Professional Documents

Culture Documents

De-Com - For Existing 8 12 Inch - Pipeline - TRA1

De-Com - For Existing 8 12 Inch - Pipeline - TRA1

Uploaded by

Darius DsouzaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

De-Com - For Existing 8 12 Inch - Pipeline - TRA1

De-Com - For Existing 8 12 Inch - Pipeline - TRA1

Uploaded by

Darius DsouzaCopyright:

Available Formats

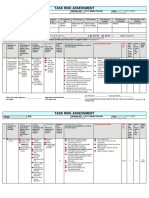

TASK RISK ASSESSMENT

Field /Terminal; NEB - AL DABBIYA TRA Ref. No TRA # 2268 Date 07/05/2019

Team Members : TRA Team TRA Member TRA Member TRA Member TRA MEMBER TRA Member TRA Member Job Performer

Leader ( JO ) (Area ADCO HSE TCM HSE Construction RSME HSE Construction RSME

Authority) (Tecnimont) (RSME)

Name:

Signature

Team Members :

Name:

Signature .

Activity: De Oiling and De Commissioning of oil lines

Work Location Al Dabbiya Phase III Onshore and offshore pipeline (Clusters 2B, 3C, 4D & 6F) Zone 0/1 Zone 2 Unclassified

Tools & equipment

Barge,Boat,Compressor, Hand Tools, Nitrogen Pump, Nitrogen Tanks, Material Container, Nitrogen Rack, Pigs, Crane, Hiab, Trailer, Hoses

Used

References HSE Procedure Manual, Volume 10/4, Method Statement – 30.78.90.3116

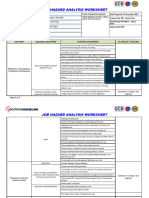

# Job Step Hazard CAUSE Consequence Potenti Existing Barrier / Recommended Action Residual ALAR Completi

Sequence of The potential to (Possible causes s al Risk Control Controls By Risk P on Date

working cause harm that will potentially (The harm H/M/ Describe all existing Describe additional H/M/L Demo

activities (Health, Injury, release a hazard) which could L barriers / controls for controls that are (with nstrat

Property damage, possibly (With no each hazard required controls ed

environment etc.) occur). controls in place (Yes /

in place) No)

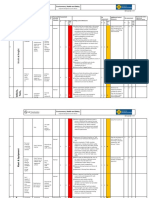

1. Mobilization of Load falling from the Improper secured Fatality H ADNOC E-PTW system Close supervision JO/Sup M Yes

Equipment, trailer loads Property in place Thorough visual inspection

Tools and Collision with other Movement of vehicles damage Follow ADNOC Road of the area and ground

Materials vehicles Wide load extended Personal injuries Safety Guidelines condition shall be carried

Hit by the extended from vehicle Environment Proper escorting out

load from other Improper damages provided Only approved routes to be

vehicle rigging/loading Load secured followed

Equipment / vehicles practice appropriately Daily driver checklist shall

fall on the open Uncontrolled Maintain safe distance be maintained

Job Performer ____________________ Issuing Authority________________________

TRA Team Leader Signature ____________________ High Risk Job Authorization____________________

(All pages) (First page only) I have checked that all controls stated in TRA are in place and conducted Tool Box Talk

TASK RISK ASSESSMENT

Field /Terminal; NEB - AL DABBIYA TRA Ref. No TRA # 2268 Date 07/05/2019

trenches / movements, sudden from trenches and Follow ADNOC approved

excavation jerks excavation edges emergency procedure

Oil / fuel leak during Nature of the load ADNOC inspected and

vehicle operations Unauthorized approved vehicles /

driver/reckless driving equipment

practice Trained flagmen

Unprotected assigned for vehicle

trenches / excavation movement

Lack of banksman Good preventive and

Mechanical failure maintenance

programme for vehicles

/ equipment followed

All personnel shall

undergo RSME HSE

Induction

2. Marine Vessel collision Improper Fatality H ADCO e PTW in place Close supervision of all RSME JP M YES 6 MONTHS

transportation LCT hitting the jetty communication Personal Proper communication activities & ENGR

and Berthing Man overboard Rough weather injury to be maintained Edge protection shall be

