Professional Documents

Culture Documents

Chiller Inductor

Uploaded by

Alberto Steven Ospino GómezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chiller Inductor

Uploaded by

Alberto Steven Ospino GómezCopyright:

Available Formats

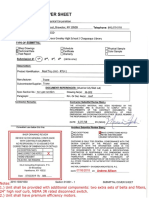

Design Conditions Datasheet

Net Cooling

Unit Tag Qty Model No Nominal Voltage Refrigerant Type

Capacity (ton.R)

CH-1 1 YLAA0041HE46XCBSXTX 38.88 460-3-60.0 R410A

PIN:

YLAA0041HE 46XCBSXTXA SXBLXCXX44 SE1XXXHXXX YAXGPXX7XX XXX1XXEXXX

....5...10 ....5...20 ....5...30 ....5...40 ....5...50 ....5...60 ....5...70 ....5...80 ....5...90

Evaporator Data Evaporator Data (Cont.) Performance Data

EWT (°F) 54.00 Fluid Volume (USGAL) 2.570 EER (Btu/W∙h) 11.45

LWT (°F) 44.00 Min. Flow Rate (USGPM) 16.00 IPLV.IP (Btu/W∙h) 17.40

NPLV.IP (Btu/W∙h) 17.30

Design Flow Rate (USGPM) 94.66 Max. Flow Rate (USGPM) 220.0

Evap. Press. Drop (ft H2O) 9.11

Propylene

Fluid

Glycol (%)

20 Condenser Data Physical Data

Strainer Press. Drop (ft H2O) 0.929 Ambient Temp. Design (°F) 95.0 Rigging Wt. (lb) 3796

Ext. Kit Press. Drop (ft H2O) 0.570 Altitude (ft) 0.000 Operating Wt. (lb) 3816

Total Press. Drop (ft H2O) 10.6 Compressor Type Scroll - Hermetic Refrigerant Charge (lb) 69.9

Fouling Factor (h.ft².F/Btu) 0.000100

Electrical Data

Circuit 1 2 3 4

Compressor RLA 18 / 18 18 / 18

Fan QTY/FLA (each) 2/4 2/4

High LRA Current 125 / 125 125 / 125

Single Point

Min. Circuit Ampacity 96

Recommended Fuse/CB Rating 110

Max. Inverse Time CB Rating 110

Max. Dual Element Fuse Size (A) 110 Operating Condition Electrical Data

Unit Short Circuit Withstand (STD) 5 [kA] Compressor kW 34.04

Wires Per Phase 1 Total Fan kW 6.720

Wire Range (Lug Size) #6 AWG - 500 kcmil Total kW 40.76

Starter Type Across The Line

Notes:

Certified in accordance with the AHRI Air-Cooled Water-Chilling Packages Certification Program,

which is based on AHRI Standard 550/590 (I-P) and AHRI Standard 551/591 (SI). Certified units

may be found in the AHRI Directory at www.ahridirectory.org.

Unit contains freeze protection fluids in the evaporator with a leaving chilled fluid temperature

above 32 DEG F [0 DEG C] and is certified when rated per the Standard with water. Auxiliary

components included in total KW - Oil heaters, Chiller controls. Auxiliary power is already included

in the compressor and fan power

ASHRAE Standard 90.1-2010 and ASHRAE Standard 90.1-2013 & 2016 Compliant.

Compliant with the requirements of the LEED Energy and Atmosphere Enhanced Refrigerant Management Credit (EAc4).

MLP Effective Date:4/15/2021 TUBO CARIBE

Generated on2021-06-11 E.21.1.26276.0-D.90.0042(REV. v8_25.idd) Datasheet Spec

Unit Folder: CH-1 Software Version: YW21.01b Page_1_of_2

Design Conditions Datasheet

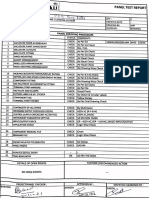

Part Load Rating Data

Unit Efficiency

Stage Ambient (°F) Capacity (ton.R) Total kW

(Btu/W∙h)

1 95.0 38.88 40.76 11.45

2 84.0 31.71 27.03 14.08

3 70.2 22.73 15.10 18.07

4 55.0 11.63 6.918 20.18

Sound Power Levels (In Accordance with AHRI 370)

Ambient 63 Hz 125 Hz 250 Hz 500 Hz 1 kHz 2 kHz 4 kHz 8 kHz

Stage LWA

(°F) (dB) (dB) (dB) (dB) (dB) (dB) (dB) (dB)

1 95.0 96 95 92 92 88 84 81 79 93

2 84.0 96 95 92 92 88 84 81 78 93

3 70.2 93 92 89 89 85 81 78 76 90

4 55.0 90 89 86 86 82 78 75 73 87

Note: Unit is equipped with Low Sound Fans.

