Professional Documents

Culture Documents

SB-11-001 Exhaust Manifold Stud Modification. J05 Engines

Uploaded by

Phil B.Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SB-11-001 Exhaust Manifold Stud Modification. J05 Engines

Uploaded by

Phil B.Copyright:

Available Formats

Group: 17- Intake and Exhaust

Warranty Code: 052

Bulletin No. SB-11-001

Issue Date: 07-21-2011

SERVICE INFORMATION BULLETIN

Subject:

EXHAUST MANIFOLD STUD MODIFICATION AND COOLANT PIPE DESIGN CHANGE FOR

J05D-TF ENGINES

This document is to inform dealers and workshops of the exhaust manifold stud modification and

coolant pipe design change.

1. RELEVANT MODELS:

2008 – 2010 NA6J (145), NB6J (165) and NC6J (185) models.

Equipped with the J05D

J05D-TF

TF engine.

engine

2. OVERVIEW:

This bulletin provides instructions for the exhaust manifold attachment modification at the #1

cylinder location. The modification consists of installing longer exhaust studs, sleeves and

double nuts to better withstand vibration and heat stress. Modifications to the manifold insulator

shield and the turbocharger coolant pipe have also been made to accommodate the longer

studs.

The installation instructions in this bulletin are limited to the modified components. Please follow

Workshop Manual Removal & Installation Instructions for the surrounding components which

need to be removed in order to complete the modification.

3

3. PARTS REQUIRED:

REQUIRED

Description Part Number Quantity

Stud SZ12610017 3

Spacer SZ91016297 3

Coolant Pipe 16895E0200 1

Gasket SL72301414 4

Nut (17mm) SZ17010022 3

Nut (14mm) SZ17010009 3

Page 1 Vendor Ref: HMM-110622-B1

Group: 17- Intake and Exhaust

Warranty Code: 052

Bulletin No. SB-11-001

Issue Date: 07-21-2011

SERVICE INFORMATION BULLETIN

Note: The remaining 9 studs, nuts, spacers and 4 gaskets below remain the same

Description Part Number Quantity

Stud SZ12610012 9

Spacer SZ91016217 9

Nut SZ17810007 9

Manifold Gaskets S171041610 4

BEFORE YOU BEGIN

Read and understand all instructions and procedures before you begin the work

Read and follow all Cautions set forth below

These alerts help to avoid damage to components, serious personal injury, or both

Park the vehicle on a level and solid surface

Apply the parking brake and confirm parking brake activation

Place wheel chocks in front of and behind all wheels

Use care when working around surfaces which may be hot

Wear safety glasses to prevent eye injuries

Properly calibrated torque wrenches must be used to prevent possible ensuing damage

Turn off the engine and remove the key from the ignition switch

4. PROCEDURE:

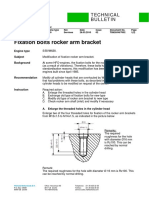

Modification of the insulator shield:

Bend

B d th

the corner off the

th shield

hi ld according

di

to the picture.

Caution: Do not cut the shield.

Page 2 Vendor Ref: HMM-110622-B1

Group: 17- Intake and Exhaust

Warranty Code: 052

Bulletin No. SB-11-001

Issue Date: 07-21-2011

SERVICE INFORMATION BULLETIN

The clearance between the insulator and

surrounding parts should be minimum 5mm.

Caution: Do not bend the shield more than 4

times to prevent strength reduction. Also

do not bend it in the opposite direction.

Exhaust Manifold attachment at cylinder #1:

After removing the original stud

stud, clean the stud

bore using a M10 x 1.5mm tap.

Install stud and torque to 22lbf.ft (30Nm)

Caution: Excessive torque on the stud may cause the

cylinder head to crack.

Insert the 45mm spacer over the stud.

Install and torque the inner nut (17mm) to 39lbf.ft

39lbf ft (53Nm)

Caution: Make sure the spacer remains centered

while tightening the nut.

Recheck torques on all 3 inner nuts prior to installing

the outer nuts.

