Professional Documents

Culture Documents

Final Report TOTAL EP MYANMAR

Uploaded by

ThirukkumaranBalasubramanianCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Final Report TOTAL EP MYANMAR

Uploaded by

ThirukkumaranBalasubramanianCopyright:

Available Formats

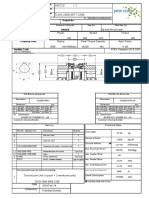

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 1 sur 24

Order Number: 8145007262

Contact Name: Mr. Yves FURMANOWSKI

Phone : + 95 1 66 04 66 ext 3146

E-mail : yves.furmanowski@total.com

Engineer: M. Momtez BEN SIK ALI

Tél. : +377 92 05 79 81

E-mail: mb@3xeng.com

GENERAL INFORMATION

Site name : YADANA Offshore Maint-Inspection TEPM-OY: U PHYO-THET-ZAW

Starting from : March 25th 2013

Order Number : 8145007262

Ending : April 3rd 2013

3X Eng. Applicator : Mr. Momtez BEN SIK ALI and Mr. Laurent VALVASSORI

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 2 sur 24

Pipeline Reinforcement

Summary

1. Preamble..........................................................................................................................3

2. The scope of work ……………………………………………………………………………..…4

2.1 Customer details…………………………………………………………………………..4

2.2 Repair Calculation for six defects…………………………………………....................5

3. Job details ……………………………………………………………………………………..…5

4. 36” EXPORT GAS PIPELINE RISER............……………………………..............................5

4.1 Above anchor flange..................................................................................................8

4.2 Below anchor flange.................................................................................................11

5. 20” UNUSED RISER AT PP…………………………………….............................................12

5.1 Above anchor flange..................................................................................................8

5.2 Below anchor flange.................................................................................................11

6. Conclusion.....................................................................................................................20

7. INSPECTION REPORT...............................................................................................21

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 3 sur 24

1. Preamble

3X Engineering is specialized in the development and commercialization of pipe repair systems mainly for corrosion and

leak maintenance (oil, gas, water and power station applications).

Its patented applications are mainly focused on the use of composite materials (Kevlar® 49 / Epoxy). 3X Engineering

currently sells the following products: REINFORCEKIT EVOLUTION, REINFORCEKIT 4D, REINFORCEKIT COATING,

REINFORCEKIT WATERSLEEVE, STOPKIT and REFLANGEKIT. Certified by Bureau Veritas (cf. attached report) the

REINFORCEKIT Evolution has been authorized for implementation by Total in 2003.

Today, in the optic of a technologic upgrading, 3X Engineering has developed the REINFORCEKIT 4D. This new

wrapping composite solution is in accordance with the last standards ISO 24.817, ASME PCC-2 and Total’s GS EP PLR 310. The

REINFORCEKIT 4D is currently tested by PRCI (Stress Engineering Services INC.) and has been validated in house by 3X

Engineering. The design incorporates the ageing criteria of the materials in order to optimize the repair system in a long term way.

3X Engineering has chosen Aramid as a base of the reinforcement material. Indeed, the Young modulus of the Aramid

fiber provides the highest performance without using conductive carbon fiber.

3X Engineering has also developed its own Pipe Defect Register (P.D.R) software. The P.D.R permits to list and fill easily

your inspection data from your NDT measurements (see below). It is also linked to finite element software called REINFORCEKiT

Evolution Analyse (R.E.A) that predicts the stresses concentration and the composite sleeve behaviour before and after the repair.

REINFORCEKiT 4D

The composite sleeve is made of a ceramic reinforced resin (until 80°C continuously) and a Kevlar® tape of 400

g/m².

The composite system is wrapped helicoidally around the pipe in order to bring the

mechanical resistance to the corroded pipe section. The number of layers, determined by

calculation, is linked not only to the pipe pressure, temperature, diameter and thickness but also to

the pit depth and length, the steel grade and the pipe location.

3X’s Aramid tape

After many tests, the design of the tape has been improved to get an easier impregnation of the resin and to

optimize the characteristics of the composite material. In order to help the technicians to overlap the Aramid tape when

wrapping, different colours lines have been woven in the Kevlar® tape.

