Professional Documents

Culture Documents

Ashirvad Pipes Pvt. LTD., Bangalore: Test Report of CPVC Pipes As Per Is 15778

Uploaded by

mohd shirazOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ashirvad Pipes Pvt. LTD., Bangalore: Test Report of CPVC Pipes As Per Is 15778

Uploaded by

mohd shirazCopyright:

Available Formats

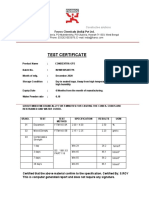

Date:03.04.

2022

ASHIRVAD PIPES PVT. LTD., BANGALORE

(AN ISO 9001:2015 COMPANY)

TEST REPORT OF CPVC PIPES AS PER IS 15778

SIZE : ½" (15.90mm OD,15mm DN) INVOICE NO. : 112204000061

TYPE : SDR 11 (CLASS 1)

PARTY NAME : M/s. HINDUSTAN PIPE SALES CORPORATION

B.No. : N.A

DIMENSIONS (in 'mm')

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

Min: 15.80

1 MEAN OUTSIDE DIAMETER 15.91 Passed

Max: 16.00

OUTSIDE DIAMETER AT ANY Min: 15.80

2 15.84/15.99 Passed

POINT Max: 16.00

Min: 1.70

3 WALL THICKNESS 1.77/1.89 Passed

Max: 2.20

4 LENGTH 3000 ± 5 3002 Passed

TESTS

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

The colour of the pipe shall be off-white.The internal

& external surface of the pipe shall be smooth,clean

1 VISUAL APPEARANCE Satisfactory Passed

and free from grooving & other defects.The ends of

the pipes are clean & square to the axis of the pipe.

2 HEAT REVERSION TEST The length shall not alter in length by more than 5%. 4.62% Passed

The density of the pipe shall be between

3 DENSITY 1.509g/cm3 Passed

1.45 and 1.65 g/cm3.

INTERNAL HYDROSTATIC 102.96 Kg/cm2

4 PRESSURE TEST The pipe should not fail during the prescribed test No sign of failure Passed

0

(At 20 C,σ=43Mpa,Duration=1Hr) duration of 1 hr.

INTERNAL HYDROSTATIC 14.04 Kg/cm2

5 PRESSURE TEST The pipe should not fail during the prescribed test No sign of failure Passed

0

(At 95 C,σ=5.6Mpa,Duration=165Hr) duration of 165 hr.

Weight: 500 gm

RESISTANCE TO EXTERNAL BLOW Height: 300 mm 0/25

6 0 Passed

AT 0 C The pipe shall have TIR not more than 10% No sign of failure

(Min no.of blows:25 Nos)

Before 60% of compression the sample should not

7 FLATTENING TEST No sign of failure Passed

tear,crack or split.

The tensile strength at yield shall not be less than

8 TENSILE TEST 55.10MPa Passed

50 Mpa.

The vicat softening temperature of the specimen

9 VICAT SOFTENING POINT 112.4˚C Passed

shall not be less than 110⁰C.

The wall of the pipe should not transmit more than

10 OPACITY 0.00% Passed

0.2% of the visible light falling on it.

REMARK: THE PIPE CONFORMS TO ABOVE SPECIFICATIONS AS PER IS 15778.

This is a computer generated test certificate. Hence signature not required.

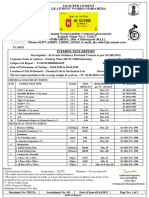

Date:30.03.2022

ASHIRVAD PIPES PVT. LTD., BANGALORE

(AN ISO 9001:2015 COMPANY)

TEST REPORT OF CPVC PIPES AS PER IS 15778

SIZE : ¾" (22.20mm OD,20mm DN) INVOICE NO. : 112204000061

TYPE : SDR 11 (CLASS 1)

PARTY NAME : M/s. HINDUSTAN PIPE SALES CORPORATION

B.No. : N.A

DIMENSIONS (in 'mm')

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

Min: 22.10

1 MEAN OUTSIDE DIAMETER 22.20 Passed

Max: 22.30

OUTSIDE DIAMETER AT ANY Min: 22.00

2 22.20/22.28 Passed

POINT Max: 22.40

Min: 2.00

3 WALL THICKNESS 2.10/2.25 Passed

Max: 2.50

4 LENGTH 3000 ± 5 3004 Passed

TESTS

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

The colour of the pipe shall be off-white.The internal &

external surface of the pipe shall be smooth,clean and

1 VISUAL APPEARANCE Satisfactory Passed

free from grooving & other defects.The ends of the

pipes are clean & square to the axis of the pipe.