Operations Embarking / Lack of access gang Asset No movements during ensured at all times

disembarking way damage adverse weather Good housekeeping to be

Finger injury Lack of competency Marine water conditions maintained at all times

Mooring lines under Uncontrolled contaminatio Access gangways to be Fender to be provided to

tension movement of people n provided for safe prevent damage the jetty

Slip / trip / falls Slippery surface embarking and from barge operation

Exposure to Release of disembarking while turning/moving

H2S/Hydro Carbon H2S/Hydro Carbon All personnel shall wear Follow Emergency

Hazards from existing facility life jackets escape and evacuation

procedure in case of

Competent personnel

H2S/Hydrocarbon

shall be utilized for

release

mooring operations /

rope handling

All personnel shall stay

away from the line of

fire

3. Loading and Crane collapses Poor ground stability Fatality H ADNOC E-PTW Close supervision JO/Sup M Yes

offloading of Falling of load Damaged / Property system in place Inspect the area before

tools/various Uncontrolled uninspected lifting damage Simple lifting plan in positioning the crane

materials movement of load tools & tackles Personal injuries place Crane set up only on stable

Movement of other Overloading Environmental All lifting equipment and ground

vehicles/equipments Improper slinging damage gears must be certified Crane outriggers are fully

/ personnel Wrong signalling by ADNOC Onshore extended

Slip, trip & fall Cranes set up at approved third party Measure the actual radius of

Oil / fuel leakage incorrect radius and colour coded the crane and set up the

Job Performer ____________________ Issuing Authority________________________

TRA Team Leader Signature ____________________ High Risk Job Authorization____________________

(All pages) (First page only) I have checked that all controls stated in TRA are in place and conducted Tool Box Talk

TASK RISK ASSESSMENT

Field /Terminal; NEB - AL DABBIYA TRA Ref. No TRA # 2268 Date 07/05/2019

during operations Unauthorized entry Crane operator and crane or load accordingly

Line of fire Inadequate riggers shall be certified Do not leave suspended

Pinch points barricade / signages by ADNOC Onshore load unattended

Hit the adjacent Lack of flagman approved third party The safe working load and

structure and Incompetent operator Good preventive and the maximum working

facilities and rigger maintenance radius shall be maintained

Uneven slippery programme for Daily checklist shall be

surface and obstacles equipment followed maintained by operator prior

Mechanical failure Maintain good to use

Congested area housekeeping and Signalling shall be done only

Nearby structures and implement waste by one rigger

facilities management as per Two tag lines with sufficient

procedure length shall be provided to

Adequate access / guide the load

egress shall be Provide barricades and

maintained safety signage

Proper coordination Assigned trained flagman

during the operation of Maintain good housekeeping

the crane and implement waste

First aider and fire management as per

fighter shall be procedures

available Adequate access / egress

shall be maintained

Proper coordination during

the operation of the crane

Maintain safe distance from

line of fire

Avoid pinch points – keep

attention & eyes on the task

Proper coordination among

various disciplines and work

groups

Lifting operation shall be

suspended if wind speed

exceed 17 knots.

T- Card system shall be in

place.

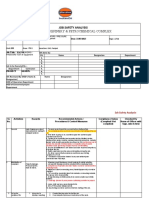

4. Pig Launching, High pressure hose Loose connections Personnel injury H E-PTW in place Authorized persons only JP/IA M Yes

Pig Receiving & Release of energy Damage hose & Asset damage Approved method allowed to enter the area

Pigging Noise connections statement & TRA must Bolts, hoses, connection

Environment

Fire Excessive pressure be available at site should be consistent to the

impact

Toxic gas Bolts failure / failure Calibrated pressure pressure rate

Fatality gauges Continues monitoring of

(Hydrocarbons / of PSV

H2S) Failure of fittings H2S detector pressure

Job Performer ____________________ Issuing Authority________________________

TRA Team Leader Signature ____________________ High Risk Job Authorization____________________

(All pages) (First page only) I have checked that all controls stated in TRA are in place and conducted Tool Box Talk

