Professional Documents

Culture Documents

Routine Maintenance Checklist REFRIGERATION PLANT CONDENSING UNIT TYPE

Uploaded by

Abraham Rodriguez0 ratings0% found this document useful (0 votes)

9 views2 pagesThe document is a routine maintenance checklist for a refrigeration plant condensing unit. It lists over 25 check points to inspect things like compressor temperatures and pressures, fan voltages and currents, condenser coil cleaning, and leak checks of piping. Any failures noted would require follow up repairs or maintenance. The checklist aims to ensure proper operation and identify any issues that require attention.

Original Description:

Original Title

Routine-maintenance-checklist-REFRIGERATION-PLANT-CONDENSING-UNIT-TYPE

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document is a routine maintenance checklist for a refrigeration plant condensing unit. It lists over 25 check points to inspect things like compressor temperatures and pressures, fan voltages and currents, condenser coil cleaning, and leak checks of piping. Any failures noted would require follow up repairs or maintenance. The checklist aims to ensure proper operation and identify any issues that require attention.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views2 pagesRoutine Maintenance Checklist REFRIGERATION PLANT CONDENSING UNIT TYPE

Uploaded by

Abraham RodriguezThe document is a routine maintenance checklist for a refrigeration plant condensing unit. It lists over 25 check points to inspect things like compressor temperatures and pressures, fan voltages and currents, condenser coil cleaning, and leak checks of piping. Any failures noted would require follow up repairs or maintenance. The checklist aims to ensure proper operation and identify any issues that require attention.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

