Professional Documents

Culture Documents

Ovf 20CR.1

Uploaded by

jahinmeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ovf 20CR.1

Uploaded by

jahinmeCopyright:

Available Formats

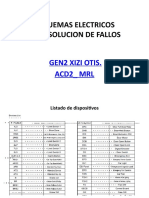

OTIS - OEC OVF20 CR Dwg : GCA21342C_CSU

Date : 2005-09-13

ENGINEERING CENTER

BERLIN Otis Variable Frequency Drive Page : 20/26

FSM Component Start up

Application with encoder

6 Appendix

6.1 5 kW Package

Unpublished Work Copyright © OTIS Elevator Company

OTIS - OEC OVF20 CR Dwg : GCA21342C_CSU

Date : 2005-09-13

ENGINEERING CENTER

BERLIN Otis Variable Frequency Drive Page : 21/26

FSM Component Start up

Application with encoder

6.2 Configuration

Unpublished Work Copyright © OTIS Elevator Company

OTIS - OEC OVF20 CR Dwg : GCA21342C_CSU

Date : 2005-09-13

ENGINEERING CENTER

BERLIN Otis Variable Frequency Drive Page : 22/26

FSM Component Start up

Application with encoder

6.3 Drive interface

6.3.1 Interface to Controller with LCB II

P7.1 24 VDC Output Supply for external features (max. 1A)

P7.2 HL2 Ground connection for 24 VDC

P7.3 U Input Up command

Connector P7

P7.4 D Input Down command

P7.5 T Input Normal run (fast run) command

P7.6 LS Input Limit switch

P7.7 1LV Input Door zone signal

P7.8 2LV Input Door zone signal

P7.9 OP Output Operating signal (no error)

P7.10 DZ Output Drive in door zone

P7.11 IP Output Counting impulse signal

P7.12 BY Output Brake lift signal

P10.1 SW1-14 NO contact dry contact with terminal 2

P10.2 SW1-13 NO contact dry contact with terminal 1

Connector P10

P10.3 SW1-A1 Coil input from safety chain

P10.4 SW1-A2 Coil ground connection

P10.5 SW1-21 NC contact dry contact with terminal 6

P10.6 SW1-22 NC contact dry contact with terminal 5

P10.7 SW1-32 NC contact dry contact with terminal 8

P10.8 SW1-31 NC contact dry contact with terminal 7

P10.9 110 VAC 110VAC supply

P10.10 HL1 Ground of 110VAC

L1

Maine

lines

L2 Power supply AC line input

L3

PE Protection earth

6.3.2 Interface to the motor

P2:4 U

P2:3 V Motor phase output

terminal

P2:2 W

Motor

P2:1 BR DBR in (connecting point for DBR)

P2:5 P0 DBR out (connecting point for DBR)