TASK RISK ASSESSMENT

Field /Terminal; NEB - AL DABBIYA TRA Ref. No TRA # 2268 Date 07/05/2019

Nitrogen leak Inadequate EEBA & SCBA Connections to be secured

Spillage of oil communication Properly rated gasket, properly

Simultaneous Unauthorized / hoses and bolts used. Avoid standing and people

operations untrained personnel Calibrated & third party movements in front of

Pig stuck or operator certified PSV must be connections, joints, bolts

Nitrogen handling Pyrophoric material installed and flanges – line of fire

Ear protection must be Whip arrestors shall be used

used while using air for all hoses connections

compressor Fire extinguishers shall be

Job specific PPE’s shall available at site

be used Area shall be barricaded

Deploy competent properly with appropriate

personnel safety signage

Activity control checklist Proper means of

shall be maintained communication to be

In case of after day maintained

light, work proper All machinery and

illumination shall be equipments must be Zone 2

maintained with clear certified and inspected by

safety glass RSME/ADNOC Onshore

Ensure availability of Trained first aider and fire

welfare facilities at site fighter shall be available at

Shift shall be not site

exceeding 12 hours Ensure availability of

Dispose wastes as per standby vehicle at site

ADNOC procedure and Follow ADNOC approved

Local Law Emergency procedure

5. Nitrogen Handling Damage of Instrument failure Asset damage E-PTW is in place Required closed supervision

& Equipment temporary fittings during monitoring Personnel injury Barriers and warning Ensure preventative

Frost bites Fittings / valve failure signs erected maintenance

during purging All fittings are rated. Equipment function checks

JO/JP/

Equipment damage H All fittings to be certified& tests on site M Yes

AA/IA

Wear the proper PPE Competent operators

for related job Back up unit on site

Fittings tested on site Unauthorized entry of non-

personnel

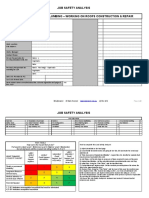

6. General Poisonous insects / Personnel unaware of Personnel injury H Use appropriate PPE as Awareness of the place JO/Sup M Yes

reptiles surrounding Fatality per the nature of the job where the work is being

Slip, trip & fall Uneven ground Ill-health performed.

Adverse weather surface Do not disturb flora and

condition High wind, sand fauna

storm, rain, fog Closed supervision shall be

maintained

Use safe route

Job Performer ____________________ Issuing Authority________________________

TRA Team Leader Signature ____________________ High Risk Job Authorization____________________

(All pages) (First page only) I have checked that all controls stated in TRA are in place and conducted Tool Box Talk

TASK RISK ASSESSMENT

Field /Terminal; NEB - AL DABBIYA TRA Ref. No TRA # 2268 Date 07/05/2019

Follow environmental

parameters (rain, sand

storm, fog visibility)

Job Performer ____________________ Issuing Authority________________________

TRA Team Leader Signature ____________________ High Risk Job Authorization____________________

(All pages) (First page only) I have checked that all controls stated in TRA are in place and conducted Tool Box Talk

TASK RISK ASSESSMENT

Field /Terminal; NEB - AL DABBIYA TRA Ref. No TRA # 2268 Date 07/05/2019

Job Performer ____________________ Issuing Authority________________________

TRA Team Leader Signature ____________________ High Risk Job Authorization____________________

(All pages) (First page only) I have checked that all controls stated in TRA are in place and conducted Tool Box Talk

You might also like

- JHA - Unloading of Sheet PileDocument3 pagesJHA - Unloading of Sheet PileJensen Sunga100% (1)

- Tower Crane Reference ManualDocument73 pagesTower Crane Reference ManualVazmeque de'Hitcher100% (9)

- Method Statement For Cable Pulling and ConnectionsDocument7 pagesMethod Statement For Cable Pulling and Connectionskamil100% (1)

- 538 Parts PDFDocument47 pages538 Parts PDFc.a.g.p.100% (1)

- Lifting PlanDocument31 pagesLifting PlanDarius DsouzaNo ratings yet

- Kimanis Power Project: Job Safety AnalysisDocument9 pagesKimanis Power Project: Job Safety Analysissimonsitompul25No ratings yet

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelNo ratings yet

- Confined Space Entry For Painting Inside PontoonDocument4 pagesConfined Space Entry For Painting Inside PontoonAchalere Shekhar Kashinath100% (1)

- JSA OF Fabrication and Installation Work ApproviedDocument3 pagesJSA OF Fabrication and Installation Work Approviedsakthi venkatNo ratings yet

