Professional Documents

Culture Documents

Saudi Aramco centrifugal pump data sheet

Uploaded by

Anshu K MuhammedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco centrifugal pump data sheet

Uploaded by

Anshu K MuhammedCopyright:

Available Formats

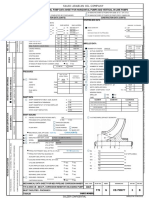

Saudi Aramco 2741-ENG (09/2015)

SAUDI ARABIAN OIL COMPANY

THIS REVISION IS NOT TO BE USED FOR

CONSTRUCTION UNTIL CERTIFIED AND

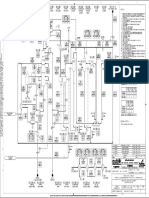

CENTRIFUGAL PUMP DATA SHEET FOR HORIZONTAL PUMPS AND VERTICAL IN-LINE PUMPS

NOTE: BY MANUFACTURER OF PUMPS PER ASME B 73.1 OR B 73.2

INDICATES INFORMATION TO BE COMPLETED BY PURCHASER; BY MANUFACTURER OF PUMPS OR PUMPS PER 31-SAMSS-004

DATED

PURCHASERS REFERENCES SITE CONDITIONS

APPLICABLE TO: PROPOSALS PURCHASE AS BUILT INDOOR OUTDOOR (Note M8) UNDER ROOF

REVISION DESCRIPTION

ON SHORE COASTAL OFF SHORE

/ PUMP MFR SULZER SAUDI PUMP COMPANY LIMITED ELECTRICAL AREA CLASS 1 , DIV. 2 , GROUP IIA/IIB, T3

/ SIZE & TYPE SPCP 3x2x13

/ SERIAL NO. S8212448, S8212449, S8212450, S8212451, S8212452, S8212453 PERFORMANCE DATA

DRIVER TYPE ELECTRIC MOTOR PERFORMANCE

THIS DATA SHEET COVER 6 (Note P6) PUMP(S)

PUMP MARK NO(S). T70 -G- 0113 A - T70 -G- 0113 B / / RATED SPEED RPM 1765

BI-10-09003

DATE

T70 -G- 0213 A - T70 -G- 0213 B / / DRIVER NAME PLATE POWER RATING HP 20

T70 -G- 0313 A - T70 -G- 0313 B

JOB ORDER/EWO NO.

/ PUMPS OF IDENTICAL TYPE & SIZE IN OPERATION RPM 1765

-G- - -G- / / PERFORMANCE AT 100% 120%

REV. NO.

MIN. CONT.STABLE NORMAL

-G- - -G- FLOW FLOW OF RATED

CAPACITY

DRIVER DATA SHEET REFER TO SHEETS 9 & 10

GEAR UNIT DATA SHEET TOTAL DIFF. HEAD Ft 148.9 134.3 134.3 126.7

LUBE OIL SYST DATA SHEET EFFICIENCY % 26.38 56.05 56.05 57.23

SAFETY INSTRUCTION SHEET REQUIRED POWER HP 9.59 13.15 13.15 14.59

BY/DATE

OTHER

LCC EF $/kW NPSH REQ'D FOR:

3% DH 1st STAGE ON H2O Ft 2.5 4.55 4.55 5.9

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

40,000 HRS LIQ'D PUMPED Ft NA NA NA NA

SERVICE

/ SHUT-OFF HEAD AT ACTUAL IMP. DIAM. Ft 150.2

OPERATIONS/DATE

PUMP FUNCTION SOUR WATER TRANSFER TO FEED TANK AT MAX. IMP. DIAM. Ft 167.5

CONTINUOUS INTERMITTENT STANDY BY CAPACITY AT END OF CURVE USGPM 346.2

ATTENDED UNATTENDED CAPACITY AT BEST EFFICIENCY POINT USGPM 266.1

INDIVIDUALLY IN SERIES IN PARALLEL TOT.DIFF. HEAD AT END OF CURVE Ft 109.2

REVIEW FOR KEY DRAWINGS

REQUIRED (SAUDI ARAMCO)

UPSTREAM OF PUMP NO(S) -G- RATIO. SHUT-OFF HEAD/RATED HEAD 1.11839166

-G- RATIO. END OF CURVE CAPACITY/RATED CAP. 1.560162235

DOWNSTREAM OF PUMP NO(S) -G- MINIMUM CONTINUOUS STABLE FLOW USGPM 68.68

CONST. AGENCY/ DATE

-G- MINIMUM CONTINUOUS THERMAL FLOW USGPM NA

MAXIMUM OPERATING TIME AT SHUT-OFF SEC 30

FIRST CRIT. SPEED; DRY RPM 15764

LIQUID CHARACTERISTICS FIRST CRIT. SPEED; WET RPM NA

MAX. ALLOWABLE SPEED RPM 3600

LIQUID PUMPED SOUR WATER (Note P8,P9) TDS NONE PPM MAX. POWER FULL CURVE ACTUAL IMP. DIAM. HP 17.66 (AT MAX SG)

O

NORMAL FLOW TEMPERATURE F 144 (Note P2) POWER AT SHUT-OFF HEAD HP 8.38

O

MAX. FLOW TEMPERATURE F 158 (Note P2) PERFORMANCE WITH MAX. AND

RELATIVE DENSITY AT NORMAL FLOW TEMP. 0.98 MIN. IMPELLER DIAMETERS

CERTIFIED/DATE

VISCOSITY AT FLOW TEMP. CS / CP / SSU 0.448 MAX. MIN.

VAPOR PRESSURE AT NORMAL TOT.DIFF. HEAD AT RATED CAPACITY Ft 151.7 100.2

DESIGN CERTIFICATION

FLOW TEMP. PSIA 8.38 (Note P9) EFFICIENCY AT RATED CAPACITY % 56.55 54

(DESIGN AGENCY)

V.P. AT MAX. FLOW TEMP. PSIA 8.38 (Note P9) REQUIRED POWER AT RATED CAP. HP 14.73 10.19

TSS NONE 300 (Note M10) PPM UNKNOWN MAX. REQUIRED POWER FULL CURVE HP 20.24 12.74

CHARACTER OF PULPY GRITTY HARD SOFT

SOLIDS: INTERMEDIATE TRANSMISSION

ENGG./DATE

GAS IN FLUID: NONE VOL. % (Note P9) UNKNOWN / GEAR BOX RATIO NA

PRINCIPAL CORROSIVES: H2S, CO2, MEG (Note P8) / HYDR. COUPL. SPEED RANGE NA % NA % OF DRIVER SPEED

pH N/A CI NONE PPM

CONSTRUCTION DATA

PUMP TYPE

OPERATING CONDITIONS HORIZONTAL (BET. BRGS) / OVERHUNG

/ VERT. IN-LINE INTEGRAL SHAFT

CAPACITY NORMAL USGPM 221.9 CASING MOUNT: CENTERLINE FLANGE CENTERLINE

IS COVERED, FOR ALL APPROVAL

RATED USGPM 221.9 FOOT

RATED TOTAL DIFFERENTIAL HEAD Ft 134.3 VERT. IN-LINE IN-LINE CASE SUPPORTED

AND CERTIFICATION REQUIREMENTS, PER SAEP-334, UNDER

NPSH AVAILABLE AT SUCTION FLG. CASING SPLIT AXIAL RADIAL

AT RATED CAPACITY Ft 26 CASING TYPE DOUBLE VOLUTE SINGLE VOLUTE

REVISION VALIDATION

AT 120% OF RATED CAPACITY Ft 26 DIFFUSOR STAGGER

VISC. CORR. FACTOR CQ; CH; CE 1 1 1 SELF PRIMING / YES / NO

DRAWING COMPLETION CERTIFICATE NO.

