Professional Documents

Culture Documents

Erection Welding Schedule: Revno: Page No. Date Doc No. Prepared Checked (W.T.C) Approved

Uploaded by

EXECUTIVE ENGINEEER BOILER MAINTENANCEOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Erection Welding Schedule: Revno: Page No. Date Doc No. Prepared Checked (W.T.C) Approved

Uploaded by

EXECUTIVE ENGINEEER BOILER MAINTENANCECopyright:

Available Formats

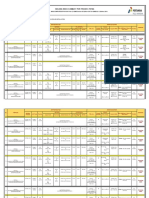

ERECTION WELDING SCHEDULE PG NO : 17

CUST No : 0322 PG NAME : Reheater System

PROJECT : KPCL / Raichur TPS Unit 4, 210 MW SYSTEM DESCRIPTION : Reheater System

WELDING CODE : IBR / ASME PRESSURE PARTS/NON PRESSURE PARTS CUST DOC NO : - CUST DOC REV : -

TYPE OF ELECTRODE FILLER SPEC PWHT

DIMENSIONS WELD MIN. TEMP. in * REF-.

DRG NO. FOR WELD GTAW SMAW WPS PRE °C

SL. DESCRIPTION OF PARTS PROCESS OF NDT METHOD/

LOCATION & MATERIAL SPEC. NO/REV HEAT REMARKS REV

NO TO BE WELDED WELDING Qty in Nos. QUANTUM ACC

IDENTIFICATION MARK NO. TEMP. TIME SPEC.

SIZE THICK Qty in Nos. Qty in gms in °C NORM

∅2.5 ∅3.15 ∅4.0 in mins NO

REF.

3.6 ER90S-B3 E9018-B3 Nil

20% RT subject to

SA213T22 + GTAW +

1 2-16-275-01778 TUBE+TUBE 54 3.6 1013/02 150 min 2 weld/

SA213T22 SMAW

welder/ shift

157 10012 - - -

3.6 ER80S-B2 E8018-B2 Nil

20% RT subject to

SA213T11 + GTAW +

2 2-16-275-01778 TUBE+TUBE 54 3.6 1009/03 150 min 2 weld/

SA213T11 SMAW

welder/ shift

157 10012 - - -

PREPARED CHECKED (W.T.C) APPROVED DATE DOC NO. REV NO : PAGE NO.

0322-17-RH-EWS X 1/1

THE INFMN ON THIS DOCUMENT IS THE PROPERTY OF BHEL. IT MUST NOT BE USED DIRECTLY OR INDIRECTLY IN ANY * REFER NDE MANUAL No.PS:CMX:002 REV.No.01/12-98. * ALSO REFER QUALITY GUIDELINE NO: SIP:PP:29 / LATEST REV. AND

CAUTION : SIP:PP:31 / LATEST REV. NOTE: HARDNESS CHECK OF 3% OF TOTAL WELD JOINTS IN ALLOY STEEL PIPES (OTHER THAN GR91) TO BE

WAY DETRIMENTAL TO INTEREST OF BHEL. CARRIED OUT (260 HV MAX).

You might also like

- Egyptian Sponge Iron & Steel Company Direct Reduction Iron Facility On/Off Control Valve ListDocument4 pagesEgyptian Sponge Iron & Steel Company Direct Reduction Iron Facility On/Off Control Valve ListMohamed Elsaid El ShallNo ratings yet

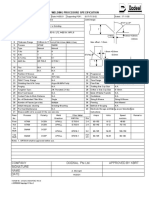

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Egyptian steel plant valve listDocument6 pagesEgyptian steel plant valve listMohamed Elsaid El ShallNo ratings yet

- 3827-E10-066 - Knife Gate (On-Off) Control Valve - DDocument2 pages3827-E10-066 - Knife Gate (On-Off) Control Valve - DMohamed Elsaid El ShallNo ratings yet

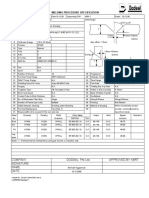

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Ethylene Project Welding Procedure SpecificationDocument1 pageEthylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS-CR 01-06-15Document1 pageWPS-CR 01-06-15majdi jerbiNo ratings yet

