Professional Documents

Culture Documents

NPT 1030 Imm

Uploaded by

The Quan BuiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NPT 1030 Imm

Uploaded by

The Quan BuiCopyright:

Available Formats

NPT-1030

Version 4.0

Installation and Maintenance Manual

NPT-1030 Installation and Maintenance Manual

V4.0

Catalog No: X91629

Drawing No: 426006-2349-013-A00

March 2015

1st Edition

ECI's NPT-1200, NPT-1020, and NPT-1010 are CE2.0 certified.

ECI's NPT-1600 complies with the MEF9 and MEF14 standards.

ECI's qualification lab is accredited by A2LA for competence in electrical testing according to

the International Standard ISO IEC 17025-2005 General Requirements for the Competence of

Testing and Calibration Laboratories.

ECI's management applications run on VMWare virtualization hypervisors.

© Copyright by ECI, 2012-2015. All rights reserved worldwide.

This is a legal agreement between you, the end user, and ECI Ltd. (“ECI”). BY OPENING THE DOCUMENTATION AND/OR DISK PACKAGE, YOU ARE

AGREEING TO BE BOUND BY THE TERMS OF THIS AGREEMENT. IF YOU DO NOT AGREE TO THE TERMS OF THIS AGREEMENT, PROMPTLY RETURN

THE UNOPENED DOCUMENTATION AND/OR DISK PACKAGE AND THE ACCOMPANYING ITEMS (INCLUDING WRITTEN MATERIALS AND BINDERS OR

OTHER CONTAINERS), TO THE PLACE FROM WHICH YOU OBTAINED THEM.

All documentation and /or disk and all information and/or data contained in the documentation and/or disk ["ECI's Proprietary"] is ECI's proprietary

and is subject to all copyright, patent, and other laws protecting intellectual property, and any international treaty provisions, as well as any specific

agreement protecting ECI's rights in the aforesaid information. Any use of ECI's Proprietary for any purposes [included but not limited: published,

reproduced, or disclosed to third parties, in whole or in part] other than those for which it was disclosed, without the express prior written

permission of ECI, is strictly forbidden.

ECI's Proprietary is provided "AS IS" and may contain flaws, omissions, or typesetting errors. No responsibility and or liability whatsoever are

assumed by ECI for you or any other party, for the use thereof, nor for the rights of third parties, nor for any loss or damage whatsoever or

howsoever caused, arising directly or indirectly in connection with ECI's Proprietary, which may be affected in any way by the use and/or

dissemination thereof. ECI reserves the right, without prior notice or liability, to make changes in equipment design or specifications including any

change in and to the ECI's Proprietary.

Any representation(s) in ECI's Proprietary concerning performance of ECI's product(s) are for informational purposes only and are not warranties of

product performance or otherwise, either express or implied. No warranty is granted nor liability assumed in relation thereto, unless specifically

undertaken in ECI's sales contract or order confirmation. ECI's Proprietary is periodically updated, and changes will be incorporated in subsequent

editions. All graphics included in this document are for illustrative purposes only and might not correspond with your specific product version.

The documentation and/or disk and all information contained therein is owned by ECI and is protected by all relevant copyright, patent, and other

applicable laws and international treaty provisions. Therefore, you must treat the information contained in the documentation and disk as any

other copyrighted material (for example, a book or musical recording).

Other Restrictions. You may not rent, lease, sell, or otherwise dispose of ECI's Proprietary, as applicable.

YOU MAY NOT USE, COPY, MODIFY, OR TRANSFER THE DOCUMENTATION AND/OR DISK OR ANY COPY IN WHOLE OR PART, EXCEPT AS EXPRESSLY

PROVIDED IN THIS LICENSE. ALL RIGHTS NOT EXPRESSLY GRANTED ARE RESERVED BY ECI.

All trademarks mentioned herein are the property of their respective holders.

Notwithstanding the generality of the aforementioned, you expressly waive any claim and/or demand regarding liability for indirect, special,

incidental, or consequential loss or damage which may arise in respect of ECI's Proprietary contained therein, howsoever caused, even if advised of

the possibility of such damages.

The end user hereby undertakes and acknowledges that they read the "Before You Start/Safety Guidelines" instructions (when provided by ECI) and

that such instructions were understood by them. ECI shall not be liable to you or to any other party for any loss or damage whatsoever or

howsoever caused, arising directly or indirectly in connection with you fulfilling and/or failure to fulfill in whole or in part the "Before You

Start/Safety Guidelines" instructions.

Contents

1 About This Manual ...................................................................................... 1-1

1.1 Overview ................................................................................................................................ 1-1

1.2 Intended Audience................................................................................................................. 1-1

1.3 Document Organization ......................................................................................................... 1-1

1.4 Notes and Warnings............................................................................................................... 1-1

1.5 Related Documentation ......................................................................................................... 1-2

1.6 How to Obtain ECI Technical Documentation ....................................................................... 1-2

1.7 Technical Assistance .............................................................................................................. 1-2

2 Introduction ................................................................................................ 2-1

2.1 NPT-1030 Platform Overview ................................................................................................ 2-1

3 Before You Start .......................................................................................... 3-1

3.1 Overview ................................................................................................................................ 3-1

3.1.1 Outline of the Installation Procedure ...................................................................................... 3-1

3.2 Site Preparation ..................................................................................................................... 3-3

3.2.1 Environmental Requirements ................................................................................................. 3-3

3.2.2 Physical Location ..................................................................................................................... 3-3

3.2.3 Power Sources ......................................................................................................................... 3-4

3.2.4 Tools and Test Equipment ....................................................................................................... 3-4

3.2.5 Cleaning Optical Connectors ................................................................................................... 3-5

3.3 Installing the NPT-1030 in Racks ............................................................................................ 3-5

3.3.1 Installation Plan ....................................................................................................................... 3-5

3.3.2 Typical NPT-1030 Installation .................................................................................................. 3-5

3.3.3 Integrating NPT-1030 Platforms and Other Equipment in One Rack ...................................... 3-6

3.4 Preparing Cables and Fibers .................................................................................................. 3-7

3.4.1 Grounding Cables .................................................................................................................... 3-8

3.4.2 DC Power Cables ..................................................................................................................... 3-8

3.4.3 Alarm Cables ........................................................................................................................... 3-9

3.4.4 Management Cables ............................................................................................................. 3-10

3.4.5 Timing (Clock) Cables ............................................................................................................ 3-10

3.4.6 Electric Traffic Cables ............................................................................................................ 3-10

3.4.7 Optical Fibers......................................................................................................................... 3-12

3.5 Work and Equipment Safety ................................................................................................ 3-13