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 4 sur 24

2. The scope of work

This scope of work of is referenced to the TEPM inspection report YAD-12-0586, Riser Neoprene, 15-Dec-

2012.

2.1 36” Riser :

To perform the engineering and step by step procedure to be submitted prior to start the job for 2m above

the anchor flange and 2.7m below the anchor flange to neoprene coated area along the 36” export

pipeline and to perform the engineering to protect the anchor flange to cut the oxygen ingression.

2.2 20” Unused Riser at PP:

To perform the engineering and step by step procedure to be submitted prior to start the job for 2m above

the anchor flange and 0.6m below the anchor flange to neoprene coated area along the 20” WP2

incoming line riser and to perform the engineering to protect the anchor flange to cut the oxygen

ingression.

2.1 Customer's details

Company: TOTAL E&P MYANMAR

Site: YADANA Platform

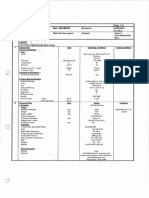

2.2 Repair Calculation for six defects

As per the design of the 3X Engineering’s REINFORCEKiT 4D, the fibers are woven in both directions (20%

axial and 80% circumferential) so that the composite will definitely sustain the circumferential and the axial

stresses.

Remaining Design Repair

Design Temperature Number of

N° Pipe Diameter thickness, Pressure, Length

°C layers

mm Bars m

1 20" 0 4

2 36" 30.79 116.5 4

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 5 sur 24

3.Job details

PIPELINE RISER view

36” EXPORT GAS PIPELINE RISER view 20” UNUSED RISER AT PP view

4. 36” EXPORT GAS PIPELINE RISER

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 6 sur 24

4.1. Above anchor flange

Pipeline

view

36” EXPORT GAS PIPELINE RISER view

(Above the flange)

Surface preparation by sand blasting

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 7 sur 24

Pipeline and the flange vew after sand blast

Degreasing the surface with Acetone around the pipe.

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 8 sur 24

Control the roughness with a calibrated roughness tester

Ceramic resin application on damaged pipe section

Application of the 4 layers with composite system and 2.2 meters overlapping around the pipe

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 9 sur 24

Apply the composite system around the above “hang off”.

(no mechanical resistance but only protection from the sea water)

Final view of the composite system apply around the “above hang off” of the 36”

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 10 sur 24

Application of external final coating

(Interzone 954)

4. 36” EXPORT GAS PIPELINE RISER

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 11 sur 24

4.1. Above anchor flange

Pipeline

view

36” EXPORT GAS PIPELINE RISER view

(Below the flange)

Surface preparation by sand blasting

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 12 sur 24

Surface preparation with MBX Bristle Blaster tool the “Neoprene” aroud the pipe.

Degreasing the surface with Acetone around the pipe.

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 13 sur 24

Apply the composite system around the below “hang off”.

(no mechanical resistance but only protection from the sea water)

F3X8 filler installation

(Sealing and restructuring of the cankers and the pinholes due to corrosion by specific putty)

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 14 sur 24

Ceramic resin application on damaged pipe section

Application of the 4 layers with composite system and 2 meters overlapping around the pipe

Final view of the composite system apply around the “below anchor hang off” of the 36”

(15 cm junction with the neoprene)

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 15 sur 24

Application of external final coating

(Interzone 954)

5. 20” UNUSED RISER AT PP

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 16 sur 24

5.1. Above anchor flange

Pipeline

view

20” UNUSED RISER AT PP view

(Above anchor flange)

Surface preparation by sand blasting

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 17 sur 24

Pipeline and the flange vew after sand blast

Control the roughness with a calibrated roughness tester

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 18 sur 24

Degreasing the surface with Acetone around the pipe.

Ceramic resin application on damaged pipe section

Application of the 4 layers with composite system ,with 2 meter overlapping around the pipe

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 19 sur 24

Apply the composite system around the above “hang off”.

