Professional Documents

Culture Documents

Material Properties:: Design of Concrete Beam

Material Properties:: Design of Concrete Beam

Uploaded by

Mark Christian EsguerraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Material Properties:: Design of Concrete Beam

Material Properties:: Design of Concrete Beam

Uploaded by

Mark Christian EsguerraCopyright:

Available Formats

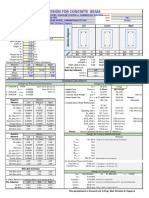

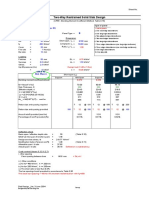

Project Name: - Design by: -

Owner: - Mark: B1

Location: - Date: 10/02/2022

Check by: Mark Christian D. Esguerra

DESIGN OF CONCRETE BEAM Structural Excell Program

Material Properties: Left Mid Right

Concrete f'c = 20.7 MPa

Reinforcing fy = 414 MPa

Stirrup fy = 276 MPa

Beam Data

Span type = Both ends continuous

Span Length = 4m

width, b = 0.2 m

height, h = 0.4 m

flexure bar Ø = 16 mm

shear bar Ø = 10 mm Layer 1 = 3 Layer 1 = 3 Layer 1 = 3

Torsion bar Ø = 16 mm Layer 2 = 2 5 pcs Layer 2 = 0 3 pcs Layer 2 = 2 5 pcs

Top

Top

Top

Layer 3 = 0 Layer 3 = 0 Layer 3 = 0

Stress Result (Any FEA or Frame Analysis)

Ratio = 0.558 Ratio = 0.193 Ratio = 0.59

Moment Left Mid Right

Layer 1 = 3 Layer 1 = 3 Layer 1 = 3

TB [kN-m] 58.47 13.24 61.81

Layer 2 = 0 3 pcs Layer 2 = 2 5 pcs Layer 2 = 0 3 pcs

Bot

Bot

Bot

BB [kN-m] 16.49 23.54 11.45

Layer 3 = 0 Layer 3 = 0 Layer 3 = 0

Left Mid Right Ratio = 0.24 Ratio = 0.225 Ratio = 0.167

Shear 57.04 0 59.45 ● Check Minimum Depth of Beam

Torsion 0.02 0 0.02 Depth = 0.19 Depth use is ok Table 9.3.1.1

4xDepth = 1.36 Depth use is ok Sec. 18.6.2.1a

ServiceMoment 37.86 15.44 40.79 Width (200 or 0.3h) = 0.2 Width use is ok Sec. 18.6.2.1b

SUMMARY CALCULATIONS

Design for Flexural Reinforcement Design for Stirrups

Used Maximum Vu = 59.45 kN Legs = 2

Top Moment Left Mid Right

The Beam Section is Adequate

Mu (kN.m) = 58.47 13.24 61.81

Distance = @50mm @2●Height

β1 value = 0.85 0.85 0.85

Applied Force, Vu = 57.22 kN 34.33 kN

Remarks = Doubly! Doubly! Doubly! Sec. 9.6.3.1

Concrete Strength, φVc= 38.67 kN 38.67 kN

ρmax = 0.0224 0.01291 0.0224

Concrete Strength, Vs max= 154.69 kN 154.69 kN

ρmin = 0.00338 0.00224 0.00338

Vmax = 193.36 kN 193.36 kN

ρused = 0.01542 0.00882 0.01542

● Compute Area Reinforcement

Reduction Fac = 0.9 0.9 0.9

Vs = 24.73 kN 0 kN

Neutral Axis = 95.5 76.8 95.5

Vs = 103.13 kN 103.13 kN

a= 81.17 65.28 81.17 Table 9.7.6.2.2

Spacing_max = 170 mm 170 mm Table 9.7.6.2.2

Tensile Strain = 0.0072 0.0104 0.0072

Av_used = 157.08 mm² 157.08 mm²

ΦMn (kN.m) = 104.84 68.71 104.84

Av/S_req = 0.26 mm²/m 0 mm²/m

Av/S_min1 = 204.41 mm²/m 204.41 mm²/m

Table 9.6.3.3a

Bot Moment Left Mid Right Av/S_min2 = 253.62 mm²/m 253.62 mm²/m

Table 9.6.3.3b

Mu (kN.m) = 16.49 23.54 11.45 Av/S_used = 263.54 mm²/m 253.62 mm²/m

β1 value = 0.85 0.85 0.85 S_req = 596.04 mm 619.34 mm

Remarks = Doubly! Doubly! Doubly! S_used = 100 mm 150 mm

ρmax = 0.01291 0.0224 0.01291 10mm : 1@50mm 10@100mm 5@150mm REST @ 250mm O.C. TO C.L.

