Professional Documents

Culture Documents

Strengthofpanelswithextrudedstiffene 4

Strengthofpanelswithextrudedstiffene 4

Uploaded by

krismkar2014Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Strengthofpanelswithextrudedstiffene 4

Strengthofpanelswithextrudedstiffene 4

Uploaded by

krismkar2014Copyright:

Available Formats

.. — . .

12 NACATN3785

.

.

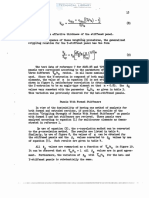

FYomtheresults

presented

infigure7, itappears

thatthe

g-correlation

scheme

forangle-

sndT-typeextrusions

permitsan inte- --

grated

approsch

“tothecrippling-strength

analysis

ofextmudedelements.

Y-stiff

enedPsnels

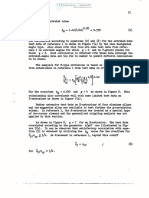

Inanslyzing

thecrippling

strength

ofmonolithic

stiffened

panels

utilizing

extruded

Y-stringers,

certain

additional

considerations

are

encountered

whichhavenotarismpreviously.

Theseinclude:

.

(1)Themethodofdeterminhgg fora stiffened

panel.

(2) Thethicknesses

ofthevarious

flanges

oftheextrusion

may

notbe constant.

(3)Thecompressive

yieldstrength

oftheextruded

stiffener

may

be signif

icautily

diff~ent

fromthatofthesheet.

Themethodofdeterminingg fm a Y-stiffened

panelisillustrated

infigure8. Sincethetestdataareforpanelstestedwithsixstiff-

eners,itisdesirabletodetemnheanaveragevalueof g fora typical

areaelement spacing.Itcanbenotedfrcmfig-

eqpaltothestiffener

ure8 thatthecutsmidwaybetween

stiffeners

arecreditedtotheelement .

totheleftofthecut. Thusthelastelement ontherighthasa value

of g ofoneunitlessthantheotherelements. Thus,theaverage

value

of g = 18.83fortheY-sttif

enedpanelaccouuts

forthisfact.

. .

FortheparticularY-extrusim

usedinreference

7,thethickness

ofthehorizontally

opposedflsnges

atthetopofthesection isgreater

thanthatof‘theotherelements

inthecrosssection,

as showninfig-

ure8. Con~equently,

indetermining

theeffective

thicknessofthe ●

stiffenert+ foruseinthegeneraliz~ crippling

relation,thefollowlng

method

ofweightingwasused:

(7)

b equation

(7),bi and ti refertothelength

endthickness,

respec-

tively,

ofthecross

-sectimal

elements.

Similarly,

forthe7075-T6alunhum-alloy

panels,thecompressive

yieldstrength

ofthestiffener(Ucyw= 78ki) was Signif

ic=tl.y

higher ‘.

thanthatofthesheet(ucys

= 67ksi). Thefollowingweighting

procedure

was used:

,

. — . -.——— .—— .—— -.—— . . .

You might also like

- Steelwise: A Quick Look at PryingDocument2 pagesSteelwise: A Quick Look at Pryingsdutta2591No ratings yet

- ECON 231 Term PaperDocument7 pagesECON 231 Term PaperSaiprakash RagiNo ratings yet

- Miracle of GoDocument278 pagesMiracle of GoArockia Berlin SoniaNo ratings yet

- Strengthofpanelswithextrudedstiffene 5Document1 pageStrengthofpanelswithextrudedstiffene 5krismkar2014No ratings yet

- Strengthofpanelswithextrudedstiffene 3Document1 pageStrengthofpanelswithextrudedstiffene 3krismkar2014No ratings yet

- Angle: ComposedDocument1 pageAngle: Composedkrismkar2014No ratings yet

- Theory: Numerical Method For Evaluating THE Ultimate Flexural Moment Gapacity of Concrete Slab Using Yield LineDocument16 pagesTheory: Numerical Method For Evaluating THE Ultimate Flexural Moment Gapacity of Concrete Slab Using Yield Lineحسن كاظم ريسان B-4No ratings yet