Measurement of sound pressure used to obtain the sound power data presented is based on AHRI-370.

Air-cooled chillers are rated in terms of sound power not sound pressure. Johnson Controls provides estimates of sound pressure, but this is not the

rating metric.

For an air-cooled chiller, sound pressure calculated from sound power varies depending on how the chiller is assumed to behave, i.e. the radiation

model. In other words, determining sound pressure from sound power requires making assumptions that result in different answers at a given distance

from the chiller. The environment also influences sound pressure in the field installation. Sound pressure estimation radiation models pertaining to air-

cooled chillers include the ‘traditional’ hemispherical model, parallelepiped model and equivalent hemispherical model.

Regarding sound power, Johnson Controls references tolerance limits based on ASHRAE guidelines. These are +/- 6dB in the 63Hz octave band, +/-

4dB in all other octave bands and +/- 3dB for the overall dBA.

Tolerance limits are based on uncertainties associated with:

1. Measurement Test Procedure

2. Repeatability

3. Production / Manufacturing Variability

Standard deviation associated with air-cooled chiller sound data is a measure of spread i.e. it indicates the range of probability of sound levels. Note

that for operating conditions other than AHRI’s Standard Rating Condition, higher levels of uncertainty can be expected.

Lead times for factory performance testing depend on test laboratory availability. Please confirm with Johnson Controls Customer Service.

Performance at AHRI Conditions

Evaporator Data Condenser Data Performance Data

EWT (°F) 54.00 Ambient Temp. (°F) 95.0 EER (Btu/W∙h) 11.63

LWT (°F) 44.00 Altitude (ft) 0.000 IPLV.IP (Btu/W∙h) 17.40

Net Cooling Capacity

Flow Rate (USGPM) 94.45 39.57

(ton.R)

Pressure Drop (ft H2O) 7.64

Fluid Water

Fouling Factor (h.ft².F/Btu) 0.000100

Fluid Volume (USGAL) 2.570

Note: Unit rated at design condition capacity.

MLP Effective Date:4/15/2021 TUBO CARIBE

Generated on2021-06-11 E.21.1.26276.0-D.90.0042(REV. v8_25.idd) Datasheet Spec

Unit Folder: CH-1 Software Version: YW21.01b Page_2_of_2

You might also like

- YLAA0155SE46 DataSheetSpecDocument2 pagesYLAA0155SE46 DataSheetSpecgustavo olveraNo ratings yet

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument2 pagesDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeFernando CabreraNo ratings yet

- Air Cooled Screw Chiller Performance DatasheetDocument2 pagesAir Cooled Screw Chiller Performance DatasheetJuan Carlos Soto OrihuelaNo ratings yet

- Performance Chiller HG QueretaroDocument2 pagesPerformance Chiller HG QueretaroAntonio Chavez GarciaNo ratings yet

- YVAA0233 (MTY) at 95 F - DataSheetSpecDocument2 pagesYVAA0233 (MTY) at 95 F - DataSheetSpecMohammed EmamNo ratings yet

- DataSheetSpec YVFA0259Document2 pagesDataSheetSpec YVFA0259Jorge Antonio Díaz NambrardNo ratings yet

- YVAA0490 - DataSheetSpec. - Rev01pdfDocument2 pagesYVAA0490 - DataSheetSpec. - Rev01pdfMohamed AskarNo ratings yet

- Performance Chiller YVAA0263BGF40BAVDocument2 pagesPerformance Chiller YVAA0263BGF40BAVEnzo VizcardoNo ratings yet

- Design Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant TypeDocument3 pagesDesign Conditions Datasheet: Unit Tag Qty Model No Net Cooling Capacity (Ton.r) Nominal Voltage Refrigerant Typealf_haroNo ratings yet

- Air Cooled Screw Chiller Performance DatasheetDocument2 pagesAir Cooled Screw Chiller Performance DatasheetYosmar GuzmanNo ratings yet