QMF-S010

Warrior Business Centre

Fitzherbert Rd

Farlington

Portsmouth

Refrigeration – Air Conditioning – Electrical PO6 1TX

Tel –023 9238 1799

Work Sheet Nº Fax 023

- 9241 7030

Date Email sales@dcirefrigeration.co.uk

PN Number

REFRIGERATION PLANT - CONDENSING UNIT TYPE

Routine Maintenance Check List

PACK / CONDENSER

√ √ √

1. CHECK UNIT DETAILS ON SERIAL PLATE □ OK □ FAIL

2. COMPRESSOR SUCTION AND DISCHARGE TEMPERATURES □ OK □ FAIL

3. COMPRESSOR SUCTION AND DISCHARGE PRESSURE □ OK □ FAIL

4. COMPRESSOR SUPPLY VOLTAGE □ BR (V) □ BL (V) □ GR (V)

5. COMPRESSOR CURRENT □ BR (A) □ BL (A) □ GR (A)

5. COMPRESSOR CURRENT □ BR (A) □ BL (A) □ GR (A)

5. COMPRESSOR CURRENT □ BR (A) □ BL (A) □ GR (A)

5. COMPRESSOR CURRENT □ BR (A) □ BL (A) □ GR (A)

5. COMPRESSOR CURRENT □ BR (A) □ BL (A) □ GR (A)

6. COMPRESSOR ANTI SHORT CYCLE TIMER FUNCTION AND SETTING □ OK □ FAIL □ N/A

6. COMPRESSOR ANTI SHORT CYCLE TIMER FUNCTION AND SETTING □ OK □ FAIL □ N/A

6. COMPRESSOR ANTI SHORT CYCLE TIMER FUNCTION AND SETTING □ OK □ FAIL □ N/A

6. COMPRESSOR ANTI SHORT CYCLE TIMER FUNCTION AND SETTING □ OK □ FAIL □ N/A

6. COMPRESSOR ANTI SHORT CYCLE TIMER FUNCTION AND SETTING □ OK □ FAIL □ N/A

7. COMPRESSOR OIL PRESSURE DIFFERENTIAL READING □ OK □ FAIL □ N/A

7. COMPRESSOR OIL PRESSURE DIFFERENTIAL READING □ OK □ FAIL □ N/A

7. COMPRESSOR OIL PRESSURE DIFFERENTIAL READING □ OK □ FAIL □ N/A

7. COMPRESSOR OIL PRESSURE DIFFERENTIAL READING □ OK □ FAIL □ N/A

7. COMPRESSOR OIL PRESSURE DIFFERENTIAL READING □ OK □ FAIL □ N/A

8. COMPRESSOR OIL LEVEL □ OK □ FAIL □ N/A

8. COMPRESSOR OIL LEVEL □ OK □ FAIL □ N/A

8. COMPRESSOR OIL LEVEL □ OK □ FAIL □ N/A

8. COMPRESSOR OIL LEVEL □ OK □ FAIL □ N/A

8. COMPRESSOR OIL LEVEL □ OK □ FAIL □ N/A

9. FUNCTION AND OPERATION OF OIL DELAY SWITCH □ OK □ FAIL □ N/A

10. CRANKCASE HEATER OPERATION □ OK □ FAIL □ N/A

11. LP SAFETY FUNCTION AND SETTING □ OK □ FAIL □ N/A

12. HP SAFETY FUNCTION AND SETTING □ OK □ FAIL □ N/A

13. LP CONTROL FUNCTION AND SETTING □ OK □ FAIL □ N/A

14. HP FAN CONTROL FUNCTION AND SETTING □ OK □ FAIL □ N/A

15. CAPACITY CONTROL OPERATION □ OK □ FAIL □ N/A

16. OPERATION AND SETTING OF ALL OVERLOAD DEVICES □ OK □ FAIL □ N/A

17. CONDENSER FAN SUPPLY VOLTAGE □ BR (V) □ BL (V) □ GR (V)

18. CONDENSER FAN CURRENT □ BR (A) □ BL (A) □ GR (A)

18. CONDENSER FAN CURRENT □ BR (A) □ BL (A) □ GR (A)

18. CONDENSER FAN CURRENT □ BR (A) □ BL (A) □ GR (A)

18. CONDENSER FAN CURRENT □ BR (A) □ BL (A) □ GR (A)

18. CONDENSER FAN CURRENT □ BR (A) □ BL (A) □ GR (A)

19. SIGHT GLASS MOISTURE INDICATOR VISUAL CHECK □ OK □ FAIL □ N/A

20. CHECK FAN MOTOR AND BLADES ROTATE FREELY □ OK □ FAIL

21. INSPECT AND CLEAN CONDENSER COIL □ OK □ FAIL □ CLEANED

22. CHECK CONDENSER AIR FLOW NO RECIRCULATION □ OK □ FAIL

23. CHECK UNIT FOR EXCESSIVE NOISE AND VIBRATION □ OK □ FAIL

24. LEAK CHECK PACK / CONDENSER / INTERCONECTING PIPEWORK □ OK □ FAIL

25. CHECK OUTDOOR PIPE WORK AND INSULATION WERE ACCESSIBLE □ OK □ FAIL

26. REPLACE LIQUID FILTER □ OK □ FAIL □ N/A

27. REPLACE LIQUID FILTER CORE □ OK □ FAIL □ N/A

28. CHECK SUCTION FELT REPLACE OR REMOVE AS NECESSARY □ OK □ FAIL □ N/A

QMF-S010

29. OIL ACID TEST □ OK □ FAIL

Nº Description of action required to rectify failure

Comments:

Materials Required:

Is equipment left running correctly? □ Yes □ No Is a return visit required? □ Yes □ No

Eng,s Signature Customers Signature

Print Name Print Name

You might also like

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Commercial HVAC Air-Handling EquipmentDocument40 pagesCommercial HVAC Air-Handling EquipmentRenan Gonzalez100% (14)

- AC Motor Inspection/Testing & Commissioning Check ListDocument9 pagesAC Motor Inspection/Testing & Commissioning Check ListAdnan AhmadNo ratings yet

- The Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreFrom EverandThe Technical, Aerodynamic & Performance Aspects of a Helicopter: A Manual for Helicopter Pilots and Engineers Who Want to Know MoreRating: 3 out of 5 stars3/5 (2)

- QRH-C-212-300 Revision 4 Jul 2019 PDFDocument91 pagesQRH-C-212-300 Revision 4 Jul 2019 PDFAndresLopezMllan100% (1)

- Vdoc - Pub Active and Passive Beam Application Design GuideDocument123 pagesVdoc - Pub Active and Passive Beam Application Design GuidetimhatchmechNo ratings yet

- Ashrae - LibraryDocument16 pagesAshrae - LibraryEmeraldi Mufti RabbaniNo ratings yet

- Chapter 10 Refrigeration SystemDocument95 pagesChapter 10 Refrigeration SystemMinh Hiếu CaoNo ratings yet

- DG Commission REPORTDocument8 pagesDG Commission REPORTsidharthNo ratings yet

- AHRI-365 - Unitary Air Conditioning UnitsDocument18 pagesAHRI-365 - Unitary Air Conditioning UnitsfasihkhNo ratings yet

- Final Drawings Yanmar 6EY26WDocument177 pagesFinal Drawings Yanmar 6EY26Wjosch90210100% (2)