Page 3 Vendor Ref: HMM-110622-B1

Group: 17- Intake and Exhaust

Warranty Code: 052

Bulletin No. SB-11-001

Issue Date: 07-21-2011

SERVICE INFORMATION BULLETIN

Install and tighten the outer nut (14mm) to

45lbf.ft (61Nm) while holding the inner nut.

Install the modified turbocharger coolant

pipe using new gaskets.

Page 4 Vendor Ref: HMM-110622-B1

You might also like

- SB-15-017 08MY - 10MY J05 Broken Exhaust Manifold StudsDocument7 pagesSB-15-017 08MY - 10MY J05 Broken Exhaust Manifold StudsPhil B.No ratings yet

- SB-15-016 13MY - 15MY J05 Broken Exhaust Manifold StudsDocument6 pagesSB-15-016 13MY - 15MY J05 Broken Exhaust Manifold StudsPhil B.No ratings yet

- TCD2015 PDFDocument67 pagesTCD2015 PDFRosa ChNo ratings yet

- TR019937011693 - en - PDF Coolant Pump Installation Instruction & RepairDocument5 pagesTR019937011693 - en - PDF Coolant Pump Installation Instruction & Repairibrahim salemNo ratings yet

- SB 08-001 Installation Procedure For Crankcase Breather Anti Freezing KitDocument8 pagesSB 08-001 Installation Procedure For Crankcase Breather Anti Freezing KitPhil B.No ratings yet

- 12165-70 - 1 Sundry Instr.Document328 pages12165-70 - 1 Sundry Instr.kodrysNo ratings yet

- SB 05-007 Water PipeDocument1 pageSB 05-007 Water PipePhil B.No ratings yet

- DAC1 79 01 Rev 0Document10 pagesDAC1 79 01 Rev 0vanNo ratings yet

- AF210 Service ManualDocument17 pagesAF210 Service ManualUEENo ratings yet

- GVAR210 Service ManualDocument17 pagesGVAR210 Service ManualUEENo ratings yet

- Service Bulletin: AB Volvo PentaDocument4 pagesService Bulletin: AB Volvo PentaDan LiamNo ratings yet

- 3 Instructions D1 - 1Document125 pages3 Instructions D1 - 1thanhNo ratings yet

- Sb-15-010 11my-15my Egr Valve HeaterDocument10 pagesSb-15-010 11my-15my Egr Valve HeaterPhil B.No ratings yet

- Pulsar 180 Ug3 PDFDocument30 pagesPulsar 180 Ug3 PDFCristian BarbozaNo ratings yet

- Instrucciones de Armado Torres Marlyn EtoDocument698 pagesInstrucciones de Armado Torres Marlyn EtoMarcoNo ratings yet

- Engineering Bulletin - EB07-006: Scope RecommendationsDocument2 pagesEngineering Bulletin - EB07-006: Scope RecommendationsBoedi SyafiqNo ratings yet

- Service NewsDocument19 pagesService NewsMuhammad HardiusNo ratings yet

- A-15-008 11MY-14MY DPR Burner Fuel Filter HeaterDocument11 pagesA-15-008 11MY-14MY DPR Burner Fuel Filter HeaterPhil B.No ratings yet

- Alle K-Infos EnglischDocument134 pagesAlle K-Infos EnglischasalinaspadillaNo ratings yet

- Van FlapDocument133 pagesVan FlapthanhNo ratings yet

- KDC InstallationDocument2 pagesKDC InstallationJIANG LUNo ratings yet

- PB DDM 026Document3 pagesPB DDM 026Jim SharpNo ratings yet

- Records: Big End Bearing BoreDocument1 pageRecords: Big End Bearing BoreDomenicoNo ratings yet

- Pulsar 200Document32 pagesPulsar 200Alfonso Guatzin De JesusNo ratings yet

- Service Bulletin - (TB628!08!7002) - Rocker Arm BracketDocument3 pagesService Bulletin - (TB628!08!7002) - Rocker Arm Bracketps_visjehotmailcomNo ratings yet

