Professional Documents

Culture Documents

Local Working Instruction (EN) Testing - Stack Emission of DG Sets

Uploaded by

Pandu BirumakovelaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Local Working Instruction (EN) Testing - Stack Emission of DG Sets

Uploaded by

Pandu BirumakovelaCopyright:

Available Formats

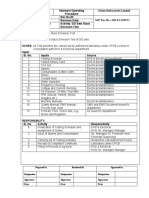

LOCAL PROCEDURE

Local working instruction (EN)

1 Area of validity [i]

Electrical Maintenance

2 Responsibilities [i]

Process owner: In-charge Electrical

Manager of necessary resources: Manager Electrical

Implementation: HOD Electrical

3 Process

Stack Emission Test of DG sets

1. The Stack Emission testing schedule is taken by EHS & Electrical HOD/ Sr.

Manager/ Manager.

2. EHS & Electrical HOD/ Sr. Manager/ Manager identify the actual schedule of the

testing and assign the appropriate Laboratory to carry out the job.

3. Shift Charge Hand/Electrician prior to starting any job, displays the board,

“Machine under Testing” on the operating panel.

4. Shift Charge Hand/Electrician properly cleans the working area.

5. As per the requirement machine manuals are taken on issue by the Electrical

HOD/ Sr. Manager/ Manager from the Library.

6. Supervisor ensures that the charge hand/electrician and other personnel involved

in this activity wears required PPEs (Gloves, Helmet, Shoes, and Mouth Mask,

etc.).

7. After testing job completion check the machine & removes the Board “Machine

under Testing” from the operating panel.

8. Collect all used items (such as used cloth, removed damage spare parts) from

the working area and dispose in the proper identified areas.

9. The waste generated from the testing activities is managed as per OCP on waste

management/ Hazardous waste management.

10. The signature of respective department’s HOD is obtained on checklist after

Stack Emission testing job completion.

11. Details in the check list and respective equipment’s tested history cards are

recorded by respective department’s HOD/ Sr. Manager/ Manager.

12. Check list properly filed up for further record.

13. Details in the log book and respective equipment’s history cards are recorded by

Sr. Foreman/Supervisor. Breakdown slip properly pinned-up for further record in

the Pin Stand

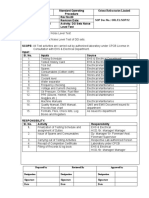

4 Risks / Opportunities / Measures [i]

Risk: DG Emissions have become a major reason of concern because it emit high levels of air

and noise polluting elements.

Oppertunity: Use Gas-based generators either by retrofitting existing generators for partial

usage of gas (a mixture of diesel and gas) or buying new gas-based generators.

Measures: Periodic testing of stack emission can reduce the risk of environmental as well as

health hazards..

.126214 Local working instruction (EN) 001/11.2017

Internal use page 1 of 3 manually controlled copy

LOCAL PROCEDURE

5 Health & Safety [i]

Exposure to diesel fumes leads to coughing, sore throat and eyes, headaches, nausea,

respiratory issues, and lung inflammation.

6 Environmental aspects [i]

Diesel emission levels of NOx, carbon monoxide and hydrocarbons contribute to poor air

quality. The smell coming from the polycyclic aromatic hydrocarbons causes cancer.

.126214 Local working instruction (EN) 001/11.2017

Internal use page 2 of 3 manually controlled copy

LOCAL PROCEDURE

.126214 Local working instruction (EN) 001/11.2017

Internal use page 3 of 3 manually controlled copy

You might also like

- 0-WD010-MZ711-10002 HSE Work Permit Procedure - Rev.1 - PDFDocument11 pages0-WD010-MZ711-10002 HSE Work Permit Procedure - Rev.1 - PDFEdu TBNo ratings yet

- Aecl Laboratory Analysis Report: Environmental MonitoringDocument14 pagesAecl Laboratory Analysis Report: Environmental MonitoringFarhan TaseenNo ratings yet

- Thermal Power Plant: Pre-Operational ActivitiesFrom EverandThermal Power Plant: Pre-Operational ActivitiesRating: 4 out of 5 stars4/5 (4)

- SOP Stack Emission of DG SetsDocument2 pagesSOP Stack Emission of DG SetsPandu BirumakovelaNo ratings yet

- Hse Plan Allied Site 1072 NewDocument46 pagesHse Plan Allied Site 1072 NewDaniel LoveNo ratings yet