3.5.1 Grounding Requirements ...................................................................................................... 3-14

ECI Telecom Ltd. Proprietary iii

NPT-1030 Installation and Maintenance Manual Contents

3.5.2 DC Power Supply Requirements ........................................................................................... 3-14

3.5.3 AC Power Supply Requirements ............................................................................................ 3-15

3.5.4 Laser Safety Requirements.................................................................................................... 3-15

3.6 Protection against Electrostatic Discharge .......................................................................... 3-18

3.6.1 Personnel Training ................................................................................................................ 3-19

3.6.2 Use of a Temporary EPA ........................................................................................................ 3-19

3.6.3 Work Arrangements within a Temporary EPA ...................................................................... 3-20

3.7 Environmental and Health Concerns ................................................................................... 3-20

4 Installing Equipment ................................................................................... 4-1

4.1 Overview ................................................................................................................................ 4-1

4.2 Preliminary Preparations ....................................................................................................... 4-1

4.3 Installation Sequence............................................................................................................. 4-1

4.4 Unpacking and Performing Visual Inspection ........................................................................ 4-3

4.5 Installation Options................................................................................................................ 4-4

4.6 Installing Ancillary Units in Racks........................................................................................... 4-7

4.6.1 Installing the RAP-BG .............................................................................................................. 4-7

4.6.2 Installing the RAP-4B ............................................................................................................. 4-13

4.6.3 Installing the FST ................................................................................................................... 4-19

4.6.4 Installing the ODF .................................................................................................................. 4-21

4.6.5 Installing the xDDF-21 Patch Panel ....................................................................................... 4-23

4.6.6 Installing the PIM2_63 Cable Guide and Holder ................................................................... 4-24

4.6.7 Installing the ICP_MCP30 ...................................................................................................... 4-24

4.6.8 Installing SM_10E/EM_10E ICPs............................................................................................ 4-25

4.6.9 Installing the AC_CONV_UNIT ............................................................................................... 4-25

4.7 Installing the NPT-1030 Platform in the Rack ...................................................................... 4-26

4.7.1 Installing the Rail Stiffeners ................................................................................................... 4-27

4.7.2 Attaching the NPT-1030 Platform in the Rack....................................................................... 4-28

4.7.3 Grounding the NPT-1030 Platform........................................................................................ 4-29

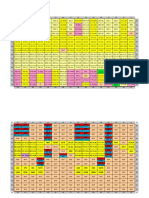

4.7.4 Identifying Slots in the NPT-1030 .......................................................................................... 4-29

4.7.5 Installing a Power Module in the NPT-1030 .......................................................................... 4-31

4.7.6 Installing an FCU_1030 in the NPT-1030 ............................................................................... 4-32

4.7.7 Installing an MCP30B/D Module ........................................................................................... 4-32

4.7.8 Connecting Power and Alarm Cables to a DC Power Source ................................................ 4-34

4.7.9 Installing XIO30 Modules in the NPT-1030............................................................................ 4-35

4.7.10 Installing Tslot Modules in the NPT-1030 ............................................................................. 4-36

4.7.11 Installing an AC_CONV_MODULE in the AC_CONV_UNIT ..................................................... 4-37

ECI Telecom Ltd. Proprietary iv

NPT-1030 Installation and Maintenance Manual Contents

4.7.12 Installing SFP Modules .......................................................................................................... 4-38

4.8 Installing the EXT-2U Platform in the Rack .......................................................................... 4-38

4.8.1 Installing the H Connector ..................................................................................................... 4-40

4.8.2 Installing the EXT-2U Platform on the NPT-1030 Platform ................................................... 4-41

4.8.3 Disassembling the EXT-2U from the NPT-1030 ..................................................................... 4-42

4.8.4 Attaching the EXT-2U Platform in the Rack ........................................................................... 4-43

4.8.5 Identifying Slots in the EXT-2U .............................................................................................. 4-44

4.8.6 Installing Power Modules in the EXT-2U ............................................................................... 4-45

4.8.7 Installing an FCU_E2U in the EXT-2U..................................................................................... 4-46

4.8.8 Installing Extension Cards in the EXT-2U ............................................................................... 4-46

4.8.9 Installing Long Cards in the EXT-2U ....................................................................................... 4-48

4.8.10 Installing Traffic Modules in the SM_10E/EM_10E ............................................................... 4-49

4.8.11 Installing Modules in the OBC ............................................................................................... 4-51

4.9 Connecting Fibers and Cables to the NPT-1030 Shelf.......................................................... 4-51

4.9.1 Connecting Optical Fibers to Optical Modules ...................................................................... 4-52

4.9.2 Routing and Connecting Electrical Interface Cables to the NPT-1030 .................................. 4-52

4.9.3 Connecting I/O Protection Cables in the NPT-1030 .............................................................. 4-57

4.9.4 Routing and Connecting Data Interface Cables to Ethernet Interfaces ................................ 4-64

4.9.5 Routing and Connecting Electrical Cables between the MCP30 and the

ICP_MCP30 ............................................................................................................................ 4-65

4.9.6 Connecting the Timing (Clock) Cable .................................................................................... 4-66

5 NPT-1030 Wall-Mounted Installations ......................................................... 5-1

5.1 Overview ................................................................................................................................ 5-1

5.2 Wall-Mounted Cabinet .......................................................................................................... 5-1

5.2.1 Installing the NPT-1030 in a Wall-Mounted Cabinet ............................................................... 5-2

5.2.2 Installing the Interior Components ......................................................................................... 5-2

5.2.3 Installing Cabling Accessories .................................................................................................. 5-7

5.3 DDF 21 E1s Unit ................................................................................................................... 5-10

5.3.1 Assembling the DDF .............................................................................................................. 5-10

5.3.2 Wiring the E1 Cables to the DDF ........................................................................................... 5-12

5.3.3 Installing the NPT-1030 and Three DDFs ............................................................................... 5-13

5.3.4 Installing the NPT-1030, Two DDFs, and an AC CONV Unit ................................................... 5-15

5.3.5 Connecting Cabinet Grounding ............................................................................................. 5-18

5.3.6 Routing and Connecting Cables and Fibers in the Cabinet ................................................... 5-19

5.3.7 Installing the Wall-Mounted Cabinet Covers and Door ........................................................ 5-24

5.4 Wall-Mounted Frame........................................................................................................... 5-27

5.4.1 Installing the Wall-Mounted Frame ...................................................................................... 5-28

ECI Telecom Ltd. Proprietary v

NPT-1030 Installation and Maintenance Manual Contents

5.4.2 Installing the NPT-1030 and Accessories in the Wall-Mounted Frame ................................. 5-30

5.4.3 Installing the Wall-Mounted Frame Front Cover .................................................................. 5-36