RATED SUCTION PRESSURE PSIA 19.7 DIR. OF ROT. / / CCW / / CW

MAX. SUCT. PR. AT RATED CAP. PSIA 22.42 (VIEWED FROM DRIVER)

MAX. SUCT. PR. AT SHUT-OFF PSIA 72.5 PUMP NOZZLES

TOTAL DIFFERENTIAL PRESSURE PSI 57 SIZE RATING FACING LOCATION

RATED DISCHARGE PRESSURE PSIA 76.7 / SUCTION 3" 150# RF SIDE

THIS REVISION NO.

MAX. DISCH. PR. AT RATED CAP. PSIA 79.42 / DISCHARGE 2" 150# RF TOP

HYDRAULIC POWER HP 7.7

MECHANICAL DATA SHEET FOR DEGASSED SOUR WATER PUMPS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

T70-G-0113/0213/0313 A/B - DEGASSED SOUR WATER PUMPS DAT

INLET FACILITIES - PACKAGE 9 T70 G CE-795879 1 B

TANAJIB SAUDI ARABIA

EKRD/2741-1-0915.XLS

SULZER CONFIDENTIAL

#

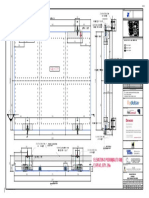

Saudi Aramco 2741-ENG (09/2015)

SAUDI ARABIAN OIL COMPANY

UNTIL CERTIFIED AND DATED

THIS REVISION IS NOT TO BE

USED FOR CONSTRUCTION

CENTRIFUGAL PUMP DATA SHEET FOR HORIZONTAL PUMPS AND VERTICAL IN-LINE PUMPS

REVISION DESCRIPTION

NOTE: BY MANUFACTURER OF PUMPS PER ASME B 73.1 OR B 73.2

INDICATES INFORMATION TO BE COMPLETED BY PURCHASER; BY MANUFACTURER OF PUMPS OR PUMPS PER 31-SAMSS-004

CONSTRUCTION DATA (CONT'D) CONSTRUCTION DATA (CONT'D)

FORCES AND MOMENTS STUFFING BOX DATA

/ ALLOWABLE FORCES AND MOMENTS

TOP NOZZLE SIDE NOZZLE END NOZZLE EACH NOZZLE INBOARD / OUTBOARD

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

Fx 1400 LB Fx 1920 LB Fx LB Mx 1200/1300 LB.FT INSIDE DIAMETER IN 2.8

Fy 1350 LB Fy 1230 LB Fy LB My 1270/350 LB.FT DEPTH IN 1.89

Fz 3250 LB Fz 1230 LB Fz LB Mz 690/350 LB.FT DISTANCE FACE OF STUFFING BOX

DATE

BI-10-09003

MISC CONNECTIONS QTY. SIZE TYPE FLANGE TO NEAREST OBSTRUCTION IN 2.95

JOB ORDER/EWO NO.

LUBE OIL INLET NA NA NA

LUBE OIL OUTLET NA NA NA

SEAL LIQUID INLET 1 1/2" 150# RF IMPELLER DATA

REV. NO.

SEAL LIQUID DRAIN 1 1/2" 150# RF FIRST FOLLOW

CASING DRAIN(S) 1 1/2" 150# RF NUMBER OF STAGES SINGLE STAGE STAGE

VENTS SELF - - / ACTUAL DIAMETER IN 11.46

COOLING WATER NA NA NA / MAXIMUM DIAMETER IN 12

STUFFING BOX NA NA NA / MINIMUM DIAMETER IN 10

BY/DATE

OTHER

BALANCE DRUM NA NA NA SINGLE / DOUBLE SUCTION SINGLE

DRAIN & VENT INDIVIDUALLY PIPED WITH BLOCK VALVES TO TERMINATE / EYE AREA IMPELLER SQ.IN 9.1

O

AT EDGE OF BASE PLATE IN COMMON AREA YES NO VANE ANGLE AT IMP. EXIT -

FLANGE RATING 2" in CLASS NPTF / NUMBER OF VANES 5

ACTUAL PERIPHERAL SPEED FT/S 88.32707

OPERATIONS/DATE

PRESSURES MAX.ALLOW.PERIPH.SP'D AT FLOW TEMP. FT/S 92.48908

MAX. ALLOW. / PATTERN NUMBER -

WORK. PRESS. HYDROST.

/ PRECISION CAST YES - NO NO

REVIEW FOR KEY DRAWINGS

REQUIRED (SAUDI ARAMCO)

TEST PRESS

O

/ PRESSURES AT Amb F / CUT WATER DIAMETER IN 13.7

CASE PSIG 232 348 SPECIFIC SPEED 715

JACKETS PSIG / SUCTION SPECIFIC SPEED AT 3% DH 7514

COILS PSIG WIDTH. IMPELLER DISCH. IN 0.5

CONST. AGENCY/DATE

DUAL MECH. UNDER / OVER FILING / V-CUT YES / NO NO

SEAL PSIG WEARING RINGS:

IMPELLER YES NO

SHAFT DATA CASE YES NO

SHAFT DIAMETER AT MECH. SEAL SLEEVE IN 1.75 ELEMENT DIAMETER CLEARANCE

SHAFT DIAMETER AT BEARINGS IN 2.36 FRONT IMPELLER WEAR RING NA

SHAFT DIAMETER AT 1ST STAGE IMPELLER IN 1 BACK IMPELLER WEAR RING NA

BEARING SPAN IN 6.62 CENTER BUSHING

CERTIFIED/DATE

STATIC SHAFT DEFLECTION IN 0.002 THROTTLE/BALANCE DRUM

DESIGN CERTIFICATION

SHAFT SEALING (Note M17)

(DESIGN AGENCY)

PACKED STUFFING BOX PACKING MAT'L. NA 1st STAGE IMPELLER INLET GEOMETRY

PROVIDED WITH LANTERN RING: YES NO

SEALING ARRANGEMENT THROUGH SEALING

DEAD ENDED

ENGG./DATE

FLUSH WITH LIQUID PUMPED GREASE

FOREIGN LIQUID BLEED OFF

MECHANICAL SEAL API CODE - (Note M4) C1A1A

ap

/ MAKE JOHN CRANE

/ MANUFACTURER MAT'L CODE X48 P147 1 X48 D86 H DPLX/HC ah

/ MODEL 5610Q SINGLE CARTRIDGE

/ API CODE MAT'L 3RD LETTER BSTIX(X - C vs S-SiC)

IS COVERED, FOR ALL APPROVAL AND

4TH LETTER

CERTIFICATION REQUIREMENTS, PER SAEP-334, UNDER DRAWING

Dh1

Dh2

Dsl

Dp

5TH LETTER

d

PIPING FOR PRIMARY SEAL API FIG. D-2 PLAN 32 / 61 (Note M4) Dp = NA IN

PIPING FOR THROTTLE BUSHING OR Dsl = NA IN (IF APPLICABLE)

AUXILIARY SEAL API FIG. D-3 PLAN Dh1 = NA IN

REVISION VALIDATION

COOLING WATER PIPING, API FIG. D-4 PLAN Dh2 = NA IN

CYCLONE SEPARATOR YES NO d = NA IN

FLOW ORIFICE IN SEAL FLUSH SUPPLY LINE YES NO ap = NA DEGREES

SEAL LEAKAGE PIPING WITH ORIFICE YES NO ah = NA DEGREES

COMPLETION CERTIFICATE NO.

