Professional Documents

Culture Documents

Inspection Test Plan - Vagadra

Uploaded by

Rahul DeoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inspection Test Plan - Vagadra

Uploaded by

Rahul DeoCopyright:

Available Formats

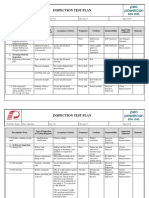

INSPECTION AND TEST PLAN

Activity: Earthworks Project: Contract No. 18 - 57B - Western Division Unseal road upgrade

ITP Number: / EAR / Location:

Drawing & Revision No:

Inspection Hold Method of Inspection / Test Type and Test Results

Construction Process Reference Inspection Frequency Signature Date Comments

/ Test By Points Inspection/Test Acceptance Criteria Received

Preliminary works

Contractors Ensure all the underground services

Existing Service Location Permit to Dig Prior to Excavation

Rep are identified and Marked

PWD

Contractors Check if clearing is as per contract

Clearing and Grubbing specification Site Inspection As Required

Rep Drawing and Specifcation

Section 201

Technical

Engineer's Check if all agreed silt,erosion& dust Prior to earthworks

Drainage Specification HOLD POINT Site Inspection

Assistant control measures are installed commences

D4.2

PWD

Engineer's

Stockpiling specification & HOLD POINT Site Inspection Engineer's Approval Identification of Dump Site

Assistant

TNZ F/1

minimum <2 - 500mm (constructed

and compacted in 2 layers of 250

DCP inferred CBR to 1m 1 test at the centre of each

Contractors normainal thickness

depth on the prepared lane, or part thereof, at 50m

Rep >2 300mm (constructed and

subgrade intervals .

compacted in 2 layers of 150

normainal thickness

Contractors

HOLD POINT Subgrade Cut Visual Check each section

Rep

Contractors

Proof Rolling Visual R.L 50mm above to 50mm

Rep

below design level

PWD Contractors Material (Fill

Approval for Sub-grade Works specification As Per Contract Specification As required

Rep Exisitng)Construction

& TNZ F/1

Contractors Layer Thickness Check each section of

200 maximun layer (Solid)

Rep Measured prepared subgrade

DCP inferred CBR to 1m 1 test at the centre of each

Contractors

HOLD POINT depth on the prepared As Per Contract Specification lane, or part thereof, at 50m

Rep

subgrade intervals .

Check each section of

HOLD POINT Proof Rolling Engineer's approval

prepared subgrade

+30mm to -30mm of final

Engineers Rep Pre Trim Level Visual

Grade

Subgrade Surface Finish Visual Within Specified Tolerences

Contractors DCP inferred CBR to 1m

Rep / depth on the prepared Engineer's approval Prior to structual repair

Section 4

Engineers subgrade

Technical

Structual Repairs Assistant

Specification Proof Rolling Engineer's approval As required

D4.4

Contractors Layer Thickness

Visual As Required

Rep Measured

Material Engineer's approval As Required

200mm (Loose) less 1.5m to

Subgrade level,300mm (Loose) for

Engineered Fill and Additional Fill Contractors greater than 1.5m from Subgrade

Rep Layer Thickness Level

As Required

Measured

PWD

Contractors Manufacturers

Geotextlie – materials specification Visual Check each lot (1 roll)

Rep compliance certificate

and TNZ F/1

Directional placement Visual

1 check per 100m2 of

PWD Tensioning laps Visual material placed with a

Geotextlie – construction TNZ F/7 specification Contractor Rep

Spacing Visual minimum of 3 tests for area

and TNZ F/1

covered

Damage Visual

PWD

Engineer's Notify Engineer a

Inspection of finished cut / fill areas specification HOLD POINT Engineer's approval On completion

Assistant minimum of 48 hours

and TNZ F/1

WORKS COMPLETE AND CONFORMING:

Authorised:

Date:

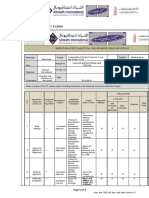

INSPECTION AND TEST PLAN

Activity: Stormwater Drainage Project: Contract No. 18 - 57B - Western Division Unseal road upgrade