- SOP Noise Testing of DG SetsDocument2 pagesSOP Noise Testing of DG SetsPandu Birumakovela100% (1)

- Environmetal Management PlanDocument4 pagesEnvironmetal Management PlanNev DelgadoNo ratings yet

- Sample 1 - Details of ProjectDocument6 pagesSample 1 - Details of ProjectErwin Bernard NionesNo ratings yet

- OCP For Welding - Gas CuttingDocument2 pagesOCP For Welding - Gas Cuttingravikpandey100% (2)

- EIA Reports On WaterDocument12 pagesEIA Reports On Waterengr_afsoomro3147No ratings yet

- Starch Pack Ehs EvaluationDocument137 pagesStarch Pack Ehs EvaluationOrhan MuneebNo ratings yet

- Generic Guidelines Environmental Protection - 1v1eDocument8 pagesGeneric Guidelines Environmental Protection - 1v1eIsac ClaroNo ratings yet

- 02 SOP Preventive Maintenance of DG SetsDocument4 pages02 SOP Preventive Maintenance of DG SetsPandu BirumakovelaNo ratings yet

- Manufacture of NaphthalenMANUFACTURE OF NAPHTHALENEDocument14 pagesManufacture of NaphthalenMANUFACTURE OF NAPHTHALENEManoj Ranjan100% (1)

- PROPOSAL EHS Compliance SANOFI R2 April2019 PDFDocument18 pagesPROPOSAL EHS Compliance SANOFI R2 April2019 PDFlaelilaeliNo ratings yet

- Cleanliness of SurfacesDocument12 pagesCleanliness of SurfacesKreshna Wisnu BrataNo ratings yet

- EOCOP 1 : Environment of Care Site Survey-Outpatient AreasDocument6 pagesEOCOP 1 : Environment of Care Site Survey-Outpatient AreasvengielNo ratings yet

- Method Statement - Site EstablishmentDocument4 pagesMethod Statement - Site EstablishmentaceNo ratings yet

- Metheod Statement Mechnical UnitDocument16 pagesMetheod Statement Mechnical UnitOliver OroscoNo ratings yet

- SMP For Calibration of Gauges & TransmittersDocument3 pagesSMP For Calibration of Gauges & Transmitterspradeep1987coolNo ratings yet

- 9-Workers Accommodation Management PlanDocument11 pages9-Workers Accommodation Management Planductaiutc100% (10)

- OCP For Welding Gas CuttingDocument2 pagesOCP For Welding Gas CuttingManu Sharma0% (1)

- Method Statement - Hazardous Substances Management and ControlDocument4 pagesMethod Statement - Hazardous Substances Management and ControlaceNo ratings yet

- Erp Ntu PDFDocument33 pagesErp Ntu PDFEdmund YoongNo ratings yet

- NEBOSH IOG1 ExaminersFeedback PDFDocument24 pagesNEBOSH IOG1 ExaminersFeedback PDFAyoola Ayodeji100% (7)

- Summer Plan Rev ADocument10 pagesSummer Plan Rev AKhaled Ismail100% (2)

- Ricoh Aficio 180 - D418 - 3218 - 2818 - 9918 - 4180 - 5218 Service ManualDocument247 pagesRicoh Aficio 180 - D418 - 3218 - 2818 - 9918 - 4180 - 5218 Service ManualJoseph RiveraNo ratings yet

- MS Concrete Crack RepairDocument6 pagesMS Concrete Crack RepairManiNo ratings yet

- Intel Construction EHS: Processes and Procedures ManualDocument116 pagesIntel Construction EHS: Processes and Procedures ManualbasshotNo ratings yet

- Environmental Compliance ChecklistDocument5 pagesEnvironmental Compliance ChecklistNIJESH100% (1)

- New Exams IGC-2Document4 pagesNew Exams IGC-2HossamKandil67% (3)

- Environmental Incident Reporting ProcedureDocument3 pagesEnvironmental Incident Reporting ProcedureRakhesh Mohan100% (1)

- Intel Construction EHS: Processes and Procedures ManualDocument127 pagesIntel Construction EHS: Processes and Procedures ManualRanjan BhaumikNo ratings yet

- IGC 2 Mock Paper and AnswersDocument7 pagesIGC 2 Mock Paper and AnswersMohammad Shahid79% (19)