BUFFER LIQUID SYSTEM YES NO

METHANOL DRIP SYSTEM YES NO

/ REQUIRED: PRESSURE PSIG; FLOW USGPM

THIS REVISION NO.

CARTRIDGE DESIGN YES NO

MECHANICAL DATA SHEET FOR DEGASSED SOUR WATER PUMPS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT.NO REV.NO.

T70-G-0113/0213/0313 A/B - DEGASSED SOUR WATER PUMPS DAT

INLET FACILITIES - PACKAGE 9 T70 G CE-795879 2 B

TANAJIB SAUDI ARABIA

# SULZER CONFIDENTIAL EKRD/2741-2-0915.XLS

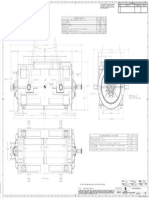

SAUDI ARABIAN OIL COMPANY

THIS REVISION IS NOT TO BE USED FOR

CONSTRUCTION UNTIL CERTIFIED AND

CENTRIFUGAL PUMP DATA SHEET FOR HORIZONTAL PUMPS AND VERTICAL IN-LINE PUMPS

NOTE: BY MANUFACTURER OF PUMPS PER ASME B 73.1 OR B 73.2

INDICATES INFORMATION TO BE COMPLETED BY PURCHASER; BY MANUFACTURER OF PUMPS OR PUMPS PER 31-SAMSS-004

CONSTRUCTION DATA (CONT'D) CONSTRUCTION DATA (CONT'D)

DATED

BEARINGS AND LUBRICATION COUPLING

BEARING TYPE RADIAL THRUST / MAKE JOHN CRANE MODEL TDKS SIZE 95.3 MM

SLEEVE SUPPLIED BY: SULZER SAUDI PUMP COMPANY LIMITED

ANTI-FRICTION TYPE

REVISION DESCRIPTION

TILTING PAD DIAPHRAGM OR DISC PACK

LUBRICATION METHOD RADIAL THRUST RIGID ADJUSTABLE

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

GREASE CLOSE COUPLED

RING-OIL CONSTANT LEVEL ELASTOMERIC

/ LUBRICATOR, MAKE TRICO HYDRAULIC FIT KEYED

OIL BATH WITH EXT'L CIRCULATION SPACER: YES, 3.75 IN NO

FORCED FEED COUPLING GUARD PARTIALLY ENCLOSED COMPLETELY ENCLOSED

BI-10-09003

OIL MIST PUMP SHAFT END CYLINDRICAL TAPERED

DATE

LUBE OIL PIPING TO AND MOUNT COUPLING HALF: PUMP YES NO

JOB ORDER/EWO NO.

FROM BEARINGS YES NO DRIVER HALF YES NO. IF SHIPPED TO DRIVER SUPPLIER

LUBE OIL PIPING UP TO L.O. SYSTEM YES NO PILOT BORED COMPLETELY MACHINED

REV. NO.

TERMINATION WITH FLANGED

CONNECTIONS AT RADIAL COUPLING BASE PLATE

PLANE YES NO

SIGHT FLOW INDICATOR IN EACH BASE PLATE OIL FIELD SKID

BY/DATE

OTHER

RETURN BRANCH MAKE MODEL SUPPLIED BY SULZER SAUDI PUMP COMPANY LIMITED

THRUST BEARING LOADS: TO ACCOMMODATE: DRIVER GEAR PUMP

MAX. ALLOWABLE AXIAL FORCE: N L.O. AND/OR S.O. SYSTEM MOUNTED ON BASE OFF BASE

DESIGN AXIAL FORCE: N DESIGNED FOR INSTALLATION ON:

CONCRETE FOUNDATION STEEL PLATFORM

OPERATIONS/DATE

LUBRICANTS DRILLED FOR DRIVER YES NO GEAR YES NO

BEARING LUBRICANT ISO GRADE 46 (Note M11) HORIZONTAL ALIGNMENT JACKSCREWS YES NO

OIL PER 26-SAMSS-088 GREASE PER 26-SAMSS-054

REVIEW FOR KEY DRAWINGS

REQUIRED (SAUDI ARAMCO)

FLOW OR SUPPLY HEAT MAX. OIL MATERIALS OF CONSTRUCTION

CAPACITY PRESSURE REMOVAL OUTL. TP. MATERIALS TO BE IN ACC. WITH CODE HD 1 (Note M16)

O

GPM/USGAL PSIG BTU/MIN F OF STD. DRAWING AD-036821

CONST. AGENCY/DATE

INB. BRG. NA NA NA NA VENDOR TO COMPLETE FOLLOWING MAT'L LISTING

OUTB. BRG. NA NA NA NA / 1 CASING ASTM A995 Gr.1B

THRUST BRG. NA NA NA NA 2 IMPELLER(S) ASTM A890 Gr.1B

NA NA NA NA 3 CASE WEAR RINGS ASTM N/A

NA NA NA NA 4 IMPELLER WEAR RINGS ASTM N/A

TOTAL 5 SHAFT ASTM A276 Type S31803

LUBE OIL SYSTEM SUPPLIED BY: PUMP VENDOR 6 SHAFT SLEEVES ASTM NA

OTHER 7 THROAT BUSHINGS ASTM A276 Type S31803

CERTIFIED/DATE

IN ACCORDANCE WITH DATA SHEET FORM 8004-ENG 8 INTERSTAGE SLEEVES ASTM NA

YES, DRAWING NO. NO 9 INTERSTAGE BUSHINGS ASTM NA

DESIGN CERTIFICATION

10 LANTERN RING (PACKED PUMPS) ASTM NA

(DESIGN AGENCY)

11 GLAND / MECH. SEAL FLANGE ASTM

COOLING 12 BEARING BRACKETS ASTM A216 Gr. WCB

BEARING COOLING 13 1 NON-WETTED STUDS / NUTS ASTM A193 B7 / A194 2H

NON-CIRCULATING SYSTEM BY: 2 WETTED FASTENERS ASTM

ENGG./DATE

SHAFT MOUNTED FAN JACKETED BEARING HOUSING 14 PIPING: PIPE / FITTINGS ASTM A790 S31803 / A182 F51

COILS IN BEARING HOUSING 15 BASE PLATE ASTM A 36

16 MECH. SEAL SPRINGS ASTM In Seal Dwg

EXTERNAL CIRCULATING SYSTEM 17 MECH. SEAL OTHER METAL PARTS ASTM In Seal Dwg

OIL COOLING BY: 18 ASTM

LIQ. PUMPED FOREIGN LIQ. AIR NONE 19 ASTM

STUFFING BOX COOLING YES NO

PEDESTAL COOLING YES NO NOISE SPECIFICATION

COOLING PIPING FOR REFER SHEET 11

IS COVERED, FOR ALL APPROVAL

AND CERTIFICATION REQUIREMENTS, PER SAEP-334, UNDER

BEARINGS STUF. BOX PEDESTALS SEAL COOLER

IN ACCORDANCE WITH API-610. FIG. D-4. PLAN MAXIMUM ALLOWABLE SOUND LEVEL

BY PURCHASER AT 3 FT. DISTANCE < 85 dBA

REVISION VALIDATION

COOLANT DATA MANUFACTURER GUARANTEED

BRG STUF PEDES- SEAL PUMP dBA

DRAWING COMPLETION CERTIFICATE NO.