(no mechanical resistance but only protection from the sea water)

Final view of the composite system apply around the “above hang off” of the 20”

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 20 sur 24

Application of external final coating

(Interzone 954)

5. 20” UNUSED RISER AT PP

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 21 sur 24

5.2. Below anchor flange

FIRST STEP (April 2013):

20” UNUSED RISER AT PP view

(Below anchor flange)

Surface preparation with MBX Bristle Blaster tools

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 22 sur 24

Surface preparation with MBX Bristle Blaster tool the “Neoprene” aroud the pipe.

F3X8 filler installation

(Sealing and restructuring of the cankers the due to corrosion by specific putty)

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 23 sur 24

Degreasing the surface with Acetone around the pipe.

Ceramic resin application on damaged pipe section

Application of the 4 layers with composite system ,with 0.4 meter overlapping around the pipe

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

FORMULAIRE MEO-FO-050

Version B

Date d’émission : 08-04-2013

FINAL REPORT Rédigé par : M. BEN SIK ALI

Page 24 sur 24

Final view of the composite system apply around the “above hang off” of the 20”

(15 cm junction with the neoprene)

8. Conclusion

Made from a ceramic charged resin for a temperature of use until 45°C continuous and

with a Kevlar tape of 400 gr/m², composite system is rolled helicoidally in order to recover

mechanical resistance for the corroded pipe. Number of layers is determined after calculation

and in function of the pressure and state of the support.

Reinforcekit 4D is designed as per ISO 24.817, ASME PCC-2 and GS EP PLR 310. The

calculations of the composite repair length and the number of layers are based on the

BARLOW Law for each defect.

Thanks to Yves FURMANOWSKI, Kyaw Thein Tun, Phyo Thet Zaw and to everyone

who helps the 3X team to perform this job in the best conditions.

3X ENGINEERING - 9 avenue Albert II- 98 000 MONACO

Tél. : +377.92.05.79.81 Fax: +377.92.05.72.71 site: www.3xengineering.com

You might also like

- Ims 52 07 06Document14 pagesIms 52 07 06marcio de rossiNo ratings yet

- CP 300 (A) - QCP-050 Cosmetic Repair of Ramp Retaning WallsDocument5 pagesCP 300 (A) - QCP-050 Cosmetic Repair of Ramp Retaning WallstarekNo ratings yet

- CP 300 (A) - QCP-049 Repair of Ground Floor Slab & Wall ExpansiDocument6 pagesCP 300 (A) - QCP-049 Repair of Ground Floor Slab & Wall ExpansitarekNo ratings yet

- Cabin Roof Panel Repair SRM Form 05-01-01Document3 pagesCabin Roof Panel Repair SRM Form 05-01-01Gabriel MarzolaNo ratings yet

- 2013-03-12 Pressure Roller Banding PhenomenonDocument2 pages2013-03-12 Pressure Roller Banding PhenomenonMiroslavStoynovNo ratings yet

- Omml 7 201 300 B enDocument7 pagesOmml 7 201 300 B enEngr Mohammed UsmaniaNo ratings yet

- DB Manual - Operational DB22 OIM R19 (106782)Document20 pagesDB Manual - Operational DB22 OIM R19 (106782)Pkk Siam Rayong co-saleNo ratings yet

- Cryostar Centrifugal Pump User ManualDocument56 pagesCryostar Centrifugal Pump User Manualtang weng wai86% (7)

- Installation / Commissioning Report: LE Division No.Document2 pagesInstallation / Commissioning Report: LE Division No.Skill IndiaNo ratings yet

- HFY 3800 0000 VED 192 QC PD 0011 A Insulation Procedure Code BDocument6 pagesHFY 3800 0000 VED 192 QC PD 0011 A Insulation Procedure Code BMohamed FarisNo ratings yet

- HM-1 (E) - Finished Drawing & Instruction Manual For Cargo Pumping System (Vol I) PDFDocument236 pagesHM-1 (E) - Finished Drawing & Instruction Manual For Cargo Pumping System (Vol I) PDFabhishekNo ratings yet