- Microfilter FinalDocument6 pagesMicrofilter FinalRobs BankNo ratings yet

- SB-14-019 05MY-07MY Allison Torque Converter Lockup ModificationDocument15 pagesSB-14-019 05MY-07MY Allison Torque Converter Lockup ModificationPhil B.No ratings yet

- Camiseta de O500Document5 pagesCamiseta de O500Miguel CardenasNo ratings yet

- PB-DDM-032 Thrust Bearing Clearence.Document8 pagesPB-DDM-032 Thrust Bearing Clearence.Jim SharpNo ratings yet

- SKF Supergrip BoltDocument18 pagesSKF Supergrip Boltformech100% (1)

- Jenbacher: 1. Replacing The Cylinder HeadDocument2 pagesJenbacher: 1. Replacing The Cylinder HeadArîfNo ratings yet

- Load-Sensing Control Block in Mono Block/sandwich Plate Design M4-12Document40 pagesLoad-Sensing Control Block in Mono Block/sandwich Plate Design M4-12Israel RuizNo ratings yet

- Clorius Controls 3-Way Control Valves TYPE Soft Seated: Nodular Cast Iron, DN 80 - 300 MM InstructionsDocument29 pagesClorius Controls 3-Way Control Valves TYPE Soft Seated: Nodular Cast Iron, DN 80 - 300 MM InstructionsromanNo ratings yet

- SL162B Helicoil PDFDocument2 pagesSL162B Helicoil PDFjeffrey_fay100% (2)

- D601000439 Man 001Document25 pagesD601000439 Man 001Riski KurniawanNo ratings yet

- 40.20.31.pdf New Labrynth Input SealDocument2 pages40.20.31.pdf New Labrynth Input SealMichel FloresNo ratings yet

- Установка ТНВД 2.9 3.6Document19 pagesУстановка ТНВД 2.9 3.6bogdanmichaelNo ratings yet

- Eg5008 0 1Document2 pagesEg5008 0 1Victor SanchezNo ratings yet

- OVHD Compressor Maintenance JobDocument8 pagesOVHD Compressor Maintenance JobMuhammad Usman KaimkhaniNo ratings yet

- Rep 24Document330 pagesRep 24ArturNo ratings yet

- Rotary Joint Unit: Supplementary Instruction ManualDocument17 pagesRotary Joint Unit: Supplementary Instruction ManualAntonio Montesinos ChavarríaNo ratings yet

- In-Bottom Out-Back Cooling Kit For FA09-FA10-M0031401 AN371942757356en-000101Document18 pagesIn-Bottom Out-Back Cooling Kit For FA09-FA10-M0031401 AN371942757356en-000101creative BrandwiseNo ratings yet

- SB-14-016 11MY-14MY Allison Torque Converter Lockup ModificationDocument15 pagesSB-14-016 11MY-14MY Allison Torque Converter Lockup ModificationPhil B.No ratings yet

- Ac Nut Splitter ManualDocument12 pagesAc Nut Splitter ManualLoveNo ratings yet

- Hose Ends - Field AttachableDocument64 pagesHose Ends - Field AttachableSasan AbbasiNo ratings yet

- Service Info Technology: Assembly Sleeves For The Valve Stem Sealing RingDocument3 pagesService Info Technology: Assembly Sleeves For The Valve Stem Sealing RingRep danNo ratings yet

- Piston Ring GapDocument1 pagePiston Ring Gapibrahim salemNo ratings yet

- 777D Liner Projection UpdateDocument4 pages777D Liner Projection UpdateAplesNo ratings yet

- SB-16-022 11MY-14MY Conventional Burner Atomizer Repair ProcedureDocument15 pagesSB-16-022 11MY-14MY Conventional Burner Atomizer Repair ProcedurePhil B.No ratings yet

- 7-Mbe900-04a InyectorDocument4 pages7-Mbe900-04a InyectorGerson AquinoNo ratings yet