- Crawler-Crane-Scc1800 SanyDocument27 pagesCrawler-Crane-Scc1800 SanyIman aprilah100% (1)

- PC490LC-11 KomatsuDocument134 pagesPC490LC-11 Komatsublaktion80% (5)

- P111-Rsme-Tra-007 - Tra For Cold Tie inDocument5 pagesP111-Rsme-Tra-007 - Tra For Cold Tie inDarius DsouzaNo ratings yet

- SS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksDocument6 pagesSS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksFarhat SetharNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNo ratings yet

- Composite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Document2 pagesComposite Works at Manglore For Hpclproject: Project No. W-488 Rev. 01 Page1 0f 2Bhargav BbvsNo ratings yet

- Jsa For Grinding WorkDocument113 pagesJsa For Grinding WorkAmit BhattNo ratings yet

- JSA For Erection of Precast..Document18 pagesJSA For Erection of Precast..Shafie ZubierNo ratings yet

- Job Safety Practices FirefightingDocument16 pagesJob Safety Practices Firefightingmohammed tofiqNo ratings yet

- Job Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedDocument2 pagesJob Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedZulfokar FahdawiNo ratings yet

- 18-JSA Dismantling of Batching PlantDocument5 pages18-JSA Dismantling of Batching Plantmohamed.elkomyNo ratings yet

- JSA ExcavationDocument6 pagesJSA ExcavationidreisNo ratings yet

- 04, Use of Hand ToolsDocument2 pages04, Use of Hand ToolsFrancis K BonfulNo ratings yet

- CamScanner 03-22-2023 07.44Document2 pagesCamScanner 03-22-2023 07.44Umar AliNo ratings yet

- DLF RCC HiraDocument8 pagesDLF RCC HiraskfahimuddinNo ratings yet

- COVID-19 Risk Assesment For NCCCLDocument3 pagesCOVID-19 Risk Assesment For NCCCLmohit100% (2)

- P-985-SH-AHA-008, AHA For Demolision WorksDocument4 pagesP-985-SH-AHA-008, AHA For Demolision WorksPatrick Bibila NdansiNo ratings yet

- SAFETY NotesDocument95 pagesSAFETY NotesKaruna KaranNo ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- Risk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)Document3 pagesRisk Assessment For Braket Scaffolding: Construction of Lubricating Oil Blending Plant (LOBP)AmeerHamzaWarraichNo ratings yet

- JHA For To Carryout Activities During Unloading of Product From Ship Rev00Document4 pagesJHA For To Carryout Activities During Unloading of Product From Ship Rev00Sreekumar100% (1)

- Safety ProgramDocument21 pagesSafety ProgramSits RdddNo ratings yet

- RISK ASSEMMENT FOR SBS Modified Bituminous Sheet Waterproofing WorksDocument9 pagesRISK ASSEMMENT FOR SBS Modified Bituminous Sheet Waterproofing Worksmohsin.meizaNo ratings yet

- JSA-Using A Type Ladder 2015Document1 pageJSA-Using A Type Ladder 2015nishanthNo ratings yet

- JHA For Hill Cutting Activities.R.01Document8 pagesJHA For Hill Cutting Activities.R.01SreekumarNo ratings yet

- SS JSP - 005 Light Material and Equipment Loading and UnloadingDocument6 pagesSS JSP - 005 Light Material and Equipment Loading and UnloadingFarhat SetharNo ratings yet

- Job Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentDocument6 pagesJob Safety Analysis - Tbl-Jsa: STEP 4: Hazard Risk AssessmentMoaatazz Nouisri100% (1)

- Job Safety Analysis Sheet: Mechanical ExcavationDocument1 pageJob Safety Analysis Sheet: Mechanical ExcavationjoshuaNo ratings yet

- Task Risk Assessment TableDocument10 pagesTask Risk Assessment TableakhmadbayNo ratings yet

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDocument4 pagesJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradNo ratings yet

- JSA NO 3-Pile CapDocument8 pagesJSA NO 3-Pile Capknabpsho50% (2)

- Risk Assesmennt For OutfallDocument9 pagesRisk Assesmennt For Outfallchinmay jagdeepNo ratings yet

- Warehouse Risk Assessment Aldir II IWPPDocument25 pagesWarehouse Risk Assessment Aldir II IWPPMadhu MohanNo ratings yet