ITP Number: / SWD / Location:

Drawing & Revision No:

Inspection Hold Method of Inspection / Test Type and Test Results

Construction Process Reference Inspection Frequency Signature Date Comments

/ Test By Points Inspection/Test Acceptance Criteria Received

Materials

PWD

Contractors

Foundation specification Material Approved Ap 65 As Required

Rep

& TNZ F/1

PWD

Contractors

Bedding& Haunching specification Submit Engineer's Approval Prior to start

Rep

& TNZ F/1

As per the contract Drawing,Should

PWD

Contractors also comply PWD 501 the

Pipes & fitting specification Specification Prior to start

Rep manufractures instruction and good

501

trade practice

Construction

PWD

Contractors

Pipe Bedding specification Visual As per Pipe Bedding Clause 501.02 As required

Rep

501

PWD

Contractors As per laying and jointing pipe Clause

Laying& Jointing Pipes specification Visual As required

Rep 501.09

501

PWD

Contractors

Drainage Structure specification Visual As per Drainage Structure Clause 1 As required

Rep

501

PWD

Contractors As per Backfilling& Compactiob

Backfilling&Reinstatement specification Visual As required

Rep standard 501.12

501

PWD

Contractors Should be completed with atleast

Surfacing of Trenches specification Visual As required

Rep 150mm compacted fill material

501

Inspection

Engineers Commencement of

General 20.3.1 Engineers Approval Every Layer

Assistant Stages

All required test needs to be

Testing 20.3.2 Contractor Rep Submit Every Layer

completed

WORKS COMPLETE AND CONFORMING:

Authorised:

Date:

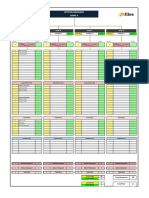

INSPECTION AND TEST PLAN

Activity: Subbase Project: Contract No. 18 - 57B - Western Division Unseal road upgrade

ITP Number: / SUB/ Location:

Drawing & Revision No:

Inspection Method of Inspection / Test Type and Test Results

Construction Process Reference Hold Point Inspection Frequency Signature Date Comments

/ Test By Inspection/Test Acceptance Criteria Received

Visual check to confirm all testing

Subgrade Signed of by Engineers Rep Site Engineer HOLD POINT Submitted Prior to start

requirements on Subgrade closed out

Material

1 / Every 2500m3 of

Grading In accordance with PWD 301 production per aggregate

source

1 / Every 2500m3 of

PWD

Crushing Resistance. In accordance with PWD 301 production per aggregate

specification

source

302 Materials

for Pavement 1 / Every 2500m3 of

Aggregate Gap 75 Contractors

Construction Flakiness Index In accordance with PWD 301 production per aggregate

Rep

source

Technical

1 / Every 2500m3 of

Specification

California Bearing Ratio In accordance with PWD 301 production per aggregate

D4.6

source

1 / Every 2500m3 of

Plasticity Index

In accordance with PWD 301 production per aggregate

Liquid Limit

source

Material Acceptance Engineers Refer Aggregate Production Sheet All

Assistant HOLD POINT Gap 75 As Required

test results comply

Placement

specification

302 Materials Shall be as shown on the drawing& in

Contractors

Spread to Required Layer Thickness for Pavement Visual accordance with TNZ B/02: 2005 < 2.5 Continuous

Rep

Construction maximum particle size

Roller compaction to achive requirment

Degree of Compaction Technical Lab Visual Continuous

as per technical specification

Specification

Verification

Contractors

Check pavement width Visual PWD specification 302.02 © 1 per 20m

Rep

PWD specification Tolerance: -30mm

Contractors

Trim to level PWD Visual +30mm 2 per 20m

Rep

specification

302 Materials Contractors

for Pavement Rep /

Surface check Construction HOLD POINT Visual Dipping Every 20m

Engineers

Assistant

Contractors Tech Spec D4.6 Clegg Impact Hammer

Compaction Visual Continuous

Rep testing at every 40m

WORKS COMPLETE AND CONFORMING:

Authorised:

Date:

INSPECTION AND TEST PLAN

Activity: Base- Course Project: Contract No. 18 - 57B - Western Division Unseal road upgrade

ITP Number: /BAS/ Location:

Drawing & Revision No:

Inspection Method of Inspection / Test Type and Test Results

Construction Process Reference Hold Point Inspection Frequency Signature Date Comments

/ Test By Inspection/Test Acceptance Criteria Received

Visual check to confirm all testing

Sub-base Signed of by Engineers Rep Site Engineer HOLD POINT Submitted Prior to start

requirements on Subgrade closed out

Material

1 / Every 2500m3 of

Grading In accordance with PWD 301 production per aggregate

source

1 / Every 2500m3 of

PWD Crushing Resistance. In accordance with PWD 301 production per aggregate

specification source

302 Materials

1 / Every 2500m3 of

Aggregate AP 40 for Pavement Contractors

Flakiness Index In accordance with PWD 301 production per aggregate

Construction Rep

source

Technical

Specification 1 / Every 2500m3 of

D4.6 California Bearing Ratio In accordance with PWD 301 production per aggregate

source

1 / Every 2500m3 of

Plasticity Index

In accordance with PWD 301 production per aggregate

Liquid Limit

source

Engineers Refer Aggregate Production Sheet All

Material Acceptance Assistant HOLD POINT Gap 75 As Required

test results comply

Placement

PWD Shall be as shown on the drawing& in

specification Contractors

Spread to Required Layer Thickness Visual accordance with TNZ B/02: 2005 < 2.5 Continuous

302 Materials Rep

maximum particle size

for Pavement

Construction

Technical

Specification Roller compaction to achive requirment

Degree of Compaction Lab Visual Continuous

D4.6 as per technical specification

Verification

Contractors

Check pavement width Visual PWD specification 302.02 © 1 per 20m

Rep

PWD specification Tolerance: -30mm

PWD Contractors

Redress Surface Visual +30mm 2 per 20m

specification Rep

302 Materials Contractors

for Pavement Rep /

Surface check Construction HOLD POINT Visual Dipping Every 20m

Engineers

Assistant

Contractors Tech Spec D4.6 Clegg Impact Hammer

Compaction Visual Continuous

Rep testing at every 40m

WORKS COMPLETE AND CONFORMING:

Authorised:

Date:

You might also like

- Lift Station Civil ItpDocument2 pagesLift Station Civil ItpsahilNo ratings yet

- Inspection & Test PlanDocument1 pageInspection & Test PlanDanielNo ratings yet

- ITP EXCAVATION BACKFILLDocument1 pageITP EXCAVATION BACKFILLDan SarmientoNo ratings yet

- Temporary Detour at Lebak Bulus: Construction of Mass Rapid Transit JakartaDocument7 pagesTemporary Detour at Lebak Bulus: Construction of Mass Rapid Transit JakartaJosua Ferry ManurungNo ratings yet

- Field Inspection & Test Plan: DoosanDocument4 pagesField Inspection & Test Plan: DoosanBalkishan DyavanapellyNo ratings yet

- TWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTDocument6 pagesTWJO-ITP-PRC-0005 Reva2 ITP For PC BoxCul in LBDPTBangkit SamosirNo ratings yet

- Inspection Test Plan Piling WorkDocument4 pagesInspection Test Plan Piling WorkAhmad AfeeqNo ratings yet

- ET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Document2 pagesET - CONCRTE GENERIC ITP - 001 - Rev0 (Prelim) 1Sagar Aliasjackey100% (1)

- 5 ITP Block WorkDocument2 pages5 ITP Block Workahmsami91No ratings yet

- ITP - Blockwork R0 - HKHDocument2 pagesITP - Blockwork R0 - HKHabdou89% (9)

- Inspection and Test Plan for Fuel Oil Piping SystemDocument2 pagesInspection and Test Plan for Fuel Oil Piping Systemachusanachu100% (1)

- Structural Cabling System Inspection & Test PlanDocument1 pageStructural Cabling System Inspection & Test PlanRommel Espinosa ParasNo ratings yet