5.4.4 Connecting Wall-Mounted Frame Grounding ....................................................................... 5-38

5.4.5 Routing and Connecting Cables and Fibers in the Frame...................................................... 5-38

6 Commissioning Tests ................................................................................... 6-1

6.1 Overview ................................................................................................................................ 6-1

6.2 Test Equipment ...................................................................................................................... 6-1

6.3 Site Commissioning Tests ...................................................................................................... 6-1

6.3.1 Checking Cards and Modules Installed in Each Shelf .............................................................. 6-1

6.3.2 Test Equipment Setup ............................................................................................................. 6-2

6.3.3 Visual Inspection and Mechanical Checks ............................................................................... 6-3

6.3.4 Measuring Optical Levels ........................................................................................................ 6-4

6.3.5 Platform Power-On Test Procedure ........................................................................................ 6-5

6.4 SDH Commissioning Tests ...................................................................................................... 6-5

6.4.1 Loss of Signal (LOS) Detection Test ......................................................................................... 6-5

6.4.2 Network Timing Synchronization Test .................................................................................... 6-5

6.4.3 Input Sensitivity Test ............................................................................................................... 6-6

6.4.4 Equipment Power-On Test ...................................................................................................... 6-6

6.4.5 Traffic Stability Test ................................................................................................................. 6-7

6.4.6 Transmission Alarm-Handling Test .......................................................................................... 6-7

6.4.7 Maintenance Action Test ........................................................................................................ 6-8

6.4.8 Path Protection and Nonretrieval Test.................................................................................... 6-8

6.4.9 Severity Assignment Test ........................................................................................................ 6-8

6.5 Data Network Commissioning Tests ...................................................................................... 6-9

6.5.1 Throughput and Latency Tests ................................................................................................ 6-9

6.5.2 System Recovery and Reset Tests ......................................................................................... 6-10

6.5.3 Frame Loss Rate Test ............................................................................................................. 6-10

6.5.4 Stability Test .......................................................................................................................... 6-11

6.5.5 Alarm-Handling Test .............................................................................................................. 6-11

7 Maintenance ............................................................................................... 7-1

7.1 Overview ................................................................................................................................ 7-1

7.2 Test Equipment, Tools, and Materials ................................................................................... 7-1

7.3 Preventive Maintenance ........................................................................................................ 7-1

7.4 Onsite Troubleshooting ......................................................................................................... 7-2

7.4.1 Troubleshooting Power Problems ........................................................................................... 7-3

7.4.2 Troubleshooting Using Component Indicators ....................................................................... 7-4

ECI Telecom Ltd. Proprietary vi

NPT-1030 Installation and Maintenance Manual Contents

7.5 Replacing Cards and Modules .............................................................................................. 7-19

7.5.1 Safety and Workmanship ...................................................................................................... 7-19

7.5.2 Replacing the MCP30B Card .................................................................................................. 7-20

7.5.3 Replacing XIO30 Cards .......................................................................................................... 7-21

7.5.4 Replacing Tslot Cards ............................................................................................................ 7-21

7.5.5 Replacing Eslot Cards ............................................................................................................ 7-22

7.5.6 Replacing Traffic Modules on the SM_10E/EM_10E ............................................................. 7-22

7.5.7 Replacing ICPs for the SM_10E/EM_10E ............................................................................... 7-23

7.5.8 Replacing Power Modules ..................................................................................................... 7-23

7.5.9 Replacing the FCU_1030/FCU_E2U Module ......................................................................... 7-24

7.5.10 Replacing an ICP for the MCP30B.......................................................................................... 7-24

7.5.11 Replacing SFP/XFP/SFP+ Transceivers ................................................................................... 7-24

8 Connection Data.......................................................................................... 8-1

8.1 Overview ................................................................................................................................ 8-1

8.2 INF_B1U/INF_30BH/INF_E2U DC Input Power Connectors .................................................. 8-1

8.3 AC_CONV_30B/AC_PS-E2U AC Input Power Connectors ...................................................... 8-1

8.4 MNG Ethernet Connector ...................................................................................................... 8-1

8.5 T3/T4 Timing Connector ........................................................................................................ 8-2

8.6 Auxiliary Connector on the MCP30B ..................................................................................... 8-3

8.7 RS-232 Connector .................................................................................................................. 8-5

8.8 Orderwire Connector ............................................................................................................. 8-6

8.9 V.11 Overhead Connector ..................................................................................................... 8-7

8.10 Alarms Connector .................................................................................................................. 8-8

8.11 E1 Connectors on the PME1_21 ............................................................................................ 8-9

8.12 PME1_63 Connection Data .................................................................................................. 8-12

8.13 Ethernet Interface Connectors ............................................................................................ 8-22

8.14 PM345_3 Card Connection Data ......................................................................................... 8-22

8.15 P345_3E Card Connection Data ........................................................................................... 8-22

8.16 PE1_63 Card Connection Data ............................................................................................. 8-22

8.17 MPS_2G_8F Card Connection Data ..................................................................................... 8-28

8.18 DMGE_1_L1 Connection Data ............................................................................................. 8-29

8.19 TP21_2 Connection Data ..................................................................................................... 8-29

8.20 TP63_1 Connection Data ..................................................................................................... 8-34

8.21 TPS1_1 Connection Data...................................................................................................... 8-34

8.22 SM_10E/EM_10E Card Connection Data ............................................................................. 8-34

ECI Telecom Ltd. Proprietary vii

NPT-1030 Installation and Maintenance Manual Contents

8.22.1 Connection Data for SM_FXO_8E and SM_FXS_8E Interfaces .............................................. 8-35

8.22.2 Connection Data for SM_EM_24W6E Interfaces .................................................................. 8-35

8.22.3 Connection Data for SM_V35E Interfaces ............................................................................. 8-37

8.22.4 Connection Data for SM_V24E Interfaces ............................................................................. 8-39

8.22.5 Connection Data for SM_V35_V11 Interfaces ...................................................................... 8-42

8.22.6 Connection Data for SM_CODIR_4E Interfaces ..................................................................... 8-44

8.22.7 Connection Data for SM_OMNI_E Interfaces ....................................................................... 8-45

8.23 ICP_VF Connection Data ...................................................................................................... 8-46

8.24 ICP_V24 Connection Data .................................................................................................... 8-47

8.25 ICP_V35 Connection Data .................................................................................................... 8-50

8.26 ICP_V11_V24 Connection Data............................................................................................ 8-51

8.27 ICP_DB37D Connection Data ............................................................................................... 8-52

8.28 RAP-4B Connectors .............................................................................................................. 8-57