- Air Cooled Screw Chiller Performance SpecificationDocument2 pagesAir Cooled Screw Chiller Performance SpecificationDajuko Butarbutar100% (1)

- Folha de Dados Do Chiller YVAA0270DUF28BAVBXXDocument3 pagesFolha de Dados Do Chiller YVAA0270DUF28BAVBXXAdler LinharesNo ratings yet

- Chiller 252 TRDocument2 pagesChiller 252 TRhector diazNo ratings yet

- Acds120 Chiller SpecsDocument8 pagesAcds120 Chiller SpecsitovelaNo ratings yet

- 425 TR - Chiller Data SheetSpecDocument2 pages425 TR - Chiller Data SheetSpecjohnsvjNo ratings yet

- Sales Report CEFTDocument3 pagesSales Report CEFTHemant Singh RajpootNo ratings yet

- Manual SiamDocument3 pagesManual SiamRicardoNo ratings yet

- Software Version: Date: YVWE Chiller Performance SpecificationDocument3 pagesSoftware Version: Date: YVWE Chiller Performance Specificationrega list100% (2)

- CRTAG - CRTAG-1 - Product ReportDocument2 pagesCRTAG - CRTAG-1 - Product ReportMohammed EmamNo ratings yet

- Chiller RATINGREPORTDocument3 pagesChiller RATINGREPORTv6656No ratings yet

- AVX-B Performance (Vertical Compressor)Document4 pagesAVX-B Performance (Vertical Compressor)Inzamam ShithilNo ratings yet

- YORK. YMC2-S1196AA PerformanceDocument2 pagesYORK. YMC2-S1196AA PerformanceMIGUELNo ratings yet

- Yvaa0490 Performance SheetDocument2 pagesYvaa0490 Performance Sheetkdpmansi0% (1)

- AVX-B & ACHX-B PerformanceDocument12 pagesAVX-B & ACHX-B PerformanceInzamam ShithilNo ratings yet

- Lats RS. Sardjito (R0)Document18 pagesLats RS. Sardjito (R0)agus abonNo ratings yet

- Datasheet H2930uabc MetricoDocument1 pageDatasheet H2930uabc MetricoRodrigo J. MarqueziniNo ratings yet

- Tag Model Location Qty: QN 21090714 Devine Mercy Hospital Bangladesh Daveen 9/30/21 2:18 PMDocument3 pagesTag Model Location Qty: QN 21090714 Devine Mercy Hospital Bangladesh Daveen 9/30/21 2:18 PMfakir mohammadNo ratings yet

- Part Load 10% - Ymc 450 TR Paralelo KW - TRDocument3 pagesPart Load 10% - Ymc 450 TR Paralelo KW - TRAdler LinharesNo ratings yet

- CRNQ 0500 CopelandDocument6 pagesCRNQ 0500 CopelandRivaldoNo ratings yet

- CL Rtu-1 MCNDocument18 pagesCL Rtu-1 MCNArq Javier Larios ArciniegaNo ratings yet

- TGZ Water Cooled Scroll ChillerDocument2 pagesTGZ Water Cooled Scroll ChillerFatiga jrNo ratings yet

- ZP31K5E PFV CompressorDocument8 pagesZP31K5E PFV CompressorAliNo ratings yet

- 13-2-2020revised Screw chiller-1502KWDocument4 pages13-2-2020revised Screw chiller-1502KWthilina lakhithaNo ratings yet

- NT 2178 GKDocument3 pagesNT 2178 GKAlla weerNo ratings yet

- DatasheetDocument3 pagesDatasheetCharles NaloNo ratings yet

- THG1365YLSDocument4 pagesTHG1365YLSRolando LopezNo ratings yet

- Sprezarka Embraco Aspera T2180GK Karta-ProduktuDocument4 pagesSprezarka Embraco Aspera T2180GK Karta-Produktucarlosmochima100% (1)

- EMU60CLP 220 V 60 HZ 1Document4 pagesEMU60CLP 220 V 60 HZ 1Jobson Lisboa FerreiraNo ratings yet

- Compressor Specifications - © Bristol Compressors International, IncDocument1 pageCompressor Specifications - © Bristol Compressors International, IncWall Art VenezuelaNo ratings yet

