Professional Documents

Culture Documents

Chapt9 - Settling of Discrete Particles - Type I Settling1

Uploaded by

dave tafadzwa kuyeriOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapt9 - Settling of Discrete Particles - Type I Settling1

Uploaded by

dave tafadzwa kuyeriCopyright:

Available Formats

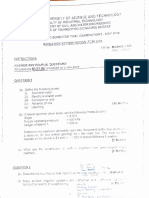

Cmutsvangwa: Water Quality and Treatment: Dept. Civil and Water Eng.

, NUST, 01/10/2013

Type settling (Discrete particles)

Settling in an ideal settling basin for type 1 particles

An ideal horizontal settling zone is free from inlet and outlet disturbance, in which

particles settle freely at terminal settling velocities in quiescent conditions without

any disturbances and flocculation is absent (Fig. 1). The particles are distributed

uniformly

In the design of sedimentation basins, the usual procedure is to select a particle

with a terminal velocity vs and to design the basin so that all the particles that

have a terminal velocity equal to or greater than vs will be removed.

Q Av s

(1)

Where: A =surface area of sedimentation basin

Q

vs =settling velocity or surface loading, m3/m2.day ( v s )

A

D

Outlet

Inlet vp zone

zone

Particle trajectory vs

h

vp

Settling zone

Fig. 1 Type I settling in a horizontal basin

Design velocity for a continuous flow sedimentation:

depth D

vs

T

det ention time

Chapter 9 Type 1 settling (discrete particles)

Cmutsvangwa: Water Quality and Treatment: Dept. Civil and Water Eng., NUST, 01/10/2013

The length of basin and time a unit of water is the basin (detention time) should

be such that all particles with velocity vs will settle at the bottom of basin, but

adjustments must be made for:

effects of inlet and outlet

turbulence

short circuiting

sludge storage

Particles with velocity less than vs will not be removed during the detention time,

but some particles with velocity less than vs which enter the tank at distance

from the bottom greater than H will be removed e.g. at h. Assuming that

particles of various sizes are uniformly distributed on the entire depth D, at inlet,

then particles with settling velocity vp less than vs will be removed in the ratio:

vp

Xr

vs

Where: Xr =fraction of particle with settling velocity vp that are removed

i.e. particle with settling velocity vp less than vs which enter the tank at a

distance from the bottom not greater than H will be removed.

To determine the efficiency of removal for a given settling time, t it is necessary

to consider the entire range of settling velocities present in tank

Determination of settling velocities

sieve analysis and hydrometer test combined with Stokes Law:

g S s 1d 2

vs

18

settling column

Settling column analysis

a settling column 2 to 3m deep, and diameter at least 100x largest particle

size to prevent wall effects is used (Fig. 2).

the initial suspended solid concentration of the suspension is noted, Co in

mg/l

sample is placed in a jar and mixed completely to ensure uniform

distribution of particle.

suspension is allowed to settle quiescently

samples are drawn at time intervals at a point h (one point) discrete

settling particles, the depth of sampling will not affect the resultant

h

distribution curves of the settling velocities: vi

ti

Chapter 9 Type 1 settling (discrete particles)

Cmutsvangwa: Water Quality and Treatment: Dept. Civil and Water Eng., NUST, 01/10/2013

all particle with velocity vp>vs will pass the sampling point and settle, and

particles remaining must have settling velocity less than vs (vp<vs).

However, there us a partial removal of some particles with velocity vp<vs

and will be removed in the ratio:

vp

Xr

vs

the procedure is repeated for time intervals t2, t3; t4; t5……..tn, and these

values of settling velocities are plotted against mass fraction remaining to

give the settling velocity characteristic distribution curve for the

suspension (Fig. 3).

vp<vs

Sampling point

h

vp>vs

Fig. 2 Column analysis for discrete particles

Chapter 9 Type 1 settling (discrete particles)

Cmutsvangwa: Water Quality and Treatment: Dept. Civil and Water Eng., NUST, 01/10/2013

1.0

1-Xs

Proportion of particles with less

Xs Removed particles

than stated velocity

Xp

Suspension settling velocity distribution

curve for the mass fraction remaining

vp vs

Settling velocities

xs

vp

The total removal is given as: R 1 x s dx

0

vs

Where; Xs =particles with vp=vs

1=Xs =fraction of particles with vp≥vs removed

xs

vp

v

0 s

dx =fraction of particles with vp<vs removed

Example

Determine the total removal efficiency given the following data:

settling analysis results Table 1

column is 1.6m deep

surface loading is 30m/day

Co=200mg/l

Table 1

Time, min 0 40 80 120 160 200 240 280

Conc, Ci, mg/l 200 175 170 160 155 110 80 35

Solution

Compute mass fraction remaining and corresponding velocities (Table 2)