ρmin = 0.00279 0.00338 0.00194

Design for Torsion Reinforcements

ρused = 0.00882 0.01542 0.00882

Tc = 1.52 < 0.02 kN-m, not to be considered!

Reduction Fac = 0.9 0.9 0.9

Total(Av+t)= 0.81 <= Av+t(prov) = 157.08 mm², O.K.

Neutral Axis = 76.8 95.5 76.8

Total(Av+t)min= 38.04 <= Av+t(prov) = 157.08 mm², O.K.

a= 65.28 81.17 65.28

Tensile Strain = 0.0104 0.0072 0.0104

ΦMn (kN.m) = 68.71 104.84 68.71

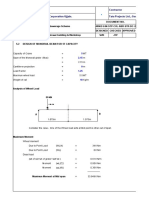

● Check Minimum according to Sec. 18.6.3

a.) 1. Least 2 at both top and bot

2. Min bar 1 (0.25*√fc)*bd/fy

2 1.4*bd/fy

3. Max bar 9 0.025*bd

b.) Positive moment at joint face shall be at least one half the negative ...

Design for Crack Control Exposure Condition = Dry Air or with Protective Membrane/ Coating

Left Mid Right

Mcr = 15.04 kN-m 15.04 kN-m 15.04 kN-m

Remark = Beam is cracking! Beam is cracking! Beam is cracking!

Crack Width = 0.357 mm 0.357 mm 0.146 mm

Table 4.1 = Crack width is ok Crack width is ok Crack width is ok

Table 4.2 = Since dt = 16mm > 10mm, ok! Since dt = 16mm > 10mm, ok! Since dt = 16mm < 32mm, ok!

Table 4.3 = Since S = 50mm < 50mm, ok! Since S = 50mm < 50mm, ok! Since S = 100mm < 300mm, ok!

You might also like

- Lab Report (Archimedes's Principle)Document3 pagesLab Report (Archimedes's Principle)Inderjit Singh100% (1)

- Hollow Pot Slabs DesignDocument4 pagesHollow Pot Slabs Designchris100% (4)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Material Properties:: Design of Concrete BeamDocument1 pageMaterial Properties:: Design of Concrete Beamking taugNo ratings yet

- Material Properties:: Design of Concrete BeamDocument4 pagesMaterial Properties:: Design of Concrete Beamaljer misoNo ratings yet

- Material Properties:: Design of Concrete BeamDocument4 pagesMaterial Properties:: Design of Concrete BeamRBV DESIGN & BUILD SERVICESNo ratings yet

- Material Properties:: Design of Concrete BeamDocument16 pagesMaterial Properties:: Design of Concrete BeamVerna Balang MartinezNo ratings yet

- Material Properties:: Design of Concrete BeamDocument1 pageMaterial Properties:: Design of Concrete BeamRBV DESIGN & BUILD SERVICESNo ratings yet

- Material Properties:: Design of Concrete BeamDocument4 pagesMaterial Properties:: Design of Concrete BeamRBV DESIGN & BUILD SERVICESNo ratings yet

- Material Properties: Reinforcement Details: Design of Concrete BeamDocument1 pageMaterial Properties: Reinforcement Details: Design of Concrete BeamNick OperarioNo ratings yet

- Roof BeamDocument7 pagesRoof BeamNick OperarioNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- 5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesDocument1 page5CD2 - E439 - 91C0 - 4CB4.: Material PropertiesMark Christian EsguerraNo ratings yet

- Design of BeamDocument1 pageDesign of Beampobre3nga3bataNo ratings yet

- PCC Tow Wall Type 1 - Height 0.8mDocument6 pagesPCC Tow Wall Type 1 - Height 0.8mPrabha KaranNo ratings yet

- Struc Ex Pro Rectangular Beam Design CalculationDocument1 pageStruc Ex Pro Rectangular Beam Design Calculationpobre3nga3bataNo ratings yet

- Elevator Wall 1Document588 pagesElevator Wall 1kanokoNo ratings yet

- One Way Continuous SlabDocument12 pagesOne Way Continuous Slabvenkatesh19701No ratings yet

- Design of Slabs: Input DataDocument6 pagesDesign of Slabs: Input Datagewegw3gNo ratings yet

- Slab Design (Pillai & Menon) (Ex 11.1)Document2 pagesSlab Design (Pillai & Menon) (Ex 11.1)Md Ghani HaiderNo ratings yet