- Pwps-Gtaw FcawDocument2 pagesPwps-Gtaw FcawAhmed ElsharkawNo ratings yet

- Epc For Rumaitha Thamama Zone B Phase Iii Expansion Development & Conversion of Ra Phase I/Ii Co2 Affected WellsDocument1 pageEpc For Rumaitha Thamama Zone B Phase Iii Expansion Development & Conversion of Ra Phase I/Ii Co2 Affected WellsBWQNo ratings yet

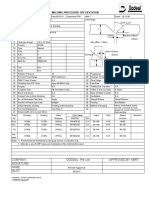

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Petroleum Equipment Assembly & Metal Structure JSC: N/A N/ADocument2 pagesPetroleum Equipment Assembly & Metal Structure JSC: N/A N/AKhôi ĐàoNo ratings yet

- WELDING BOOK SUMMARY FOR PIPING PROCESS REFERENCEDocument6 pagesWELDING BOOK SUMMARY FOR PIPING PROCESS REFERENCEFerdie OSNo ratings yet

- Ele Vir Flush Ring 160 0001 To 0008Document16 pagesEle Vir Flush Ring 160 0001 To 0008rahul o gNo ratings yet

- WPS CR 01-08-09Document1 pageWPS CR 01-08-09majdi jerbiNo ratings yet

- Welding Procedure Specification (WPS) : N.A N.ADocument1 pageWelding Procedure Specification (WPS) : N.A N.AMajdi JerbiNo ratings yet

- AWS WPS for welding steel with SMAWDocument2 pagesAWS WPS for welding steel with SMAWSleyda MunozNo ratings yet

- TMK - Insp of Fuel Filter.342Document2 pagesTMK - Insp of Fuel Filter.342sivaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure for Stainless Steel PipingDocument1 pageWelding Procedure for Stainless Steel Pipingmajdi jerbiNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Wps Repair WorDocument1 pageWps Repair WorMajdi JerbiNo ratings yet

- 0 Gtaw TR-235 FW-10 Field TW-665 N/A 10.00 S-20 Butt Pipe To Pipe HD-EC-TF-DR5001-008Document1 page0 Gtaw TR-235 FW-10 Field TW-665 N/A 10.00 S-20 Butt Pipe To Pipe HD-EC-TF-DR5001-008Anonymous AdofXEYAgENo ratings yet

- FA-For ReferenceDocument1 pageFA-For ReferenceUmer KhanNo ratings yet

- Visual 23 Januari 24Document1 pageVisual 23 Januari 24Abd Chalik Faja Dawani SiraitNo ratings yet

- PARAMETROSDocument2 pagesPARAMETROSEdson AragaNo ratings yet

- KOC FIRE & GAS PIPE THREAD SUMMARYDocument1 pageKOC FIRE & GAS PIPE THREAD SUMMARYKuwait Gulf CircleNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Central de Generación: Power Plant Pressure - Temperature Regulator ValveDocument1 pageCentral de Generación: Power Plant Pressure - Temperature Regulator Valvejuan carlos suaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 pagesList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNo ratings yet

- Q-Chem Ethylene Project Welding Procedure SpecificationDocument1 pageQ-Chem Ethylene Project Welding Procedure SpecificationS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 1 Full Segment: Abu Dhabi Oil Co., LTD (Japan)Document1 page1 Full Segment: Abu Dhabi Oil Co., LTD (Japan)Anonymous AdofXEYAgENo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- CC Schedule HEGDocument16 pagesCC Schedule HEGvomicih221No ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document2 pagesWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- WPS PTR 01-08-09Document1 pageWPS PTR 01-08-09majdi jerbiNo ratings yet

- Fit-Up Piping B192-5-S2Document22 pagesFit-Up Piping B192-5-S2Prathamesh OmtechNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Fill Data SheetDocument4 pagesFill Data Sheethector thomasNo ratings yet

- Manual Standard WeldingDocument192 pagesManual Standard WeldingGEORGE IVAN0% (1)

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- Request welding procedure approvalDocument18 pagesRequest welding procedure approvalecsuperal100% (1)

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Document1 pageWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaNo ratings yet