8.28.1 SHELF ALARM Connectors ..................................................................................................... 8-57

8.28.2 ALARM IN/OUT Connector .................................................................................................... 8-58

9 Rack Installation .......................................................................................... 9-1

9.1 Installing Equipment Racks .................................................................................................... 9-1

9.1.1 Marking Rack Floor.................................................................................................................. 9-1

9.1.2 Installing the Rack on Concrete Floors .................................................................................... 9-2

9.1.3 Installing the Rack on Wooden Floors ..................................................................................... 9-2

9.1.4 Installing the Rack on Floating (Suspended) Floors................................................................. 9-4

9.1.5 Installing the Rack on Suspended Overhead Trays ................................................................. 9-5

9.1.6 Installing Extendable Rails ....................................................................................................... 9-5

9.1.7 Grounding the Rack ................................................................................................................. 9-5

9.2 Installing 19" Racks ................................................................................................................ 9-6

ECI Telecom Ltd. Proprietary viii

List of Figures

Figure 2-1: Typical NPT-1030 platform ........................................................................................................... 2-1

Figure 3-1: Typical installation of four NPT-1030 platforms in an ETSI 2200 rack ......................................... 3-7

Figure 3-2: Laser warning label..................................................................................................................... 3-16

Figure 3-3: Basic ESD warning symbol .......................................................................................................... 3-18

Figure 3-4: Pollution control logos ............................................................................................................... 3-21

Figure 3-5: WEEE recycling symbol............................................................................................................... 3-22

Figure 4-1: Typical installation of a single NPT-1030 platform in a 2200 ETSI rack........................................ 4-2

Figure 4-2: Typical installation of four NPT-1030 platforms .......................................................................... 4-6

Figure 4-3: Location of RAP-BG grounding stud ............................................................................................. 4-9

Figure 4-4: Identification of RAP-BG cable routes .......................................................................................... 4-9

Figure 4-5: Connecting DC power cables to the RAP-BG.............................................................................. 4-10

Figure 4-6: RAP-BG platform power cable grounding screws ...................................................................... 4-11

Figure 4-7: RAP-BG front cover removal ...................................................................................................... 4-11

Figure 4-8: RAP-BG circuit breaker installation ............................................................................................ 4-12

Figure 4-9: Platform DC input power connector pin functions .................................................................... 4-12

Figure 4-10: Locating RAP-4B grounding stud .............................................................................................. 4-14

Figure 4-11: RAP-4B with grounding cable ................................................................................................... 4-15

Figure 4-12: Identifying RAP-4B cable routes ............................................................................................... 4-15

Figure 4-13: Connecting DC power cables to the RAP-4B ............................................................................ 4-16

Figure 4-14: RAP-4B platform power cable grounding screws..................................................................... 4-17

Figure 4-15: RAP-4B front cover removal ..................................................................................................... 4-18

Figure 4-16: RAP-4B circuit breaker installation........................................................................................... 4-18

Figure 4-17: Platform DC input power connector pin functions .................................................................. 4-19

Figure 4-18: Threading optical fibers in the FST ........................................................................................... 4-20

Figure 4-19: Attaching rack mounting brackets to the ODF ......................................................................... 4-21

Figure 4-20: ODF front panel ........................................................................................................................ 4-21

Figure 4-21: ODF open view ......................................................................................................................... 4-22

Figure 4-22: ODF fiber routes ....................................................................................................................... 4-22

Figure 4-23: Installing ICP_MCP30 in the rack.............................................................................................. 4-24

Figure 4-24: Installing SM_10E/EM_10E ICPs in the rack............................................................................. 4-25

Figure 4-25: Installing the AC_CONV_UNIT in the rack ................................................................................ 4-26

Figure 4-26: Installing rail stiffeners in the rack ........................................................................................... 4-28

Figure 4-27: NPT-1030 slots.......................................................................................................................... 4-29

Figure 4-28: Installing a power module in the NPT-1030 ............................................................................. 4-31

Figure 4-29: Installing an FCU_1030 module in the NPT-1030 .................................................................... 4-32

Figure 4-30: Location of the CF card inside the MCP30B/D ......................................................................... 4-33

Figure 4-31: Installing a CF card into the MCP30B/D ................................................................................... 4-33

Figure 4-32: Installing an MCP30B module in the NPT-1030 ....................................................................... 4-34

Figure 4-33: Installing an XIO30 module in the NPT-1030 ........................................................................... 4-35

Figure 4-34: Installing a Tslot module in the NPT-1030 ............................................................................... 4-36

ECI Telecom Ltd. Proprietary ix

NPT-1030 Installation and Maintenance Manual List of Figures

Figure 4-35: Installing an AC_CONV_MODULE in the AC_CONV_UNIT ....................................................... 4-37

Figure 4-36: Installing an SFP/XFP module in the NPT-1030 ........................................................................ 4-38

Figure 4-37: Installing the H connector ........................................................................................................ 4-40

Figure 4-38: Installing the EXT-2U ................................................................................................................ 4-41

Figure 4-39: Removing the BG-30E from the BG-30B .................................................................................. 4-42

Figure 4-40: Inserting the thin flat-head tool ............................................................................................... 4-42

Figure 4-41: Raising the rivet cap ................................................................................................................. 4-43

Figure 4-42: Removing the rivet ................................................................................................................... 4-43

Figure 4-43: EXT-2U regular slots layout ...................................................................................................... 4-44

Figure 4-44: EXT-2U slots layout with ES 3# extended ................................................................................. 4-44

Figure 4-45: Installing a power module in the EXT-2U ................................................................................. 4-45

Figure 4-46: Installing FCU_E2U in EXT-2U................................................................................................... 4-46

Figure 4-47: Installing an extension card in the EXT-2U ............................................................................... 4-47

Figure 4-48: Removing the blank panel ........................................................................................................ 4-48

Figure 4-49: Removing the card guide ......................................................................................................... 4-48

Figure 4-50: Installing a long card in the EXT-2U.......................................................................................... 4-49

Figure 4-51: Installing traffic module in the SM_10E/EM_10E .................................................................... 4-50

Figure 4-52: Installing a module in the OBC ................................................................................................. 4-51

Figure 4-53: PME1_63 traffic cable .............................................................................................................. 4-55

Figure 4-54: PME1_63 traffic cable installation ........................................................................................... 4-56

Figure 4-55: L114 protection jumper cable schematic diagram................................................................... 4-59

Figure 4-56: L123 protection jumper cable schematic diagram................................................................... 4-60

Figure 4-57: L128 protection jumper cable schematic diagram................................................................... 4-61

Figure 4-58: L127 protection jumper cable schematic diagram................................................................... 4-62