HSG BOX TAL COOLER DRIVER dBA

TOTAL FLOW USGPM NA NA NA NA OTHER dBA

INLET PRESS. PSIG NA NA NA NA COMPLETE TRAIN dBA

O

TEMP. INLET F NA NA NA NA

O

TEMP. OUTLET F NA NA NA NA

THIS REVISION NO.

COOLING MEDUIM NA NA NA NA

MECHANICAL DATA SHEET FOR DEGASSED SOUR WATER PUMPS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO

T70-G-0113/0213/0313 A/B - DEGASSED SOUR WATER PUMPS

DAT

INLET FACILITIES - PACKAGE 9 T70 G CE-795879 3 B

TANAJIB SAUDI ARABIA

EKRD/2741-3-0915.XLS

SULZER CONFIDENTIAL

#

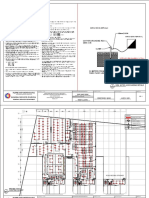

Saudi Aramco 2741-ENG (09/2015)

THIS REVISION IS NOT TO BE USED

SAUDI ARABIAN OIL COMPANY

FOR CONSTRUCTION UNTIL

CERTIFIED AND DATED

CENTRIFUGAL PUMP DATA SHEET FOR HORIZONTAL PUMPS AND VERTICAL IN-LINE PUMPS

NOTE: BY MANUFACTURER OF PUMPS PER ASME B 73.1 OR B 73.2

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

REVISION DESCRIPTION

INDICATES INFORMATION TO BE COMPLETED BY PURCHASER; BY MANUFACTURER OF PUMPS OR PUMPS PER 31-SAMSS-004

UTILITIES (Note M6) INSPECTION AND TESTS (Note M5)

OBSER'D

CERT'D

WITN'D

NONE

ELECTRIC POWER AVAILABLE VENDOR'S STANDARD SHOP TEST

AC PHASE AS FOLLOWS

VOLTS

DC HZ HYDROSTATIC TEST

MAIN ELECTRIC DRIVER AC 460 3 / 60 WATER KEROSENE

CONTROLS AND PROTECTION RUNNING TEST

PERFORMANCE TEST

BI-10-09003

DATE

AIR AVAILABLE MEASURE DP ACROSS STUFFING BOX

JOB ORDER/EWO NO.

PSIG NPSH TEST (Note M19)

CONTROLS AND PROTECTION DISMANTLING (Note M20)

RADIOGRAPHIC INSPECTION IMPELLER

REV. NO.

DYE PENETRANT EXAMINATION IMPELLER

AVAIL INLET OUTLET REQ'D DYNAMIC BALANCE IMPELLER(S)

PSIG O O O

AVAIL COOLING F F F DYNAMIC BALANCE ROTOR

WATER 80 102 130 DYNAMIC BALANCE COUPLING

BY/DATE

OTHER

VIBRATION, MEASUREMENTS

WELL WATER TREATED WATER SEA WATER TESTS TO BE CARRIED WITH:

ONCE THROUGH SYSTEM CLOSED LOOP SYSTEM ACTUAL DRIVER MANUFACTURER'S DRIVER (Note 21)

AT RATED SPEED DERATED SPEED: RPM

OPERATIONS/DATE

INSTRUMENTATION & CONTROLS

DRAWINGS AND OTHER DATA (Note M12)

REVIEW FOR KEY DRAWINGS

REQUIRED (SAUDI ARAMCO)

TEMPERATURE RADIAL THRUST CASING

MONITORING BEARINGS BEARINGS THERMOWELL MANUFACTURER'S DRAWING OR DOCUMENT

YES REQUIRED

PROVISIONS ONLY YES NO

DIMENSIONAL DRAWING OF

CONST. AGENCY/DATE

O

ALARM SETTING F COMPLETELY ASSEMBLED UNIT

O

SHUTDOWN SETTING F OPER. & MAINT. INSTRUCTIONS

CROSS SECT. DRW. WITH PART NO'S.

VIBRATION / DISPLACEMENT MONITORING MECHANICAL SEAL DRAWING

BILLS OF MATERIALS

POSITION RADIAL BRG'S THRUST BRG. BRG. HSG COMPLETED PUMP DATA SHEET

TYPE PROXIMITY PROXIMITY SEISMIC AUXILIARY PIPING DWG.

CERTIFIED TEST CURVE & DATA

YES RECOMMENDED SPARES LIST

PROVISIONS ONLY INSTR. WIRING DIAGRAM

CERTIFIED/DATE

SPEED TORQUE CURVE

ALARM / SHUTDOWN COLD ALIGNMENT CURVE

DESIGN CERTIFICATION

SETTING: MILS P-P / DATA L. & T. VIBR. ANALYSIS

(DESIGN AGENCY)

MILS P-P /

IN / SEC RMS /

SEISMIC PNEUMATIC MISCELLANEOUS

ELECTRICAL

PROXIMITY PAINTING

ENGG./DATE

SHAFT SEAL LEAKAGE CONTROL: YES NO

ELECTRICAL PNEUMATIC BUYER'S PAINT SPECIFICATION: SAES-H-001 / SAES-H-101V

/ PRES. SWITCH MAKE MODEL VENDOR'S STANDARD:

/ PRESSURE SETTING *SHUTDOWN* PSIG

LEVEL SWITCH MAKE MODEL

/ TIME DELAY SETTING CONTR.ORIFICE IN SPECIFICATION

AND CERTIFICATION REQUIREMENTS, PER SAEP-334, UNDER

IS COVERED, FOR ALL APPROVAL

MASSES PUMPS TO BE IN ACCORDANCE WITH:

31-SAMSS-004

/ PUMP LBS 380 ASME B 73.1 ASME B 73.2

REVISION VALIDATION

DRAWING COMPLETION CERTIFICATE NO.

PUMP ROTATING ASSEMBLY LBS INCLUDED OR ISO 2858 & ISO 5199

CASING (UPPER HALF) LBS INCLUDED

BASEPLATE LBS 1000

COUPLING LBS INCLUDED

DRIVER LBS 320

DRIVER ROTATING ASSEMBLY LBS INCLUDED

TOTAL MASS LBS 1700

THIS REVISION NO.