2 HEAT REVERSION TEST The length shall not alter in length by more than 5%. 4.33% Passed

The density of the pipe shall be between 1.45 and

3 DENSITY 1.507g/cm3 Passed

1.65 g/cm3.

INTERNAL HYDROSTATIC 85.15 Kg/cm2

4 PRESSURE TEST The pipe should not fail during the prescribed test No sign of failure Passed

0

(At 20 C,σ=43Mpa,Duration=1Hr) duration of 1 hr.

INTERNAL HYDROSTATIC 11.09 Kg/cm2

5 PRESSURE TEST The pipe should not fail during the prescribed test No sign of failure Passed

0

(At 95 C,σ=5.6Mpa,Duration=165Hr) duration of 165 hr.

Weight: 500 gm

RESISTANCE TO EXTERNAL BLOW Height: 400 mm 0/25

6 0 Passed

AT 0 C The pipe shall have TIR not more than 10% No sign of failure

(Min no.of blows:25 Nos)

Before 60% of compression the sample should not

7 FLATTENING TEST No sign of failure Passed

tear,crack or split.

The tensile strength at yield shall not be less than 50

8 TENSILE TEST 55.21MPa Passed

Mpa.

The vicat softening temperature of the specimen shall

9 VICAT SOFTENING POINT 112.9˚C Passed

not be less than 110⁰C.

The wall of the pipe should not transmit more than

10 OPACITY 0.00% Passed

0.2% of the visible light falling on it.

REMARK: THE PIPE CONFORMS TO ABOVE SPECIFICATIONS AS PER IS 15778.

This is a computer generated test certificate. Hence signature not required.

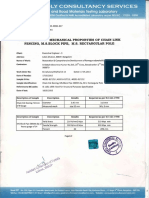

Date:12.04.2022

ASHIRVAD PIPES PVT. LTD., BANGALORE

(AN ISO 9001:2015 COMPANY)

TEST REPORT OF CPVC PIPES AS PER IS 15778

SIZE : 1" (28.60 mm OD,25mm DN) INVOICE NO. : 112204000061

TYPE : SDR 11 (CLASS 1)

PARTY NAME : M/s. HINDUSTAN PIPE SALES CORPORATION

B.No. : N.A

DIMENSIONS (in 'mm')

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

Min: 28.50

1 MEAN OUTSIDE DIAMETER 28.61 Passed

Max: 28.70

OUTSIDE DIAMETER AT ANY Min: 28.40

2 28.54/28.68 Passed

POINT Max: 28.80

Min: 2.60

3 WALL THICKNESS 2.68/2.83 Passed

Max: 3.10

4 LENGTH 3000 ± 5 3003 Passed

TESTS

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

The colour of the pipe shall be off-white.The internal

& external surface of the pipe shall be smooth,clean

1 VISUAL APPEARANCE Satisfactory Passed

and free from grooving & other defects.The ends of

the pipes are clean & square to the axis of the pipe.

2 HEAT REVERSION TEST The length shall not alter in length by more than 5%. 3.47% Passed

The density of the pipe shall be between 1.45 and

3 DENSITY 1.507g/cm3 Passed

1.65 g/cm3.

INTERNAL HYDROSTATIC 86.00 Kg/cm2

4 PRESSURE TEST The pipe should not fail during the prescribed test No sign of failure Passed

0

(At 20 C,σ=43Mpa,Duration=1Hr) duration of 1 hr.

INTERNAL HYDROSTATIC 11.20 Kg/cm2

5 PRESSURE TEST The pipe should not fail during the prescribed test No sign of failure Passed

0

(At 95 C,σ=5.6Mpa,Duration=165Hr) duration of 165 hr.

Weight: 500 gm

RESISTANCE TO EXTERNAL BLOW Height: 500 mm 0/25

6 0 Passed

AT 0 C The pipe shall have TIR not more than 10% No sign of failure

(Min no.of blows:25 Nos)

Before 60% of compression the sample should not

7 FLATTENING TEST No sign of failure Passed

tear,crack or split.

