Professional Documents

Culture Documents

Chery Arrizo 7 SQRE4G16+EMISSION+CONTROL+SYSTEM

Uploaded by

SuckmytickOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chery Arrizo 7 SQRE4G16+EMISSION+CONTROL+SYSTEM

Uploaded by

SuckmytickCopyright:

Available Formats

SQRE4G16 EMISSION CONTROL SYSTEM

GENERAL INFORMATION 09-3 Activated Charcoal Canister

Description 09-3 Assembly 09-9

Specifications 09-4 Removal 09-9

Tool 09-4 Installation 09-10

Circuit Diagram 09-5 PCV Valve 09-11

Removal 09-11

DIAGNOSIS & TESTING 09-6 Inspection 09-11

Leakage Inspection 09-6 Installation 09-11

Activated Charcoal Canister Upstream Oxygen Sensor 09-12

Inspection 09-6

Removal 09-12

Fuel Tank Cap Assembly Inspection 09-6

Inspection 09-13

ON-VEHICLE SERVICE 09-7 Installation 09-13

Activated Charcoal Canister Downstream Oxygen Sensor 09-14

Solenoid Valve and Bracket 09-7 Removal 09-14

Removal 09-7 Inspection 09-15

Inspection 09-8 Installation 09-15

Installation 09-8 09

Chery Automobile Co., Ltd. 09–1

09

09–2 Chery Automobile Co., Ltd.

09 - SQRE4G16 EMISSION CONTROL SYSTEM

GENERAL INFORMATION

SQRE4G16 EMISSION CONTROL SYSTEM

Description

09

RM16090010

1 - Activated Charcoal Canister Solenoid Valve 2 - PCV Valve

3 - Activated Charcoal Canister Assembly 4 - Fuel Tank Assembly

Emission control system recovers and burns fuel vapor to prevent the vapor in fuel tank from being

discharged into the atmosphere. It monitors the oxygen content in exhaust gas, so as to guarantee the

maximum efficiency of catalytic converter assembly in converting the HC, CO and NOx in exhaust gas.

Activated charcoal canister assembly plays an important role in the emission control system and it is used to

absorb and filter moisture and fuel vapor. Fresh air enters the bottom of activated charcoal canister assembly

while fuel vapor enters the top of activated charcoal canister through pipe. When engine stops operating, the

fuel vapor and fresh air will be stored in the activated charcoal canister assembly. When canister solenoid

valve opens, the fuel vapor will enter intake manifold to burn.

Oxygen sensor consists of upstream oxygen sensor and downstream oxygen sensor. Upstream oxygen

sensor is installed on exhaust manifold assembly, and downstream oxygen sensor is installed on main

catalytic converter assembly. Oxygen sensor can detect the oxygen content in exhaust gas, and determine

whether combustible air-fuel mixture is completely burnt out or not, so as to guarantee the maximum

efficiency of catalytic converter assembly in converting the HC, CO and NOx in exhaust gas.

Chery Automobile Co., Ltd. 09–3

09 - SQRE4G16 EMISSION CONTROL SYSTEM

Specifications

Torque Specifications

Description Torque (N·m)

Activated Charcoal Canister Solenoid Valve Bracket

8±1

Fixing Bolt

Coupling Bolt Between Activated Charcoal Canister

5±1

Assembly and Body

Exhaust Manifold Heat Insulator Fixing Bolt 8+3

Upstream Oxygen Sensor 40 - 60

Downstream Oxygen Sensor 40 - 60

Tool

General Tool

09

Digital Multimeter

RCH0000002

09–4 Chery Automobile Co., Ltd.

09 - SQRE4G16 EMISSION CONTROL SYSTEM

Circuit Diagram

Emission Control System

BATTERY

85 87

ENGINE

ECM COMPARTMENT

MAIN FUSE AND

RELAY RELAY BOX (A/B/F)

EF37 86 30 E-016

10A B-021

B-022

EF30 EF32 EF36 EF34

15A 7.5A 7.5A 15A

B5 F15 B9 A8 B8 A10

RW

RL

RB

RW

09

1 4 1 4 DOWN- 1

UPSTREAM CANISTER

STREAM

RW

RW

OXYGEN

YR

RY

OXYGEN SOLENOID

SENSOR VALVE

E-027 SENSOR

E-014

2 3 2 3 B-005 2

GBr

GrB

BW

BW

LR

Gr

2-20 2-5 2-15 2-16 1-16 1-40 1-9 2-43 2-21 2-48 1-30

ECM (1/2)