- Lessons Learnt - Trench CollapseDocument2 pagesLessons Learnt - Trench CollapseEhab SaadNo ratings yet

- JSA For MobilizationDocument3 pagesJSA For MobilizationHossain amjad Hossain100% (1)

- 09 JSA For Excavation and Blinding at Pump House 1 & 3Document4 pages09 JSA For Excavation and Blinding at Pump House 1 & 3Hilbrecht De Pedro100% (1)

- TieDocument5 pagesTieshinto LawrenceNo ratings yet

- JSA For Scaffolding Erection Dismantling and Modification WorkDocument20 pagesJSA For Scaffolding Erection Dismantling and Modification Workbagas prakoso100% (1)

- Al-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetDocument3 pagesAl-Khalij 3X450 MW Power Plant Project Job Safety Analysis WorksheetMustafa hse JafferNo ratings yet

- Hot Work Activities (Cutting)Document9 pagesHot Work Activities (Cutting)Al Mughsar CompanyNo ratings yet

- Environmental, Health and Safety Risks AnalysisDocument2 pagesEnvironmental, Health and Safety Risks AnalysisKrishna Patil100% (1)

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- Task Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)Document2 pagesTask Risk Assessment Engineering Kinetics (PVT.) LTD: Risk Evaluation (Refer To Evaluation Form)andreNo ratings yet

- TSA 005 Rev 0 General LiftingDocument5 pagesTSA 005 Rev 0 General LiftingMusadiq HussainNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- Trial Pit During ExcavationDocument3 pagesTrial Pit During Excavationmujahid1137No ratings yet

- Job Safety Analysis (JSA) - Painting DateDocument2 pagesJob Safety Analysis (JSA) - Painting DatenabeelNo ratings yet

- PDB Jha 03 Install Vent PipeDocument9 pagesPDB Jha 03 Install Vent PipeAmyn BakriNo ratings yet

- 7-609 Back Filling HiraDocument1 page7-609 Back Filling Hirar2mgt28ssvNo ratings yet

- Hydro TestDocument8 pagesHydro Testmozzammil saqibNo ratings yet

- WBS & Pre-Job Risk Assessment: (Low/Medium/ High)Document8 pagesWBS & Pre-Job Risk Assessment: (Low/Medium/ High)Ahmed KhalifaNo ratings yet

- Job Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairDocument14 pagesJob Safety Analysis Roof Plumbing - Working On Roofs Construction & RepairLokesh AravindanNo ratings yet

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- TTEC Fencing RADocument7 pagesTTEC Fencing RAGeml TrinidadNo ratings yet

- B&R MONSOON - PLAN (Final) Rev-00Document12 pagesB&R MONSOON - PLAN (Final) Rev-00MD Abdullah100% (1)

- 14-Telescopic Forklift Check List Hindi English - Page - 1Document1 page14-Telescopic Forklift Check List Hindi English - Page - 1Darius DsouzaNo ratings yet

- P111-Rsme-Tra-007 - Tra For Cold Tie inDocument5 pagesP111-Rsme-Tra-007 - Tra For Cold Tie inDarius DsouzaNo ratings yet

- Combustible DustDocument12 pagesCombustible DustDarius DsouzaNo ratings yet

- Heat Stress Program - J38Document24 pagesHeat Stress Program - J38Darius DsouzaNo ratings yet

- Aspire 001 IGC I Element 1-Foundations - IGC IDocument48 pagesAspire 001 IGC I Element 1-Foundations - IGC IDarius DsouzaNo ratings yet

- TRA # 102 For Installation of Piping and Pipe SupportsDocument5 pagesTRA # 102 For Installation of Piping and Pipe SupportsDarius DsouzaNo ratings yet

- P111-RSME-TRA-007 - TRA For Cold Tie in PDFDocument4 pagesP111-RSME-TRA-007 - TRA For Cold Tie in PDFDarius DsouzaNo ratings yet

- MNGMNT CNTRCTR HSE Procedure Manual 10-4Document258 pagesMNGMNT CNTRCTR HSE Procedure Manual 10-4Darius Dsouza100% (1)

- Valve Station DrawingDocument1 pageValve Station DrawingDarius DsouzaNo ratings yet