- Nozzle InstallationDocument6 pagesNozzle InstallationlmjustinianoNo ratings yet

- PE34461 - AP2000 - DV6D - Engine Spares Manual - REV-1Document30 pagesPE34461 - AP2000 - DV6D - Engine Spares Manual - REV-1Hendro Syahputra100% (1)

- Iston With Undulated Piston Crown: Lmbo QFKD Fkpqor'qflkDocument2 pagesIston With Undulated Piston Crown: Lmbo QFKD Fkpqor'qflkRonald Bienemi Paez100% (2)

- Shogun 2001 Fuel ProblemDocument6 pagesShogun 2001 Fuel ProblemJose GilmerNo ratings yet

- SB-15-028 12MY-16MY COE Stability UpgradeDocument11 pagesSB-15-028 12MY-16MY COE Stability UpgradePhil B.No ratings yet

- BMW E60 Engine Seals NotebookDocument24 pagesBMW E60 Engine Seals NotebookPeter McCracken100% (6)

- DT 55 (1985-1987) DT 65 (1985-1987)Document57 pagesDT 55 (1985-1987) DT 65 (1985-1987)Antonio MatroneNo ratings yet

- Piezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingDocument10 pagesPiezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingZdravko DudicNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- RPM Tech LM220 Snow Blower BrochureDocument4 pagesRPM Tech LM220 Snow Blower BrochurePhil B.No ratings yet

- Allison Tranmission Wiring Diagram - Wtec III.3000 & 4000 Transid 2Document11 pagesAllison Tranmission Wiring Diagram - Wtec III.3000 & 4000 Transid 2fragman06825100% (4)

- Allison - Wtec III - Transid 1Document12 pagesAllison - Wtec III - Transid 1Phil B.100% (1)

- RPM Tech LM220 Brochure 01 2020 en SourcewellDocument4 pagesRPM Tech LM220 Brochure 01 2020 en SourcewellPhil B.No ratings yet

- RPM Tech LM220 Parts Catalog s0300 Pmef 2676 and More Rev2Document100 pagesRPM Tech LM220 Parts Catalog s0300 Pmef 2676 and More Rev2Phil B.No ratings yet

- Allison - WTEC III.3000 & 4000 TransID 1Document13 pagesAllison - WTEC III.3000 & 4000 TransID 1fragman0682575% (4)

- Allison - WTEC III.1000 & 2000 PDFDocument7 pagesAllison - WTEC III.1000 & 2000 PDFLgvasquez Vásquez100% (1)

- SB-16-039 DTC P206D Single Plate ClutchDocument6 pagesSB-16-039 DTC P206D Single Plate ClutchPhil B.No ratings yet

- Allison - 3000 & 4000 Gen 5Document8 pagesAllison - 3000 & 4000 Gen 5fragman06825100% (4)

- Allison - WTEC II PDFDocument7 pagesAllison - WTEC II PDFluis100% (1)

- Allison - WTEC III - TransID 2Document12 pagesAllison - WTEC III - TransID 2Phil B.33% (3)

- SB-17-001 Connector Name Workshop Manual CorrectionDocument3 pagesSB-17-001 Connector Name Workshop Manual CorrectionPhil B.No ratings yet

- Allison - 1000 & 2000 Gen 4Document7 pagesAllison - 1000 & 2000 Gen 4Freddy Villegas67% (6)

- SB-16-036 Unification of Part Numbers Workshop Manual CorrectionDocument6 pagesSB-16-036 Unification of Part Numbers Workshop Manual CorrectionPhil B.No ratings yet

- SB-16-035 DTC From P1681, P1682 To P04D5, P04D6 Workshop Manual CorrectiDocument4 pagesSB-16-035 DTC From P1681, P1682 To P04D5, P04D6 Workshop Manual CorrectiPhil B.No ratings yet

- SB-16-027 J08E Rocker Arm Torque Bolt Change Workshop Manual CorrectionDocument4 pagesSB-16-027 J08E Rocker Arm Torque Bolt Change Workshop Manual CorrectionPhil B.No ratings yet