- StanadyneDocument1 pageStanadyneJunior IungNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- SPL-MFP-MEC-IR-002A Rev. 0-PQR WELDER QUALIFICATION DATA SHEETDocument1 pageSPL-MFP-MEC-IR-002A Rev. 0-PQR WELDER QUALIFICATION DATA SHEETgopuvinu4uNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Assessment of Erosion resistance through CFD modelingDocument5 pagesAssessment of Erosion resistance through CFD modelingEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Electrode SummaryDocument1 pageElectrode SummaryEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- 80 Love Quotes From A Parent To A Child - LoveToKnowDocument35 pages80 Love Quotes From A Parent To A Child - LoveToKnowEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- 37 Newborn Baby Quotes To Share The LoveDocument39 pages37 Newborn Baby Quotes To Share The LoveEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- 103 Sweet New Baby Quotes To Welcome Them Home - Gifts - Com BlogDocument17 pages103 Sweet New Baby Quotes To Welcome Them Home - Gifts - Com BlogEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- BoilerDocument48 pagesBoilerJuan Francisco CHavez ViladegutNo ratings yet

- KPCL DAV HIGH SCHOOL STUDY MATERIALDocument6 pagesKPCL DAV HIGH SCHOOL STUDY MATERIALEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- 84 Inspirational Baby Quotes and Sayings - ShutterflyDocument19 pages84 Inspirational Baby Quotes and Sayings - ShutterflyEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Boiler hydrostatic test procedure under 40 charsDocument6 pagesBoiler hydrostatic test procedure under 40 charsBIRANCHINo ratings yet

- Emergency Operations: Shaikh Feroz AliDocument15 pagesEmergency Operations: Shaikh Feroz AliEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Boiler 210mwDocument15 pagesBoiler 210mwishakNo ratings yet

- Case Studies in Engineering Failure Analysis: S.W. Liu, W.Z. Wang, C.J. LiuDocument5 pagesCase Studies in Engineering Failure Analysis: S.W. Liu, W.Z. Wang, C.J. LiuSushil KumarNo ratings yet

- Case Studies in Engineering Failure Analysis: S.W. Liu, W.Z. Wang, C.J. LiuDocument5 pagesCase Studies in Engineering Failure Analysis: S.W. Liu, W.Z. Wang, C.J. LiuSushil KumarNo ratings yet

- Boiler 210mwDocument15 pagesBoiler 210mwishakNo ratings yet

- 4188-22942-1-PB Failure Analysis of SH TubesDocument13 pages4188-22942-1-PB Failure Analysis of SH TubesEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Automatic Detection and Analysis of Boiler Tube LeDocument6 pagesAutomatic Detection and Analysis of Boiler Tube Lesachin gautamNo ratings yet

- RTPS Unit Shut Down ProceduresDocument22 pagesRTPS Unit Shut Down ProceduresEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Loesche Optimization & Efficiency Improvement in Coal PulverisersDocument34 pagesLoesche Optimization & Efficiency Improvement in Coal PulverisersEXECUTIVE ENGINEEER BOILER MAINTENANCE100% (1)

- Start UpsDocument31 pagesStart UpsEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- The Boilers Act, 1923 SummaryDocument30 pagesThe Boilers Act, 1923 SummaryEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- 1319 3 Guidelines For WeldingDocument64 pages1319 3 Guidelines For Weldingg_sanchetiNo ratings yet

- Mill & Mill Rejects WriteupDocument10 pagesMill & Mill Rejects WriteupEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- ISO 9001 What Are The Changes - Arun SinhaDocument8 pagesISO 9001 What Are The Changes - Arun SinhaEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Thermal Drain ValvesDocument2 pagesThermal Drain ValvesEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Deriving Energy Efficiency From Coal Mill Gear Box - DR JaiswalDocument22 pagesDeriving Energy Efficiency From Coal Mill Gear Box - DR JaiswalEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Performance of Governor Oil - Soumik Majumdar & Sanjay DasDocument21 pagesPerformance of Governor Oil - Soumik Majumdar & Sanjay DasEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Empowering Reliability Through Lubrication Program Development (LPD) Udey DhirDocument28 pagesEmpowering Reliability Through Lubrication Program Development (LPD) Udey DhirEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Aph BasketDocument38 pagesAph BasketEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- Coal NozzlesDocument29 pagesCoal NozzlesEXECUTIVE ENGINEEER BOILER MAINTENANCENo ratings yet

- HighPerformanceSteel (ForBridgeConstrunction) en PDFDocument20 pagesHighPerformanceSteel (ForBridgeConstrunction) en PDFrajagouthamNo ratings yet

- Grinding & Finishing (Me)Document14 pagesGrinding & Finishing (Me)amar chakrabortyNo ratings yet