- Removal of Factory Plant Equipment Checklist v2Document1 pageRemoval of Factory Plant Equipment Checklist v2DamianNo ratings yet

- Commissioning Statement For Car Park PDFDocument19 pagesCommissioning Statement For Car Park PDFNguyễn Thế PhongNo ratings yet

- Clean Room HandbookDocument80 pagesClean Room HandbookPecingina Dalia DanielNo ratings yet

- Pump Method StatementDocument5 pagesPump Method StatementIkenna NdiNo ratings yet

- Temporary GeneratorDocument11 pagesTemporary Generatorraju_civilengNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument8 pagesCambridge International General Certificate of Secondary EducationHiphop602No ratings yet

- MS Concrete Crack RepairDocument5 pagesMS Concrete Crack Repairjoseph guiyab100% (1)

- IGC3 - Exam TemplateDocument17 pagesIGC3 - Exam Templatevishal_sonari100% (1)

- 01 SOP Preventive Maintenance - MachineDocument4 pages01 SOP Preventive Maintenance - MachinePandu Birumakovela100% (1)

- All Check List SafetyDocument5 pagesAll Check List SafetynormalNo ratings yet

- Diesel Generator Risk AssessmentDocument5 pagesDiesel Generator Risk AssessmentAlvinNo ratings yet

- Assessment of Indoor Air Quality in An Automobile IndustryDocument8 pagesAssessment of Indoor Air Quality in An Automobile IndustryInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Ethanol Plant Commissioning Startup and ShutdownDocument5 pagesEthanol Plant Commissioning Startup and Shutdowntsrinivasan5083No ratings yet

- AE - , AKN - , AL - , AP, AT, K - , L - , T: Installation, Operation and Maintenance InstructionsDocument24 pagesAE - , AKN - , AL - , AP, AT, K - , L - , T: Installation, Operation and Maintenance InstructionsGabrielNo ratings yet

- Corrective MaintenanceDocument7 pagesCorrective Maintenancedennisjuntak100% (1)

- Construction Environmental Management Plan ENC023 Workshop 1.0Document86 pagesConstruction Environmental Management Plan ENC023 Workshop 1.0Pang Lee ChingNo ratings yet

- Safety and Health in Chemical IndustriesDocument18 pagesSafety and Health in Chemical IndustriesMubarak AhmadNo ratings yet

- ENGN4625 Lab Exp Risk Assessment - 2012Document11 pagesENGN4625 Lab Exp Risk Assessment - 2012Chuah Chian YeongNo ratings yet

- Correspondence 298268Document3 pagesCorrespondence 298268sjmpakNo ratings yet

- Chapter-10 Environment and Safety: 10-1 IntroductionDocument8 pagesChapter-10 Environment and Safety: 10-1 IntroductionPedro Paulo CordeiroNo ratings yet

- Environment Management Plan P-04Document8 pagesEnvironment Management Plan P-04khurram shahzad0% (1)

- Health Safety Original ManualDocument74 pagesHealth Safety Original ManualVictor TasieNo ratings yet

- 051020176Q7SE9W3Annexure documentofRiskAssessmentDocument7 pages051020176Q7SE9W3Annexure documentofRiskAssessmentdilekNo ratings yet

- NEA Office IAQ GuidelinesDocument47 pagesNEA Office IAQ GuidelinesAndy AnxietyNo ratings yet

- Method Statement - Fauna and Flora ManagementDocument4 pagesMethod Statement - Fauna and Flora ManagementaceNo ratings yet

- Fire Fighting Pumping Systems at Industrial FacilitiesFrom EverandFire Fighting Pumping Systems at Industrial FacilitiesRating: 4.5 out of 5 stars4.5/5 (3)

- SINAMICS V50 - JX Power Module Electrical Installa - 200904Document10 pagesSINAMICS V50 - JX Power Module Electrical Installa - 200904Pandu BirumakovelaNo ratings yet

- 01 World Class EE UnitsDocument19 pages01 World Class EE UnitsPandu BirumakovelaNo ratings yet

- 0003 mrl-rss36-rst36-1 enDocument10 pages0003 mrl-rss36-rst36-1 enPandu BirumakovelaNo ratings yet

- Sinamics g120 Ac DrivesDocument10 pagesSinamics g120 Ac DrivesPandu Birumakovela0% (1)