- ITP - Subgrade.Document2 pagesITP - Subgrade.Manish PatilNo ratings yet

- Fiberglass and Foster - Inspection Test Plan - ITPDocument4 pagesFiberglass and Foster - Inspection Test Plan - ITPAlaa Ali100% (1)

- Drainage Work - Inspection Test Plan - ITPDocument4 pagesDrainage Work - Inspection Test Plan - ITPAlaa Ali67% (3)

- QAP FinalDocument6 pagesQAP FinalANSHUMAN KUMARNo ratings yet

- GroutingDocument1 pageGroutingAlif Rahmat FebriantoNo ratings yet

- Excavation and Backfilling in Earth Works ChecklistDocument1 pageExcavation and Backfilling in Earth Works ChecklistJoe PsNo ratings yet

- ITP For CCTV System Testing & CommissioningDocument1 pageITP For CCTV System Testing & CommissioningTamer EidNo ratings yet

- Inspection and Test Plan For Waterproofing WorksDocument8 pagesInspection and Test Plan For Waterproofing WorksResearcherNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- 7 ITP PlasterDocument1 page7 ITP Plasterahmsami91No ratings yet

- Kaden Road Utilities Civil Works ITP Inspection PlanDocument3 pagesKaden Road Utilities Civil Works ITP Inspection Planmd_rehan_2No ratings yet

- Itp Repair Works 79Document2 pagesItp Repair Works 79Mohamed GamalNo ratings yet

- TWJO-ITP-GEN-0009 Reva0 ITP For Precast Box Culvert in L B Depot AreaDocument5 pagesTWJO-ITP-GEN-0009 Reva0 ITP For Precast Box Culvert in L B Depot AreaBangkit SamosirNo ratings yet

- ITP For BLOCKWORKDocument4 pagesITP For BLOCKWORKimkashifsaleemNo ratings yet

- Fabrication of Steel Structure and Steel Equipmentitp PDF FreeDocument4 pagesFabrication of Steel Structure and Steel Equipmentitp PDF FreeAhmed GhareebNo ratings yet

- Inspection and Test Plan: Tile WorksDocument2 pagesInspection and Test Plan: Tile WorksAlvene Tagoc100% (2)

- Appendix H: Design and Construction Manual Design RequirementsDocument17 pagesAppendix H: Design and Construction Manual Design RequirementsPageduesca RouelNo ratings yet

- CGC-ITP-MECH-002-Irrigation SystemDocument6 pagesCGC-ITP-MECH-002-Irrigation SystemSajad Pk100% (1)

- 18.9 ITP SUB BASE Rev01Document2 pages18.9 ITP SUB BASE Rev01YEHIA100% (1)

- Inspection and test plan for retaining wall constructionDocument11 pagesInspection and test plan for retaining wall constructionBangkit SamosirNo ratings yet

- Transformer Inspection Checklist: DepartmentDocument18 pagesTransformer Inspection Checklist: DepartmentADEN LIU100% (1)

- Inspection Test Plan (Itp) : Althamra Self Owned Property Leasing & Management ServicesDocument11 pagesInspection Test Plan (Itp) : Althamra Self Owned Property Leasing & Management Servicespunk cmNo ratings yet

- Inspection & Test Plan: Ramsis Job No: 20BG1251 Item No: Bapco Gas Product LineDocument2 pagesInspection & Test Plan: Ramsis Job No: 20BG1251 Item No: Bapco Gas Product LineSanjit TiwariNo ratings yet

- Attach-2 ITP For Building WaterDocument29 pagesAttach-2 ITP For Building WaterSukalyan BasuNo ratings yet

- Inspection and Test Plan Installation and Testing of Sewerage PipingDocument3 pagesInspection and Test Plan Installation and Testing of Sewerage Pipingmd_rehan_2No ratings yet

- ITP For For Precast BalconyDocument4 pagesITP For For Precast BalconydamianNo ratings yet

- ITP For Structured Cabling System & Accessories InstallationDocument1 pageITP For Structured Cabling System & Accessories InstallationInfas YahyaNo ratings yet