Figure 4-59: TP21_2 1:2 protection scheme example.................................................................................. 4-63

Figure 4-60: TP21_2 1:1 protection scheme example.................................................................................. 4-63

Figure 4-61: TP63_1_1 (two PE1_63 cards) 1:1 protection scheme example.............................................. 4-63

Figure 4-62: TPS1_1 (two SMQ1&4 modules) 1:1 protection scheme example .......................................... 4-64

Figure 5-1: Wall-mounted cabinet general view ............................................................................................ 5-1

Figure 5-2: Tools required for cabinet installation ......................................................................................... 5-2

Figure 5-3: Wall-mounted cabinet interior components ............................................................................... 5-3

Figure 5-4: Preparing the rear panel holes ..................................................................................................... 5-4

Figure 5-5: Installing the rear panel ............................................................................................................... 5-5

Figure 5-6: Installing the support rails ............................................................................................................ 5-5

Figure 5-7: Installing the 19" vertical extrusions ............................................................................................ 5-6

Figure 5-8: Installing the C-rail ....................................................................................................................... 5-7

Figure 5-9: Cabling accessories installed in the cabinet ................................................................................. 5-7

Figure 5-10: Cabling accessories..................................................................................................................... 5-8

Figure 5-11: DDF general view...................................................................................................................... 5-10

Figure 5-12: Installing the brackets for ETSI installation .............................................................................. 5-11

Figure 5-13: Attaching the connection blocks .............................................................................................. 5-12

ECI Telecom Ltd. Proprietary x

NPT-1030 Installation and Maintenance Manual List of Figures

Figure 5-14: Installing an NPT-1020 platform and three DDFs..................................................................... 5-13

Figure 5-15: Clip nuts distance in mm (NPT-1030 and three DDFs) ............................................................. 5-14

Figure 5-16: Installing a NPT-1030 platform, two DDFs, and an AC CONV unit ........................................... 5-16

Figure 5-17: Clip nuts distance in mm (NPT-1030, two DDFs, AC CONV unit) ............................................. 5-17

Figure 5-18: Wall-mounted cabinet cabling ................................................................................................. 5-19

Figure 5-19: Wall-mounted cabinet cables routing front view .................................................................... 5-20

Figure 5-20: Wall-mounted cabinet cables routing left side view ............................................................... 5-21

Figure 5-21: Installing top and bottom covers ............................................................................................. 5-25

Figure 5-22: Connecting grounding cables ................................................................................................... 5-25

Figure 5-23: Installing side covers ................................................................................................................ 5-26

Figure 5-24: Connecting grounding cables ................................................................................................... 5-26

Figure 5-25: Installing the front door ........................................................................................................... 5-27

Figure 5-26: Connecting the door grounding cable...................................................................................... 5-27

Figure 5-27: Wall-mounted frame installation ............................................................................................. 5-28

Figure 5-28: Attaching the fiber guide tube ................................................................................................. 5-29

Figure 5-29: Holes location for wall-mounted frame ................................................................................... 5-30

Figure 5-30: Installing a NPT-1030 and three DDFs...................................................................................... 5-31

Figure 5-31: Installing a NPT-1030, a DDF, and a RAP-BG ............................................................................ 5-32

Figure 5-32: Installing a NPT-1030, an ICP_MCP30, and a DDF.................................................................... 5-33

Figure 5-33: Installing a NPT-1030, a DDF, and an AC/DC CONV ................................................................. 5-34

Figure 5-34: Installing a NPT-1030 and a DDF .............................................................................................. 5-35

Figure 5-35: Installing the front cover .......................................................................................................... 5-37

Figure 5-36: Routing and connecting cables and fibers in the wall-mounted frame ................................... 5-39

Figure 5-37: Wall-mounted frame cable routing - left side view ................................................................. 5-40

Figure 7-1: Inserting an SFP/XFP/SFP+ transceiver into a module ............................................................... 7-25

Figure 8-1: POWER IN input power connector, pin functions ........................................................................ 8-1

Figure 8-2: AC input power connector ........................................................................................................... 8-1

Figure 8-3: Ethernet connector, pin identification ......................................................................................... 8-2

Figure 8-4: T3/T4 connector, pin identification.............................................................................................. 8-2

Figure 8-5: Auxiliary connector for MCP30/MCP30B, pin identification........................................................ 8-3

Figure 8-6: RS-232 overhead connectors, pin identification .......................................................................... 8-5

Figure 8-7: RS-232 overhead cable ................................................................................................................. 8-5

Figure 8-8: RS-232 overhead cable label ........................................................................................................ 8-5

Figure 8-9: OW connector, pin identification ................................................................................................. 8-6

Figure 8-10: V.11 connector, pin identification.............................................................................................. 8-7

Figure 8-11: Alarms connector, pin identification .......................................................................................... 8-8

Figure 8-12: E1 connectors for PME1_21, pin identification ......................................................................... 8-9

Figure 8-13: PME1_63 connector pin identification..................................................................................... 8-12

Figure 8-14: Typical E1 connector for PE1_63, pin identification ................................................................ 8-23

Figure 8-15: E1 connectors for TP21_2, pin identification ........................................................................... 8-29

Figure 8-16: SM_10E/EM_10E traffic module connector, pin identification ............................................... 8-34

ECI Telecom Ltd. Proprietary xi

NPT-1030 Installation and Maintenance Manual List of Figures

Figure 8-17: 25-pin D-type male connector, pin identification .................................................................... 8-48

Figure 8-18: 9-pin D-type male connector, pin identification ...................................................................... 8-49

Figure 8-19: M34 female connector, pin identification ............................................................................... 8-50

Figure 8-20: 15-pin D-type female connector, pin identification ................................................................. 8-51

Figure 8-21: 25-pin D-type male connector, pin identification .................................................................... 8-51

Figure 8-22: 37-pin D-type female connector, pin identification ................................................................. 8-53

Figure 8-23: RAP-4B SHELF ALARM connector, pin identification................................................................ 8-57

Figure 8-24: RAP-4B ALARM IN/OUT connector, pin identification ............................................................. 8-58

Figure 9-1: Mounting diagrams for ETSI racks................................................................................................ 9-3

Figure 9-2: Mounting diagrams for 19" and 23" racks ................................................................................... 9-4

Figure 9-3: Rack mounting diagram for attachment to suspended overhead tray (2200 mm

rack).............................................................................................................................................. 9-5

Figure 9-4: Example of an approved European 19” rack ................................................................................ 9-6

ECI Telecom Ltd. Proprietary xii

List of Tables

Table 3-1: Typical NPT-1030 equipment installation sequence ..................................................................... 3-1