Chapter 9 Type 1 settling (discrete particles)

Cmutsvangwa: Water Quality and Treatment: Dept. Civil and Water Eng., NUST, 01/10/2013

Time 40 80 120 160 200 240 280

(min)

Mass 0.88 0.85 0.8 0.78 0.55 0.4 0.175

fraction

remaining,

C

xi i

Co

h 0.04 0.02 0.013 0.01 0.008 0.0067 0.0007

vs ,

t

m/min

vs 4x10-2 2x10- 1.3x10-2 1x10-2 0.8x10-2 0.67x10- 0.07x10-

2 2 2

(m/min)

Chapter 9 Type 1 settling (discrete particles)

Cmutsvangwa: Water Quality and Treatment: Dept. Civil and Water Eng., NUST, 01/10/2013

Chapter 9 Type 1 settling (discrete particles)

Cmutsvangwa: Water Quality and Treatment: Dept. Civil and Water Eng., NUST, 01/10/2013

Chapter 9 Type 1 settling (discrete particles)

You might also like

- Interactions between Electromagnetic Fields and Matter: Vieweg Tracts in Pure and Applied PhysicsFrom EverandInteractions between Electromagnetic Fields and Matter: Vieweg Tracts in Pure and Applied PhysicsNo ratings yet

- Chapt5 - Theory of Sedimentation PDFDocument18 pagesChapt5 - Theory of Sedimentation PDFNgoni Mukuku100% (1)

- Problems in Quantum Mechanics: Third EditionFrom EverandProblems in Quantum Mechanics: Third EditionRating: 3 out of 5 stars3/5 (2)

- 11 - Particulate Control Systems - Section - 1Document77 pages11 - Particulate Control Systems - Section - 1Meryem LamhamdiNo ratings yet

- Chap 10Document5 pagesChap 10apratim.chatterjiNo ratings yet

- Hydrodynamics#05Document23 pagesHydrodynamics#05navrosepreetsingh8a4hhps14No ratings yet

- Analytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportFrom EverandAnalytical Modeling of Solute Transport in Groundwater: Using Models to Understand the Effect of Natural Processes on Contaminant Fate and TransportNo ratings yet

- CHAPTER 02 Common Conditions in EORDocument144 pagesCHAPTER 02 Common Conditions in EORVelya Galyani Pasila GallaNo ratings yet

- 03-Control of Primary PatriculatesDocument239 pages03-Control of Primary PatriculatesYolanda Hadameon SiregarNo ratings yet

- Navier Stokes EquationsDocument17 pagesNavier Stokes EquationsAlice LewisNo ratings yet

- Chapter 4. Design of Canals: Presented By: Er. NP DawadiDocument17 pagesChapter 4. Design of Canals: Presented By: Er. NP DawadinikhilNo ratings yet

- Settling DWDocument13 pagesSettling DWLenin MaldonadoNo ratings yet

- 22.05 Reactor Physics - Part Nine: Neutron Flux, Reaction Rates, Group Constants, and Neutron CurrentDocument10 pages22.05 Reactor Physics - Part Nine: Neutron Flux, Reaction Rates, Group Constants, and Neutron CurrentmsakowskNo ratings yet

- 2010 NJC Prelim H2 Physics Paper 1.QPDocument17 pages2010 NJC Prelim H2 Physics Paper 1.QPcjcsucksNo ratings yet

- 2 DakeDocument20 pages2 Dakealikadhim1933No ratings yet

- Chapter 6. Convective Mass Transfer PDFDocument47 pagesChapter 6. Convective Mass Transfer PDFHasan AkhuamariNo ratings yet

- L03 Wastewater Treatment Part IVDocument27 pagesL03 Wastewater Treatment Part IVAmanthi InduminiNo ratings yet

- Bhat Lect1Document45 pagesBhat Lect1atanu1820dasNo ratings yet

- Ch2 Fluid DynamicsDocument49 pagesCh2 Fluid Dynamicsgaith syoofNo ratings yet

- Lecture - 12 Control Volume ApproachDocument5 pagesLecture - 12 Control Volume ApproachSnigdha YadavNo ratings yet

- NS Equation Classes 1 - 2Document22 pagesNS Equation Classes 1 - 2Ashish RanjanNo ratings yet

- Chapter Six (Mass Energy Analysis of Control Volume) PDFDocument51 pagesChapter Six (Mass Energy Analysis of Control Volume) PDFايات امجد امجدNo ratings yet