- Make Money With Your Captain's License: How to Get a Job or Run a Business on a BoatFrom EverandMake Money With Your Captain's License: How to Get a Job or Run a Business on a BoatNo ratings yet

- Cooling Tower PDFDocument7 pagesCooling Tower PDFShahid HussainNo ratings yet

- Transportation, Rigging, Installation, Operation & Maintenance Manual (Summarized Version)Document28 pagesTransportation, Rigging, Installation, Operation & Maintenance Manual (Summarized Version)Abraham Rodriguez100% (1)

- Design of H Tail UavDocument26 pagesDesign of H Tail Uavrohith-161937100% (1)

- Boiler Cooling MethodDocument7 pagesBoiler Cooling Methodjp mishra100% (1)

- Test ListDocument8 pagesTest ListUmamaheshwarrao VarmaNo ratings yet

- Carlyle IOM 5H-F CompressorDocument40 pagesCarlyle IOM 5H-F CompressorBenito Antonio Formoso LouroNo ratings yet

- Chiller Vs VRF 12345Document26 pagesChiller Vs VRF 12345Aeon Systems100% (1)

- Manual Brosure CSG 120-2Document32 pagesManual Brosure CSG 120-2Louis TambunanNo ratings yet

- Inspection Report - Hired Assets: Annexure 2Document1 pageInspection Report - Hired Assets: Annexure 2ranvijay dubeyNo ratings yet

- Sop of k3 A B Off Gas Compressor Start Up After Maintenance.Document4 pagesSop of k3 A B Off Gas Compressor Start Up After Maintenance.00083583rfNo ratings yet

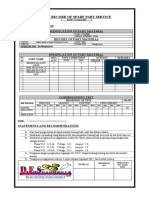

- Test Record of Spare Part Service: Spesification of Part Material History of Part MaterialDocument4 pagesTest Record of Spare Part Service: Spesification of Part Material History of Part MaterialKhalidperkasaNo ratings yet

- Gc2300 SeriesDocument19 pagesGc2300 SeriesRyan DosseyNo ratings yet

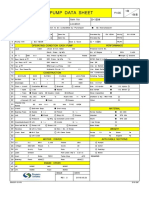

- S-1504 Pump Data Sheet 3 PhaseDocument1 pageS-1504 Pump Data Sheet 3 PhaseHoonNo ratings yet

- F-14B ChecklistDocument13 pagesF-14B Checklistapollocampaign1969No ratings yet

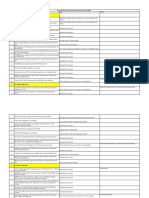

- GIS High-Voltage Test Check List: No Description Contractor Check Result Hyosung VerificationDocument1 pageGIS High-Voltage Test Check List: No Description Contractor Check Result Hyosung Verificationessam khalilNo ratings yet

- 30001-Technical Specification Sheet (Datasheet)Document6 pages30001-Technical Specification Sheet (Datasheet)ali valatabar100% (1)

- 7 Screw CompressorsDocument37 pages7 Screw Compressorsalisamir7305No ratings yet

- Electrical AlarmsDocument6 pagesElectrical AlarmsCiprian MariusNo ratings yet

- 110-KA-701B Maint ReportDocument15 pages110-KA-701B Maint ReportDIPANKAR LALANo ratings yet

- Package SsDocument2 pagesPackage SsNagaraj VjNo ratings yet

- Specification PumpDocument1 pageSpecification PumpshadowNo ratings yet

- Engine Generator Set Inspection ChecklistDocument1 pageEngine Generator Set Inspection ChecklistRicardo DalisayNo ratings yet

- Daily PC1250 FormDocument1 pageDaily PC1250 FormlilikNo ratings yet

- (HSE-ForM-A.05) Form Inspection Rough Terrain CraneDocument6 pages(HSE-ForM-A.05) Form Inspection Rough Terrain CraneIvansyah SastrowardoyoNo ratings yet

- Cleaning Fuel Injector NozzlesDocument6 pagesCleaning Fuel Injector NozzlesRay DutchmanNo ratings yet

- Heavy Equipment ChecklistDocument2 pagesHeavy Equipment ChecklistCharles DoriaNo ratings yet

- Tech 1469 ManDocument25 pagesTech 1469 ManRiski KurniawanNo ratings yet

- S.No. Tag Name Tag Description Type Signal From-ToDocument10 pagesS.No. Tag Name Tag Description Type Signal From-Towqs_19No ratings yet