MECHANICAL DATA SHEET FOR DEGASSED SOUR WATER PUMPS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT.NO. REV.NO.

T70-G-0113/0213/0313 A/B - DEGASSED SOUR WATER PUMPS DAT

INLET FACILITIES - PACKAGE 9 T70 G CE-795879 4 B

TANAJIB SAUDI ARABIA

# SULZER CONFIDENTIAL EKRD/2741-4-0915.XLS

Saudi Aramco 2616-ENG (11/2010)

SAUDI ARABIAN OIL COMPANY

UNTIL CERTIFIED AND DATED

THIS REVISION IS NOT TO BE

USED FOR CONSTRUCTION

NOTES: (P-NOTES: BY PROCESS ; M-NOTES: BY MECHANICAL)

P1. CENTRIFUGAL PUMP SHUT-OFF HEAD SHALL NOT EXCEED 125% OF SPECIFIED DIFFERENTIAL HEAD INCLUSIVE OF ALL TOLERANCES.

REVISION DESCRIPTION

P2. PUMPING SYSTEM DESIGN TEMPERATURE: 210 °F

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

P3. REPORTED NPSHA APPLIES AT PUMP CENTERLINE (ASSUMED AS 3Ft FROM GRADE) AND SUCTION VESSEL BTL ASSUMED

AT AN ELEVATION OF 14.5 FT. NPSHA DOES NOT INCLUDE ANY MARGIN.

P4. VENDOR TO ENSURE NPSHA AT RATED FLOW EXCEEDS NPSH3 BY 3.28 FEET. NO MARGIN IS REQUIRED WHEN CONSIDERING

NPSH3 AT 120% OF RATED CAPACITY. NPSHA AT 120% RATED CAPACITY BASED ON SUCTION VESSEL LLL AT AN ELEVATION OF 14.5

FT.

DATE

BI-10-09003

P5. DELETED.

JOB ORDER/EWO NO.

P6. THIS PUMP DATASHEET COVERS TRAINS 1, TRAIN 2 AND TRAIN 3. PUMP T70-G-0113 A/B ( 2X 100%) FOR TRAIN 1, T70-G-0213 A/B

(2 X 100%) AND T70-G-0313 A/B FOR TRAIN 3. ONE PUMP IN SERVICE AND ONE PUMP STANDBY IN EACH TRAIN.

REV. NO.

P7 DELETED

P8 SOUR WATER CONTAIN THE FOLLOWING COMPONENTS (MASS FLOW AND MOLE % OBTAINED FROM SW H&MB, REV D):

H2S = 40 PPM

BY/DATE

OTHER

CO2 = 278 PPM

MEG = 460 PPM

MAX H2S=50PPMW. PUMP IS IN WET H2S SERVICE.

P9. SOUR WATER CONTAINS DISSOLVED GASES. VAPOR PRESSURE ESTIMATED BY MAX 3% VOLUME FLASH OF PUMP LIQUID, AT

OPERATIONS/DATE

OPERATING CONDITION IN TANK.

P10. APPLICABLE PFD & P&ID DOCUMENT NUMBERS ARE T70-A-PFD-CA-789868-001 & T70-A-PID-CA-789955-003 RESPECTIVELY.

REVIEW FOR KEY DRAWINGS

REQUIRED (SAUDI ARAMCO)

P11 MAXIMUM SUCTION PRESSURE AT SHUT-OFF IS ESTIMATED AT MAXIMUM RELATIVE DENSITY OF 0.98.

P12 PLANT TURNDOWN IS 40%.

CONST. AGENCY/DATE

P13. PUMP RATED CAPACITY IS BASED ON WINTER 2025 HMB CASE - TGTU SWS SERVICE. (T80-A-DOC-CD-789835_Rev00A CASE 2026 SUMMER)

P14. LOWEST NORMAL FLOW = 107.9 USGPM ACCORDING TO MATERIAL BALANCE

P15. PUMP TO BE CONSIDERED AS FRICTION DOMINATED.

CERTIFIED/DATE

P16. THE PUMP SYSTEM DESIGN PRESSURE IS 130 PSIG AT 210 ºF.

DESIGN CERTIFICATION

P17. MDMT = 32 ºF

(DESIGN AGENCY)

ENGG./DATE

IS COVERED, FOR ALL APPROVAL

AND CERTIFICATION REQUIREMENTS, PER SAEP-334, UNDER

REVISION VALIDATION

DRAWING COMPLETION CERTIFICATE NO.

THIS REVISION NO.

MECHANICAL DATA SHEET FOR DEGASSED SOUR WATER PUMPS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT.NO REV.NO.

T70-G-0113/0213/0313 A/B - DEGASSED SOUR WATER PUMPS DAT

INLET FACILITIES - PACKAGE 9 T70 G CE-795879 5 B

TANAJIB SAUDI ARABIA

EKRD/2616-1110.XLS

# SULZER CONFIDENTIAL

Saudi Aramco 2616-ENG (11/2010)

SAUDI ARABIAN OIL COMPANY

UNTIL CERTIFIED AND DATED

THIS REVISION IS NOT TO BE

USED FOR CONSTRUCTION

NOTES: (P-NOTES: BY PROCESS ; M-NOTES: BY MECHANICAL)

REVISION DESCRIPTION

THIS DRAWING AND THE INFORMATION CONTAINED HEREIN ARE THE SOLE PROPERTY OF SAUDI ARAMCO. NO REPRODUCTION IN FULL OR IN PART SHALL BE OBTAINED FROM THIS DOCUMENT WITHOUT THE WRITTEN CONSENT OF ITS OWNER.

M1. MAXIMUM ALLOWABLE SOUND LEVEL FOR PUMP / MOTOR SET SHALL NOT EXCEED 85 dB(A) AT A DISTANCE OF 3.28 Ft.

M2. DELETED

M3. IN HAZARDOUS, FLAMABLE OR TOXIC SERVICE, MECHANICAL SEALS SHALL BE IN ACCORDANCE WITH 31-SAMSS-012

M4. SECONDARY SEALING ELEMENT SHALL BE PERFLOURO ELASTOMER. VENDOR SHALL REVIEW SEAL SELECTION MADE IN DATASHEET.

DATE

BI-10-09003

JOB ORDER/EWO NO.

M5. TESTING SHALL BE AS PER 175-310500.

REV. NO.

M6. FOR SITE DATA AND UTILITIES REFER TO BEDD DOCUMENT NO. T80-A-DAT-CE-796542

M7. VENDOR TO COMPLETE ALL DATA FOR THE EQUIPMENT PROPOSED.

BY/DATE

OTHER

M8. EQUIPMENT LOCATION WILL BE SUBJECTED TO DIRECT SUNLIGHT, HUMIDITY TO 100% AND SAND / DUST STORMS. I.E., HIGHLY

CORROSIVE ENVIRONMENT CLASSIFICATION (SEVERE FOR ELECTRICAL EQUIPMENT).