The tensile strength at yield shall not be less than

8 TENSILE TEST 55.23MPa Passed

50 Mpa.

The vicat softening temperature of the specimen

9 VICAT SOFTENING POINT 112.5˚C Passed

shall not be less than 110⁰C.

The wall of the pipe should not transmit more than

10 OPACITY 0.00% Passed

0.2% of the visible light falling on it.

REMARK: THE PIPE CONFORMS TO ABOVE SPECIFICATIONS AS PER IS 15778.

This is a computer generated test certificate. Hence signature not required.

Date:06.04.2022

ASHIRVAD PIPES PVT. LTD., BANGALORE

(AN ISO 9001:2015 COMPANY)

TEST REPORT OF CPVC PIPES AS PER IS 15778

SIZE : 1¼" (34.90 mm OD,32mm DN) INVOICE NO. : 112204000061

TYPE : SDR 11 (CLASS 1)

PARTY NAME : M/s. HINDUSTAN PIPE SALES CORPORATION

B.No. : N.A

DIMENSIONS (in 'mm')

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

Min: 34.80

1 MEAN OUTSIDE DIAMETER 34.90 Passed

Max: 35.00

OUTSIDE DIAMETER AT ANY Min: 34.70

2 34.84/34.96 Passed

POINT Max: 35.10

Min: 3.20

3 WALL THICKNESS 3.27/3.41 Passed

Max: 3.70

4 LENGTH 3000 ± 5 3002 Passed

TESTS

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

The colour of the pipe shall be off-white.The internal

& external surface of the pipe shall be smooth,clean

1 VISUAL APPEARANCE Satisfactory Passed

and free from grooving & other defects.The ends of

the pipes are clean & square to the axis of the pipe.

2 HEAT REVERSION TEST The length shall not alter in length by more than 5%. 3.17% Passed

The density of the pipe shall be between 1.45 and

3 DENSITY 1.511g/cm3 Passed

1.65 g/cm3.

INTERNAL HYDROSTATIC 86.81 Kg/cm2

4 PRESSURE TEST The pipe should not fail during the prescribed test No sign of failure Passed

0

(At 20 C,σ=43Mpa,Duration=1Hr) duration of 1 hr.

INTERNAL HYDROSTATIC 11.31 Kg/cm2

5 PRESSURE TEST The pipe should not fail during the prescribed test No sign of failure Passed

0

(At 95 C,σ=5.6Mpa,Duration=165Hr) duration of 165 hr.

Weight: 500 gm

RESISTANCE TO EXTERNAL BLOW Height: 600 mm 0/25

6 0 Passed

AT 0 C The pipe shall have TIR not more than 10% No sign of failure

(Min no.of blows:25 Nos)

Before 60% of compression the sample should not

7 FLATTENING TEST No sign of failure Passed

tear,crack or split.

The tensile strength at yield shall not be less than

8 TENSILE TEST 55.27MPa Passed

50 Mpa.

The vicat softening temperature of the specimen

9 VICAT SOFTENING POINT 112.5˚C Passed

shall not be less than 110⁰C.

The wall of the pipe should not transmit more than

10 OPACITY 0.00% Passed

0.2% of the visible light falling on it.

REMARK: THE PIPE CONFORMS TO ABOVE SPECIFICATIONS AS PER IS 15778.

This is a computer generated test certificate. Hence signature not required.

Date:10.04.2022

ASHIRVAD PIPES PVT. LTD., BANGALORE

(AN ISO 9001:2015 COMPANY)

TEST REPORT OF CPVC PIPES AS PER IS 15778

SIZE : 1½" (41.30 mm OD,40mm DN) INVOICE NO. : 112204000061

TYPE : SDR 11 (CLASS 1)

PARTY NAME : M/s. HINDUSTAN PIPE SALES CORPORATION

B.No. : N.A

DIMENSIONS (in 'mm')