Table 3-2: Environmental requirements ........................................................................................................ 3-3

Table 3-3: Equipment dimensions .................................................................................................................. 3-4

Table 3-4: Recommended coaxial cable assembly tools ................................................................................ 3-4

Table 3-5: Traffic cables mating connector data for NPT-1030.................................................................... 3-10

Table 3-6: Traffic cables mating connector data for EXT-2U ........................................................................ 3-11

Table 3-7: Optical fibers and mating connector data for NPT-1030 ............................................................ 3-12

Table 3-8: Optical fibers and mating connector data for EXT-2U ................................................................ 3-13

Table 3-9: NPT-1030 and EXT-2U circuit breaker data ................................................................................. 3-15

Table 3-10: NPT-1030 and EXT-2U recommended circuit breakers ............................................................. 3-15

Table 3-11: LC transceivers laser information STM-4 SFP ............................................................................ 3-17

Table 3-12: LC transceivers laser information STM-1/100BaseFX SFP ......................................................... 3-17

Table 3-13: LC transceivers laser information GbE SFP (OTGBE) ................................................................. 3-18

Table 4-1: Outline of typical NPT-1030 equipment installation sequence..................................................... 4-3

Table 4-2: NPT-1030 modules ...................................................................................................................... 4-29

Table 4-3: EXT-2U modules .......................................................................................................................... 4-44

Table 4-4: Protection and protected cards summary................................................................................... 4-58

Table 4-5: Protection jumper cables usage .................................................................................................. 4-62

Table 4-6: TPS1_1 1:1 I/O protection slot allocation.................................................................................... 4-64

Table 6-1: Card and module inventory NPT-1030 platform ........................................................................... 6-2

Table 6-2: 2 Mbps tests .................................................................................................................................. 6-2

Table 6-3: 34 Mbps tests ................................................................................................................................ 6-2

Table 6-4: 45 Mbps tests ................................................................................................................................ 6-2

Table 6-5: SDH tests........................................................................................................................................ 6-3

Table 6-6: Visual inspection and mechanical checks ...................................................................................... 6-3

Table 6-7: Measured optical levels ................................................................................................................. 6-4

Table 6-8: Traffic stability test time intervals ................................................................................................. 6-7

Table 6-9: Throughput and latency test results ........................................................................................... 6-10

Table 6-10: Frame loss rate test results ....................................................................................................... 6-11

Table 7-1: Preventive maintenance inspection and checks ........................................................................... 7-1

Table 7-2: Troubleshooting power problems ................................................................................................. 7-3

Table 7-3: General troubleshooting procedures for NPT-1030 power-on based on MCP30B

panel LEDs .................................................................................................................................... 7-5

Table 7-4: General troubleshooting procedures for Tslot or XIO panels ....................................................... 7-7

Table 7-5: General troubleshooting procedures for the MCP30B ................................................................. 7-8

Table 7-6: General troubleshooting procedures on Tslot and XIO module panels ........................................ 7-8

Table 7-7: General troubleshooting procedures for the INF_B1U/INF_30BH and INF_E2U .......................... 7-9

Table 7-8: General troubleshooting procedures for the FCU_1030 ............................................................. 7-10

Table 7-9: General troubleshooting procedures for optical transceiver plug-ins ........................................ 7-10

Table 7-10: Special troubleshooting procedures for DMFE_4_L1, DMFE_4_L2, and DMEOP_4 ................. 7-12

ECI Telecom Ltd. Proprietary xiii

NPT-1030 Installation and Maintenance Manual List of Tables

Table 7-11: General troubleshooting procedures for extended cards (PE1_63, P345_3, SM_10E,

S1_4, and S4_1) .......................................................................................................................... 7-13

Table 7-12: Special troubleshooting procedures for P345_3 card ............................................................... 7-14

Table 7-13: General troubleshooting procedures for daughterboards on SM_10E cards ........................... 7-14

Table 7-14: Special troubleshooting procedures for SM_EOP daughter boards ......................................... 7-15

Table 7-15: Special troubleshooting procedures for OW box ...................................................................... 7-15

Table 7-16: Special troubleshooting procedures for TP21_2/TP63_1/TPS1_1 cards .................................. 7-17

Table 7-17: Special troubleshooting procedures for DMFX_4_L1 and DMFX_4_L2 .................................... 7-17

Table 7-18: Special troubleshooting procedures for DMGE_1_L1 ............................................................... 7-18

Table 7-19: Special troubleshooting procedures for DMGE_4_L1 ............................................................... 7-19

Table 8-1: Ethernet connector, pin assignment ............................................................................................. 8-2

Table 8-2: T3/T4 connector, PIN identification .............................................................................................. 8-3

Table 8-3: V.11 Auxiliary connector, pin assignment ..................................................................................... 8-3

Table 8-4: RS-232 connectors, pin assignment .............................................................................................. 8-5

Table 8-5: OW connector, pin assignment ..................................................................................................... 8-6

Table 8-6: V.11 overhead connector, pin assignment .................................................................................... 8-7

Table 8-7: Alarms connector, pin assignment ................................................................................................ 8-8

Table 8-8: PME1_21 connector, pin assignment ............................................................................................ 8-9

Table 8-9: Connector P1 E1 #1 to E1 #21 Tx lines ........................................................................................ 8-13

Table 8-10: Connector P3 E1 #1 to E1 #21 Rx lines ...................................................................................... 8-14

Table 8-11: Connector P1 E1 #22 to E1 #42 Tx lines .................................................................................... 8-16

Table 8-12: Connector P3 E1 #22 to E1 #42 Rx lines .................................................................................... 8-17

Table 8-13: Connector P1 E1 #43 to E1 #63 Tx lines .................................................................................... 8-19

Table 8-14: Connector P3 E1 #43 to E1 #63 Rx lines .................................................................................... 8-20

Table 8-15: PE1_63 typical E1 connector (P2), pin assignment ................................................................... 8-23

Table 8-16: PE1_63 typical connector (P1), pin assignment ........................................................................ 8-25

Table 8-17: Gigabit Ethernet connector, pin assignment............................................................................. 8-29

Table 8-18: Twin 68-pin VHDCI connector (P2), pin assignment.................................................................. 8-29

Table 8-19: Twin 68-pin VHDCI connector (P1), pin assignment.................................................................. 8-32

Table 8-20: SM_10E/EM_10E SM_FXO_8 and SM_FXS_8 connector, pin assignment ................................ 8-35

Table 8-21: SM_10E/EM_10E SM_EM_24W6E connector, pin assignment ................................................ 8-36

Table 8-22: SM_10E SM_V35E connector, pin assignment.......................................................................... 8-38