- SB-16-031 DTC P20DF Workshop Manual CorrectionDocument1 pageSB-16-031 DTC P20DF Workshop Manual CorrectionPhil B.No ratings yet

- SB-16-028 J05C Rocker Arm Torque Bolt Change Workshop Manual CorrectionDocument4 pagesSB-16-028 J05C Rocker Arm Torque Bolt Change Workshop Manual CorrectionPhil B.No ratings yet

- SB-16-034 COE Hydroboost Reservoir Fluid OverflowDocument8 pagesSB-16-034 COE Hydroboost Reservoir Fluid OverflowPhil B.No ratings yet

- SB-16-030 DTC P20DE Workshop Manual CorrectionDocument3 pagesSB-16-030 DTC P20DE Workshop Manual CorrectionPhil B.No ratings yet

- SB-16-029 Fuel Pipe Installation Workshop Manual CorrectionDocument3 pagesSB-16-029 Fuel Pipe Installation Workshop Manual CorrectionPhil B.No ratings yet

- Sb-16-019 15my-17my Conventional DTC p0005 P20de or p20dfDocument2 pagesSb-16-019 15my-17my Conventional DTC p0005 P20de or p20dfPhil B.No ratings yet

- SB-16-025 Clutch Learning Workshop Manual CorrectionDocument4 pagesSB-16-025 Clutch Learning Workshop Manual CorrectionPhil B.No ratings yet

- SB-16-022 11MY-14MY Conventional Burner Atomizer Repair ProcedureDocument15 pagesSB-16-022 11MY-14MY Conventional Burner Atomizer Repair ProcedurePhil B.No ratings yet

- SB-16-021 Connector Electrical Diagram Workshop Manual CorrectionDocument2 pagesSB-16-021 Connector Electrical Diagram Workshop Manual CorrectionPhil B.No ratings yet

- Sb-16-016 13my-17my Coe Dcu Software UpdateDocument3 pagesSb-16-016 13my-17my Coe Dcu Software UpdatePhil B.No ratings yet

- SB-16-012 17MY Conventional P0300 False DetectionDocument2 pagesSB-16-012 17MY Conventional P0300 False DetectionPhil B.No ratings yet

- SB-16-015 11MY-17MY Conventional DCU Software UpdateDocument3 pagesSB-16-015 11MY-17MY Conventional DCU Software UpdatePhil B.No ratings yet

- Sb-16-020 13my-17my Coe DTC p0005 P20de or p20dfDocument2 pagesSb-16-020 13my-17my Coe DTC p0005 P20de or p20dfPhil B.No ratings yet

- SB-16-010 DPR Filter Inspection Workshop Manual CorrectionDocument2 pagesSB-16-010 DPR Filter Inspection Workshop Manual CorrectionPhil B.No ratings yet

- Cisco SIEM Deployment GuideDocument19 pagesCisco SIEM Deployment GuideShruthi Kavya KNo ratings yet

- LG 49UF7700 Chassis LJ53JDocument119 pagesLG 49UF7700 Chassis LJ53Jleonardogustavoc100% (1)

- 661FX-M (1.0)Document60 pages661FX-M (1.0)sarokihNo ratings yet

- Shilpi Agarwal ResumeDocument3 pagesShilpi Agarwal ResumeShilpi AgarwalNo ratings yet

- Sonifier SFX250 and SFX550 Cell Disruptors and HomogenizersDocument6 pagesSonifier SFX250 and SFX550 Cell Disruptors and HomogenizersAlison AlcarazNo ratings yet

- Prueba y Ajuste de Ventilador de 330c-DkyDocument7 pagesPrueba y Ajuste de Ventilador de 330c-DkyBrahian Mijael Garrado GonzalesNo ratings yet

- HP 6220 6050a0066801-Mb-A02 SchematicsDocument68 pagesHP 6220 6050a0066801-Mb-A02 SchematicsGerman ValenciaNo ratings yet