- Design of Machine Elements (Me)Document3 pagesDesign of Machine Elements (Me)Mathews JosephNo ratings yet

- G Strengthofpanelswithextrudedstiffene 1Document1 pageG Strengthofpanelswithextrudedstiffene 1krismkar2014No ratings yet

- Chapter 7 PDFDocument36 pagesChapter 7 PDFMaha RajNo ratings yet

- Compressive and Torsional Buckling of Thin-Walled Cylinder in Yield RegionDocument43 pagesCompressive and Torsional Buckling of Thin-Walled Cylinder in Yield RegionfankenstainNo ratings yet

- CHAPTER 4 Network Realizability TheoryDocument64 pagesCHAPTER 4 Network Realizability TheoryminteNo ratings yet

- Elber-FATIGUE CRACK CLOSUREDocument10 pagesElber-FATIGUE CRACK CLOSUREMohammed Bouchelarm100% (1)

- Elastic Properties of Zinc-Blende and Wurtzite AlN, GaN, and InN (Ref)Document8 pagesElastic Properties of Zinc-Blende and Wurtzite AlN, GaN, and InN (Ref)Amor BchetniaNo ratings yet

- Peierls Instabilities & Charge OrderDocument3 pagesPeierls Instabilities & Charge Orderhafefif99No ratings yet

- Naca TR 734Document11 pagesNaca TR 734Murat CelikNo ratings yet

- SolidWorks Simulation (093-095)Document3 pagesSolidWorks Simulation (093-095)Jose EnriquezNo ratings yet

- Elastic Properties of Zinc-Blende and Wurtzite Aln, Gan, and InnDocument8 pagesElastic Properties of Zinc-Blende and Wurtzite Aln, Gan, and InnAbheek BardhanNo ratings yet

- Analysis of Double Layer Grids With Material Non-linearities!IIW - A Practical ApproachDocument8 pagesAnalysis of Double Layer Grids With Material Non-linearities!IIW - A Practical Approachr_zoro87No ratings yet

- Tati2019 Article FreeVibrationOfThermallyStressDocument11 pagesTati2019 Article FreeVibrationOfThermallyStressHako KhechaiNo ratings yet

- EstimationofwarpageofconstrainedsinteringceramicfilmDocument10 pagesEstimationofwarpageofconstrainedsinteringceramicfilmB.EKICINo ratings yet

- Final FormulaDocument22 pagesFinal FormulaKunal YadavNo ratings yet

- Microstrip Discontinuity Capacitances For Right-An81e Bends, T Junctions, and CrossingsDocument6 pagesMicrostrip Discontinuity Capacitances For Right-An81e Bends, T Junctions, and CrossingsElectronic BoyNo ratings yet

- Dakshit Shah - OC Assignment2Document6 pagesDakshit Shah - OC Assignment2Ishaan ThanekarNo ratings yet

- Nieto Vesperinas1987Document3 pagesNieto Vesperinas1987Rafik Et-TrabelsiNo ratings yet

- 1952 G Gerard & S Wildhorn A Study of Poisson's Ratio in The Yield Region NASA TN 2561Document31 pages1952 G Gerard & S Wildhorn A Study of Poisson's Ratio in The Yield Region NASA TN 2561raduag7No ratings yet

- Failure Mechanics Day3Document15 pagesFailure Mechanics Day3bakabakaNo ratings yet

- 08 Yang, Nana PDFDocument8 pages08 Yang, Nana PDFMouhat OuadiaNo ratings yet

- Data-Adaptive Robust Optimization Method For The Economic Dispatch of Active Distribution NetworksDocument10 pagesData-Adaptive Robust Optimization Method For The Economic Dispatch of Active Distribution NetworksSeptian Wahyu ArjunadyNo ratings yet

- A) Inference: To Invesdtgate The Relationship Betueen DenshyDocument4 pagesA) Inference: To Invesdtgate The Relationship Betueen Denshynur syafiqah riza sahlanNo ratings yet