- ERTAF - ERTAF-2 maco-2 - Product ReportDocument2 pagesERTAF - ERTAF-2 maco-2 - Product ReportKaran GnaniNo ratings yet

- ACHX-B Performance (Horizontal Compressor)Document3 pagesACHX-B Performance (Horizontal Compressor)Inzamam ShithilNo ratings yet

- Submittal FCQ24MVJU - RZQ24MVJU 07-06 - DaikinDocument1 pageSubmittal FCQ24MVJU - RZQ24MVJU 07-06 - Daikinedward sabedraNo ratings yet

- YLAA Performance - W Q FansDocument2 pagesYLAA Performance - W Q FanssamersibaniNo ratings yet

- NJ9226E 208-230 V 60 HZ 1Document4 pagesNJ9226E 208-230 V 60 HZ 1Leonardo GiarolaNo ratings yet

- NEK2160U 220-240 V 50 HZ 1Document3 pagesNEK2160U 220-240 V 50 HZ 1ciprian ilieNo ratings yet

- FFU160HAX 220 V 60 HZ 1Document3 pagesFFU160HAX 220 V 60 HZ 1Amauri RogérioNo ratings yet

- Compressor Technical DataDocument3 pagesCompressor Technical DataGabriel RodriguezNo ratings yet

- Submittal FCQ36MVJU - RZQ36MVJU 07-06 - DaikinDocument1 pageSubmittal FCQ36MVJU - RZQ36MVJU 07-06 - Daikinedward sabedraNo ratings yet

- Jenbacher Combustion Air CoolingDocument10 pagesJenbacher Combustion Air CoolingAli AbbasiNo ratings yet

- Copeland-Cr42k6-Pfv-Recip-Compressor-Technical SpecificationsDocument1 pageCopeland-Cr42k6-Pfv-Recip-Compressor-Technical SpecificationscarlosmochimaNo ratings yet

- 30XA200Document3 pages30XA200Leonardo Martinho DobrianskyjNo ratings yet

- ERTWF - Screw Chiller Shockwave Product Report (Sao-Tam Giac)Document2 pagesERTWF - Screw Chiller Shockwave Product Report (Sao-Tam Giac)Vu Thieu TuanNo ratings yet

- 7 7 Embraco Compressor NEK2134GKDocument3 pages7 7 Embraco Compressor NEK2134GKMayteNo ratings yet

- EGAS80HLP 220 V 60 HZ 1Document4 pagesEGAS80HLP 220 V 60 HZ 1Daniel Avelar LinsNo ratings yet

- Digital Power Electronics and ApplicationsFrom EverandDigital Power Electronics and ApplicationsRating: 3.5 out of 5 stars3.5/5 (3)

- 8051 Microcontroller: An Applications Based IntroductionFrom Everand8051 Microcontroller: An Applications Based IntroductionRating: 5 out of 5 stars5/5 (6)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsFrom EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsRating: 3.5 out of 5 stars3.5/5 (6)

- Physics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSIFrom EverandPhysics and Technology of Crystalline Oxide Semiconductor CAAC-IGZO: Application to LSINo ratings yet

- Screw Jacks 0.25 Ton 250 TonDocument23 pagesScrew Jacks 0.25 Ton 250 TonAlberto Steven Ospino GómezNo ratings yet

- 150 72-Eg6Document68 pages150 72-Eg6ks aksNo ratings yet

- 1 s2.0 S0263786317300029 MainDocument12 pages1 s2.0 S0263786317300029 MainKiflom BirhaneNo ratings yet

- Valve Material EquivalentsDocument3 pagesValve Material EquivalentsAndre Villegas Romero100% (1)

- Etm Api 600 Trim Material PDFDocument1 pageEtm Api 600 Trim Material PDFbenabdallah131No ratings yet

- CAT 4135 CV CheckValves Dec2010Document60 pagesCAT 4135 CV CheckValves Dec2010Dragan LazicNo ratings yet

- Garlock GYLON Style 3500 Spec Sheet - (NA) 2016-12 ENDocument1 pageGarlock GYLON Style 3500 Spec Sheet - (NA) 2016-12 ENAlberto Steven Ospino GómezNo ratings yet

- Valvula Bola 1500 PsiDocument8 pagesValvula Bola 1500 PsibetojulioNo ratings yet

- HandrailDesign NAAM AMP 521-12 PDFDocument50 pagesHandrailDesign NAAM AMP 521-12 PDFfarhadmrt6923No ratings yet