M9. MANUFACTURER STANDARD FOR EXTERNAL COATING IS ACCEPTABLE PROVIDED THAT VENDOR COATING IS SUITABLE FOR

ENVIRONMENTAL CONDITIONS OF THE SITE. AS A MINIMUM, THE COATING SYSTEM SHALL BE EQUIVALENT TO ISO 12944-5,

OPERATIONS/DATE

CORROSION CATEGORY C5-M HIGH DURABILITY FOR OFFSHORE (EQUIVALENT TO Cx IN ISO 12944-2:2017) AND C5-I

HIGH DURABILITY FOR ONSHORE (EQUIVALENT TO C5 IN ISO 12944-2:2017). THE PRIMER BINDER SHALL BE EPOXY OR ETHYL

SILICATE EXCEPT WHERE ALTERNATOVES ARE APPROVED FOR HIGH TEMPERATURES.

REVIEW FOR KEY DRAWINGS

REQUIRED (SAUDI ARAMCO)

THE VENDOR’S PAINTING PROCEDURES SHALL BE ISSUED FOR CONTRACTOR/COMPANY REVIEW AND APPROVAL.

STAINLESS STEEL SHALL BE PAINTED IN ACCORDANCE WITH SAES-H-001 - SYSTEM APCS-1B UP TO 248°F OR APCS-11C

FOR HIGHER TEMPERATURES.

GALVANISED CARBON STEELS SHALL BE PAINTED IN ACCORDANCE WITH SAES-H-001.

CONST. AGENCY/DATE

M10. PUMPS SHALL BE DESIGNED FOR A MINIMUM SUSPENDED SOLIDS OF 0.03% (300 PPM) BY WEIGHT ACCORDING TO

SECTION 4.1.1.11 OF SAES-G-005

CERTIFIED/DATE

M11. ISO GRADE 46 OIL SHALL BE USED FOR BEARING LUBRICATION.

DESIGN CERTIFICATION

(DESIGN AGENCY)

M12. DOCUMENTS AND OTHER DATA SHALL BE SUPPLIED AS PER NMR SA 7902.

M13. DELETED

ENGG./DATE

M14. DELETED

M15. DELETED

M16. MATERIALS PMI CHECK IS REQUIRED FOR ALLOY COMPONENTS.

M17. DELETED.

M18. HAZARDOUS AREA CLASIFFICATION IS: CLASS 1, ZONE 2, GROUP IIA/IIB, CLASS T3.

IS COVERED, FOR ALL APPROVAL

AND CERTIFICATION REQUIREMENTS, PER SAEP-334, UNDER

M19. NPSH TESTING IS REQUIRED ON ALL IDENTICAL PUMPS WHEN MARGIN BETWEEN NPSHA AND NPSH3 IS LESS THAN 3.3 FEET

AT 120% OF THE RATED FLOW. OTHERWISE ONLY ONE PUMP REQUIRES NPSH TESTING

REVISION VALIDATION

M20. PUMP SHALL BE DISMANTLED TO INVESTIGATE THE CAUSE OF ANY UNSATISFACTORY PERFORMANCE, NPSH, OR RUNNING TESTS

DRAWING COMPLETION CERTIFICATE NO.

M21. TEST SHALL BE PERFORMED WITH CALIBRATED DRIVERS

M22. SS 316/316L IN SOUR SERVICE SHALL BE CERTIFIED IN ACCORDANCE WITH THE REQUIREMENTS OF NACE MR0175/ISO 15156-3.

IN NO CASE HARDNESS SHALL EXCEED 22HRC.

THIS REVISION NO.

MECHANICAL DATA SHEET FOR DEGASSED SOUR WATER PUMPS DWG. TYPE PLANT NO. INDEX DRAWING NO. SHT.NO REV.NO.

T70-G-0113/0213/0313 A/B - DEGASSED SOUR WATER PUMPS DAT

INLET FACILITIES - PACKAGE 9 T70 G CE-795879 6 B

TANAJIB SAUDI ARABIA

EKRD/2616-1110.XLS

# SULZER CONFIDENTIAL

You might also like

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDocument6 pagesSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNo ratings yet

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDocument6 pagesSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNo ratings yet

- Saudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsDocument6 pagesSaudi Arabian Oil Company: Centrifugal Pump Data Sheet For Horizontal Pumps and Vertical In-Line PumpsAnshu K MuhammedNo ratings yet

- Saudi Aramco centrifugal pump data sheetDocument7 pagesSaudi Aramco centrifugal pump data sheetBilel MahjoubNo ratings yet

- Effluent Water Pump - Nmr-601 M13-G-0948A/B: Upgrade Pier Marine Facilities at TanajibDocument15 pagesEffluent Water Pump - Nmr-601 M13-G-0948A/B: Upgrade Pier Marine Facilities at TanajibchaitanyaNo ratings yet

- T70-G-Dat-Ce-795877 - 00C T70-G-0008 - Not IssueDocument6 pagesT70-G-Dat-Ce-795877 - 00C T70-G-0008 - Not IssueAnshu K MuhammedNo ratings yet

- Rotary Pump (Api 676-3Rd) Data Sheet: U.S. CustomaryDocument3 pagesRotary Pump (Api 676-3Rd) Data Sheet: U.S. CustomaryEduin MorenoNo ratings yet

- Saudi Arabian Oil Company: Instrument Specification Sheet - Pressure and Differential Pressure GaugesDocument2 pagesSaudi Arabian Oil Company: Instrument Specification Sheet - Pressure and Differential Pressure GaugesMuhammad ShahidNo ratings yet

- Saudi Aramco 2616-ENG (03/99) Data ScheduleDocument3 pagesSaudi Aramco 2616-ENG (03/99) Data ScheduleJohn BuntalesNo ratings yet

- Nitrogrn - Gate Valve Data SheetDocument2 pagesNitrogrn - Gate Valve Data SheetHabib ur rahmanNo ratings yet

- Project data sheet for rotary pumpDocument3 pagesProject data sheet for rotary pumpeduinNo ratings yet

- 3 - 2C Ah-2vomDocument1 page3 - 2C Ah-2vomMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- 330D & 336D Hyd System Without Heavy Lift & Fine SwingDocument2 pages330D & 336D Hyd System Without Heavy Lift & Fine SwingmahmudiNo ratings yet

- Saudi Arabian Oil Company: Instrument Specification Sheet Level SwitchesDocument1 pageSaudi Arabian Oil Company: Instrument Specification Sheet Level SwitchesDineshNo ratings yet

- C23-Yf60-Q-7855 - A - Sa3-Ps3, Emg-Ff Building, Telephone System Conduit Routing and Cabling & Block Diagram and Details Layout SHT.1Document1 pageC23-Yf60-Q-7855 - A - Sa3-Ps3, Emg-Ff Building, Telephone System Conduit Routing and Cabling & Block Diagram and Details Layout SHT.1sartajNo ratings yet

- Safety Instruction Sheet For Cross Country Pipeline - Critical PipingDocument1 pageSafety Instruction Sheet For Cross Country Pipeline - Critical PipingJohn BuntalesNo ratings yet

- Elevation-3 Podium (Aq To Am) E3-PD-43, QTY-2 NoDocument1 pageElevation-3 Podium (Aq To Am) E3-PD-43, QTY-2 Nomeera binsyedNo ratings yet