- Paper 2Document13 pagesPaper 2saviyasathuNo ratings yet

- Kuliah 6 - 7 - Mampu KerasDocument36 pagesKuliah 6 - 7 - Mampu KerasEsti Nur AmaliaNo ratings yet

- Iron AlloysDocument6 pagesIron AlloysHieu NguyenNo ratings yet

- Ductile or Partial Ductile Mode Machining of Brittle MaterialsDocument7 pagesDuctile or Partial Ductile Mode Machining of Brittle MaterialsHangi TakimlisinNo ratings yet

- Ferrite Testing ProcedureDocument6 pagesFerrite Testing ProcedureReadersmo0% (1)

- M2502 Rev1Document2 pagesM2502 Rev1Pablo GonzalesNo ratings yet

- Bijou Siglo XXI Corporate ProfileDocument16 pagesBijou Siglo XXI Corporate ProfileBijou Siglo XXINo ratings yet

- FEDERAL STANDARD FOR STEEL CHEMICAL COMPOSITION AND HARDENABILITYDocument16 pagesFEDERAL STANDARD FOR STEEL CHEMICAL COMPOSITION AND HARDENABILITYrobert_in_arNo ratings yet

- Dental Casting AlloysDocument22 pagesDental Casting AlloysSurabhi RairamNo ratings yet

- Galvanized Rebar Vs Epoxy RebarDocument4 pagesGalvanized Rebar Vs Epoxy RebarvintagerulzNo ratings yet

- Hard Chrome PlatingDocument1 pageHard Chrome PlatingKishora BhatNo ratings yet

- Powder Metallurgy Processes and Making Metal Powder: October 2020Document4 pagesPowder Metallurgy Processes and Making Metal Powder: October 2020mmNo ratings yet

- Hot Rolled HR Formable F HA3 Steel: General Description Typical UsesDocument2 pagesHot Rolled HR Formable F HA3 Steel: General Description Typical UsesBaziNo ratings yet

- A Guide To CNC Milling CuttersDocument1 pageA Guide To CNC Milling CuttersazharzebNo ratings yet

- Detection and Analysis of Magnetic Particle Testing Defects On Heavy Truck Crankshaft Manufactured by Microalloyed Medium-Carbon Forging SteelDocument10 pagesDetection and Analysis of Magnetic Particle Testing Defects On Heavy Truck Crankshaft Manufactured by Microalloyed Medium-Carbon Forging SteelprabuNo ratings yet

- Designation system for imperfections in welding and allied processesDocument33 pagesDesignation system for imperfections in welding and allied processesStuart WickensNo ratings yet

- Asme Section Ii A-2 Sa-814 Sa-814mDocument8 pagesAsme Section Ii A-2 Sa-814 Sa-814mdavid perezNo ratings yet

- Cadmium in Silver Soldering or BrazingDocument3 pagesCadmium in Silver Soldering or BrazingAli HashemiNo ratings yet

- Mine Plan - Nickel MiningDocument23 pagesMine Plan - Nickel Miningzainul fitriNo ratings yet

- Ras Shastra PPT 6Document10 pagesRas Shastra PPT 6Soham BhureNo ratings yet

- A370-14 Standard Test Methods and Definitions For Mechanical Testing of Steel ProductsDocument7 pagesA370-14 Standard Test Methods and Definitions For Mechanical Testing of Steel ProductsChutha100% (2)

- Oxy/Acetylene Welding and Cutting GuideDocument13 pagesOxy/Acetylene Welding and Cutting GuideYousuf MemonNo ratings yet

- Types of Casting Defects: Admin November 23, 2017 Casting Defect1Document5 pagesTypes of Casting Defects: Admin November 23, 2017 Casting Defect1Nasir SoudagarNo ratings yet

- Valve Material ApplicationDocument16 pagesValve Material Applicationme100% (1)

- 2012 PacBay CatalogDocument88 pages2012 PacBay CatalogDušan IvanovNo ratings yet

- Indexing Plungers: Steel / Stainless Steel Without Rest PositionDocument2 pagesIndexing Plungers: Steel / Stainless Steel Without Rest PositionClecio FelixNo ratings yet

- IK Module 6 Easa Part 66Document246 pagesIK Module 6 Easa Part 66Hamzeh Al-QaisiNo ratings yet

- Soldering 101: A Really TopicDocument24 pagesSoldering 101: A Really TopicGanesh ThakurNo ratings yet