P2:6 DC+ Positive DC-Link voltage

P2:7 DC- Negative DC-Link voltage

Unpublished Work Copyright © OTIS Elevator Company

OTIS - OEC OVF20 CR Dwg : GCA21342C_CSU

Date : 2005-09-13

ENGINEERING CENTER

BERLIN Otis Variable Frequency Drive Page : 23/26

FSM Component Start up

Application with encoder

6.4 Parameter setup: OVF20

6.4.1 Contract parameter: <M> <3> <1>

Parameter min. Default (DF=6) max. Current

Con Spe [0,01 m / s] 25 160 180

CON Nmot [rpm] 80 1425 3960

Mot Fnom [0.1Hz] 250 500 600

Mot Nnom [rpm] 80 1425 3600

ENCODER PULSES 0 1024 3600

ENCODER TRACES 1 2 2

2LV avail 0 0 1

DDP [s] 1 20 45

CONTR TYPE 4 4 4

TOP FLOOR 1 1 31

BOTTOM FLOOR 0 0 0

FLOORS IN 1LS 0 1 2

BrakeSW type 0 0 3

Chk I_Brake avai 0 1 1

Motor Dir [0/1] 0 0 1

Encoder Dir *) [0/1] 0 0 1

PowerSave D [min] 0 0 255

*) visible only for "ENCODER TRACES" = 2

6.4.2 Drive parameter: <M> <3> <2>

Parameter min. Default (DF=6) max. Current

INS SPE [0,01 m / s] 3 30 60

NOM SPE [0,01 m / s] 20 160 180

SHR SPE [0,01 m / s] 0 0 *) 120

REL SPE [0,01 m / s] 0 0 10

CRE SPE [0,01 m / s] 3 6 15

2

ACC [0,01 m /s ] 5 80 200

2

DEC [0,01 m /s ] 5 80 200

*) Values are invisible after default setting

6.4.3 Vane parameter: <M> <3> <3>

Parameter min . Default (DF=6) max. Current

IPU DLY [mm] 0 120 *) 2600

IPD DLY [mm] 0 120 *) 2600

LV DLY UP [mm] 0 50 250

LV DLY DOWN [mm] 0 50 250

1 LS DLY [mm] 0 50 600

2 LS DLY [mm] 0 50 600

SLU DLY [mm] 0 50 *) 1600

SLD DLY [mm] 0 50 *) 1600

T_creep [10ms] 1 64 300

*) Values are invisible after default setting

Unpublished Work Copyright © OTIS Elevator Company

OTIS - OEC OVF20 CR Dwg : GCA21342C_CSU

Date : 2005-09-13

ENGINEERING CENTER

BERLIN Otis Variable Frequency Drive Page : 24/26

FSM Component Start up

Application with encoder

6.4.4 Start/stop parameter: <M> <3> <4>

Parameter min. Default (DF=6) max. Current

LFT BK DLY [10 ms] 0 0 999

PROF DLY [10 ms] 0 5 999

PRET FREQ [0,1 Hz] 0 2 100

NEG PRET [0,1 Hz] 0 0 100

PRET SLOPE 0 10 100

RMP DWN T2 [10 ms] 20 50 500

DRP BK DLY [10 ms] 20 45 500

EL HLT PER [10 ms] 0 20 500

DEMAG PER [10 ms] 2 5 500

ACC PRECTR 0 6 20

SLIP LOAD 0 60 250

6.4.5 Engineering parameter: <M> <3> <5>

6.4.5.1 Motor parameter: <M> <3> <5> <1>

Parameter min . Default (DF=6) max. Current

Mot Fnom [0,1 Hz] 250 500 600

Mot Vnom [V] 200 400 500

Mot Nnom [rpm] 80 1425 3600

6.4.5.2 Control parameter: <M> <3> <5> <2>

Parameter min. Default (DF=6) max. Current

N CTR: kp [%] 0 50 500

N CTR: Ti [10 ms] 5 10 50

N CTR: Td [10 ms] 0 10 100

SLIP LIMIT [% fn] 6 22 30

Red I1 Limit [%] 100 195 250

6.4.5.3 Voltage/frequency (V/f) parameter: <M> <3> <5> <3>

Parameter min. Default (DF=6) max. Current

Vstart [0,1 % Un ] 0 20 250

Vacc [0,1 % Un ] 500 1000 1600

Vslip [0,1 % Un ] 0 150 500

Unpublished Work Copyright © OTIS Elevator Company

OTIS - OEC OVF20 CR Dwg : GCA21342C_CSU

Date : 2005-09-13

ENGINEERING CENTER

BERLIN Otis Variable Frequency Drive Page : 25/26

FSM Component Start up

Application with encoder

6.5 Parameter description

6.5.1 Contract parameter: <M> <3> <1>

Parameter Description

Con Spe[0.01m/s] Defined contract speed of the unit

Example: for contract speed = 1,60m/s set Con Spe = 160

Con Nmot [rpm] Required motor r.p.m. to reach contract speed

Con Spe [0,01m/s]∗ gear ratio ∗ roping∗ 60

Con Nmot [rpm]=

sheavediameter[0,01]∗ ʌ

Mot Fnom [0.1Hz] Nominal motor frequency specified by motor name plate

Mot Nnom [rpm] Nominal asynchronous rpm specified by motor name plate

ENCODER PULSES Used encoder type (pre-defined):

Standard: incremental encoder with 1024 ppr and 2 traces

ENCODER TRACES 1: encoder with 1 trace

2: encoder with 2 traces

2LV avail One or two LV sensors used:

0: only 1LV is used

1: 1LV and 2LV are used (e.g. for RLEV)

DDP [s] DDP timeout value (set to default value of 20sec.)