- Bearing Capacity Calculation Shallow Found - FinalDocument2 pagesBearing Capacity Calculation Shallow Found - Finalabcd efghNo ratings yet

- ACI 318 08 Design of Retaining Wall With Counterfort Rev1Document3 pagesACI 318 08 Design of Retaining Wall With Counterfort Rev1januarto jamadiNo ratings yet

- Desige of Long Column: Input Data: Out of Plan (B)Document25 pagesDesige of Long Column: Input Data: Out of Plan (B)bra22222No ratings yet

- Design of Two-Way SlabDocument1 pageDesign of Two-Way Slabpobre3nga3bataNo ratings yet

- Slab Design OriginalDocument4 pagesSlab Design Originalsyed kashif pervezNo ratings yet

- Chequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaDocument1 pageChequer Platform-Flat Bar Design - L 1.112m - SDL 10kpaGOHNo ratings yet

- NSCP 2015 TrainingDocument30 pagesNSCP 2015 TrainingGhiovani DayananNo ratings yet

- Concrete Steel: Selected Design Case: 2Document25 pagesConcrete Steel: Selected Design Case: 2venu manikantaNo ratings yet

- Block AB Mezzanine FloorDocument5 pagesBlock AB Mezzanine FloorYuvarasuNo ratings yet

- SSE Sub-Frame Analysisv1 - 07 - F1 - 20211109 - 2238 - 11Document1 pageSSE Sub-Frame Analysisv1 - 07 - F1 - 20211109 - 2238 - 11SES DESIGNNo ratings yet

- Strap Beam FootingDocument6 pagesStrap Beam FootingBinod Raj GiriNo ratings yet

- common design parameters: Strength Ratio, m= 17.39 0.85 0.0034 0.0289 0.0209 24870.062324 3.7040518355 n= 8 Factor, β = ρ = ρ = ρ = E = f =Document8 pagescommon design parameters: Strength Ratio, m= 17.39 0.85 0.0034 0.0289 0.0209 24870.062324 3.7040518355 n= 8 Factor, β = ρ = ρ = ρ = E = f =ramel sigueNo ratings yet

- Column Design 1Document9 pagesColumn Design 1shamen amarasekaraNo ratings yet

- Slab Analysis: Gato, Jocelyn BSCE-IVBDocument24 pagesSlab Analysis: Gato, Jocelyn BSCE-IVBjoanNo ratings yet

- 3.S5 and S6 (3rdFlr and 2ndFlr)Document15 pages3.S5 and S6 (3rdFlr and 2ndFlr)Dolci ConstNo ratings yet

- Column Design With ExcelDocument47 pagesColumn Design With ExcelMatiur Rahman BasumNo ratings yet

- CE 806-3 (Slab Analysis)Document15 pagesCE 806-3 (Slab Analysis)Md. Nahid HossainNo ratings yet

- Lorai (Foundation Program)Document15 pagesLorai (Foundation Program)Loremae Masong JusgaNo ratings yet

- SSE Circular Column Designer - EC2v1 - 07 - C15 - 20211109 - 0009 - 54Document9 pagesSSE Circular Column Designer - EC2v1 - 07 - C15 - 20211109 - 0009 - 54SES DESIGNNo ratings yet

- Client Contractor Ujjain Municipal Corporation-Ujjain. Tata Projects Ltd.,-SecunderabadDocument32 pagesClient Contractor Ujjain Municipal Corporation-Ujjain. Tata Projects Ltd.,-Secunderabadepe civil1No ratings yet

- Design Calculation: Base Pressure OkayDocument2 pagesDesign Calculation: Base Pressure Okaymassive85No ratings yet

- PEDESTAL - P1 - VlookupDocument4 pagesPEDESTAL - P1 - Vlookupraghav abudhabiNo ratings yet

- Under Ground SumpDocument7 pagesUnder Ground SumpMariappan .PNo ratings yet

- Concentric Foundation Revised 2.15Document5 pagesConcentric Foundation Revised 2.15Eldho GeorgeNo ratings yet

- Seismic EvalDocument32 pagesSeismic EvalNick OperarioNo ratings yet

- Continious Beam Design Refer Name of Beam B3 & B4 Continuous Beam AnalysisDocument4 pagesContinious Beam Design Refer Name of Beam B3 & B4 Continuous Beam AnalysisfarithNo ratings yet

- Column Design CalculationsDocument7 pagesColumn Design CalculationsArnold VercelesNo ratings yet

- Jacking Pad DesignDocument3 pagesJacking Pad DesignAmarjit KulkarniNo ratings yet