- Onyx820i OM PDFDocument42 pagesOnyx820i OM PDFJohnNo ratings yet

- Audit Under Computerized Information System (CIS)Document61 pagesAudit Under Computerized Information System (CIS)Charla SuanNo ratings yet

- Chapter 6 - Foundations of Business Intelligence Databases and Information Management - Hamid - PUDocument44 pagesChapter 6 - Foundations of Business Intelligence Databases and Information Management - Hamid - PUbareerawaheed888No ratings yet

- Types of ComputerDocument41 pagesTypes of ComputerAngelita CapagalanNo ratings yet

- CAPE Physics Workshop Op Amp Workbook 2021Document45 pagesCAPE Physics Workshop Op Amp Workbook 2021KayenNo ratings yet

- WCF TutorialDocument104 pagesWCF TutorialBozsóki IstvánNo ratings yet

- Electric Forklift Trucks 7FBMF 16,18 7FBMF 20,25 7FBMF 30,35 7FBMF 40,45,50Document23 pagesElectric Forklift Trucks 7FBMF 16,18 7FBMF 20,25 7FBMF 30,35 7FBMF 40,45,50Tieko TuijnmanNo ratings yet

- BTS Installation GuidelineDocument74 pagesBTS Installation Guidelinekhalis@hotmail.comNo ratings yet

- Revolutionize Today'S Workspace: Multifunction, Color, Wireless Laser PrinterDocument8 pagesRevolutionize Today'S Workspace: Multifunction, Color, Wireless Laser PrinterNBS MarketingNo ratings yet

- SMART UNO/Refarm RET Cabling & Naming Convention: (Needs Site Testing and Verification Before Taken in Use!)Document19 pagesSMART UNO/Refarm RET Cabling & Naming Convention: (Needs Site Testing and Verification Before Taken in Use!)ismuwahyudiNo ratings yet

- Light and Lighting - Lighting of Work Places - Part 1: Indoor Work PlacesDocument9 pagesLight and Lighting - Lighting of Work Places - Part 1: Indoor Work Placesrakib.techlinkNo ratings yet

- Department of Technical EducationDocument2 pagesDepartment of Technical Educationraghgk2012No ratings yet

- Esp32-S2 Datasheet enDocument45 pagesEsp32-S2 Datasheet enWesllen Dias SouzaNo ratings yet

- PPMappDocument14 pagesPPMappUmida MukumovaNo ratings yet

- Air Separators - How To Size (B&G)Document2 pagesAir Separators - How To Size (B&G)Ben SyNo ratings yet

- Blockchain IITKDocument40 pagesBlockchain IITKBob BuilderNo ratings yet

- Computer Systems Servicing NC IiDocument26 pagesComputer Systems Servicing NC IiHitomi KanzakiNo ratings yet

- The Impact of Information and Communication Technologies On The Human Development in The Gulf Cooperation Council Countries: An Empirical StudyDocument35 pagesThe Impact of Information and Communication Technologies On The Human Development in The Gulf Cooperation Council Countries: An Empirical StudyGuivis ZeufackNo ratings yet

- Acme Engineering College, Sitapaila, Kathmandu, Nepal: Purbanchal UniversityDocument13 pagesAcme Engineering College, Sitapaila, Kathmandu, Nepal: Purbanchal UniversityAnish TiwariNo ratings yet

- CHPC Transfer Switch Closed Transition: Description FeaturesDocument9 pagesCHPC Transfer Switch Closed Transition: Description FeaturesBNo ratings yet

- 253407Document204 pages253407ajay singhNo ratings yet

- Designing Youtube or NetflixDocument11 pagesDesigning Youtube or NetflixBhargav MohantyNo ratings yet

- Grandstream Networks, Inc.: Analog Telephone Adaptor With FXS/FXO PortDocument20 pagesGrandstream Networks, Inc.: Analog Telephone Adaptor With FXS/FXO PortJulian RamirezNo ratings yet