Has to be increased according to contract speed and floor distance, if required.

CONTR TYPE 0: two speed AC, MS300, MCS310

1: MCS220 (M) – controller without coded interface

2: MCS220 (M) – controller with coded interface, without learn run,

4: MCS220 (M) – controller with coded interface, with learn run

TOP FLOOR Top position. Must match to OCSS system parameter "TOP".

Example: for a unit with 8 floors set TOP FLOOR = 7

BOTTOM FLOOR bottom position. Must match to OCSS system parameter "BOTTOM".

FLOORS IN 1LS Number of floors in 1LS (default = 1)

Exception: for 2 floors within 1LS area(e.g.short rise) set FLOORS IN 1LS = 2

BrakeSWtype used Brake switch type:

0: noneÆ no brake switch checking

1: 2xNC parallel Æ normally-closed contacts; wired in parallel

2: 2xM&B with.SW Æ make&break contacts with additional SW or BR contact

Chk I_Brake avai In case of special applications in modernization the measurement of the current

through the brake may not be available. The check of the brake current must then

be disabled by parameter.

Motor Dir [0/1] Change motor direction using the parameter value 0 or 1

Encoder Dir [0/1] Set the parameter value to 0 or 1 if encoder signals are reversed and shut down

occurred.

PowerSave D [min] When the drive is in IDLE mode for longer than a defined time, the DC Link is

diconnected from the main supply

Æ Delay time in [min] (A value of 0 or 255disables the power save mode)

The power save mode parameter on the LCB_II has no influence any more

Unpublished Work Copyright © OTIS Elevator Company

OTIS - OEC OVF20 CR Dwg : GCA21342C_CSU

Date : 2005-09-13

ENGINEERING CENTER

BERLIN Otis Variable Frequency Drive Page : 26/26

FSM Component Start up

Application with encoder

6.5.2 Profile Parameters: <M> <3> <2>

These parameters are set automatically to common values when parameter "Con Spe" has

been changed.

Parameter Description

INS SPE [0.01m/s] Speed at inspection run.

Example: for inspection run with 0,5m/s set INS SPE = 50

NOM SPE [0.01m/s] Nominal speed at constant run (normally set to "Con Spe").

Can be used to reduce nominal speed for test purposes.

Example: to run a 1,6m/s -unit at half speed set NOM SPE = 80

SHR SPE [0.01m/s] --- not used for this SW version ---

REL SPE [0.01m/s] Releveling speed. The releveling speed should be 2...3 [0.01m/s].

CRE SPE [0.01m/s] Creep speed. The creep speed should be 6...8 [0.01m/s]. Do not exceed

recommended max. value of 10.

ACC [0.01m/s^2] Acceleration rate. Can be decreased independently from nominal speed or

deceleration. Do not exceed recommended value of 80.

2

Example: for an acceleration rate of 0,5m/s set ACC = 50 [0.01m/s²]

DEC [0.01m/s^2] Deceleration rate. Can be decreased independently from nominal speed or

acceleration. Do not exceed recommended value of 80.

2

Example: for a deceleration rate of 0,5m/s set DEC = 50 [0.01m/s²]

Unpublished Work Copyright © OTIS Elevator Company

OTIS - OEC OVF20 CR Dwg : GCA21342C_CSU

Date : 2005-09-13

ENGINEERING CENTER

BERLIN Otis Variable Frequency Drive Page : 27/26

FSM Component Start up

Application with encoder

6.5.3 Vane parameter: <M> <3> <3>

Parameter Description

LV DLY UP [mm] Distance between the rising edge of the LV signal and the beginning of the profile

ramp down to stopping phase (in UP direction).