- FC' 20.68 Mpa Cement Finish 1.53 Kpa Ceiling Suspended Loads 0.48 Kpa Fy 230.00 MpaDocument19 pagesFC' 20.68 Mpa Cement Finish 1.53 Kpa Ceiling Suspended Loads 0.48 Kpa Fy 230.00 Mparamel sigueNo ratings yet

- Flat Slab 6 X 6 Ext PNLDocument5 pagesFlat Slab 6 X 6 Ext PNLDarshan Shah100% (1)

- TRIPLE BOX 511 Cush 1mDocument18 pagesTRIPLE BOX 511 Cush 1mAmit SinghNo ratings yet

- Design of Cantilever SlabDocument2 pagesDesign of Cantilever SlabChidambaram SethumahadevanNo ratings yet

- SSE Sub-Frame Gravity Analysis Sse-Excel-Section: The Auther Will Not Be Responsible For Any Uses of This Software!Document1 pageSSE Sub-Frame Gravity Analysis Sse-Excel-Section: The Auther Will Not Be Responsible For Any Uses of This Software!SES DESIGNNo ratings yet

- Camber by Coefficients of Pci-Bridge Design ManualDocument4 pagesCamber by Coefficients of Pci-Bridge Design ManualFAIZAN AHMED100% (1)

- common design parameters: Strength Ratio, m= 17.39 0.85 0.0034 0.0289 0.0209 24870.062324 3.7040518355 n= 8 Factor, β = ρ = ρ = ρ = E = f =Document9 pagescommon design parameters: Strength Ratio, m= 17.39 0.85 0.0034 0.0289 0.0209 24870.062324 3.7040518355 n= 8 Factor, β = ρ = ρ = ρ = E = f =ramel sigueNo ratings yet

- Top LVL of Landing SlabDocument3 pagesTop LVL of Landing SlabMuhammad HasanNo ratings yet

- 2 Cell Box CulvertDocument22 pages2 Cell Box Culvertabhijeet sahuNo ratings yet

- SlabDocument621 pagesSlabkanokoNo ratings yet

- (From Is 875-Part 3) : Pxl/AwDocument2 pages(From Is 875-Part 3) : Pxl/AwSantosh BapuNo ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Mpa M # Mpa M M M M M Kpa Kn/M3 M M Exterior: Engr. Mark Christian D. EsguerraDocument2 pagesMpa M # Mpa M M M M M Kpa Kn/M3 M M Exterior: Engr. Mark Christian D. EsguerraMark Christian EsguerraNo ratings yet

- RB1 1Document1 pageRB1 1Mark Christian EsguerraNo ratings yet

- Structual Plan 2-Storey ResidentialDocument9 pagesStructual Plan 2-Storey ResidentialMark Christian EsguerraNo ratings yet

- Second Floor PlanDocument1 pageSecond Floor PlanMark Christian EsguerraNo ratings yet

- PlanDocument8 pagesPlanMark Christian EsguerraNo ratings yet

- SlabDocument4 pagesSlabMark Christian EsguerraNo ratings yet

- Material Properties Reinforcement Details: Design of Concrete ColumnDocument1 pageMaterial Properties Reinforcement Details: Design of Concrete ColumnMark Christian EsguerraNo ratings yet

- Ground Floor PlanDocument1 pageGround Floor PlanMark Christian EsguerraNo ratings yet

- Introduction To Design of Steel Strucutres: Lecturer: Mark Christian D. Esguerra, MSCE-SE CandidateDocument20 pagesIntroduction To Design of Steel Strucutres: Lecturer: Mark Christian D. Esguerra, MSCE-SE CandidateMark Christian EsguerraNo ratings yet

- Ultimate Strength Design (Usd) : Lecturer: Mark Christian D. Esguerra, MSCE-SE CandidateDocument18 pagesUltimate Strength Design (Usd) : Lecturer: Mark Christian D. Esguerra, MSCE-SE CandidateMark Christian EsguerraNo ratings yet

- Material Properties Reinforcement Details: Design of Concrete Column Seismic DetailingDocument1 pageMaterial Properties Reinforcement Details: Design of Concrete Column Seismic DetailingMark Christian EsguerraNo ratings yet

- Material Properties Reinforcement Details: Design of Concrete ColumnDocument1 pageMaterial Properties Reinforcement Details: Design of Concrete ColumnMark Christian EsguerraNo ratings yet

- Introduction To Concrete & Reinforced Concrete: Lecturer: Mark Christian D. Esguerra, MSCE-SE CandidateDocument42 pagesIntroduction To Concrete & Reinforced Concrete: Lecturer: Mark Christian D. Esguerra, MSCE-SE CandidateMark Christian EsguerraNo ratings yet