- Instrument Air - Gate Valve Data SheetDocument2 pagesInstrument Air - Gate Valve Data SheetHabib ur rahmanNo ratings yet

- 4M Change Summary Sheet - PRFDocument4 pages4M Change Summary Sheet - PRFkumar QANo ratings yet

- This Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedDocument1 pageThis Document Shall Be Revised in Its Entirety. All Sheets of This Document Are The Same Revision Level As IndicatedR- Md Masud Rana B-110No ratings yet

- Front Elevation Escalator Section Escalator Section: Top Support Enlarge Scale 1: 4Document1 pageFront Elevation Escalator Section Escalator Section: Top Support Enlarge Scale 1: 4Habibulla BavajiNo ratings yet

- Blower Data Sheet-Aeration TankDocument1 pageBlower Data Sheet-Aeration TankMohammed Abdul MoiedNo ratings yet

- Saudi Arabian Oil Company: Instrument Specification Sheet - Hydrocarbon Liquid Sampling SystemsDocument1 pageSaudi Arabian Oil Company: Instrument Specification Sheet - Hydrocarbon Liquid Sampling SystemsMuhammad SalmanNo ratings yet

- Crci M98 32 M210 DaDocument6 pagesCrci M98 32 M210 Darajindo1No ratings yet

- Datasheet d801001Document6 pagesDatasheet d801001Hammad HussainNo ratings yet

- Drawings 001Document23 pagesDrawings 001John Philip BuntalesNo ratings yet

- New Sih Building: Extension of Instrument Room FOR (BI-10-00043-001)Document25 pagesNew Sih Building: Extension of Instrument Room FOR (BI-10-00043-001)John Philip BuntalesNo ratings yet

- 3 - 2C Ah-6vcmDocument1 page3 - 2C Ah-6vcmMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- 4 - 3D Ah-5vcmDocument1 page4 - 3D Ah-5vcmMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- KGSB 170074 Af 06 - A0 PDFDocument1 pageKGSB 170074 Af 06 - A0 PDFLallamaNo ratings yet

- 324DL Heavy Lift Hyd SCHDocument2 pages324DL Heavy Lift Hyd SCHEmmanuel solomonNo ratings yet

- Saudi Aramco Requirements Technical Links, Comments & ExceptionsDocument2 pagesSaudi Aramco Requirements Technical Links, Comments & ExceptionsJohn BuntalesNo ratings yet

- MangalaDocument1 pageMangalashakuntla5bankerNo ratings yet

- Khu - 11 - G - Bac20 - Ea - 004 - 2Document18 pagesKhu - 11 - G - Bac20 - Ea - 004 - 2Shafiqul IslamNo ratings yet

- MN Cal003 001 PDFDocument60 pagesMN Cal003 001 PDFBayari ArNo ratings yet

- Acc - Fqap - P3011 - R2 - RewaDocument2 pagesAcc - Fqap - P3011 - R2 - RewaHema NandhNo ratings yet

- Kobelco Mark IV: KobeiDocument12 pagesKobelco Mark IV: KobeiVictor Hugo MezquitaNo ratings yet

- 12-10G GH-3VCMDocument1 page12-10G GH-3VCMMamiherintsoa Issaia RanaivoarimananaNo ratings yet

- 07 A-R Implimentation1 & Carrier Inter Tripping 10-20Document5 pages07 A-R Implimentation1 & Carrier Inter Tripping 10-20ADE MRTNo ratings yet

- General Notes: Philippine Charity Sweepstakes OfficeDocument15 pagesGeneral Notes: Philippine Charity Sweepstakes OfficeNelson OrejudosNo ratings yet

- 324DL Hyd SCHDocument2 pages324DL Hyd SCHEmmanuel solomonNo ratings yet

- Diagrama Hidráulico 320d SISDocument2 pagesDiagrama Hidráulico 320d SISFranklin BeaumontNo ratings yet

- Ad 036785 001Document1 pageAd 036785 001hai sunNo ratings yet

- Saudi Aramco Pipeline Safety SheetDocument1 pageSaudi Aramco Pipeline Safety SheetJohn BuntalesNo ratings yet

- Kobelco Mark 6e Training ManualDocument8 pagesKobelco Mark 6e Training ManualMahmoud SaudyNo ratings yet

- 2 CQC Trienergy 5000027066 50506 - Data SheetDocument4 pages2 CQC Trienergy 5000027066 50506 - Data SheetIgor HernandezNo ratings yet

- Wire Cable/ Wire Cable/: NotesDocument10 pagesWire Cable/ Wire Cable/: Notesmahesh reddy mNo ratings yet

- Recovered Oil Pump - Nmr-601 M13-G-0949A/B: Upgrade Pier Marine Facilities at TanajibDocument53 pagesRecovered Oil Pump - Nmr-601 M13-G-0949A/B: Upgrade Pier Marine Facilities at TanajibchaitanyaNo ratings yet

- C22-YS20-S-7960 - 1 - Cooling Tower Layout - PS2 PDFDocument3 pagesC22-YS20-S-7960 - 1 - Cooling Tower Layout - PS2 PDFsartajNo ratings yet

- Re-Xxxxx.001 - Crude OilDocument1 pageRe-Xxxxx.001 - Crude Oiltouseef88No ratings yet

- Legends & Abbreviations: Ground Floor PlanDocument1 pageLegends & Abbreviations: Ground Floor PlanGANESHNo ratings yet

- TP - 01 Welding For Split TeeDocument1 pageTP - 01 Welding For Split TeeLeonardo ManurungNo ratings yet

- NBC Jaf GQC RT A 150,151,152,153Document4 pagesNBC Jaf GQC RT A 150,151,152,153Akansha SharmaNo ratings yet

- 320D & 320D L Excavator Hydraulic System Schematic PDFDocument2 pages320D & 320D L Excavator Hydraulic System Schematic PDFchanlin100% (5)

- Saudi Arabian Oil Company Valve Data Sheet General DataDocument2 pagesSaudi Arabian Oil Company Valve Data Sheet General Datasalihmohammed533No ratings yet

- 17-MP-0201.01-MP0201.01Document1 page17-MP-0201.01-MP0201.01ISH-QUENo ratings yet

- H2S Removal Unit: NotesDocument1 pageH2S Removal Unit: NotesHsein WangNo ratings yet

- Schedule of Material Submittals Submittal Register: No. of Copies Required Before Constr After ConstrDocument2 pagesSchedule of Material Submittals Submittal Register: No. of Copies Required Before Constr After ConstrWissam AhmedNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- T70-G-Dat-Ce-795877 - 00C T70-G-0008 - Not IssueDocument6 pagesT70-G-Dat-Ce-795877 - 00C T70-G-0008 - Not IssueAnshu K MuhammedNo ratings yet

- SDFSDocument1 pageSDFSAnshu K MuhammedNo ratings yet

- DBRYSDocument2 pagesDBRYSAnshu K MuhammedNo ratings yet

- Attend HRMDocument1 pageAttend HRMAnshu K MuhammedNo ratings yet

- Material List of ABHD-614KRSN-131 Rev C 10 30Document148 pagesMaterial List of ABHD-614KRSN-131 Rev C 10 30Anshu K MuhammedNo ratings yet