- Bscu - Brakes Released Auto BRK Fault at Landing PDFDocument4 pagesBscu - Brakes Released Auto BRK Fault at Landing PDFWei LiaoNo ratings yet

- User's Surface: Guide: Double Bituminous TreatmentDocument26 pagesUser's Surface: Guide: Double Bituminous TreatmentShoyeeb AhmedNo ratings yet

- Mellitah Oil & Gas BV: Field Bending OF LinepipeDocument4 pagesMellitah Oil & Gas BV: Field Bending OF LinepipeThirukkumaranBalasubramanianNo ratings yet

- 2013-MMAC-TR-006 - Mechanical Seal Leak Desalter Feed Pump 10210PA001CDocument5 pages2013-MMAC-TR-006 - Mechanical Seal Leak Desalter Feed Pump 10210PA001CMohammed ElarbedNo ratings yet

- Pipe Laying Method StatementDocument5 pagesPipe Laying Method StatementburereyNo ratings yet

- MFE-PRO-003.G Self - Climbing Safety Screen Method StatementDocument48 pagesMFE-PRO-003.G Self - Climbing Safety Screen Method Statementamit.patra100% (1)

- Saipem Support Drw.1Document345 pagesSaipem Support Drw.1sirajNo ratings yet

- Clemenceau Medical Centre: Tender DesignDocument4 pagesClemenceau Medical Centre: Tender DesignOmer HayatNo ratings yet

- NBE-204!04!002 R3 Schemetic UNIT AUX UpdateDocument31 pagesNBE-204!04!002 R3 Schemetic UNIT AUX UpdateSamsudin AhmadNo ratings yet

- Cnes / Esa: RF / Microwave Printed Circuit Boards For Space ApplicationsDocument29 pagesCnes / Esa: RF / Microwave Printed Circuit Boards For Space ApplicationsMehmet KibarNo ratings yet

- Engineering Report For Composite Repair On Enang 48 E Well Flowline-Live-0Document7 pagesEngineering Report For Composite Repair On Enang 48 E Well Flowline-Live-0Chukwuma Emmanuel OnwufujuNo ratings yet

- Load Testing and Testing of Shock Absorption and Vertical Deformation of Test Floors For Sports Purposes, Round 2Document10 pagesLoad Testing and Testing of Shock Absorption and Vertical Deformation of Test Floors For Sports Purposes, Round 2Paulo BravoNo ratings yet

- Etnstci/Etnstcilf Ice/sand Protected Tanks Installation ManualDocument14 pagesEtnstci/Etnstcilf Ice/sand Protected Tanks Installation ManualRafael ReisNo ratings yet

- 5 DAILY CHECK (DL) Rev. 2Document9 pages5 DAILY CHECK (DL) Rev. 2YERSON MUNARNo ratings yet

- C-16 Cyclinder LinerDocument3 pagesC-16 Cyclinder LinerDzung HoangNo ratings yet

- Waterproofing Treatment and Installation Work Procedure FOR SRA - 03 Raj InfiniaDocument6 pagesWaterproofing Treatment and Installation Work Procedure FOR SRA - 03 Raj InfiniaThink itNo ratings yet

- Entegra: Installation ManualDocument111 pagesEntegra: Installation Manualzach100% (1)

- Turbo Docs P-01267 - Repair MHI ST Rotor Unit 5-1Document34 pagesTurbo Docs P-01267 - Repair MHI ST Rotor Unit 5-1yuliantoNo ratings yet

- Safety 60950 Move2500Document224 pagesSafety 60950 Move2500vishalvsinghonlineNo ratings yet

- Corrosion protection converter platform repair instructionsDocument13 pagesCorrosion protection converter platform repair instructionsIliyanPetrovNo ratings yet

- Precast Concrete Headwalls - NydotDocument6 pagesPrecast Concrete Headwalls - NydotgemotorresNo ratings yet

- Trelleborg Fender CatalogueDocument34 pagesTrelleborg Fender CatalogueIgnatius SamrajNo ratings yet

- Operator E-Jets News Rel 019Document9 pagesOperator E-Jets News Rel 019jivomirNo ratings yet