- NE570 ApplicationsDocument6 pagesNE570 ApplicationsAbcd9032100% (1)

- SimplifiedDesign CompositeMaterials StephenWTsai Patterson USAirForceDocument7 pagesSimplifiedDesign CompositeMaterials StephenWTsai Patterson USAirForceHow-Wei ChenNo ratings yet

- Deep Rolling Process Simulation - Impact of Kinematic Hardening On Residual StressesDocument5 pagesDeep Rolling Process Simulation - Impact of Kinematic Hardening On Residual Stressesesteban vasquezNo ratings yet

- A Stiffness Degradation Based Fatigue Damage ModelDocument14 pagesA Stiffness Degradation Based Fatigue Damage ModelPharindra PathakNo ratings yet

- Excitation: Sate看1ite Cont「o看by Di「ect Ha「mon雪cDocument5 pagesExcitation: Sate看1ite Cont「o看by Di「ect Ha「mon雪cjmcbasNo ratings yet

- Extraction The Inp/Gainas Heterojunction Bipolar Transistor Small-Signal Equivalent CircuitDocument6 pagesExtraction The Inp/Gainas Heterojunction Bipolar Transistor Small-Signal Equivalent CircuitVegit RunNo ratings yet

- Advanced Fiber Spinning Technology (1994) - Chapter 8 - Gel Spinning ProcessesDocument15 pagesAdvanced Fiber Spinning Technology (1994) - Chapter 8 - Gel Spinning ProcessesAlexandre Ferro RochaNo ratings yet

- Ball As 2006Document8 pagesBall As 2006Mudavath BaburamNo ratings yet

- Performance Analysis A Three-Phase Induction Generator Self-Excited With A Single CapacitanceDocument7 pagesPerformance Analysis A Three-Phase Induction Generator Self-Excited With A Single CapacitanceBabis Kala DeNo ratings yet

- Digidepo 10944698 Po ART0003861854Document8 pagesDigidepo 10944698 Po ART0003861854Trushar ParmarNo ratings yet

- RakMek 38 1 2005 1Document10 pagesRakMek 38 1 2005 1aminashash95No ratings yet

- A Mesoscopic Approach For The Simulation of Woven Fibre Composite FormingDocument9 pagesA Mesoscopic Approach For The Simulation of Woven Fibre Composite FormingPablo NingunoNo ratings yet

- Crippling Analysis of Composite Stringers PDFDocument9 pagesCrippling Analysis of Composite Stringers PDFDhimas Surya NegaraNo ratings yet

- Soil ReportDocument20 pagesSoil ReportSitche ZisoNo ratings yet

- Jsme1958 28 617Document6 pagesJsme1958 28 617shiva kamraniNo ratings yet

- New Unified Fracture Toughness EstimatioDocument11 pagesNew Unified Fracture Toughness EstimatiodrzoldbergNo ratings yet

- Joules/mm: SpecimenDocument4 pagesJoules/mm: SpecimenSmile LordNo ratings yet

- Enhanced Structure Cae Solution With Molding Effect For Automotive PartsDocument5 pagesEnhanced Structure Cae Solution With Molding Effect For Automotive PartsFerney AlexisNo ratings yet

- Design of Tension MembersDocument19 pagesDesign of Tension MembersRoopesh KumarNo ratings yet

- Fatigue Behaviour and Mean Effects in Grey Cast Iron: J. Fash and D. F. SocieDocument6 pagesFatigue Behaviour and Mean Effects in Grey Cast Iron: J. Fash and D. F. SocieLuis Silva NavarroNo ratings yet

- Shot Peening Compressor Blades 1Document9 pagesShot Peening Compressor Blades 1chandruNo ratings yet

- SCid PDFDocument7 pagesSCid PDFMobo LegendNo ratings yet

- IMPES Stability Selection ofDocument7 pagesIMPES Stability Selection ofmohamadi42No ratings yet

- Knut Fatigue Curves 1996Document7 pagesKnut Fatigue Curves 1996Osama AshourNo ratings yet