- Acronal 5018Document1 pageAcronal 5018Paul ChendeNo ratings yet

- Techflow Bagfilter DrawingDocument23 pagesTechflow Bagfilter DrawingRahul KumarNo ratings yet

- Betopom Arastirma 2Document31 pagesBetopom Arastirma 2KvncGmz DzrNo ratings yet

- 138 Top Machine Design Question and AnswersDocument16 pages138 Top Machine Design Question and AnswersIlhariri Muhammad IrlisNo ratings yet

- Composite Steel Beam DesignDocument4 pagesComposite Steel Beam Designmagi100% (1)

- 39CQM A15 1PDDocument29 pages39CQM A15 1PDnhat100% (1)

- RV WU1348 Eldoret Mtungi Road - DesignDocument6 pagesRV WU1348 Eldoret Mtungi Road - DesignIKO NETWORKNo ratings yet

- Construction and Building Materials: Z. Makhloufi, T. Bouziani, M. Hadjoudja, M. BederinaDocument10 pagesConstruction and Building Materials: Z. Makhloufi, T. Bouziani, M. Hadjoudja, M. BederinaTarek ChikerNo ratings yet

- Product Catalogue Flexible Ducting: Serpent Underground Ventilation SystemDocument28 pagesProduct Catalogue Flexible Ducting: Serpent Underground Ventilation SystemRakeshNo ratings yet

- Austenitic stainless steels properties and welding guideDocument4 pagesAustenitic stainless steels properties and welding guideandy1036No ratings yet

- Mep Vendor ListDocument13 pagesMep Vendor ListAlaa Anwer100% (1)

- Internship Report on Construction of 10 Storey BuildingDocument17 pagesInternship Report on Construction of 10 Storey Building20135A0120 PINNIKA RAMESHNo ratings yet

- Architectural Design Estimates and ControlsDocument41 pagesArchitectural Design Estimates and ControlsAbanilla BLouieNo ratings yet

- SATIP-K-001-03 - HVAC Metal Duct System - Rev. 6Document3 pagesSATIP-K-001-03 - HVAC Metal Duct System - Rev. 6imrankhan220% (1)

- PCD324 - 2023 - Lesson - 2 - Part 2Document27 pagesPCD324 - 2023 - Lesson - 2 - Part 2Gatmin, Patrick M.No ratings yet

- Asme NDT StandardsDocument9 pagesAsme NDT Standardstbmari50% (6)

- TYPE A - Real Time Quiz End Semester Examination - ME331Document7 pagesTYPE A - Real Time Quiz End Semester Examination - ME331Selvi RNo ratings yet

- Ene 2018Document48 pagesEne 2018Cristian SNo ratings yet

- Astm F2787 09Document10 pagesAstm F2787 09dhruvikavinodNo ratings yet

- Piping Class SpecificationDocument6 pagesPiping Class Specificationcitra puspita sariNo ratings yet

- ASME B31.3 Pre Heat & PWHT PDFDocument4 pagesASME B31.3 Pre Heat & PWHT PDFGANGADHAR SAHUNo ratings yet

- Tle 7 - Q1 - Wk1-EditedDocument13 pagesTle 7 - Q1 - Wk1-EditedMichael Amores67% (3)

- Multi-Storey Building Analysis and DesignDocument5 pagesMulti-Storey Building Analysis and DesignSyed Azeem0% (1)

- Item 346 Block Valve - 3 SectionsDocument2 pagesItem 346 Block Valve - 3 SectionsAlexDorNo ratings yet

- Emerging Trends in Advancement of Formwork: March 2021Document14 pagesEmerging Trends in Advancement of Formwork: March 2021leovinNo ratings yet

- RTHD Series-CatalogueDocument40 pagesRTHD Series-CatalogueRobecal GeneralNo ratings yet

- BP220 NotesDocument83 pagesBP220 NotesSakura KinomotoNo ratings yet

- Di Ab An - SystemDocument8 pagesDi Ab An - SystemPranks9827653878No ratings yet

- Guide to Soot Blowers and Furnace Temperature ProbesDocument18 pagesGuide to Soot Blowers and Furnace Temperature Probesupt vadodaraNo ratings yet

- Hillerborg Strip MethodDocument28 pagesHillerborg Strip MethodKreen13271% (7)