- Injection Pipe Crack FixDocument4 pagesInjection Pipe Crack Fixfrancisca19No ratings yet

- MC 10168762 0001Document5 pagesMC 10168762 0001Vernon ParkerNo ratings yet

- I-Et-3010 63-1300-140-TKP-001 - F PDFDocument37 pagesI-Et-3010 63-1300-140-TKP-001 - F PDFOrlando PWRNo ratings yet

- Alignment and Installation Procedure For UW EqptsDocument79 pagesAlignment and Installation Procedure For UW EqptsSanthosh Kumar100% (1)

- 9686-6130-FQ-000-0010 - Polyprime SB Application - Issued To OTTCODocument3 pages9686-6130-FQ-000-0010 - Polyprime SB Application - Issued To OTTCOANIL PLAMOOTTILNo ratings yet

- Thermal Spray Coating Application of AluminumDocument14 pagesThermal Spray Coating Application of AluminumAntônio BravoNo ratings yet

- DB Manual - Operational DB3-5.5 OIM (107599)Document17 pagesDB Manual - Operational DB3-5.5 OIM (107599)Pkk Siam Rayong co-saleNo ratings yet

- NTB02 068Document4 pagesNTB02 068PMNo ratings yet

- BR Iom Bx-Be-Bn-Mx-Me-M STD Eng r02 1Document36 pagesBR Iom Bx-Be-Bn-Mx-Me-M STD Eng r02 1Hoài LyNo ratings yet

- TD2019-13-E Installation Instructions DTOX S OIL-SF6 R ADocument22 pagesTD2019-13-E Installation Instructions DTOX S OIL-SF6 R Ap m yadavNo ratings yet

- METHOD STATEMENT FOR REPAIRING HONEYCOMBS IN CONCRETEDocument5 pagesMETHOD STATEMENT FOR REPAIRING HONEYCOMBS IN CONCRETEudithaNo ratings yet

- CHAPTER 11 GIs, Letters and ReferencesDocument12 pagesCHAPTER 11 GIs, Letters and ReferencesMahrouz MadoNo ratings yet

- File PDFDocument5 pagesFile PDFMuhammad AsyrafNo ratings yet

- FPSO Painting SpecificationDocument33 pagesFPSO Painting SpecificationOrlando PWRNo ratings yet

- Wi-Fac-005 Frame PaintingDocument3 pagesWi-Fac-005 Frame PaintingGanesh R NairNo ratings yet

- ZM00373 302Document22 pagesZM00373 302ausgestobeneNo ratings yet

- Repairing Cement Lining in PipesDocument4 pagesRepairing Cement Lining in Pipestoni blaireNo ratings yet

- APGENCO Proposal For ORG WP On 13-12-23 PDFDocument6 pagesAPGENCO Proposal For ORG WP On 13-12-23 PDFSun NyNo ratings yet

- Air BleedDocument5 pagesAir BleedvinayNo ratings yet

- CP 300 (A) - QCP-038 Kerbs Pre-Casting & InstallationDocument7 pagesCP 300 (A) - QCP-038 Kerbs Pre-Casting & InstallationtarekNo ratings yet

- WBT - Coating Maintenance and RepairsDocument15 pagesWBT - Coating Maintenance and RepairsAhmed ShakirNo ratings yet

- 2.1. FT MANHOLE D400.ro.enDocument5 pages2.1. FT MANHOLE D400.ro.enVerde GriNo ratings yet

- CP 300 (A) - QCP-039 Installation of Ceramic Floor TilesDocument6 pagesCP 300 (A) - QCP-039 Installation of Ceramic Floor TilestarekNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Trilogy of Connectors: Basic Principles and Connector Design ExplanationsFrom EverandTrilogy of Connectors: Basic Principles and Connector Design ExplanationsRating: 5 out of 5 stars5/5 (1)

- Summarized Technical - Information Data'sDocument1 pageSummarized Technical - Information Data'sThirukkumaranBalasubramanianNo ratings yet

- Job Description-Process EngineerDocument1 pageJob Description-Process EngineerThirukkumaranBalasubramanianNo ratings yet