If LV1 and LV2 are used, the inner LV zone is used (both signals logically AND'ed).

The value is valid for all LV zones of the unit.

If the feature RLEV is used, LV DLY UP and LV DLY DOWN must be identical.

LV DLY DOWN Distance between the rising edge of the LV signal and the beginning of the profile

[mm] ramp down to stopping phase (in DOWN direction).

If LV1 and LV2 are used, the inner LV zone is used (both signals logically AND'ed).

The value is valid for all LV zones of the unit.

If the feature RLEV is used, LV DLY UP and LV DLY DOWN must be identical.

1LS DLY [mm] Delay of the hoistway switch 1LS.

If deceleration is initiated by 1LS a ”>” is displayed. The first normal run after an

inspection run is a correction run and the deceleration is initiated by 1LS.

Adjust 1LS DLY so that the creep time at a correction run is about 0.5 - 1 seconds.

The deceleration rate of a correction run is always the maximum one and

independent from the DEC value. Therefore 1LS DLY must not be modified after

changing the deceleration rate for a normal run.

2LS DLY [mm] Delay of the hoistway switch 2LS.

If deceleration is initiated by 2LS a ”>” is displayed. The first normal run after an

inspection run into 1LS is a correction run and the deceleration is initiated by 2LS.

Adjust 2LS DLY so that the creep time at a correction run is about 0.5 -1 seconds.

The deceleration rate of a correction run is always the maximum one and

independent from the DEC value. Therefore 2LS DLY must not be modified after

changing the deceleration rate for a normal run.

T_creep[10ms] Creep time for normal runs (not initiated by 1LS / 2LS).

The actual creep time is faded into the SVT display for easier adjusting. Min.- and

Max.- values are logged in SVT Menu DATALOG (M-2-5).

To avoid the error MLS : < Dec Dist, the minimum values of the creep time should be

20 to 30 [*10ms].

6.5.4 Eng-Motor parameter: <M> <3> <5> <1>

The following parameters are set automatically by parameter "Motor Type" and cannot be

modified for pre-defined motor types:

Parameter Description

Mot Fnom [0.1Hz] Nominal motor frequency specified by motor name plate

Mot Vnom [V] Nominal phase-to-phase voltage specified by motor name plate *)

Mot Nnom [rpm] Nominal asynchronous rpm specified by motor name plate

Unpublished Work Copyright © OTIS Elevator Company

You might also like

- IM - TEC.032.EN - Rev.2 - MM13 CONTROL CABINETDocument30 pagesIM - TEC.032.EN - Rev.2 - MM13 CONTROL CABINETMustafaNo ratings yet

- Ovf20 CR: Repair Instructions ServiceDocument7 pagesOvf20 CR: Repair Instructions ServiceMatti HynniNo ratings yet

- D10C607 KLB KLF Electric Operation Guide of - Without InvertorDocument42 pagesD10C607 KLB KLF Electric Operation Guide of - Without InvertorHabibulla Bavaji100% (2)

- ZXK 1200 Ascensor Hidrocableado Chino - User Manual (Hydraulic Drive System)Document24 pagesZXK 1200 Ascensor Hidrocableado Chino - User Manual (Hydraulic Drive System)BrianEstebanNo ratings yet

- ME320L N Elevator Specialized Inverter User Manual PDFDocument132 pagesME320L N Elevator Specialized Inverter User Manual PDFMAG.NET TechnicNo ratings yet

- AMC 528 V8: User'S Manual And Technical Specification GSM 89864.4000МЕDocument23 pagesAMC 528 V8: User'S Manual And Technical Specification GSM 89864.4000МЕAbenether Bekele100% (1)

- ENG LiSA20-Fehlermeldungen R111Document36 pagesENG LiSA20-Fehlermeldungen R111Adarsh Manoharan100% (1)

- Dielro 101 EsDocument50 pagesDielro 101 Eschiki_0No ratings yet

- Nova Ev3200 ManualDocument25 pagesNova Ev3200 ManualCarolina Sansón100% (1)