- Index: "Defr"Document3 pagesIndex: "Defr"Luis Fernando ZampieriNo ratings yet

- 8FG D CE048-03 - 0608 TQ ConverterDocument38 pages8FG D CE048-03 - 0608 TQ ConverterDuong Van Hoan100% (1)

- TFR MtnceDocument18 pagesTFR MtnceRajesh TKNo ratings yet

- HF14Document20 pagesHF14HonoluluNo ratings yet

- Revisedvehicle EquipmentchecklistrequestformDocument2 pagesRevisedvehicle EquipmentchecklistrequestformMiguel Benedict GarciaNo ratings yet

- Veco Engineering Ltd. Equipment Data Sheet: Centrifugal FanDocument9 pagesVeco Engineering Ltd. Equipment Data Sheet: Centrifugal Fanwado11No ratings yet

- Disel Pump Acceptance ReportDocument4 pagesDisel Pump Acceptance ReportNOMAN100% (1)

- Boeing XF8B-1 Pilots ManualDocument112 pagesBoeing XF8B-1 Pilots ManualTateNo ratings yet

- Scania Dc16: Disassembling Check SheetDocument3 pagesScania Dc16: Disassembling Check SheetJaya PranataNo ratings yet

- Data Book P-8A01 FinalDocument129 pagesData Book P-8A01 FinalRUBEN ACOSTANo ratings yet

- Turbine Punch Point Closeout Status-For HURLDocument7 pagesTurbine Punch Point Closeout Status-For HURLpriyajit sahooNo ratings yet

- Bongaigaon Unit-1 Reapir ScheduleDocument1 pageBongaigaon Unit-1 Reapir SchedulePremkishanNo ratings yet

- Conveyor - 7A Motor 1 Fire DIDocument8 pagesConveyor - 7A Motor 1 Fire DIPrem SagarNo ratings yet

- Skill Developement On K3AB Start UpDocument2 pagesSkill Developement On K3AB Start Up00083583rfNo ratings yet

- Check List Technam P2002Document2 pagesCheck List Technam P2002Gourav DasNo ratings yet

- Car Inspection Selling GuideDocument1 pageCar Inspection Selling GuideThomas GallegosNo ratings yet

- BC-P2026-01-012 Agitator Commissioning ProcedureDocument4 pagesBC-P2026-01-012 Agitator Commissioning ProcedureWirken GranatiNo ratings yet

- Phila BackflowDocument1 pagePhila BackflowDon WaiteNo ratings yet

- K018 - OHSE Crane ChecklistDocument1 pageK018 - OHSE Crane ChecklistRajib MondalNo ratings yet

- Damper DS - 1196DPR-430Document2 pagesDamper DS - 1196DPR-430harishcsharmaNo ratings yet

- AES NGOM Inspection ChecklistDocument2 pagesAES NGOM Inspection ChecklistEric WilsonNo ratings yet

- Gas Compressor Unit (7 Compressor) ON-Z-1301 A/B/C/D/E/F/GDocument28 pagesGas Compressor Unit (7 Compressor) ON-Z-1301 A/B/C/D/E/F/GSoumitra GuptaNo ratings yet

- 803 14Document8 pages803 14Cesar AbarcaNo ratings yet

- Additions, Revisions, or Updates: Subject DateDocument5 pagesAdditions, Revisions, or Updates: Subject DateKevinCalderonNo ratings yet

- Sample Report As Motor Repair Report ACME 75HPDocument13 pagesSample Report As Motor Repair Report ACME 75HPAnggoroNo ratings yet

- HT Main Incomer Main GateDocument1 pageHT Main Incomer Main GateManoj SaliNo ratings yet

- 4.2 - 20 FUI EX2378 - 26 - Apr - 20 - PS250Document2 pages4.2 - 20 FUI EX2378 - 26 - Apr - 20 - PS250Dwiyono Wiji astopoNo ratings yet

- Brake Binding PreventionDocument40 pagesBrake Binding Preventionkr_abhijeet72356587100% (9)

- Catalogo Patrol 672GDocument4 pagesCatalogo Patrol 672GJulio cesarNo ratings yet

- Introduction to SEL Relays for New UsersDocument48 pagesIntroduction to SEL Relays for New UsersAbraham RodriguezNo ratings yet

- Analytical Approach To Estimate Feeder AccommodatiDocument16 pagesAnalytical Approach To Estimate Feeder AccommodatiAbraham RodriguezNo ratings yet

- TM 10 104-109 Plath 2Document6 pagesTM 10 104-109 Plath 2Abraham RodriguezNo ratings yet