- Job Description-Piping EngineerDocument1 pageJob Description-Piping EngineerThirukkumaranBalasubramanianNo ratings yet

- CEIL Engineering FinHR Advt 202324 02Document6 pagesCEIL Engineering FinHR Advt 202324 02ThirukkumaranBalasubramanianNo ratings yet

- Job Description-Mechanical EngineerDocument1 pageJob Description-Mechanical EngineerThirukkumaranBalasubramanianNo ratings yet

- CUI Risk Factors on Insulated PipingDocument21 pagesCUI Risk Factors on Insulated PipingRenan Soares KieferNo ratings yet

- D2-001-AM Part 1Document118 pagesD2-001-AM Part 1ThirukkumaranBalasubramanianNo ratings yet

- DS 7502Document4 pagesDS 7502ThirukkumaranBalasubramanianNo ratings yet

- PALL FILTER - Process Data SheetDocument2 pagesPALL FILTER - Process Data SheetThirukkumaranBalasubramanianNo ratings yet

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureDocument19 pagesMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanianNo ratings yet

- Visual Inspection WeldDocument53 pagesVisual Inspection Weldshifa100% (1)

- Guide to Failure Analysis in Oil and Gas IndustryDocument6 pagesGuide to Failure Analysis in Oil and Gas IndustryThirukkumaranBalasubramanian100% (1)

- Mellitah Oil & Gas BV: Welding Procedure Specification For Stainless Steel PipingDocument9 pagesMellitah Oil & Gas BV: Welding Procedure Specification For Stainless Steel PipingThirukkumaranBalasubramanianNo ratings yet

- Mellitah Oil & Gas BV: Field Bending OF LinepipeDocument4 pagesMellitah Oil & Gas BV: Field Bending OF LinepipeThirukkumaranBalasubramanianNo ratings yet

- Execution of Tie-Ins Without A Plant ShutdownDocument3 pagesExecution of Tie-Ins Without A Plant ShutdownThirukkumaranBalasubramanianNo ratings yet

- INITIAL RISK REVIEW - WAFA Cold CutDocument6 pagesINITIAL RISK REVIEW - WAFA Cold CutThirukkumaranBalasubramanianNo ratings yet

- Cold CuttingDocument2 pagesCold CuttingThirukkumaranBalasubramanianNo ratings yet

- JERES-D-001 Design Criteria For Pressure VesselsDocument37 pagesJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianNo ratings yet

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureDocument583 pagesMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanian0% (1)

- Atlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFDocument57 pagesAtlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFMikku KattaNo ratings yet

- Non Oily Wastewater To The SeaDocument1 pageNon Oily Wastewater To The SeaThirukkumaranBalasubramanianNo ratings yet

- Mellitah Oil & Gas BVDocument12 pagesMellitah Oil & Gas BVThirukkumaranBalasubramanianNo ratings yet

- Installation PlanDocument28 pagesInstallation PlanThirukkumaranBalasubramanianNo ratings yet

- Aspee Hi-Tech: Knapsack SprayerDocument2 pagesAspee Hi-Tech: Knapsack SprayerThirukkumaranBalasubramanianNo ratings yet

- JERES-D-001 Design Criteria For Pressure VesselsDocument37 pagesJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianNo ratings yet

- PSG 15 Repairs or Modifications Dated 13th Nov 2013 PDFDocument13 pagesPSG 15 Repairs or Modifications Dated 13th Nov 2013 PDFThirukkumaranBalasubramanianNo ratings yet

- Reference ListDocument28 pagesReference ListThirukkumaranBalasubramanianNo ratings yet

- DataSheet 105723Document2 pagesDataSheet 105723ThirukkumaranBalasubramanianNo ratings yet

- DataSheet 105723Document2 pagesDataSheet 105723ThirukkumaranBalasubramanianNo ratings yet

- Catalogue - Hilux - 2021 (1) - 0Document6 pagesCatalogue - Hilux - 2021 (1) - 0Hermawan AnggraeniNo ratings yet