- One Dimensional Transport in Laminar Flow (Shell Balance) : Unit IiDocument136 pagesOne Dimensional Transport in Laminar Flow (Shell Balance) : Unit IiArun Prem Anand NatarajanNo ratings yet

- Edit MCQ 9702 - m20 - QP - 12Document18 pagesEdit MCQ 9702 - m20 - QP - 12anitajohnson.prakriyaNo ratings yet

- Alternative Shaly Sands Water Saturation Equations ComparisonDocument32 pagesAlternative Shaly Sands Water Saturation Equations ComparisonKartiko WibowoNo ratings yet

- Pgs. 3.59 - 3.66Document8 pagesPgs. 3.59 - 3.66Pranav EshverNo ratings yet

- CIVE 3305 LECTURE 3 - SedimentationDocument36 pagesCIVE 3305 LECTURE 3 - SedimentationIlyas Mohamed AliNo ratings yet

- Ch2 Fundamental ConceptsDocument62 pagesCh2 Fundamental ConceptsDavid RiveraNo ratings yet

- CME 301 - Mass Transfer Convective Mass Transfer: Dr. Chandra Mouli MRDocument31 pagesCME 301 - Mass Transfer Convective Mass Transfer: Dr. Chandra Mouli MRNajmul Puda PappadamNo ratings yet

- Fluid Mechanics Solution Sem 4 CBCGS-May 2018Document24 pagesFluid Mechanics Solution Sem 4 CBCGS-May 2018prithvirajNo ratings yet

- HS - 2 - CH - 1 (Part 2)Document18 pagesHS - 2 - CH - 1 (Part 2)Mikiyas AkliluNo ratings yet

- Chapter Four SedimantationDocument52 pagesChapter Four SedimantationJarso buke Buke GalgaloNo ratings yet

- Sedimentation Transport 23 November 2012Document16 pagesSedimentation Transport 23 November 2012Reza YogiswaraNo ratings yet

- Hydraulic RoutingDocument25 pagesHydraulic RoutingSileshi GizachewNo ratings yet

- Planing Vessels 1Document13 pagesPlaning Vessels 1Ahmet GelisliNo ratings yet

- Quantum tunneling and wave packet evolution in different potentialsDocument4 pagesQuantum tunneling and wave packet evolution in different potentialsessaidNo ratings yet

- rk_ask_chaotic_rheologyDocument6 pagesrk_ask_chaotic_rheologyrkailashNo ratings yet

- High Rate Settling: L V D V V L W WDocument2 pagesHigh Rate Settling: L V D V V L W WRoger MirandaNo ratings yet

- Final 00016Document7 pagesFinal 00016kurniawan waskitoNo ratings yet

- 2014 Midterm Exam SolutionDocument11 pages2014 Midterm Exam Solution이태일No ratings yet

- Geotechnical Engineering I: Soil ClassificationDocument13 pagesGeotechnical Engineering I: Soil ClassificationtimozhengNo ratings yet

- B. Oe4625 Chapter01 PDFDocument18 pagesB. Oe4625 Chapter01 PDFdanielmergulhoNo ratings yet

- Incipient Particle Motion Shields Diagram ExplainedDocument51 pagesIncipient Particle Motion Shields Diagram ExplainedTsegaw FikaduNo ratings yet

- Lecture 8 Suspended Sediment TransportDocument6 pagesLecture 8 Suspended Sediment TransportPras Si Syecher PurwodadiNo ratings yet

- Boundary Transitions.Document11 pagesBoundary Transitions.Angela MatamorosNo ratings yet

- ENVE 317 Midterm SolutionsDocument9 pagesENVE 317 Midterm Solutions이태일No ratings yet

- Course on Transport PhenomenaDocument15 pagesCourse on Transport PhenomenaGowri ShankarNo ratings yet

- Conservation of MassDocument6 pagesConservation of Massshiyu xiaNo ratings yet

- B M E E, 2011: Achelor OF Echanical Ngineering XaminationDocument2 pagesB M E E, 2011: Achelor OF Echanical Ngineering XaminationNiraj MishraNo ratings yet

- Anomalus Drude ModelsDocument4 pagesAnomalus Drude ModelsLuisAlfredoMartinezQNo ratings yet

- UTM Jet Impact Lab ReportDocument8 pagesUTM Jet Impact Lab ReportAhmad IhyasolihinNo ratings yet

- 9 Dam Break PDFDocument13 pages9 Dam Break PDFBrandon ArmeroNo ratings yet

- Hydraulic Engineering Design Course Covers Urban Drainage SystemsDocument26 pagesHydraulic Engineering Design Course Covers Urban Drainage SystemsAl Patrick Dela CalzadaNo ratings yet