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

Min: 41.20

1 MEAN OUTSIDE DIAMETER 41.31 Passed

Max: 41.40

OUTSIDE DIAMETER AT ANY Min: 41.10

2 41.22/41.38 Passed

POINT Max: 41.50

Min: 3.80

3 WALL THICKNESS 3.88/3.99 Passed

Max: 4.30

4 LENGTH 3000 ± 5 3001 Passed

TESTS

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

The colour of the pipe shall be off-white.The internal

& external surface of the pipe shall be smooth,clean

1 VISUAL APPEARANCE Satisfactory Passed

and free from grooving & other defects.The ends of

the pipes are clean & square to the axis of the pipe

2 HEAT REVERSION TEST The length shall not alter in length by more than 5%. 3.80% Passed

The density of the pipe shall be between 1.45 and

3 DENSITY 1.506g/cm3 Passed

1.65 g/cm3

INTERNAL HYDROSTATIC 87.15 Kg/cm2

4 PRESSURE TEST The pipe should not fail during the prescribed test No sign of failure Passed

0

(At 20 C,σ=43Mpa,Duration=1Hr) duration of 1 hr.

INTERNAL HYDROSTATIC 11.35 Kg/cm2

5 PRESSURE TEST The pipe should not fail during the prescribed test No sign of failure Passed

0

(At 95 C,σ=5.6Mpa,Duration=165Hr) duration of 165 hr.

Weight: 500 gm

RESISTANCE TO EXTERNAL BLOW Height: 800 mm 0/25

6 0 Passed

AT 0 C The pipe shall have TIR not more than 10% No sign of failure

(Min no.of blows:25 Nos)

Before 60% of compression the sample should not

7 FLATTENING TEST No sign of failure Passed

tear, crack or split.

The tensile strength at yield shall not be less than

8 TENSILE TEST 55.49MPa Passed

50 Mpa.

The vicat softening temperature of the specimen

9 VICAT SOFTENING POINT 112.7˚C Passed

shall not be less than 110⁰C.

The wall of the pipe should not transmit more than

10 OPACITY 0.00% Passed

0.2% of the visible light falling on it.

REMARK: THE PIPE CONFORMS TO ABOVE SPECIFICATIONS AS PER IS 15778.

This is a computer generated test certificate. Hence signature not required.

Date: 07.04.2022

ASHIRVAD PIPES PVT. LTD., BANGALORE

(AN ISO 9001:2015 COMPANY)

TEST REPORT OF CPVC PIPES AS PER IS 15778

SIZE : 2" (54.00 mm OD,50mm DN) INVOICE NO. : 112204000061

TYPE : SDR 11 (CLASS 1)

PARTY NAME : M/s. HINDUSTAN PIPE SALES CORPORATION

B.No. : N.A

DIMENSIONS (in 'mm')

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

Min: 53.90

1 MEAN OUTSIDE DIAMETER 54.00 Passed

Max: 54.10

OUTSIDE DIAMETER AT ANY Min: 53.70

2 53.92/54.10 Passed

POINT Max: 54.30

Min: 4.90

3 WALL THICKNESS 4.97/5.09 Passed

Max: 5.50

4 LENGTH 3000 ± 5 3003 Passed

TESTS

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

The colour of the pipe shall be off-white.The internal

& external surface of the pipe shall be smooth,clean

1 VISUAL APPEARANCE Satisfactory Passed

and free from grooving & other defects.The ends of

the pipes are clean & square to the axis of the pipe

2 HEAT REVERSION TEST The length shall not alter in length by more than 5%. 3.81% Passed

The density of the pipe shall be between 1.45 and

3 DENSITY 1.508g/cm3 Passed

1.65 g/cm3

INTERNAL HYDROSTATIC 85.82 Kg/cm2

4 PRESSURE TEST The pipe should not fail during the prescribed test No sign of failure Passed

0

(At 20 C,σ=43Mpa,Duration=1Hr) duration of 1 hr.

INTERNAL HYDROSTATIC 11.18 Kg/cm2

5 PRESSURE TEST The pipe should not fail during the prescribed test No sign of failure Passed

0

(At 95 C,σ=5.6Mpa,Duration=165Hr) duration of 165 hr.

Weight: 500 gm

RESISTANCE TO EXTERNAL BLOW Height: 1000 mm 0/25

6 0 Passed

AT 0 C The pipe shall have TIR not more than 10% No sign of failure

(Min no.of blows:25 Nos)

Before 60% of compression the sample should not

7 FLATTENING TEST No sign of failure Passed

tear, crack or split.

The tensile strength at yield shall not be less than

8 TENSILE TEST 55.49*MPa Passed

50 Mpa.

The vicat softening temperature of the specimen

9 VICAT SOFTENING POINT 112.2˚C Passed

shall not be less than 110⁰C.