Table 8-23: SM_10E/EM_10E SM_V24E connector, pin assignment for 8 x V.24 transparent

without controls mode .............................................................................................................. 8-39

Table 8-24: SM_V24E connector, pin assignment ........................................................................................ 8-40

Table 8-25: SM_10E/EM_10E SM_V24E connector, pin assignment for 2 x V.24 synchronous

with controls mode .................................................................................................................... 8-41

Table 8-26: SM_10E/EM_10E SM_V35_V11 connector, pin assignment .................................................... 8-42

Table 8-27: SM_V35_V11 pin assignment per interface type ...................................................................... 8-43

Table 8-28: SM_10E/EM_10E SM_CODIR_4E connector, pin assignment ................................................... 8-44

Table 8-29: SM_10E/EM_10E SM_OMNI_E connector, pin assignment ..................................................... 8-45

Table 8-30: ICP_VF RJ-45 connector, pin assignment for serving SM_FXS_8E or SM_FXO_8E ................... 8-46

ECI Telecom Ltd. Proprietary xiv

NPT-1030 Installation and Maintenance Manual List of Tables

Table 8-31: ICP_VF RJ-45 connector, pin assignment for serving SM_EM_24W6E ..................................... 8-47

Table 8-32: ICP_VF RJ-45 connector, pin assignment for serving SM_CODIR_4E ........................................ 8-47

Table 8-33: ICP_V24 synchronous V.24 25-pin D-type connector, pin assignment ..................................... 8-48

Table 8-34: ICP_V24 asynchronous V.24 9-pin D-type connector, pin assignment ..................................... 8-49

Table 8-35: ICP_V24 transparent V.24 9-pin D-type connector, pin assignment......................................... 8-49

Table 8-36: ICP_V35 M34 female connector, pin assignment ..................................................................... 8-50

Table 8-37: ICP_V11_V24 15-pin D-type connector, pin assignment .......................................................... 8-51

Table 8-38: ICP_V11_V24 V.24 25-pin D-type connector, pin assignment .................................................. 8-52

Table 8-39: ICP_DB37D 37 pin D-type connector, pin assignment .............................................................. 8-53

Table 8-40: ICP_DB37D 37-pin D-type connector, RS-449 pin assignment .................................................. 8-54

Table 8-41: ICP_DB37D 37-pin D-type connector, RS-422 pin assignment .................................................. 8-54

Table 8-42: ICP_DB37D 37-pin D-type connector, V.36 pin assignment ...................................................... 8-54

Table 8-43: ICP_DB37D 37-pin D-type connector, V.35 pin assignment ...................................................... 8-55

Table 8-44: ICP_DB37D 37-pin D-type connector, V.11/X.24 pin assignment ............................................. 8-56

Table 8-45: ICP_DB37D 37-pin D-type connector, synchronous V.24 pin assignment ................................ 8-56

Table 8-46: RAP-4B PLATFORM ALARM connector, pin assignment............................................................ 8-57

Table 8-47: RAP-4B ALARM IN/OUT connector, pin assignment ................................................................. 8-59

ECI Telecom Ltd. Proprietary xv

1 About This Manual

1.1 Overview

The NPT-1030 Installation, and Maintenance Manual (IMM) describes how to install NPT-1030 platforms

and how to install and replace hardware components, including cards, modules, and accessories.

1.2 Intended Audience

The NPT-1030 IMM is intended for installation and other qualified service personnel responsible for

installing the platform and its accessories.

1.3 Document Organization

This manual contains the following information:

Installation

Operation

Maintenance

Additional functionality

1.4 Notes and Warnings

When applicable, this guide uses the following notes and warnings:

NOTE: clarifying information, specific instructions, commentary, sidelights, or interesting

points of information.

CAUTION: failure to follow directions could result in damage to equipment or loss of

information.

WARNING: failure to follow directions could result in bodily harm or loss of life.

LASER WARNING: how to avoid personal injury. All personnel involved in equipment

installation, operation, and maintenance must be aware that laser radiation is invisible.

Therefore, although protective devices generally prevent direct exposure to the beam,

personnel must strictly observe the applicable safety precautions and, in particular, must

avoid staring into optical connectors, either directly or using optical instruments.

ECI Telecom Ltd. Proprietary 1-1

NPT-1030 Installation and Maintenance Manual About This Manual

ESD: information on how to avoid discharge of static electricity and subsequent damage to

the unit.

TIP: helpful information and handy hints that can make your task easier.

IMPORTANT: essential information to which you must pay attention.

1.5 Related Documentation

The following publications might be of assistance to you:

NPT Product Line General Description

NPT Product Line System Specifications

NPT Product Line Reference Manual

NPT EMS-APT User Manual

NPT LCT-APT User Manual

LightSoft® Network Management System User Manual

IEC Publication 825 - Laser Safety Requirements

1.6 How to Obtain ECI Technical Documentation

To obtain technical documentation related to any ECI product, contact:

ECI Telecom Ltd.

ECI Documentation Group

30 Hasivim St.

Petach Tikva 4959388 – Israel

Fax: +972-3-9268060

Email: techdoc.feedback@ecitele.com

1.7 Technical Assistance

The configuration, installation, and operation of NPT series and its operation in a network are highly

specialized processes. Due to the different nature of each installation, some planning aspects might not be

covered in this manual.

ECI Telecom Ltd. Proprietary 1-2

NPT-1030 Installation and Maintenance Manual About This Manual

If you have questions or concerns about your network design or if you require installation personnel to

perform the actual installation process, ECI maintains a staff of design engineers and highly trained field

service personnel. The services of this group are available to customers at any time.

To obtain design assistance or a network installation plan from ECI's Customer Support team, contact your

ECI sales representative. With any support related issues, technical or logistic, please contact the ECI

Customer Support center at your location. If you are not familiar with that location, or contact our

Customer Support Center action line at:

Telephone +972-3-9266000

Telefax +972-3-9266370

Email on.support@ecitele.com

ECI Telecom Ltd. Proprietary 1-3

2 Introduction

2.1 NPT-1030 Platform Overview

ECI’s NPT-1030 delivers a cost-effective and affordable mix of Ethernet, SDH, PDH, and PCM services that

result in new revenue-generating opportunities. It offers a wide variety of features and benefits, including:

High traffic survivability through main hardware duplication.

Ultra-high scalability based on coupling the NPT-1030 to the EXT-2U to make a build-as-you-grow™

solution.

Gradual capacity expansion based on service provisioning needs from ADM1 up to ADM16.

Ability to add interfaces easily while the network element (NE) is working by plugging in appropriate

cards ranging from E1 cards for multiple ports to STM-4 cards.