- Experimental Investigation of The PlungeDocument22 pagesExperimental Investigation of The PlungePrakash Duraisamy CITNo ratings yet

- Lecture2 - CFD - Course - Governing Equations (Compatibility Mode) PDFDocument132 pagesLecture2 - CFD - Course - Governing Equations (Compatibility Mode) PDFvibhor28No ratings yet

- Impact of Jet Momentum VerificationDocument3 pagesImpact of Jet Momentum VerificationankitNo ratings yet

- Nays2DH Solver in iRIC SoftwareDocument41 pagesNays2DH Solver in iRIC Softwaretri radinal saputraNo ratings yet

- NS EquationDocument81 pagesNS EquationRitik ChaturvediNo ratings yet

- Optimum fly ash composition for concreteDocument18 pagesOptimum fly ash composition for concretedave tafadzwa kuyeriNo ratings yet

- Project Design GuidelinesDocument17 pagesProject Design Guidelinesdave tafadzwa kuyeri100% (1)

- Revised Wurayayi ProjectDocument27 pagesRevised Wurayayi Projectdave tafadzwa kuyeriNo ratings yet

- Question and AnswersDocument4 pagesQuestion and Answersdave tafadzwa kuyeriNo ratings yet

- Punungwe Modelling of Water Pipe Bursts in HarareDocument36 pagesPunungwe Modelling of Water Pipe Bursts in Hararedave tafadzwa kuyeriNo ratings yet

- FiltrationDocument7 pagesFiltrationdave tafadzwa kuyeriNo ratings yet

- ProjectDocument12 pagesProjectdave tafadzwa kuyeriNo ratings yet

- Research MSCDocument48 pagesResearch MSCdave tafadzwa kuyeriNo ratings yet

- DisinfectionDocument5 pagesDisinfectiondave tafadzwa kuyeriNo ratings yet

- Research ProjectsDocument3 pagesResearch Projectsdave tafadzwa kuyeriNo ratings yet

- Civil Engineering Journal: Strengthening and Repair of A Precast Reinforced Concrete Residential BuildingDocument17 pagesCivil Engineering Journal: Strengthening and Repair of A Precast Reinforced Concrete Residential Buildingdave tafadzwa kuyeriNo ratings yet

- Chapt9 Plate SettlersDocument9 pagesChapt9 Plate Settlersdave tafadzwa kuyeri100% (1)

- IndexDocument99 pagesIndexdave tafadzwa kuyeriNo ratings yet

- Coagulation and Flocculation ProcessDocument50 pagesCoagulation and Flocculation Processdave tafadzwa kuyeriNo ratings yet

- Civil Engineering JournalDocument14 pagesCivil Engineering Journaldave tafadzwa kuyeriNo ratings yet

- Irrigation 2013Document4 pagesIrrigation 2013dave tafadzwa kuyeriNo ratings yet

- Introduction To Irrigation DesignDocument40 pagesIntroduction To Irrigation DesignEifa Mat LazimNo ratings yet

- cmutsvangwa: Water Quality and Treatment: Dept. Civil and Water Eng., NUST, 10/10/2006 7-1Document5 pagescmutsvangwa: Water Quality and Treatment: Dept. Civil and Water Eng., NUST, 10/10/2006 7-1dave tafadzwa kuyeriNo ratings yet

- Irrigation 2014Document4 pagesIrrigation 2014dave tafadzwa kuyeriNo ratings yet

- Irrigation 2017Document3 pagesIrrigation 2017dave tafadzwa kuyeriNo ratings yet

- Chapt1 - Course Outline and Recommended LiteratureDocument1 pageChapt1 - Course Outline and Recommended Literaturedave tafadzwa kuyeriNo ratings yet

- Chapt8 SedimentationDocument6 pagesChapt8 Sedimentationdave tafadzwa kuyeriNo ratings yet

- Water Quality & Treatment: Flocculation ProcessDocument16 pagesWater Quality & Treatment: Flocculation ProcessNgoni MukukuNo ratings yet

- Chapt8 - Vertical Flow ClarifiersDocument4 pagesChapt8 - Vertical Flow Clarifiersdave tafadzwa kuyeriNo ratings yet

- Chapt2 - Introduction To Water TreatmentDocument3 pagesChapt2 - Introduction To Water Treatmentdave tafadzwa kuyeriNo ratings yet