- Full Color 7" TFT Display Module For LiftsDocument8 pagesFull Color 7" TFT Display Module For LiftsMahran MastouriNo ratings yet

- D10D622 Drive CircutDocument31 pagesD10D622 Drive CircutVertec Engineering0% (1)

- OTIS (Instruction Manual For TOMCB Converter Board)Document26 pagesOTIS (Instruction Manual For TOMCB Converter Board)Ariel LeonNo ratings yet

- Network Commands Cheat SheetDocument4 pagesNetwork Commands Cheat SheetSteve NewshamNo ratings yet

- The UML-51 / ELV-5R: Advance Elevator ControllerDocument25 pagesThe UML-51 / ELV-5R: Advance Elevator ControllerCristian Millan100% (1)

- GBA 26800 H III Service Handling PDFDocument15 pagesGBA 26800 H III Service Handling PDFKopi HitamNo ratings yet

- Control electronic door operator C4T in 40 charactersDocument2 pagesControl electronic door operator C4T in 40 charactersAnonymous 0QeJ6DxMaKNo ratings yet

- IRIS_NV Control Panel OverviewDocument20 pagesIRIS_NV Control Panel OverviewHeiner HidalgoNo ratings yet

- GAA 24350 AW11 IVa PDFDocument31 pagesGAA 24350 AW11 IVa PDFEvgeniyNo ratings yet

- Characteristics - Igtf Landing ArrangementDocument56 pagesCharacteristics - Igtf Landing ArrangementMAYESTON100% (1)

- Lift Control Board: English User ManualDocument89 pagesLift Control Board: English User ManualAbenetherNo ratings yet

- Manual of GAA21750AK3 Elevator Service Tool: WWW - Escalatorparts.cnDocument70 pagesManual of GAA21750AK3 Elevator Service Tool: WWW - Escalatorparts.cnDio ChanNo ratings yet

- C U H Máy Kéo Sigma OtisDocument45 pagesC U H Máy Kéo Sigma OtisQuang Pham DuyNo ratings yet

- 140VAT, OtisDocument12 pages140VAT, OtisRellim AugustoNo ratings yet

- Dbss - HSDD - Startup Routine: Field Component ManualDocument25 pagesDbss - HSDD - Startup Routine: Field Component ManualМихаил100% (1)

- LBII ParametrosDocument37 pagesLBII ParametrosPolinho Donacimento100% (1)

- Gba 26800 H II StartupDocument15 pagesGba 26800 H II StartupPeter100% (4)

- MicroZed-3.5 Operators Manual PDFDocument60 pagesMicroZed-3.5 Operators Manual PDFwasbac50% (2)

- Detecting door status and vehicle speed using microprocessorDocument11 pagesDetecting door status and vehicle speed using microprocessorPercy Flores AquiseNo ratings yet

- BLT MPK708CDocument185 pagesBLT MPK708CFabian Garrido100% (2)

- Elevator Control Module: User'SDocument9 pagesElevator Control Module: User'SjhfbtyNo ratings yet

- Memcom Emergency Telephone Wiring DiagramDocument10 pagesMemcom Emergency Telephone Wiring DiagramDrtesla100% (1)

- Dossier 6170 (1) .FR - enDocument48 pagesDossier 6170 (1) .FR - enSatheesh Rama100% (1)

- Main Control Board User ManualDocument15 pagesMain Control Board User Manualmohammedalathwary100% (1)

- ARL-500 UCM Test Instructions For Gearless Machines - enDocument2 pagesARL-500 UCM Test Instructions For Gearless Machines - enHenri KleineNo ratings yet

- Otis SigmaDocument56 pagesOtis SigmaSERIMER SAS100% (1)

- KYM08L电梯用户手册 ?? 14-4-15Document94 pagesKYM08L电梯用户手册 ?? 14-4-15enrique cortes100% (1)

