

- MEM Micro-ProjectDocument16 pagesMEM Micro-ProjectGanesh GoreNo ratings yet

- Urine Eaxmintaion ReportDocument7 pagesUrine Eaxmintaion Reportapi-3745021No ratings yet

- Standardized Recipes - Doc2Document130 pagesStandardized Recipes - Doc2epic failNo ratings yet

- ResiboDocument1 pageResiboAlex RespicioNo ratings yet

- Sub-Zero Icing Your Testicles For Increased Male Performance - MyBioHack Unlock Your Maximus PotentialDocument7 pagesSub-Zero Icing Your Testicles For Increased Male Performance - MyBioHack Unlock Your Maximus PotentialfortnitediscordbgweeNo ratings yet

- Exercise 5 - Journalizing TransactionsDocument10 pagesExercise 5 - Journalizing TransactionsMichael DiputadoNo ratings yet

- RP F107 PDFDocument45 pagesRP F107 PDFPriyam KmNo ratings yet

- ActinobacillosisDocument16 pagesActinobacillosisMd Shamim AhasanNo ratings yet

- Screenshot 2021-06-06 at 11.13.56Document1 pageScreenshot 2021-06-06 at 11.13.56Momina Ibrahim AhmedNo ratings yet

- Viom Networks Becomes The First Indian Telecom Infrastructure Company To Receive ISO 14001 & OHSAS 18001 CertificationDocument2 pagesViom Networks Becomes The First Indian Telecom Infrastructure Company To Receive ISO 14001 & OHSAS 18001 CertificationViom NetworksNo ratings yet

- EVBAT00100 Batterij ModuleDocument1 pageEVBAT00100 Batterij ModuleSaptCahbaguzNo ratings yet

- 18 National Indicator Framework For Monitoring Evaluation Myanmar Ye Naing HtetDocument9 pages18 National Indicator Framework For Monitoring Evaluation Myanmar Ye Naing HtetKo KyawNo ratings yet

- Thermo Fluids LabDocument23 pagesThermo Fluids LabMuket AgmasNo ratings yet

- A Review of Empathy Education in NursingDocument11 pagesA Review of Empathy Education in Nursinglora ardyaNo ratings yet

- PPR - LISTS - Registered Medicine Price List - 20221127 BahrainDocument318 pagesPPR - LISTS - Registered Medicine Price List - 20221127 BahrainvdvedNo ratings yet

- Specification for Child MUAC Tape Quality ChecksDocument4 pagesSpecification for Child MUAC Tape Quality ChecksM HussainNo ratings yet

- RMLNLU Moot Court Competition (Funding & Reimbursement) Policy, 2019.Document4 pagesRMLNLU Moot Court Competition (Funding & Reimbursement) Policy, 2019.Aakash ChauhanNo ratings yet

- Vegetarianism A Salvation Issue?Document7 pagesVegetarianism A Salvation Issue?ChetiweKapilaNo ratings yet

- Etymology: StructureDocument2 pagesEtymology: StructureNaga VNo ratings yet

- Install Panel WallDocument10 pagesInstall Panel WallLuis PalaciosNo ratings yet

- Let's Cook: Basic EnglishDocument6 pagesLet's Cook: Basic EnglishVincentNo ratings yet