The wall of the pipe should not transmit more than

10 OPACITY 0.00% Passed

0.2% of the visible light falling on it.

REMARK: THE PIPE CONFORMS TO ABOVE SPECIFICATIONS AS PER IS 15778.

This is a computer generated test certificate. Hence signature not required.

DATE:05.04.2022

ASHIRVAD PIPES PVT. LTD., BANGALORE

(AN ISO 9001:2015 COMPANY)

TEST REPORT OF CPVC PIPES AS PER ASTM F 441

SIZE : 2½" (65mm DN) INVOICE NO. : 112204000061

TYPE : SCH 40

PARTY NAME : M/s. HINDUSTAN PIPE SALES CORPORATION

B.No. : N.A

DIMENSIONS (in 'mm')

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

OUTSIDE DIAMETER AT ANY Min: 72.84

1 72.90/73.04 Passed

POINT Max: 73.20

Min: 5.16

2 WALL THICKNESS 5.20/5.39 Passed

Max: 5.77

3 LENGTH 3000 ± 5 3003 Passed

TESTS

Sl. No. PARAMETER SPECIFICATION OBSERVATION RESULT

The colour of the pipe shall be off-white.The internal

& external surface of the pipe shall be smooth,clean

1 VISUAL APPEARANCE Satisfactory Passed

and free from grooving & other defects.The ends of

the pipes are clean & square to the axis of the pipe.

2 HEAT REVERSION TEST (IS 15778) The length shall not alter in length by more than 5%. 2.81% Passed

The density of the pipe shall be between 1.45 and 3

3 DENSITY (IS 15778) 1.510g/cm Passed

1.65 g/cm3.

Withstood

BURST PRESSURE TEST

4 Sample should withstand 68.22.Kg/cm2 pressure. 68.22Kg/cm

2

Passed

(At 230C,Duration : 60 - 70Sec.)

pressure,no burst

Weight: 800 gm

RESISTANCE TO EXTERNAL BLOW Height: 1000 mm 0/25

5 Passed

AT 00C (IS 15778) The pipe shall have TIR not more than 10% No sign of failure

(Min no.of blows:25 Nos)

Before 60% of compression the sample should not

6 FLATTENING TEST No sign of failure Passed

tear,crack or split.

The tensile strength at yield shall not be less than

7 TENSILE STRENGTH (IS 15778) 55.53MPa Passed

50 Mpa.

VICAT SOFTENING POINT The vicat softening temperature of the specimen

8 112.5˚C Passed

(IS 15778) shall not be less than 110⁰C.

The wall of the pipe should not transmit more than

9 OPACITY (IS 15778) 0.00% Passed

0.2% of the visible light falling on it.

REMARK: THE PIPE CONFORMS TO ABOVE SPECIFICATIONS.

This is a computer generated test certificate. Hence signature not required.

You might also like

- SWR Is 13592 Test ReportDocument4 pagesSWR Is 13592 Test Reportmohd shirazNo ratings yet

- Ashirvad Pipes Pvt. LTD.: Test Report of Upvc Agri Pipes As Per Is 4985:2021Document6 pagesAshirvad Pipes Pvt. LTD.: Test Report of Upvc Agri Pipes As Per Is 4985:2021mohd shiraz100% (1)

- Ashirvad Pipes Pvt. LTD., Bangalore: Test Report of Upvc Reclaim Pipes As Per Astm D 1785Document9 pagesAshirvad Pipes Pvt. LTD., Bangalore: Test Report of Upvc Reclaim Pipes As Per Astm D 1785mohd shirazNo ratings yet

- HDPE Pipe Test ReportDocument8 pagesHDPE Pipe Test Reportshhussaini067% (3)

- Gland 9087 18.12 PDFDocument1 pageGland 9087 18.12 PDFSachin wakeNo ratings yet

- Brick Test ReportDocument1 pageBrick Test Reportsudugouda100% (2)

- VRF/VRV Air Conditioning System: DSR & AorDocument28 pagesVRF/VRV Air Conditioning System: DSR & AorHarvendra SinghNo ratings yet

- MTC Conbextra Gp2Document1 pageMTC Conbextra Gp2kartick adhikary0% (1)

- Ultratech Cement LTD.: Concrete Mix Design Data For M-10Document2 pagesUltratech Cement LTD.: Concrete Mix Design Data For M-10Laxmi Kant PradhanNo ratings yet