- Traction Transformers From SiemensDocument10 pagesTraction Transformers From Siemenscosty_transNo ratings yet

- Naukri RohinLohat (10y 0m) PDFDocument5 pagesNaukri RohinLohat (10y 0m) PDFayesha siddiquiNo ratings yet

- Battery Lelvel Indicator ProjectDocument10 pagesBattery Lelvel Indicator ProjectANTON GINO J A 21ITR005No ratings yet

- ANSYS IGBT Inverter Multiphysics SolutionDocument56 pagesANSYS IGBT Inverter Multiphysics Solution黃宋儒100% (1)

- DAL Keystones SSDocument8 pagesDAL Keystones SSyordanNo ratings yet

- Substation Energization - LEADDocument11 pagesSubstation Energization - LEADAbhiyan Anala Arvind100% (1)

- INTERNSHIPDocument29 pagesINTERNSHIPAnkita Mohanty0% (1)

- FANUC Series 0M-D Machining Center ManualDocument406 pagesFANUC Series 0M-D Machining Center Manualcesar_abdd100% (1)

- Dam PluggingDocument104 pagesDam PluggingMpho Vince MatlouNo ratings yet

- Principles of Lighting DesignDocument3 pagesPrinciples of Lighting DesignnpfhenriquesNo ratings yet

- Experiment #8 - Slender MemberDocument4 pagesExperiment #8 - Slender MemberLuís Alberto Tang YorisNo ratings yet

- For Drifting and Tunneling: Sandvik RT300-seriesDocument6 pagesFor Drifting and Tunneling: Sandvik RT300-seriesДамир НазиповNo ratings yet

- Volvo Plane Ice ReportDocument18 pagesVolvo Plane Ice ReportAreebNo ratings yet

- Harris 25GX 250 580Document2 pagesHarris 25GX 250 580Sadot GutierrezNo ratings yet

- BPUT Preformulation Studies Chapter 1 SummaryDocument18 pagesBPUT Preformulation Studies Chapter 1 Summarykartik sharmaNo ratings yet

- 16 Mark Questions OOADDocument9 pages16 Mark Questions OOADsaravanan_saptc100% (2)

- Backscatter and Seabed Image ReflectivityDocument5 pagesBackscatter and Seabed Image ReflectivityJuan David SantanaNo ratings yet

- CM Position Paper - Cyclists and SidewalksDocument3 pagesCM Position Paper - Cyclists and SidewalksTom BradfordNo ratings yet

- QUOTATION For ARIS 05 12 23Document5 pagesQUOTATION For ARIS 05 12 23Kasarachi AmadiNo ratings yet

- Mud Pump MeasurementsDocument13 pagesMud Pump MeasurementsHassan KhattabNo ratings yet

- Structural CalculationDocument5 pagesStructural CalculationEze NonsoNo ratings yet

- Chapter 10Document9 pagesChapter 10J.K HomerNo ratings yet

- CHEM 1315 Exam 3 Practice BDocument6 pagesCHEM 1315 Exam 3 Practice BmikamundkurNo ratings yet

- Name of Work: Estimation For Proposed Construction of Tara Ramesh, Tangali, Kadur Taluk, Chikkamagalur DistrictDocument25 pagesName of Work: Estimation For Proposed Construction of Tara Ramesh, Tangali, Kadur Taluk, Chikkamagalur DistrictDEEPIKANo ratings yet

- Parts Guide Manual: Bizhub PRO 951 A4EwDocument257 pagesParts Guide Manual: Bizhub PRO 951 A4EwYessica MontenegroNo ratings yet

- Fanuc CodeDocument11 pagesFanuc CoderlwersalNo ratings yet

- 36 Insp Pad Plate A OriDocument2 pages36 Insp Pad Plate A OriHastagnya Jangan LupaNo ratings yet

- Las 2Document3 pagesLas 2James Honrubia (titobibot)No ratings yet

- Integration of SAP Into The Laboratory WorkflowDocument5 pagesIntegration of SAP Into The Laboratory WorkflowgvlaxmipathiNo ratings yet