E-018

B-002

A1 A2 A3 A4 A5 B1 B2 B3 B4 B5

37 38 39 40 41 42 43 44 45 46 47 48

A6 A7 A8 A9 A10 25 26 27 28 29 30 31 32 33 34 35 36

B6 B7 B8 B9 B10 E-018

13 14 15 16 17 18 19 20 21 22 23 24 B

E-016 B-021 1 2 3 4 5 6 7 8 9 10 11 12

Gr Y

F1 F2 F3 F4 F5 F6 F7 F8 F9 F10 F11 F12

F13 F14 F15 F16 F17 F18 F19 F20 F21 F22 F23 F24

49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

B-022 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

W

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

1 2 3 4 1 2

E-027 B-005 B-002

E-014

B B B EM16090010

B

Chery Automobile Co., Ltd. 09–5

09 - SQRE4G16 EMISSION CONTROL SYSTEM

DIAGNOSIS & TESTING

Leakage Inspection

Visually check that hoses, connections and gaskets have no cracks, leaks or damage.

CAUTION

Removal of engine oil dipstick, filler cap, PCV hose and other components or other problems in them

may cause the engine to run improperly.

Air suction caused by disconnections, looseness or cracks in intake system pipes related to throttle

assembly will result in engine failure or abnormal operation. Replace the parts as necessary.

Activated Charcoal Canister Inspection

1. Close port C and blow compressed air into port A, check

that air flows from port B. If result is not as specified, B

replace the canister. C

2. Close port C and blow compressed air into port B, check

A

09 that air flows from port A. If result is not as specified,

replace the canister.

RM16090020

Fuel Tank Cap Assembly Inspection

1. Visually check that fuel tank cap assembly is not deformed or damaged.

2. If result is not as specified, replace the fuel tank cap assembly.

09–6 Chery Automobile Co., Ltd.

09 - SQRE4G16 EMISSION CONTROL SYSTEM

ON-VEHICLE SERVICE

Activated Charcoal Canister Solenoid Valve and Bracket

Removal

CAUTION

Be sure to wear necessary safety equipment to prevent accidents when repairing.

Try to prevent body paint surface from being scratched during removal and installation.

Before removal, mark the fuel vapor pipe III assembly and outlet hoses to avoid confusion.

1. Turn off all electrical equipment and the ignition switch.

2. Disconnect the negative battery cable.

3. Remove the engine trim cover.

4. Remove the activated charcoal canister solenoid valve.

a. Disconnect the activated charcoal canister solenoid

valve connector (arrow). 09

RM16090030

b. Loosen the elastic clamps (arrow), and disconnect the

connection between hose and activated charcoal

canister solenoid valve.

RM16090040

CAUTION

Positioning distance from hose end to elastic clamp is 3 to 5 mm.

c. Remove the charcoal canister solenoid valve from bracket.

Chery Automobile Co., Ltd. 09–7

09 - SQRE4G16 EMISSION CONTROL SYSTEM

5. Remove the activated charcoal canister solenoid valve bracket.

a. Remove the activated charcoal canister solenoid

valve bracket fixing bolt (arrow), and remove the

activated charcoal canister solenoid valve bracket (1).

(Tightening torque: 8 ± 1 N·m)

RM16090050

Inspection

Measure the resistance between 2 terminals of charcoal

canister solenoid valve with a digital multimeter.

+ -

1

Multimeter Measurement

2

Specification (Ω)

Connection Temperature

Terminal 1 -

20°C 26 ± 4

09 Terminal 2

RM16090060

Installation

Installation is in the reverse order of removal.

09–8 Chery Automobile Co., Ltd.

09 - SQRE4G16 EMISSION CONTROL SYSTEM

Activated Charcoal Canister Assembly

Removal

CAUTION

Be sure to wear necessary safety equipment to prevent accidents when repairing.

Try to prevent body paint surface from being scratched during removal and installation.

Before removal, mark the fuel vapor hose II, fuel vapor hose I and charcoal canister breather pipe to

avoid confusion.

1. Turn off all electrical equipment and the ignition switch.

2. Disconnect the negative battery cable.

3. Remove the rear right wheel house protector (See page 49-32).

4. Remove the activated charcoal canister assembly.

a. Remove the coupling bolt (arrow) between activated

charcoal canister assembly and body.

(Tightening torque: 5 ± 1 N·m)

b. Remove the activated charcoal canister assembly

09

from body bracket in the direction of arrow as shown

in the illustration.