- Air Leakages Up To 10.3.2024Document2 pagesAir Leakages Up To 10.3.2024Pandu BirumakovelaNo ratings yet

- PID5030 M53om101 Issue14 Dt.23.10.13Document21 pagesPID5030 M53om101 Issue14 Dt.23.10.13Pandu BirumakovelaNo ratings yet

- Risk Assessment (RA) : Part 1: Location DetailsDocument3 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu Birumakovela0% (1)

- SINAMICS V50 - FX Power Module Electrical Installa - 200904Document8 pagesSINAMICS V50 - FX Power Module Electrical Installa - 200904Pandu BirumakovelaNo ratings yet

- Sinamics G120 Ac DrivesDocument10 pagesSinamics G120 Ac DrivesPandu BirumakovelaNo ratings yet

- Getting - Started - Guide - SINAMICSV50I - 112009 With CoverDocument42 pagesGetting - Started - Guide - SINAMICSV50I - 112009 With CoverPandu BirumakovelaNo ratings yet

- SOP-09 Preventive Maintenance - MachineDocument10 pagesSOP-09 Preventive Maintenance - MachinePandu BirumakovelaNo ratings yet

- Risk Assessment (RA) : Part 1: Location DetailsDocument4 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu BirumakovelaNo ratings yet

- 01 SOP Preventive Maintenance - MachineDocument4 pages01 SOP Preventive Maintenance - MachinePandu Birumakovela100% (1)

- Identification and Evaluation of Aspects and Impacts N-Non e W-Work InstructionDocument40 pagesIdentification and Evaluation of Aspects and Impacts N-Non e W-Work InstructionPandu BirumakovelaNo ratings yet

- 02 SOP Preventive Maintenance of DG SetsDocument4 pages02 SOP Preventive Maintenance of DG SetsPandu BirumakovelaNo ratings yet

- Evaluation Environmental Aspects ActivitywiseDocument4 pagesEvaluation Environmental Aspects ActivitywisePandu BirumakovelaNo ratings yet

- Environmental Register Evaluation of Possible Emergencies (FMEA)Document4 pagesEnvironmental Register Evaluation of Possible Emergencies (FMEA)Pandu BirumakovelaNo ratings yet

- Operation & Maint - DG SetsDocument4 pagesOperation & Maint - DG SetsPandu BirumakovelaNo ratings yet

- Environmental Register: Process: Preventive & General Maintenance of Equipment A 1Document1 pageEnvironmental Register: Process: Preventive & General Maintenance of Equipment A 1Pandu BirumakovelaNo ratings yet

- Risk Assessment (RA) : Part 1: Location DetailsDocument3 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu BirumakovelaNo ratings yet

- Risk Assessment (RA) : Part 1: Location DetailsDocument3 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu BirumakovelaNo ratings yet

- Machinewise Risk Assessment FormatDocument5 pagesMachinewise Risk Assessment FormatPandu BirumakovelaNo ratings yet

- Environmental Register - MasterDocument22 pagesEnvironmental Register - MasterPandu Birumakovela100% (1)

- Environmental Register: Process: Operation & Maintenance of DG Sets A 1Document1 pageEnvironmental Register: Process: Operation & Maintenance of DG Sets A 1Pandu BirumakovelaNo ratings yet

- 05 SOP Thermocouple - DTC CalibrationDocument4 pages05 SOP Thermocouple - DTC CalibrationPandu BirumakovelaNo ratings yet

- SOP Noise Testing of DG SetsDocument2 pagesSOP Noise Testing of DG SetsPandu Birumakovela100% (1)

- Environmental Register: Electrical Power Distribution & Maintenance of 33Kv Transformer A 1Document2 pagesEnvironmental Register: Electrical Power Distribution & Maintenance of 33Kv Transformer A 1Pandu Birumakovela100% (1)

- SOP-08 Thermocouple - DTC CalibrationDocument9 pagesSOP-08 Thermocouple - DTC CalibrationPandu BirumakovelaNo ratings yet

- 03 SOP Preventive Maintenance of TransformerDocument5 pages03 SOP Preventive Maintenance of TransformerPandu Birumakovela100% (2)

- By Conducting A PESTEL Analysis, Assess How The General Environment Would Impact The Strategies of Mahindra Electric Mobility Limited (MEML)Document1 pageBy Conducting A PESTEL Analysis, Assess How The General Environment Would Impact The Strategies of Mahindra Electric Mobility Limited (MEML)sushanthNo ratings yet