Carrier class Ethernet-over-WAN/MAN solution with SDH reliability, security, and management of

data services.

Sublambda grooming for high utilization of existing fiber and top efficiency in transmission of

different types of services.

PCM service interfaces and 1/0 digital cross-connect functions to facilitate the construction and

maintenance of various private networks.

Multi-ADM and cross-connect functionality, ideal for deployment in flexible network topologies like

ring, mesh, and star.

Compactness and resiliency, making it perfectly suited for both indoor and outdoor enclosures. Due

to its extended operating temperature range, it is also most suitable for harsh environmental

conditions.

Figure 2-1: Typical NPT-1030 platform

ECI Telecom Ltd. Proprietary 2-1

3 Before You Start

3.1 Overview

This chapter contains important information that will help you carry out a safe and trouble-free installation.

3.1.1 Outline of the Installation Procedure

The following table describes the main steps involved in the installation of NPT-1030 equipment. Consult

your site installation plans for specific details.

Table 3-1: Typical NPT-1030 equipment installation sequence

No. Task Reference

1 Prepare the installation site and check the physical location, Before You Start

environmental compliance, and availability of power

sources.

2 Prepare power, alarm, management, and transmission Before You Start and Equipment

cables at the installation site. Installation

3 Route the required power, alarm, management, and Equipment Installation

transmission cables to the intended NPT-1030 equipment

location.

4 If required, install the equipment racks. Equipment Installation

5 Mark the location of each NPT-1030 platform, relevant Equipment Installation

accessories (Fiber Storage Tray [FST], Optical

Distribution Frame [ODF], Digital Distribution Frame

[DDF], and MCP30B Interconnection Panel

[ICP_MCP30]) on each rack, in accordance with the site

installation plan.

Notes:

For NPT-1030-only installation, it is recommended you

leave at least 4 U of space above the platform to enable

future installation of the EXT-2U.

The NPT-1030 can only support balanced E1 interfaces

directly. For unbalanced E1s, the xDDF-21 patch panel

must be configured, which provides conversion between

balanced and unbalanced E1s for 21 x E1s.

When auxiliary interfaces like RS-232, orderwire (OW),

or V.11 are used in your application, the ICP_MCP30

should be installed in order to distribute the

concentrated Auxiliary connector into dedicated

connectors for each function.

6 When applicable, install the EMS-APT management station. EMS-APT Installation Guide

ECI Telecom Ltd. Proprietary 3-1

NPT-1030 Installation and Maintenance Manual Before You Start

No. Task Reference

7 Install the Rack Alarm Panel (RAP) and other equipment Equipment Installation

needed in each rack.

8 Install the NPT-1030 platforms in the appropriate rack. Equipment Installation

9 For each NPT-1030 platform where optical modules are Equipment Installation

used, install an FST under the NPT-1030 platform and route

the optical fibers to the FST.

Note: Even if you are not currently installing an FST, it is

recommended that you leave enough space beneath the

NPT-1030 platform to enable future installation.

10 Install the prescribed modules in the NPT-1030 platform,

including two INF_B1U or INF_30BH modules, FCU_1030,

MCP30B, two XIO30 modules (XIO30_1, XIO30Q_1&4,

XIO30_4, or XIO30_16), and optional Tslot modules.

Install the prescribed modules in the EXT-2U platform,

including two INF_E2U modules, FCU_E2U, or other

extension cards, such as the PE1_63, P345_3E, and SM_10E.

11 Install the SFP modules for XIO30 modules. Equipment Installation

12 Depending on the modules or cards in your NPT-1030 Equipment Installation

platform:

Route the PDH electrical cables from the DDF to the E1

interfaces on the front panel of PME1_21 modules, the

E3/DS-3 interfaces on the front panel of PM345_3

modules, and STM-1e interfaces on the STM-1 electrical

SFPs.

Route the data cables to the Fast Ethernet (FE)

interfaces on the front panel of DMFE_4_L1 modules.

If the ICP_MCP30 is installed, route the special cables to

connect the ICP_MCP30 and the MCP30B, and route

cables for interfaces on the ICP_MCP30 panel. If the

ICP_MCP30 is not installed and external alarms

interfaces are used, route the special Alarms cable from

the MCP30B Auxiliary connector to the RAP.

Note: The DDF can be installed on the same rack as the

NPT-1030 platform, or on a different rack.

13 Connect management cables between the equipment Equipment Installation

installed in the rack and the management station.

14 Connect power cables from the RAP panel to each NPT-1030 Equipment Installation

platform installed in the rack.

ECI Telecom Ltd. Proprietary 3-2

NPT-1030 Installation and Maintenance Manual Before You Start

3.2 Site Preparation

Perform a preliminary survey of the installation site, taking the following into consideration:

System environmental requirements

Physical location of the NPT-1030 platforms

Location of power sources

Types of interfaces used at the site (optical, electrical, management, alarm monitoring, and so on)

Work and equipment safety requirements

3.2.1 Environmental Requirements

The environmental conditions listed in the following table are applicable to NPT-1030 equipment and must

be ensured at the installation site.

Table 3-2: Environmental requirements

Parameter Compliance requirements

Electromagnetic interference EN 55022/94, EN 50082-1/92

Temperature ETSI ETS 300-19-2-3 Test Spec. T3.1

3.2.2 Physical Location

WARNING: NPT-1030 platforms are intended for installation in restricted-access areas only.

Before you start:

Choose the physical location of the NPT-1030 platforms, taking the following aspects into consideration:

1. Equipment dimensions (see the following table).

2. Required floor loading capability: 100 kg for a typical eight-platform installation.

3. Routing requirements for grounding, power, alarm monitoring, management cables, and optical

fibers. To ensure convenient access to cables and fibers, it is recommended, whenever possible, to

use overhead cable ladders to bring the cables/fibers to the top of each rack.

4. When a network management station, for example, the EMS-APT, is installed on the site, consider the

method of connection to the local network management station and the maximum allowed distance.

ECI Telecom Ltd. Proprietary 3-3

NPT-1030 Installation and Maintenance Manual Before You Start

Table 3-3: Equipment dimensions

Equipment type Height (mm) Width (mm) Depth (mm) Max. weight (kg)

NPT-1030 44 440 243 5

EXT-2U 88.9 443.4 243 4.5

RAP-BG 88 440 150 4

RAP-4B 88 447 155 2.4

FST 44.5 440 240 5

ODF 44.5 440 240 8

xDDF-21 44.5 440 150 1.5

ICP_MCP30 44 440 140 1.5

3.2.3 Power Sources

NPT-1030 platforms can be powered by DC sources complying with the applicable sections of ETSI 300