- HSE REMINDER-March 2012-Plant Turnaround SafetyDocument1 pageHSE REMINDER-March 2012-Plant Turnaround SafetyDarius DsouzaNo ratings yet

- HSE REMINDER-April 2012-Unsafe Acts & Unsafe ConditionsDocument1 pageHSE REMINDER-April 2012-Unsafe Acts & Unsafe ConditionsDarius DsouzaNo ratings yet

- HIP-Wastewater Revision 03Document14 pagesHIP-Wastewater Revision 03Darius DsouzaNo ratings yet

- Construction Division: Polycarbonate Plant Project Saudi Kayan Petrochemical Complex CRC-KY8501Document1 pageConstruction Division: Polycarbonate Plant Project Saudi Kayan Petrochemical Complex CRC-KY8501Darius DsouzaNo ratings yet

- Code of Practice For Safe Lifting Operations at Workplaces OnlineDocument38 pagesCode of Practice For Safe Lifting Operations at Workplaces OnlineDarius Dsouza100% (1)

- EXPRO Policies and Safety: Section 1Document29 pagesEXPRO Policies and Safety: Section 1RyanNo ratings yet

- MacGregor K4 CraneDocument2 pagesMacGregor K4 CraneZenobiaNo ratings yet

- DBE 04769dengDocument341 pagesDBE 04769dengThaigroup CementNo ratings yet

- Qulting16115001jc JDN GruasDocument4 pagesQulting16115001jc JDN GruasMartin AndradeNo ratings yet

- Glossary of Port & Harbour Terms (Recovered)Document15 pagesGlossary of Port & Harbour Terms (Recovered)Claudia Silva0% (1)

- Mazzella BTHConsiderationsDesignSheet 0919Document3 pagesMazzella BTHConsiderationsDesignSheet 0919Gustavo ArancibiaNo ratings yet

- 500mw Boiler Erection SequenceDocument74 pages500mw Boiler Erection SequenceKaleeswaran Subramanian100% (1)

- Hiab 055: Range 4-6 TMDocument92 pagesHiab 055: Range 4-6 TMMike GuerrerosNo ratings yet

- Construction Equipment IntroductionDocument13 pagesConstruction Equipment IntroductionChinkuNo ratings yet

- Reductor Puente GrúaDocument8 pagesReductor Puente GrúaMauricio CarestiaNo ratings yet

- HDPE Pipe Installation GuideDocument48 pagesHDPE Pipe Installation GuideAkhil Syamkumar86% (7)

- GQCCO Company ProfileDocument38 pagesGQCCO Company ProfileRam SinghNo ratings yet

- SM PC1800-6 Sebm027706 PDFDocument955 pagesSM PC1800-6 Sebm027706 PDFanggieNo ratings yet

- 4.0 Crane Basic Single Telescope Large CraneDocument12 pages4.0 Crane Basic Single Telescope Large CraneMaz Ariez EkaNo ratings yet

- Guidelines For Marine Lifting Operations Noble DentonDocument39 pagesGuidelines For Marine Lifting Operations Noble DentonJason SmithNo ratings yet

- Extraordinary Construction On GermanyDocument1 pageExtraordinary Construction On Germanyzainulmhd867No ratings yet

- 10MT Gantry DesignDocument7 pages10MT Gantry Designvinit soodNo ratings yet

- Fleet AngleDocument16 pagesFleet AngleMoses Frank OduoriNo ratings yet

- Short MODU Specs of Cuu LongDocument2 pagesShort MODU Specs of Cuu LongThem Bui XuanNo ratings yet

- ZX4 Hoist User ManualDocument64 pagesZX4 Hoist User ManualAries CardiñoNo ratings yet

- Lsi Ascorel Brochure 1Document4 pagesLsi Ascorel Brochure 1mgoguNo ratings yet

- GL - Lifting Appliances and LiftsDocument10 pagesGL - Lifting Appliances and Liftshal720No ratings yet

- Prefab - Delivery-Handling-Storage-01 PDFDocument17 pagesPrefab - Delivery-Handling-Storage-01 PDFAbhishek GadadossNo ratings yet

- Iso 4309 2017Document10 pagesIso 4309 2017C. de JongNo ratings yet

- Rigging Inspection Safety TrainingDocument92 pagesRigging Inspection Safety TrainingD Srinivasa RaoNo ratings yet