- Inspection Test FormDocument3 pagesInspection Test FormsreejeshNo ratings yet

- Inspection and Test Plan For Cpno5 Installation of Conduits and Boxes For All BuildingDocument1 pageInspection and Test Plan For Cpno5 Installation of Conduits and Boxes For All BuildingJoyce GordonioNo ratings yet

- Gate Installation ReportDocument3 pagesGate Installation ReportKumar AbhishekNo ratings yet

- 2021.12.13 ITP - Concreting (5244.009) V.0Document4 pages2021.12.13 ITP - Concreting (5244.009) V.0huot phirunNo ratings yet

- ITP-00010 Pavement Road WorksDocument3 pagesITP-00010 Pavement Road WorksIsmail MydeenNo ratings yet

- ITP List For Electrical Works (Chimney)Document16 pagesITP List For Electrical Works (Chimney)Ivan BabicNo ratings yet

- Construct Facilities Support MH-60R AircraftDocument3 pagesConstruct Facilities Support MH-60R AircraftAlvene TagocNo ratings yet

- Excavation PermitDocument1 pageExcavation Permitamenmohamm3dNo ratings yet

- 11 - TRF (RCC Pour Card)Document2 pages11 - TRF (RCC Pour Card)Santosh KumarNo ratings yet

- Posorja Multipurpose Terminal Terminal Works: High-Mast and CCTV Poles InstallationDocument5 pagesPosorja Multipurpose Terminal Terminal Works: High-Mast and CCTV Poles Installationhz135874No ratings yet

- TWJO-ITP-PRC-0005 Revc ITP For Box Culvert at LB DepotDocument9 pagesTWJO-ITP-PRC-0005 Revc ITP For Box Culvert at LB DepotBangkit SamosirNo ratings yet

- EPCMD-2-QM00-ITP-CS-003Document2 pagesEPCMD-2-QM00-ITP-CS-003SURAJ PRSADNo ratings yet

- Ayc Inspection Checklist: Linolium Sheet Pre - Installation Inspection Industrial Support Facilities BuildingDocument6 pagesAyc Inspection Checklist: Linolium Sheet Pre - Installation Inspection Industrial Support Facilities Buildingmoytabura96No ratings yet

- Tins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)Document4 pagesTins-Gen-Itp-M-001 To 005-r00 - Mechanical Works (Logo 2)achusanachuNo ratings yet

- Itp - Water ProofingDocument1 pageItp - Water ProofingUbaidullah KhanNo ratings yet

- ITP For Block WorkDocument9 pagesITP For Block WorkMohammed Ghareib Nasr100% (1)

- Inspection-Test-plan For Block WorkDocument3 pagesInspection-Test-plan For Block WorkAbdulrahman Alkilani100% (2)

- ITP Inspection and Testing Plan For Above Ground Water Supply PipesDocument1 pageITP Inspection and Testing Plan For Above Ground Water Supply Pipessarmad spectrumNo ratings yet

- ITP For Access Control SystemTesting and CommissioningDocument1 pageITP For Access Control SystemTesting and CommissioningTamer EidNo ratings yet

- FRA 18-57B Weekly Progress Report 76 Weekly Ending 17-07-22Document4 pagesFRA 18-57B Weekly Progress Report 76 Weekly Ending 17-07-22Rahul DeoNo ratings yet

- Promex Consulting PTE Limited Consulting Engineers and Project ManagersDocument1 pagePromex Consulting PTE Limited Consulting Engineers and Project ManagersRahul DeoNo ratings yet

- Environmental: Site Inspection ChecklistDocument4 pagesEnvironmental: Site Inspection ChecklistRahul DeoNo ratings yet

- April 2022MDRA2022.05.03 11.59.25Document1 pageApril 2022MDRA2022.05.03 11.59.25Rahul DeoNo ratings yet

- Section Manager Name #: Zone A Zone B Zone C Zone DDocument1 pageSection Manager Name #: Zone A Zone B Zone C Zone DRahul DeoNo ratings yet