- Information To Be Included Within A Coal Mining Risk AssessmentDocument2 pagesInformation To Be Included Within A Coal Mining Risk AssessmentAlf HorsemanNo ratings yet

- Essay Impact of Water PollutionDocument2 pagesEssay Impact of Water PollutionMuhammad Khawar Hezazy UthmanNo ratings yet

- Tertiary Treatment:: Nutrient Removal, Solids Removal, and DisinfectionDocument31 pagesTertiary Treatment:: Nutrient Removal, Solids Removal, and Disinfectiondanena88No ratings yet

- Pas 2050Document43 pagesPas 2050Pili ESNo ratings yet

- Monitoring Air Quality LabDocument5 pagesMonitoring Air Quality Labapi-293913139No ratings yet

- Global Warming (Word Formation)Document2 pagesGlobal Warming (Word Formation)EvaNo ratings yet

- Case Study On Ozone LayerDocument33 pagesCase Study On Ozone LayerVivek KumarNo ratings yet

- EHS PresentationDocument18 pagesEHS Presentationsailesh bhattarai100% (1)

- An Introduction To Recycling - StuffDocument2 pagesAn Introduction To Recycling - StuffJames MaxwellNo ratings yet

- Street Design Manual WebinarDocument2 pagesStreet Design Manual WebinarJulius FisherNo ratings yet

- Chapter 6 The Contemporary WorldDocument3 pagesChapter 6 The Contemporary WorldLeslie Ann PotencianoNo ratings yet

- Nadi Muslim College English Research Project Year 12Document20 pagesNadi Muslim College English Research Project Year 12Mitesh KumarNo ratings yet

- Intro TR-55Document15 pagesIntro TR-55mariaincocivNo ratings yet

- MSDS Perseo (GB) PDFDocument10 pagesMSDS Perseo (GB) PDFRazvan PredaNo ratings yet

- Waste Disposal: November-March 2020 - 2021 Garbage .-Environmental Consequences and ChallengesDocument7 pagesWaste Disposal: November-March 2020 - 2021 Garbage .-Environmental Consequences and ChallengesRosa CapeloNo ratings yet

- John Deere Powersource - Tier 4 Engines On Godwin Pumps PDFDocument2 pagesJohn Deere Powersource - Tier 4 Engines On Godwin Pumps PDFAlvaro TreviñoNo ratings yet

- b690 Boysen Quick Drying Enamel BlackDocument8 pagesb690 Boysen Quick Drying Enamel Blackraighnejames19100% (2)

- VI.008. MSDS True Glue, WavinDocument7 pagesVI.008. MSDS True Glue, Wavinhin4moriNo ratings yet

- Greenhouse EffectDocument7 pagesGreenhouse EffectThuy ThanhNo ratings yet

- OAI551 Environment and AgricultureDocument4 pagesOAI551 Environment and AgricultureSaravanan SundaramNo ratings yet

- Pidato Bahasa Inggris Tentang Global WarmingDocument2 pagesPidato Bahasa Inggris Tentang Global WarmingIrwan NoviantoNo ratings yet

- Essay TopicsDocument2 pagesEssay TopicsJoe Calvin RossarioNo ratings yet

- Example of Research IntroductionDocument14 pagesExample of Research IntroductionroviannmaehlidemNo ratings yet

- Msds - VK JellyDocument3 pagesMsds - VK JellyArun33% (3)

- Building Services Assignment 1 PDFDocument27 pagesBuilding Services Assignment 1 PDFZulkifliNo ratings yet

- From Dump To Sanitary Landfill and What Next - A Case Study From The Lebanese Capital BeirutDocument8 pagesFrom Dump To Sanitary Landfill and What Next - A Case Study From The Lebanese Capital BeirutMario WhoeverNo ratings yet

- Environmental Management PlanDocument38 pagesEnvironmental Management PlanDaniel60% (5)

- Republic Act 8749Document4 pagesRepublic Act 8749sean PalomaNo ratings yet

- Assessment of Ground Water Quality Around Industrial Area in Aurangabad, MaharashtraDocument4 pagesAssessment of Ground Water Quality Around Industrial Area in Aurangabad, MaharashtraIOSRjournalNo ratings yet