- JK 43 Opc Test CertificateDocument1 pageJK 43 Opc Test CertificateRavi kumar100% (1)

- RMC Plant Calibration ReportDocument5 pagesRMC Plant Calibration ReportSurendra kumar50% (2)

- High Performance Concrete SuperplasticizerDocument2 pagesHigh Performance Concrete SuperplasticizerSanthoshKumarSharmaCHNo ratings yet

- Is 14333 HDPE For SewerageDocument35 pagesIs 14333 HDPE For SewerageSAURABH_SINGH2676No ratings yet

- DLC Degin GulbaxaniDocument6 pagesDLC Degin GulbaxaniImran KhanNo ratings yet

- Test Certificate For Galvanized Steel CoilsDocument1 pageTest Certificate For Galvanized Steel CoilsS.SHANMUGA SABAREESANNo ratings yet

- SmartCare TechnoPlast S 300Document2 pagesSmartCare TechnoPlast S 300raviteja036100% (1)

- Checklist for vacuum dewatered flooringDocument1 pageChecklist for vacuum dewatered flooringGabriel Gabe100% (2)

- 1C-Checklist For Installation of GI Pipe For DrainageDocument1 page1C-Checklist For Installation of GI Pipe For DrainageRajput Amit100% (1)

- Boq 30583Document33 pagesBoq 30583Digendra Rathore100% (1)

- Checklist For Design & Drawing of Compound Wall and Main GateDocument2 pagesChecklist For Design & Drawing of Compound Wall and Main GateRupesh KhandekarNo ratings yet

- Rebound Hammer Test - HT2102004 - 1Document1 pageRebound Hammer Test - HT2102004 - 1Yasndra AbeygunewardhaneNo ratings yet

- Blue SealDocument3 pagesBlue Sealpandey7108767% (3)

- Specs Pull Off Cement Plaster General PurposeDocument3 pagesSpecs Pull Off Cement Plaster General PurposeKhan Shahzeb100% (2)

- DSR Cost IndexDocument3 pagesDSR Cost Indexతేజ చొల్లంగి100% (3)

- Methodology For Emb With Pond AshDocument10 pagesMethodology For Emb With Pond Ashjitendra100% (4)

- Concrete Core Strength CalculationDocument2 pagesConcrete Core Strength CalculationkalyanqaqcNo ratings yet

- Concrete batching sheetDocument1 pageConcrete batching sheetarpit1121100% (1)

- DSR 2022 E&mDocument591 pagesDSR 2022 E&mnitesh mulhall100% (6)

- Slump Cone and Rod - CalibrationDocument1 pageSlump Cone and Rod - CalibrationKannan MurugesanNo ratings yet

- List of BIS StandardsDocument9 pagesList of BIS StandardsKumar100% (1)

- Auramix BCI Corrosion ProtectionDocument2 pagesAuramix BCI Corrosion Protectionraviteja036No ratings yet

- Lug - 9086-18.12Document1 pageLug - 9086-18.12Sachin wakeNo ratings yet

- J.K.Cement Works-Muddapur J K Super Cement: END of ReportDocument12 pagesJ.K.Cement Works-Muddapur J K Super Cement: END of ReportSiddhesh Kamat MhamaiNo ratings yet

- Is 16098 2 2013Document44 pagesIs 16098 2 2013ses2003_k100% (2)

- WMM Moisture Correction SheetDocument34 pagesWMM Moisture Correction SheetQuality JamNo ratings yet

- Vinothkumar-Qaqc CVDocument6 pagesVinothkumar-Qaqc CVsoorajNo ratings yet

- Microtech Testing & Research Laboratory: Condition of Sample, When Received: SatisfactoryDocument1 pageMicrotech Testing & Research Laboratory: Condition of Sample, When Received: SatisfactoryKumar AbhishekNo ratings yet

- FOSROC SPECS - HDPE - P STD + Proofex 3000VDocument15 pagesFOSROC SPECS - HDPE - P STD + Proofex 3000VAjin Sharma100% (1)

- Mechanical Test Report on Construction MaterialsDocument2 pagesMechanical Test Report on Construction Materialsankit67% (3)

- Polycab WireDocument4 pagesPolycab WireMAYUR GENSET100% (1)