- MiscccDocument8 pagesMiscccAnshu K MuhammedNo ratings yet

- ReggDocument2 pagesReggAnshu K MuhammedNo ratings yet

- NytvjDocument4 pagesNytvjAnshu K MuhammedNo ratings yet

- WPQTDocument6 pagesWPQTAnshu K MuhammedNo ratings yet

- Asoiu GHDocument2 pagesAsoiu GHAnshu K MuhammedNo ratings yet

- Asoiu GHDocument2 pagesAsoiu GHAnshu K MuhammedNo ratings yet

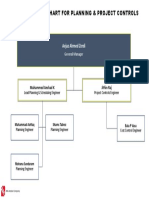

- Organisation Chart for Planning & Project ControlsDocument1 pageOrganisation Chart for Planning & Project ControlsAnshu K MuhammedNo ratings yet

- HoursDocument7 pagesHoursAnshu K MuhammedNo ratings yet

- QTIF-716 27-Feb-2020Document3 pagesQTIF-716 27-Feb-2020Anshu K Muhammed100% (1)

- The Reasons Which Cause Mahabbah (Love) of Allâh - Ibn Al Qayyim (Rahimahullaah) PDFDocument1 pageThe Reasons Which Cause Mahabbah (Love) of Allâh - Ibn Al Qayyim (Rahimahullaah) PDFAnshu K MuhammedNo ratings yet

- Every Islamic Book Contains TheseDocument4 pagesEvery Islamic Book Contains TheseAnshu K MuhammedNo ratings yet

- HoursDocument7 pagesHoursAnshu K MuhammedNo ratings yet

- OracleDocument1 pageOracleramyasree59No ratings yet

- Project Milestone ScheduleDocument1 pageProject Milestone ScheduleAnshu K MuhammedNo ratings yet

- Adjustable Legs, Thumb Turn/Slide, Hinges, Door Knob, and Coat Hooks Product ListDocument2 pagesAdjustable Legs, Thumb Turn/Slide, Hinges, Door Knob, and Coat Hooks Product ListAnshu K MuhammedNo ratings yet

- WebsiteDocument1 pageWebsiteAnshu K MuhammedNo ratings yet

- UpdatesDocument1 pageUpdatesAnshu K MuhammedNo ratings yet

- Earned Value Cheat Sheet: General TermsDocument1 pageEarned Value Cheat Sheet: General TermsAhmed Hamdy HusseinNo ratings yet

- Issue Id Location Line Item Issue Description Priority Responsible Party Responsible Person Status Resolution Date Comments No CommentsDocument1 pageIssue Id Location Line Item Issue Description Priority Responsible Party Responsible Person Status Resolution Date Comments No CommentsAnshu K MuhammedNo ratings yet

- Abuhammaad Website LinksDocument1 pageAbuhammaad Website LinksAnshu K MuhammedNo ratings yet

- Websites SalafiDocument2 pagesWebsites SalafiAnshu K MuhammedNo ratings yet

- KalorimetriDocument7 pagesKalorimetriRatih DSNo ratings yet

- Hydraulic CalculationDocument11 pagesHydraulic CalculationNethaji100% (1)

- Control Valve Question and Answer - 2Document13 pagesControl Valve Question and Answer - 2TATA STEELNo ratings yet

- FHWA Basics HydraulicsHDS4 - 608Document203 pagesFHWA Basics HydraulicsHDS4 - 608Helmer Edgardo Monroy GonzálezNo ratings yet

- LNG VS GTLDocument1 pageLNG VS GTLdishankmpatelNo ratings yet

- Gulftherm Oil PDFDocument1 pageGulftherm Oil PDFDiego Mendoza LorduyNo ratings yet

- Mathcad - Blast LoadingDocument5 pagesMathcad - Blast Loadinglnt40% (1)

- Lecture 6 | Refrigeration & Liquefaction - J. G. Weisend IIDocument36 pagesLecture 6 | Refrigeration & Liquefaction - J. G. Weisend IIVishvesh T SNo ratings yet

- H81Hmt Example Sheet 6 (Radiation)Document1 pageH81Hmt Example Sheet 6 (Radiation)Xiao ThAmNo ratings yet

- Pipe Wall ThicknessDocument2 pagesPipe Wall ThicknessTomi Kazuo0% (1)

- Technical Information: Directional Control ValvesDocument68 pagesTechnical Information: Directional Control ValvesPedro FernandezNo ratings yet

- Hydro Generators Losses Measurement in Accordance To IEEE-STD-115 and IEC-60034-2Document7 pagesHydro Generators Losses Measurement in Accordance To IEEE-STD-115 and IEC-60034-2saliyarumesh2292No ratings yet

- CounterweightDocument25 pagesCounterweightLami BojaNo ratings yet

- Solution Manual For An Introduction To Fluid Mecha B.qs. Z. MorrisonDocument1,057 pagesSolution Manual For An Introduction To Fluid Mecha B.qs. Z. MorrisonSaraNo ratings yet

- Hydrocyclone Process Simulation Using Aspen HYSYSDocument8 pagesHydrocyclone Process Simulation Using Aspen HYSYSmadhav287No ratings yet

- Tel Is Romero 2006Document7 pagesTel Is Romero 2006Alex Samuel SilvaNo ratings yet

- WWTP Mardan 1st PhaseDocument41 pagesWWTP Mardan 1st Phasemohammad armaghan100% (1)

- HW2Document2 pagesHW2lucasNo ratings yet

- Formula Sheet: F V GDDocument3 pagesFormula Sheet: F V GDKarla Isabel Salgado SánchezNo ratings yet

- 3 - Seepage AnalysisDocument39 pages3 - Seepage AnalysisFaran Assif0% (1)

- Sheet 4 (Generation)Document4 pagesSheet 4 (Generation)Rafi Mahmoud SulaimanNo ratings yet

- Properties of saturated water tableDocument1 pageProperties of saturated water tabletemumangga50% (2)

- Kinetics Homework 3 Reaction RatesDocument4 pagesKinetics Homework 3 Reaction RatesRizkiNo ratings yet

- API 675 - 3ra Edic - Nov 2012 y ErrataDocument72 pagesAPI 675 - 3ra Edic - Nov 2012 y ErrataGabriel CarmonaNo ratings yet

- Basics-Of-Hydraulics 8159920 PowerpointDocument26 pagesBasics-Of-Hydraulics 8159920 PowerpointbeselamuNo ratings yet

- Toughness TestDocument25 pagesToughness TestNehaJainNo ratings yet

- Facts at Your Fingertips-200903-Membrane ConfigurationsDocument1 pageFacts at Your Fingertips-200903-Membrane Configurationsonizuka-t2263No ratings yet

- EVAPORATION AND DEHYDRATION TECHNIQUESDocument23 pagesEVAPORATION AND DEHYDRATION TECHNIQUESRogelyn JosolNo ratings yet

- Vignesh (2015) - Reactor DesignDocument8 pagesVignesh (2015) - Reactor DesigngandurikNo ratings yet

- M-54 K4670433 Sewage Treatment SystemDocument8 pagesM-54 K4670433 Sewage Treatment SystemeconmechNo ratings yet