RM16090070

c. Loosen the hose clamps (arrow), disconnect the

connection between hose and activated charcoal

canister assembly, and remove the activated charcoal 1

canister assembly.

d. Loosen the elastic clamp (1), and remove the

charcoal canister breather pipe from activated

charcoal canister assembly.

RM16090080

CAUTION

Positioning distance from hose end to elastic clamp is 3 to 5 mm.

ENVIRONMENTAL PROTECTION

Unneeded activated charcoal canister assembly should be handled by the specialized department

according to local laws and regulations. Never discard it at will.

Chery Automobile Co., Ltd. 09–9

09 - SQRE4G16 EMISSION CONTROL SYSTEM

Installation

Installation is in the reverse order of removal.

HINT:

When installing charcoal canister breather pipe, be careful to

align the white mark (1) on charcoal canister breather pipe

with the side seam (2) of activated charcoal canister

assembly. 1

RM16090090

09

09–10 Chery Automobile Co., Ltd.

09 - SQRE4G16 EMISSION CONTROL SYSTEM

PCV Valve

Removal

CAUTION

Be sure to wear necessary safety equipment to prevent accidents when repairing.

Try to prevent body paint surface from being scratched during removal and installation.

1. Turn off all electrical equipment and the ignition switch.

2. Disconnect the negative battery cable.

3. Remove the engine trim cover.

4. Remove the PCV valve.

a. Disconnect the clamp (arrow) between PCV valve and

hose with a tool.

09

RM16090100

CAUTION

Positioning distance from hose end to clamp is 3 to 5 mm.

b. Loosen and remove the PCV valve from cylinder head cover.

(Tightening torque: 3 ± 1 N·m)

Inspection

1. Install a clean hose to PCV valve.

2. Check the PCV valve operation.

a. Blow air into the cylinder head side, and check that air flows smoothly.

WARNING

DO NOT suck air through valve. Petroleum substances inside the valve are hazardous to your health.

b. Blow air into the intake manifold side, and check that air flows difficultly.

If result is not as specified, replace PCV valve.

3. Remove the clean hose from PCV valve.

Installation

Installation is in the reverse order of removal.

Chery Automobile Co., Ltd. 09–11

09 - SQRE4G16 EMISSION CONTROL SYSTEM

Upstream Oxygen Sensor

Removal

WARNING

The temperature of exhaust system is very high when engine is running. Before removal, you must make

sure that engine has shut off, and exhaust system has cooled down sufficiently, otherwise, there is a risk

of scald injury.

Be sure to wear necessary safety equipment to prevent accidents when repairing.

Try to prevent body paint surface from being scratched during removal and installation.

1. Turn off all electrical equipment and the ignition switch.

2. Disconnect the negative battery cable.

3. Remove the engine trim cover.

4. Remove the upstream oxygen sensor.

a. Remove and disconnect the upstream oxygen sensor

connector (arrow) from bracket.

09

RM16090110

b. Remove 3 fixing bolts (arrow) from exhaust manifold

heat insulator, and remove the exhaust manifold heat

insulator.

(Tightening torque: 8 + 3 N·m)

RM16090120

c. Remove the upstream oxygen sensor (arrow) from

exhaust manifold.

(Tightening torque: 40 - 60 N·m)

RM16090130

09–12 Chery Automobile Co., Ltd.

09 - SQRE4G16 EMISSION CONTROL SYSTEM

Inspection

1. Measure the resistance of upstream oxygen sensor with

a digital multimeter.

+ -

Multimeter Specified D C B A

Condition

Connection Condition

Terminal C -

20°C 7 - 11 Ω

Terminal D

Terminal A -

Terminal B

RM16090140

Terminal A -

Terminal C

Terminal A -

Always No continuity

Terminal D

Terminal B -

Terminal C

Terminal B -

Terminal D

If result is not as specified, replace the upstream oxygen

sensor.

09

Installation

Installation is in the reverse order of removal.

Chery Automobile Co., Ltd. 09–13

09 - SQRE4G16 EMISSION CONTROL SYSTEM

Downstream Oxygen Sensor

Removal

WARNING

The temperature of exhaust system is very high when engine is running. Before removal, you must make

sure that engine has shut off, and exhaust system has cooled down sufficiently, otherwise, there is a risk

of scald injury.

Be sure to wear necessary safety equipment to prevent accidents when repairing.

Try to prevent body paint surface from being scratched during removal and installation.