- TCW 3105 Transportation Engineering and Planning I 2018-2019Document57 pagesTCW 3105 Transportation Engineering and Planning I 2018-2019dave tafadzwa kuyeriNo ratings yet

- Energy Balance and Thermo PresentationDocument83 pagesEnergy Balance and Thermo Presentationca2n27No ratings yet

- Alfa VapDocument2 pagesAlfa Vapkresimir.mikoc9765No ratings yet

- Seoul National University Studies High Entropy Alloys' Fracture Toughness Using Indentation TestingDocument23 pagesSeoul National University Studies High Entropy Alloys' Fracture Toughness Using Indentation TestingOğuzhan AtmacaNo ratings yet

- Bubble Point Pressure DeterminationDocument5 pagesBubble Point Pressure DeterminationjeedNo ratings yet

- Reator Tubular EMSODocument31 pagesReator Tubular EMSOBereket TadesseNo ratings yet

- Side & Full Stream FiltrationDocument12 pagesSide & Full Stream FiltrationambuenaflorNo ratings yet

- Turbomachinery: ME-326 Fluid Mechanics Wah Engineering CollegeDocument35 pagesTurbomachinery: ME-326 Fluid Mechanics Wah Engineering CollegeSayam AliNo ratings yet

- Bernoulli Eqn Waste Water LabDocument10 pagesBernoulli Eqn Waste Water LabMuhamad IzzanNo ratings yet

- Bomba de Calor Hn1636Document42 pagesBomba de Calor Hn1636Raul SantosNo ratings yet

- Catalytic Cracking of PetroleumDocument12 pagesCatalytic Cracking of Petroleummessy munozNo ratings yet

- Corrosion HandbookDocument448 pagesCorrosion HandbookEvgeny TregubNo ratings yet

- American Steel Pipe Dimensions and SpecificationsDocument5 pagesAmerican Steel Pipe Dimensions and SpecificationsUdin DzonoNo ratings yet

- Gao-Cfd RefrigeratorDocument13 pagesGao-Cfd RefrigeratorMonowarul IslamNo ratings yet

- Sub-Water Demand Cal (27062010)Document59 pagesSub-Water Demand Cal (27062010)Tiffany CombsNo ratings yet

- Thermal Analysis of Shell and Tube Heat ExchangerDocument6 pagesThermal Analysis of Shell and Tube Heat ExchangerInternational Journal of Research in Engineering and TechnologyNo ratings yet

- Aniline Process DescriptionDocument13 pagesAniline Process Descriptionkeyur1109100% (3)

- BS HvacDocument12 pagesBS HvacRamiAl-fuqahaNo ratings yet

- Qty. Description CR 4-30 A-A-A-BUBE: Company Name: Created By: Phone: DateDocument12 pagesQty. Description CR 4-30 A-A-A-BUBE: Company Name: Created By: Phone: Dateabhe prasetyaNo ratings yet

- Mechanical Engineering Hydraulic Mechanics Important MCQ PDFDocument11 pagesMechanical Engineering Hydraulic Mechanics Important MCQ PDFGaneshNo ratings yet

- Product Data Sheet CTOLDocument2 pagesProduct Data Sheet CTOLvudinhtucp6No ratings yet

- Chemical Kinetics Rate Equations and Rate LawsDocument116 pagesChemical Kinetics Rate Equations and Rate LawsSai Vishnu GainiNo ratings yet

- MCQ'SDocument14 pagesMCQ'SAnees EjazNo ratings yet

- Experiment T4 For CN2108Document8 pagesExperiment T4 For CN2108Kiang Teng LimNo ratings yet

- Product IntroDocument50 pagesProduct IntroMahmoud Ahmed Ali AbdelrazikNo ratings yet

- Theory and Experiment ProcedureDocument25 pagesTheory and Experiment ProcedureNazrul HafizNo ratings yet

- Hydraulic SystemDocument81 pagesHydraulic SystemMaritza Gabriela Arizabal MedinaNo ratings yet

- Correlations To Predict Frictional Pressure Loss of Hydraulic-Fracturing Slurry in Coiled TubingDocument15 pagesCorrelations To Predict Frictional Pressure Loss of Hydraulic-Fracturing Slurry in Coiled TubingErdal AYDINNo ratings yet

- LEVAPOR Step Feed IFAS ProcessDocument9 pagesLEVAPOR Step Feed IFAS ProcessAmit ChristianNo ratings yet

- Science - CM Chong: 2.9.1-HeatDocument2 pagesScience - CM Chong: 2.9.1-HeatChloe KhorNo ratings yet

- Inert Gas OverviewDocument6 pagesInert Gas OverviewRahulChoudharyNo ratings yet