- Phuong-Phap-Phan-Tu-Huu-Han - Trinh-Anh-Ngoc - Me582-Ch-06 - (Cuuduongthancong - Com)Document30 pagesPhuong-Phap-Phan-Tu-Huu-Han - Trinh-Anh-Ngoc - Me582-Ch-06 - (Cuuduongthancong - Com)Trần Đình TốNo ratings yet

- Chapter 30: Principles of Active Vibration Control: Piezoelectric AccelerometersDocument8 pagesChapter 30: Principles of Active Vibration Control: Piezoelectric AccelerometersTamil ChandranNo ratings yet

- 5143 Greenwood PublisherDocument2 pages5143 Greenwood PublisherPhan Thanh HiếuNo ratings yet

- Typo, WesselinkDocument1 pageTypo, WesselinkGuru PrasadNo ratings yet

- 6.6. DR Riven Pile La Ateral Load - Deflection ( (P-Y) Respon NsesDocument1 page6.6. DR Riven Pile La Ateral Load - Deflection ( (P-Y) Respon NsesKavan Gt12No ratings yet

- Multiobjective Design of Laminated Plates For Maximum Stability Using The ®nite Element MethodDocument5 pagesMultiobjective Design of Laminated Plates For Maximum Stability Using The ®nite Element MethodAbdelillah feghoulNo ratings yet

- Aging-Aware Lifetime Enhancement For Memristor-Based Neuromorphic ComputingDocument6 pagesAging-Aware Lifetime Enhancement For Memristor-Based Neuromorphic Computingali shaarawyNo ratings yet

- Old and New Problems in Elementary ParticlesFrom EverandOld and New Problems in Elementary ParticlesG PuppiNo ratings yet

- Strengthofpanelswithextrudedstiffene 3Document1 pageStrengthofpanelswithextrudedstiffene 3krismkar2014No ratings yet

- Strengthofpanelswithextrudedstiffene 5Document1 pageStrengthofpanelswithextrudedstiffene 5krismkar2014No ratings yet

- Angle: ComposedDocument1 pageAngle: Composedkrismkar2014No ratings yet

- G Fge.I U1R :L Iir Ci:' F ? D. (Fbi R: (BFT/LFDocument1 pageG Fge.I U1R :L Iir Ci:' F ? D. (Fbi R: (BFT/LFkrismkar2014No ratings yet

- D - 1.0 Is The Top 11ne: Lei:gtnDocument1 pageD - 1.0 Is The Top 11ne: Lei:gtnkrismkar2014No ratings yet

- 1 - I I I 'L' I I: Critical (SucklinDocument1 page1 - I I I 'L' I I: Critical (Sucklinkrismkar2014No ratings yet

- A Assume A Different Value of P2,: Cal UlateDocument1 pageA Assume A Different Value of P2,: Cal Ulatekrismkar2014No ratings yet

- L .Itlli'.H?Tttm:Nmf L : SD: . 1.1 1, Ti::Omj.1, PusDocument1 pageL .Itlli'.H?Tttm:Nmf L : SD: . 1.1 1, Ti::Omj.1, Puskrismkar2014No ratings yet

- MMPDS-11 1 July 2016: CR P T PL T PL Cy TDocument2 pagesMMPDS-11 1 July 2016: CR P T PL T PL Cy Tkrismkar2014No ratings yet

- MMPDS RMDocument1 pageMMPDS RMkrismkar2014No ratings yet

- Osg MMDocument1 pageOsg MMkrismkar2014No ratings yet

- Crack Base SAS CertificationDocument35 pagesCrack Base SAS CertificationhimaNo ratings yet

- InFaSo - Design-Manual - II - en 36Document1 pageInFaSo - Design-Manual - II - en 36jcvalenciaNo ratings yet

- Valvula HauckDocument13 pagesValvula HauckRebeca Horna TrujilloNo ratings yet

- Teaching Design of Experiment and Response Surface Methodology Using Paper Helicopter ExperimentDocument11 pagesTeaching Design of Experiment and Response Surface Methodology Using Paper Helicopter ExperimentEven OngNo ratings yet