- Environmental Characteristics of HVDC Overhead TransmissionDocument10 pagesEnvironmental Characteristics of HVDC Overhead TransmissionPrazetyo Adi NugrohoNo ratings yet

- Proceedings of The Institute of AcousticsDocument11 pagesProceedings of The Institute of AcousticsdanielcristobalNo ratings yet

- Water Stability - What Does It Mean and How Do You Measure It ?Document9 pagesWater Stability - What Does It Mean and How Do You Measure It ?Richard EscueNo ratings yet

- Practice Questions Lecture 35 To 45 With SolutionDocument7 pagesPractice Questions Lecture 35 To 45 With SolutionlordjjNo ratings yet

- Assembly DrawingsDocument12 pagesAssembly DrawingsThangadurai Senthil Ram PrabhuNo ratings yet

- Wireless Electro OsmosisDocument6 pagesWireless Electro Osmosishyu2123No ratings yet

- Using Bellville Springs To Maintain Bolt PreloadDocument30 pagesUsing Bellville Springs To Maintain Bolt PreloadsulemankhalidNo ratings yet

- General Science Physics Laws in TamilDocument2 pagesGeneral Science Physics Laws in TamilKavi Yarasu JM100% (3)

- Control of Nuclear Gloveboxes and Enclosures Using The No-Moving-Part Vortex Amplifier (VXA)Document11 pagesControl of Nuclear Gloveboxes and Enclosures Using The No-Moving-Part Vortex Amplifier (VXA)Dennis ChanNo ratings yet

- UnitsDocument206 pagesUnitsSomya Shukla100% (3)

- Science 7 q3Document8 pagesScience 7 q3cattleya abelloNo ratings yet

- Aerodynamics of Paper AirplanesDocument16 pagesAerodynamics of Paper AirplanesBrindleSmith111No ratings yet

- Econometrics Chapter 1 UNAVDocument38 pagesEconometrics Chapter 1 UNAVRachael VazquezNo ratings yet

- Curtain Wall With HZ & VL Louvers Structural Calculation For Building a-PART (6) at AXIS (34-42) - A'Document59 pagesCurtain Wall With HZ & VL Louvers Structural Calculation For Building a-PART (6) at AXIS (34-42) - A'نصر عبدالسلامNo ratings yet

- 12419+Vivid+E9+TransGuide v3Document4 pages12419+Vivid+E9+TransGuide v3rafaelortizgesmNo ratings yet

- Plastic Analysis of Beams: CEE 201L. Uncertainty, Design, and OptimizationDocument6 pagesPlastic Analysis of Beams: CEE 201L. Uncertainty, Design, and OptimizationYacoub CheikhNo ratings yet

- The Polynomials AssignmentDocument3 pagesThe Polynomials AssignmentMarc LambertNo ratings yet

- New-Problems-Chapter-21 Convective Mass TransferDocument2 pagesNew-Problems-Chapter-21 Convective Mass TransferKhanh NhiNo ratings yet

- CSIR-NET Lifes Sciences (LSA Gwalior) PDFDocument669 pagesCSIR-NET Lifes Sciences (LSA Gwalior) PDFDr-Priyanka AgarwalNo ratings yet

- C2 Foundation Revision Questions - Sets 3,4&5Document45 pagesC2 Foundation Revision Questions - Sets 3,4&5madhujayanNo ratings yet

- Resimold Resiglas CRT DryType CommercialBrochure enDocument12 pagesResimold Resiglas CRT DryType CommercialBrochure engreyllom9791No ratings yet

- Choked Flow of FluidsDocument4 pagesChoked Flow of FluidsGnana Subramanian ArumugamNo ratings yet

- Common Questions in Thesis Proposal DefenseDocument7 pagesCommon Questions in Thesis Proposal Defensebrendapotterreno100% (2)

- Renderoc LaxtraDocument2 pagesRenderoc LaxtraBalasubramanian AnanthNo ratings yet

- Haloareans and Halo AlkanesDocument23 pagesHaloareans and Halo Alkanesthinkiit100% (1)

- 01 Exercise 1 FORM 1Document20 pages01 Exercise 1 FORM 1Jiang ZhongWanNo ratings yet

- CEMS GuidlinesDocument94 pagesCEMS GuidlinesBiohm ConsultareNo ratings yet

- Line Sizing N2 Generator Package: Doc. No.Document23 pagesLine Sizing N2 Generator Package: Doc. No.Anonymous DHPrXHxhNo ratings yet