- M35 Concrete Mix Design for Pile FoundationsDocument4 pagesM35 Concrete Mix Design for Pile FoundationsPaulos Wodajenehe TessemaNo ratings yet

- Brick Test FormateDocument3 pagesBrick Test FormateVarun SharmaNo ratings yet

- Alccofine 1108SR : Description Typical PropertiesDocument2 pagesAlccofine 1108SR : Description Typical Propertiesravi100% (1)

- Earth Pit Test ReportDocument2 pagesEarth Pit Test ReportRavi Saini100% (1)

- ITP For Plumbing & Drainage SystemDocument97 pagesITP For Plumbing & Drainage Systemmagdi badran100% (7)

- Technical Specifications of Boundary WallDocument5 pagesTechnical Specifications of Boundary WallAndy100% (1)

- T119Document2 pagesT119Katerin HernandezNo ratings yet

- Quick reference guide to standard sizes, foundation requirements and specifications for diesel generator setsDocument13 pagesQuick reference guide to standard sizes, foundation requirements and specifications for diesel generator setsYamral WubetuNo ratings yet

- Somasila Grey Granite Test ReportDocument2 pagesSomasila Grey Granite Test ReportRakesh ReddyNo ratings yet

- QAP For Road WorksDocument25 pagesQAP For Road WorksBhawesh AshuNo ratings yet

- BS 873 - Road StudsDocument18 pagesBS 873 - Road StudsVicky Munien100% (1)

- Wet Mix Macadam (WMM) Technical Specifications As Per MORTH and Indian StandardDocument40 pagesWet Mix Macadam (WMM) Technical Specifications As Per MORTH and Indian StandardRAMPALLI GATTAIAH0% (1)

- Method Statement For TRAFFIC SIGNSDIRECTIONAL SIGNS-RajDocument18 pagesMethod Statement For TRAFFIC SIGNSDIRECTIONAL SIGNS-RajRaj100% (2)

- Paver Block ChecklistDocument6 pagesPaver Block ChecklistAnkur BarsainyaNo ratings yet

- Test CertificateDocument1 pageTest CertificateViswa BhuvanNo ratings yet

- Tested By: Alok Shukla Approved By: Executive /chemist Suman Khuntia Manager - Quality AssuranceDocument1 pageTested By: Alok Shukla Approved By: Executive /chemist Suman Khuntia Manager - Quality AssurancedipeshlodhiqseplNo ratings yet

- Resilient wedge gate valves testingDocument4 pagesResilient wedge gate valves testingroxxxNo ratings yet

- HDPE Tube Bundle SpecificationDocument2 pagesHDPE Tube Bundle SpecificationAlvaro Segura JavierNo ratings yet

- 1554-2Cx6mm AluminumDocument3 pages1554-2Cx6mm AluminumSandeep BhutaniNo ratings yet

- Test Certificate: Upvc Fittings To Bs en 1401 LPO Ref: 352004218 DN Number: 33458977Document9 pagesTest Certificate: Upvc Fittings To Bs en 1401 LPO Ref: 352004218 DN Number: 33458977Karlo Sam DiegoNo ratings yet

- Zoloto-1083A - Swing Type CastIronNonReturnValvePN1.6FlangedDocument1 pageZoloto-1083A - Swing Type CastIronNonReturnValvePN1.6Flangedmohd shirazNo ratings yet

- Product Replacement Form: Customer InformationDocument1 pageProduct Replacement Form: Customer Informationmohd shirazNo ratings yet

- Report - Food & GroceryDocument15 pagesReport - Food & Grocerymohd shirazNo ratings yet

- ResponseDocument1 pageResponsemohd shirazNo ratings yet

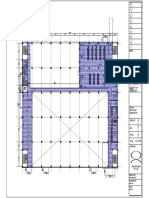

- First Floor RCPDocument9 pagesFirst Floor RCPmohd shirazNo ratings yet

- ResponseDocument1 pageResponsemohd shirazNo ratings yet

- Ground Floor RCPDocument1 pageGround Floor RCPmohd shirazNo ratings yet

- NDT Training Course BrochureDocument10 pagesNDT Training Course Brochuresatya srinivas anasuriNo ratings yet

- Secondary Beam - BM and Shear ForceDocument11 pagesSecondary Beam - BM and Shear ForcerameshkaaNo ratings yet