- O' Level Physics Revision Thermal PhysicsDocument4 pagesO' Level Physics Revision Thermal Physicsjumaa12345No ratings yet

- Math 102 PT - Set ADocument2 pagesMath 102 PT - Set ALEIDI CARREL OPAMIN PADUGANANNo ratings yet

- Production/ Development Team For Self-Learning Modules Learning Area: BASIC CALCULUS Grade Level: 11Document2 pagesProduction/ Development Team For Self-Learning Modules Learning Area: BASIC CALCULUS Grade Level: 11xyron amsr paulinoNo ratings yet

- SQL Server XMLDocument118 pagesSQL Server XMLMogasi100% (1)

- Research Papers of Mathematical EconomicsDocument7 pagesResearch Papers of Mathematical Economicsefeq3hd0100% (1)

- Joint Efficiency RuleDocument4 pagesJoint Efficiency RulesubhaNo ratings yet

- Mercer P - More Calculus For A Single VariableDocument419 pagesMercer P - More Calculus For A Single VariableWichi100% (4)

- Harmonic Analysis and Representation Theory For Groups Acting ON Homogeneous Trees PDFDocument161 pagesHarmonic Analysis and Representation Theory For Groups Acting ON Homogeneous Trees PDFAndrea GiudiciNo ratings yet

- 954/3 STPM: One and Half HoursDocument4 pages954/3 STPM: One and Half HoursPeng Peng KekNo ratings yet

- Hanoi Open Mathematical Competition 2016: Junior SectionDocument8 pagesHanoi Open Mathematical Competition 2016: Junior Sectionscribd.thctNo ratings yet

- Verification of Truth Tables For Logic GatesDocument69 pagesVerification of Truth Tables For Logic GatesT V Murali KrishnaNo ratings yet

- Publication Internationale 102017Document21 pagesPublication Internationale 102017imant197812gmail.comNo ratings yet

- Branch: Electronics and Communication Engineering Ec010 502-Control SystemsDocument3 pagesBranch: Electronics and Communication Engineering Ec010 502-Control SystemsMoh OkoeNo ratings yet

- Generalized Maha Distance For Mixed DataDocument12 pagesGeneralized Maha Distance For Mixed DataSylvia Cheung100% (1)

- Analog/Mixed-Signal Simulation and ModelingDocument51 pagesAnalog/Mixed-Signal Simulation and ModelingAhmed AtefNo ratings yet

- AISC (2010) Specifications Chapter CDocument12 pagesAISC (2010) Specifications Chapter CEmanuel GevaraNo ratings yet

- Dampak Otonomi Khusus Terhadap Kesejahteraan Masyarakat Asli Papua Di Distrik Mimika Timur Kabupaten Mimika Provinsi PapuaDocument13 pagesDampak Otonomi Khusus Terhadap Kesejahteraan Masyarakat Asli Papua Di Distrik Mimika Timur Kabupaten Mimika Provinsi PapuaLafikasya Puteri KamiliaNo ratings yet

- 6.1.1 Working With Multi-Variable EquationsDocument2 pages6.1.1 Working With Multi-Variable EquationsAlbertNo ratings yet

- Nordic Steel 2012 BDocument14 pagesNordic Steel 2012 BFeba ThomasNo ratings yet

- Getting Started With ANSYSDocument19 pagesGetting Started With ANSYSThulasi RamNo ratings yet

- MathDocument2 pagesMathMuhammad AhmadNo ratings yet

- Tensor Networks Meet Neural Networks: A Survey: January 2023Document21 pagesTensor Networks Meet Neural Networks: A Survey: January 2023Gajh 420No ratings yet

- Terence McKenna and Ralph Abraham - Dynamics of HyperspaceDocument17 pagesTerence McKenna and Ralph Abraham - Dynamics of HyperspaceZero One100% (2)

- Expt 9 BJT Two Stage AmplifierDocument7 pagesExpt 9 BJT Two Stage Amplifiersamarth100% (1)