- SLYCMA Door Operator - Ariane 3 Set Up Procedure 2 PDFDocument23 pagesSLYCMA Door Operator - Ariane 3 Set Up Procedure 2 PDFMickael BourdoiseauNo ratings yet

- Otis E411 Fault CodesDocument2 pagesOtis E411 Fault CodesAyra Elevator perkasaNo ratings yet

- DiSi (210) TroubleshootingDocument4 pagesDiSi (210) TroubleshootingFERNSNo ratings yet

- DCSS BD Service Tool Manual GAA31064AAA 2007-01-19 10417955481260589056Document42 pagesDCSS BD Service Tool Manual GAA31064AAA 2007-01-19 10417955481260589056Ace Noah SomintacNo ratings yet

- Solucion de Problemas Sigma Solon LD 1Document9 pagesSolucion de Problemas Sigma Solon LD 1Jms QuinteroNo ratings yet

- Gcs - Gecb: List of Installation ParametersDocument58 pagesGcs - Gecb: List of Installation ParametersAlexis Mauricio100% (1)

- MCS220-MCS120 parameters-GAA30082DAC InsDocument43 pagesMCS220-MCS120 parameters-GAA30082DAC InsCoil98No ratings yet

- Manual Guide For Thysseen Door Controller IMS-DS20P2B1540370583512Document14 pagesManual Guide For Thysseen Door Controller IMS-DS20P2B1540370583512aziz faizNo ratings yet

- FSD GAA30780EAN Feature and Set Up Description - 2015!05!28Document196 pagesFSD GAA30780EAN Feature and Set Up Description - 2015!05!28Nebyu GetachewNo ratings yet

- Lift Monitoring & Diagnostics: SystemDocument53 pagesLift Monitoring & Diagnostics: SystemMohd Abu AjajNo ratings yet

- Star-Up Lbii BD Component Start Up Gaa30163aaf - 2007!10!11Document17 pagesStar-Up Lbii BD Component Start Up Gaa30163aaf - 2007!10!11Polinho DonacimentoNo ratings yet

- Gcs - Gecb: Service Tool ManualDocument29 pagesGcs - Gecb: Service Tool ManualAju S NairNo ratings yet

- Manual Sigma BG221Document29 pagesManual Sigma BG221Quang Pham DuyNo ratings yet

- Esquema Electrico Acd2 ControllerDocument11 pagesEsquema Electrico Acd2 ControllerMoises PerelloNo ratings yet

- Canny Instalacion Mecanica Manual InglesDocument57 pagesCanny Instalacion Mecanica Manual InglesBeltran Héctor100% (1)

- RCBII RSL Parameters - 4767764251226047386845665916 PDFDocument67 pagesRCBII RSL Parameters - 4767764251226047386845665916 PDFBartz Santos0% (1)

- Hidral Uh DiagramasDocument4 pagesHidral Uh DiagramasSaul Castillo100% (1)

- BL2000 Elevator Control System Wiring DiagramDocument28 pagesBL2000 Elevator Control System Wiring DiagramAnderley Quintero100% (1)

- 3.CS.17 - SAR2 Manual Basico Instalacion en r0Document16 pages3.CS.17 - SAR2 Manual Basico Instalacion en r0tamineNo ratings yet

- MTELecoGO Pro-Eco H enDocument9 pagesMTELecoGO Pro-Eco H enRaja DuraiNo ratings yet

- 02 - Acd3 PCBDocument32 pages02 - Acd3 PCBRenee Carranza100% (1)

- Manual DiagPC ENGDocument66 pagesManual DiagPC ENGZurab ChanturiaNo ratings yet

- Semiconductor Technical Data: Pinout: 20-Lead (Top View)Document9 pagesSemiconductor Technical Data: Pinout: 20-Lead (Top View)Juan Carlos MartinezNo ratings yet

- Tqm-221105-c - 220kw Tech & Drawing(Tradeone)Document2 pagesTqm-221105-c - 220kw Tech & Drawing(Tradeone)Louie FernandezNo ratings yet

- The El Door Controller Operating Manual PDFDocument13 pagesThe El Door Controller Operating Manual PDFEduardoNo ratings yet