- BTicino BTI-F4N300Document1 pageBTicino BTI-F4N300Abraham RodriguezNo ratings yet

- TM 10 104-109 PlathDocument8 pagesTM 10 104-109 PlathAbraham RodriguezNo ratings yet

- 240.12 System Coordination or Selectivity: What Is The Importance of This Section?Document2 pages240.12 System Coordination or Selectivity: What Is The Importance of This Section?Abraham RodriguezNo ratings yet

- Apprentice Substation Technician - PAT Prep GuideDocument39 pagesApprentice Substation Technician - PAT Prep GuideAbraham RodriguezNo ratings yet

- Selective Coordination Requirements Inspection FormDocument1 pageSelective Coordination Requirements Inspection FormAbraham RodriguezNo ratings yet

- Electric Service Manual: Section 1 - IntroductionDocument115 pagesElectric Service Manual: Section 1 - IntroductionAbraham RodriguezNo ratings yet

- Arc-Flash Safety Handbook: Remote Racking SolutionsDocument78 pagesArc-Flash Safety Handbook: Remote Racking SolutionsAbraham RodriguezNo ratings yet

- Edison Fuse Links Catalog Ca132008enDocument12 pagesEdison Fuse Links Catalog Ca132008enAbraham RodriguezNo ratings yet

- C210 WML 208Document9 pagesC210 WML 208Efrén SantínNo ratings yet

- Toshiba Rotary Compressor Tech SpecsDocument1 pageToshiba Rotary Compressor Tech Specscalvin.bloodaxe447880% (5)

- Vitocal 300-g Technicalguidefeb2010Document76 pagesVitocal 300-g Technicalguidefeb2010cosmynnsNo ratings yet

- Chapter 5. Ultra Low Temperature Refrigeration SystemsDocument35 pagesChapter 5. Ultra Low Temperature Refrigeration SystemsHosnii QamarNo ratings yet

- IntrCooll - Modbus InterfaceDocument1 pageIntrCooll - Modbus InterfaceAlzubair salahNo ratings yet

- General Brochure - Johnson ControlsDocument4 pagesGeneral Brochure - Johnson Controlst_i_f_anoNo ratings yet

- Dehumidifier FH GHDocument6 pagesDehumidifier FH GHNikosNo ratings yet

- Chapter 3 Vapour Compression Refrigeration Systems L1Document22 pagesChapter 3 Vapour Compression Refrigeration Systems L1Toke BekeleNo ratings yet

- Lecture 3 BSE2201 PsychrometryDocument63 pagesLecture 3 BSE2201 PsychrometryBrian LiNo ratings yet

- Kertas Arahan Makmal: Bbm40501 Amali KejuruteraanDocument6 pagesKertas Arahan Makmal: Bbm40501 Amali KejuruteraanschaNo ratings yet

- BSP Catalogue Full enDocument78 pagesBSP Catalogue Full encriveranNo ratings yet

- Abbattitore Di Temperatura Mod. BE-R101 - UKDocument3 pagesAbbattitore Di Temperatura Mod. BE-R101 - UKConrado TangariNo ratings yet

- ERU280HSP (LBP) - DatasheetDocument4 pagesERU280HSP (LBP) - Datasheet31806133No ratings yet

- Abts Basement-FIRE FIGHTINGDocument1 pageAbts Basement-FIRE FIGHTINGSiddhie DeshpandeNo ratings yet

- KoppelDocument2 pagesKoppelLeomark RespondeNo ratings yet

- Multi-Split Type Air ConditionersDocument21 pagesMulti-Split Type Air ConditionersLAB DONKASNo ratings yet

- Expansion Tank - Cooling Systems - CM20160713-53120-13199-024-028Document5 pagesExpansion Tank - Cooling Systems - CM20160713-53120-13199-024-028AVINASH ANAND RAONo ratings yet

- LG Multi V - VRF Catalogue 2016Document119 pagesLG Multi V - VRF Catalogue 2016Hung Tran50% (2)

- Larkin's Thermosyphon Solar Air HeaterDocument3 pagesLarkin's Thermosyphon Solar Air HeaterAbhishek MishraNo ratings yet

- dgr10 2020 07 18Document16 pagesdgr10 2020 07 18Data CentrumNo ratings yet

- Operation Manual WBL-100/101/200: 3, Hagavish St. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529Document5 pagesOperation Manual WBL-100/101/200: 3, Hagavish St. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529Celeynes RTNo ratings yet