- Daily Site ReportDocument3 pagesDaily Site ReportRahul DeoNo ratings yet

- Erotic MassageDocument113 pagesErotic MassageMahmoud El Mohamdy75% (4)

- Essotherm 500 PDFDocument8 pagesEssotherm 500 PDFdonyaNo ratings yet

- Amco Veba Marine - Brochure - LRDocument24 pagesAmco Veba Marine - Brochure - LRHươngTpuNo ratings yet

- Manual Hoist ProductsDocument40 pagesManual Hoist Productskavin bhagavathyNo ratings yet

- Hydromechanical Piercing Perforation: Oil Service Innovation TechnologiesDocument8 pagesHydromechanical Piercing Perforation: Oil Service Innovation TechnologiesЕлена ПаниотNo ratings yet

- Pharmaceutical Ingredients and Excipient - LastpptDocument72 pagesPharmaceutical Ingredients and Excipient - LastpptFANTANo ratings yet

- Well Rounded.: 360 CassetteDocument12 pagesWell Rounded.: 360 CassetteMonty Va Al MarNo ratings yet

- Meralco Bill 330370940102 04142023Document2 pagesMeralco Bill 330370940102 04142023Jha CruzNo ratings yet

- 0610 m16 QP 62Document12 pages0610 m16 QP 62faryal khanNo ratings yet

- Queer Ecology Critique - Georgetown 2014Document104 pagesQueer Ecology Critique - Georgetown 2014Evan JackNo ratings yet

- Ras Abu Aboud Stadium Daily Report 040 (20190613)Document4 pagesRas Abu Aboud Stadium Daily Report 040 (20190613)tuan50% (2)

- Mobile Network Optimization MapDocument1 pageMobile Network Optimization MapShahzad Farooq100% (1)

- General ALT Model For Step Stress TestDocument12 pagesGeneral ALT Model For Step Stress TestAnshul NautiyalNo ratings yet

- Legend of Nueva VizcayaDocument10 pagesLegend of Nueva VizcayaAndreanna Maria100% (1)

- Deks Olje ArticleDocument5 pagesDeks Olje ArticleTomMacNaughtonNo ratings yet

- Fair Directory 02-2016Document44 pagesFair Directory 02-2016Ravichandran SNo ratings yet

- GROHE Specification Sheet 19443000-1Document2 pagesGROHE Specification Sheet 19443000-1Fred PrzNo ratings yet

- 5988-4082EN Designers GuidDocument82 pages5988-4082EN Designers GuidAndreaNo ratings yet

- Wda 201Document72 pagesWda 201MoussaNo ratings yet

- 07 IRIS NV PCB OtherDocument15 pages07 IRIS NV PCB OtherArnaldo cordovaNo ratings yet

- Parapsychology QP - WikiDocument371 pagesParapsychology QP - WikiAdamNo ratings yet

- Am 363 PDFDocument4 pagesAm 363 PDFsunsirNo ratings yet

- Memorial Garden Policies and Guidelines St. Mark's Episcopal Church, Raleigh, North CarolinaDocument7 pagesMemorial Garden Policies and Guidelines St. Mark's Episcopal Church, Raleigh, North Carolinaestela maria dulaganNo ratings yet

- Kyle 106 - 119 - 131 - 141Document1 pageKyle 106 - 119 - 131 - 141Gerson SouzaNo ratings yet

- FIKE RD Combo With Relief ValvesDocument11 pagesFIKE RD Combo With Relief ValvesAnkit GandhiNo ratings yet

- Galactic Handbook and Synchronized MeditationsDocument91 pagesGalactic Handbook and Synchronized Meditationslapiton100% (10)

- SPC英文版教材Document83 pagesSPC英文版教材bing cai100% (2)

- CaseStudy AmtrakDocument14 pagesCaseStudy Amtraksnob_kNo ratings yet

- Auomotivr Fuel TanksDocument9 pagesAuomotivr Fuel Tankscolumba_mcNo ratings yet

- Sabp X 002Document18 pagesSabp X 002Hassan MokhtarNo ratings yet