- Philippine Revolution 02Document32 pagesPhilippine Revolution 02Lexi LoreNo ratings yet

- Secrets of The Holy MountainDocument85 pagesSecrets of The Holy MountainCalhounNo ratings yet

- 3 AAPP005-4-2 AssignmentDocument12 pages3 AAPP005-4-2 AssignmentYasmine YousNo ratings yet

- Delivering An Informative SpeechDocument14 pagesDelivering An Informative SpeechMapi ChiriNo ratings yet

- SMC6000 HMDocument33 pagesSMC6000 HMNo KidderNo ratings yet

- Direct and Indirect SpeechDocument6 pagesDirect and Indirect SpeechNata RudNo ratings yet

- Pismeni 7. Razred Sedam PrimerakaDocument1 pagePismeni 7. Razred Sedam PrimerakaDarko NesicNo ratings yet

- ADA Programming LanguageDocument2 pagesADA Programming LanguageLakshmi N SureshNo ratings yet

- TM103 Chapter 2Document66 pagesTM103 Chapter 2johnnader1254No ratings yet

- B2 UNIT 3 Test StandardDocument8 pagesB2 UNIT 3 Test Standardhi100% (1)

- Integrating Snort and OSSIMDocument7 pagesIntegrating Snort and OSSIMMarcelo LaurentiNo ratings yet

- Maximum Mark: 80: Cambridge International General Certificate of Secondary Education (9-1)Document10 pagesMaximum Mark: 80: Cambridge International General Certificate of Secondary Education (9-1)anduNo ratings yet

- English4 ST4 Q3Document3 pagesEnglish4 ST4 Q3BELLA V. TADEONo ratings yet

- Learn alphabetical order with practice word listsDocument1 pageLearn alphabetical order with practice word listsJen MatundingNo ratings yet

- Mechanical (Production)Document13 pagesMechanical (Production)Lovejinder KaurNo ratings yet

- SALE JA GEC 6 W6 2T Assessment 1Document3 pagesSALE JA GEC 6 W6 2T Assessment 1Jay AnnNo ratings yet

- Vocabulary Words Kate L. MacabalosDocument18 pagesVocabulary Words Kate L. MacabalosTrisha Faye SagadalNo ratings yet

- How to Add Output Variables and Diagnostics to WRF Using the RegistryDocument62 pagesHow to Add Output Variables and Diagnostics to WRF Using the RegistryPutu Agus Dedy PermanaNo ratings yet

- Computer Networks 4th ClassDocument14 pagesComputer Networks 4th ClassShubham SinghNo ratings yet

- Intermediate Quick Check Test 7A: GrammarDocument1 pageIntermediate Quick Check Test 7A: GrammarTeo TeoNo ratings yet

- The Powerful TeacherDocument58 pagesThe Powerful Teacherrachael92% (12)

- Tutorial 2Document1 pageTutorial 2gunjan ranabhattNo ratings yet

- Unit III Knowledge, Reasoning and PlanningDocument99 pagesUnit III Knowledge, Reasoning and PlanningPallavi BhartiNo ratings yet

- EE124 Sessional IDocument2 pagesEE124 Sessional IkishorebabNo ratings yet

- Keyboard shortcuts tableDocument15 pagesKeyboard shortcuts tableDragan ObucinaNo ratings yet

- Checklist For Code ReviewsDocument2 pagesChecklist For Code ReviewsNoni NabraNo ratings yet

- I. Fill in The Correct Form of The Verb Given. 30 P: NAMEDocument2 pagesI. Fill in The Correct Form of The Verb Given. 30 P: NAMEIoana MandikNo ratings yet

- Region Bangsamoro Armm Bshm-21202Document94 pagesRegion Bangsamoro Armm Bshm-21202Michael Angelo D. RubicNo ratings yet

- (MAA 1.8) METHODS OF PROOF - EcoDocument4 pages(MAA 1.8) METHODS OF PROOF - EcoAarishiNo ratings yet