- Lesson Plan in Chemistry - PasaDocument6 pagesLesson Plan in Chemistry - PasaPenelope Soria EjadaNo ratings yet

- Vacuum Technology Book II Part 1 PDFDocument88 pagesVacuum Technology Book II Part 1 PDFMuhammad Maratab Ali ZiaiNo ratings yet

- Problem Solving 2Document14 pagesProblem Solving 2Therezze Jane ParanadaNo ratings yet

- A333 - 18 PDFDocument8 pagesA333 - 18 PDFRamyMoustafaNo ratings yet

- KS3 Magnetism Worksheet: 1) A) Draw The Shape and Direction of The Magnetic Field Around The Barmagnet BelowDocument4 pagesKS3 Magnetism Worksheet: 1) A) Draw The Shape and Direction of The Magnetic Field Around The Barmagnet BelowAmal GeorgeNo ratings yet

- Body Sealing PDFDocument22 pagesBody Sealing PDFoz23No ratings yet

- Telomeres and The Moringa Antioxidant Assortment2Document8 pagesTelomeres and The Moringa Antioxidant Assortment2seemanta_dasNo ratings yet

- Exposure PhotoresistDocument7 pagesExposure PhotoresistyhyhNo ratings yet

- ARC SD4i Datasheet - ENDocument1 pageARC SD4i Datasheet - ENnorsahiramaslazimNo ratings yet

- JEE MAINS - Test 07 - Solution Notes (Chemistry) - Test 07 Chem SolDocument33 pagesJEE MAINS - Test 07 - Solution Notes (Chemistry) - Test 07 Chem SolMohit SuaradkarNo ratings yet

- Physics MCQs For Class 12 CH 11 Dual Nature of Matter and RadiationDocument7 pagesPhysics MCQs For Class 12 CH 11 Dual Nature of Matter and RadiationAkshith ReddyNo ratings yet

- Modeling CO2 Storage in Aquifers With A Fully-CoupDocument17 pagesModeling CO2 Storage in Aquifers With A Fully-CoupFatimah Az ZahraNo ratings yet

- Introduction to Chemical Processes Exam 1 ProblemsDocument7 pagesIntroduction to Chemical Processes Exam 1 ProblemsDaniela Andrea Vargas MedinaNo ratings yet

- Rao CBM 96 (2015) 508-517Document11 pagesRao CBM 96 (2015) 508-517Ali AliievNo ratings yet

- DC SIM+User+GuideDocument115 pagesDC SIM+User+GuideSegundopqNo ratings yet

- Safety Data Sheet Cosmorol Gq6Document7 pagesSafety Data Sheet Cosmorol Gq6Mohammed IsmailNo ratings yet

- 6242 01 Rms 20060616Document10 pages6242 01 Rms 20060616UncleBulgariaNo ratings yet

- Chapter 3Document38 pagesChapter 3Teddy Matthew AudleyNo ratings yet

- Induction FurnaceDocument7 pagesInduction FurnaceDeepak Velusamy100% (2)

- NSS Chemistry Part 2 Microscopic World I - LQ - PDFDocument22 pagesNSS Chemistry Part 2 Microscopic World I - LQ - PDFSiu Hon ChengNo ratings yet

- Week06outlinesf11 PDFDocument6 pagesWeek06outlinesf11 PDFaashique hussainNo ratings yet

- Air Sentry Dessicant Breathers BrochureDocument14 pagesAir Sentry Dessicant Breathers BrochureNelson PeraltaNo ratings yet

- SWG 30 WDocument1 pageSWG 30 WRajesh RoyNo ratings yet

- GATE Chemical Engineering 1991Document7 pagesGATE Chemical Engineering 1991rahulNo ratings yet

- Chemical Engineering, BSC PDFDocument41 pagesChemical Engineering, BSC PDFCássio Soares100% (1)

- H-DC-0033 Natural High Clarity Dishwashing LiquidDocument1 pageH-DC-0033 Natural High Clarity Dishwashing Liquid120984100% (1)

- Adenosine 5'-Triphosphate Disodium SaltDocument1 pageAdenosine 5'-Triphosphate Disodium Saltmononoketangqihotmail.comNo ratings yet

- 04 Model-Model Sumber (Source Models) PDFDocument98 pages04 Model-Model Sumber (Source Models) PDFDio Nur RachmanNo ratings yet