1. Turn off all electrical equipment and the ignition switch.

2. Disconnect the negative battery cable.

3. Remove the downstream oxygen sensor.

a. Remove and disconnect the downstream oxygen

sensor connector (arrow) from bracket.

09

RM16090141

b. Raise the vehicle to a proper position.

c. Remove the downstream oxygen sensor (arrow) from

main catalytic converter assembly.

(Tightening torque: 40 - 60 N·m)

RM16090150

09–14 Chery Automobile Co., Ltd.

09 - SQRE4G16 EMISSION CONTROL SYSTEM

Inspection

1. Measure the resistance of downstream oxygen sensor

with a digital multimeter.

+ -

Multimeter Specified D C B A

Condition

Connection Condition

Pin C - Pin D 20°C 7 - 11 Ω

Terminal A -

Terminal B

Terminal A -

RM16090140

Terminal C

Terminal A -

Always No continuity

Terminal D

Terminal B -

Terminal C

Terminal B -

Terminal D

If result is not as specified, replace the downstream oxygen

sensor.

09

Installation

Installation is in the reverse order of removal.

Chery Automobile Co., Ltd. 09–15

- MEMO -

09–16 Chery Automobile Co., Ltd.

You might also like

- Engine Controls and Fuel Part 2 PDFDocument705 pagesEngine Controls and Fuel Part 2 PDFManuel Fernandez100% (3)

- Automotive Sensor Testing and Waveform AnalysisFrom EverandAutomotive Sensor Testing and Waveform AnalysisRating: 4.5 out of 5 stars4.5/5 (13)

- Daf Cf65 Cf75 Cf85 From Chassis 0e621376 Z Electrical Wiring DiagramDocument20 pagesDaf Cf65 Cf75 Cf85 From Chassis 0e621376 Z Electrical Wiring Diagrammanuel100% (50)

- Spare Parts Catalogue: (Export)Document51 pagesSpare Parts Catalogue: (Export)visugue_26No ratings yet

- D20Dtf Engine: 1. SpecificationDocument26 pagesD20Dtf Engine: 1. SpecificationKada Ben youcefNo ratings yet

- Mikuni HSR Instructions Dkh1699Document18 pagesMikuni HSR Instructions Dkh1699BrianCookNo ratings yet

- Nissan - SR - Engine TypeDocument9 pagesNissan - SR - Engine TypeSuckmytick0% (1)

- Ta-30 Manual MaintenanceDocument29 pagesTa-30 Manual MaintenanceAntonio Carrion100% (1)

- Hydraulic PumpsDocument35 pagesHydraulic PumpsMohammed Al-Odat100% (1)

- Merlins Ecuflash Evo 7-8-9 Tuning Guide-V1.7aDocument172 pagesMerlins Ecuflash Evo 7-8-9 Tuning Guide-V1.7aLevi Little100% (3)

- Fiat X19 Performance Handbook - Ron Collins PDFDocument64 pagesFiat X19 Performance Handbook - Ron Collins PDFAnderson ZambrzyckiNo ratings yet

- Hino P11CDocument180 pagesHino P11CВалерий Герасимов0% (1)

- Carraro Tlb1 Up Parts CatalogDocument15 pagesCarraro Tlb1 Up Parts CatalogЮрий100% (1)

- ATA 71 Eng Operating LimitsDocument13 pagesATA 71 Eng Operating Limitsanarko arsipelNo ratings yet

- 5.12 Bop Es 15MDocument30 pages5.12 Bop Es 15MJavier Rivas50% (2)

- LM2500+ Shutdown SequencesDocument6 pagesLM2500+ Shutdown Sequencesrenzobermudez89No ratings yet

- HawkgtmanualDocument256 pagesHawkgtmanualColin SmithNo ratings yet

- Fortens® H4.0FT5, H4.0FT6, H4.5FTS5, H4.5FT6, H5.0FT, H5.5FT (P005)Document818 pagesFortens® H4.0FT5, H4.0FT6, H4.5FTS5, H4.5FT6, H5.0FT, H5.5FT (P005)pruhavNo ratings yet

- Free Piston Engine PDFDocument2 pagesFree Piston Engine PDFWilliamNo ratings yet

- AGC-3 Operators Manual 4189340525 ESDocument40 pagesAGC-3 Operators Manual 4189340525 ESWilliam AlvaradoNo ratings yet

- 2003 SV1000 Repair Manual Part 9: Emission Control InformationDocument17 pages2003 SV1000 Repair Manual Part 9: Emission Control Informationhn7410No ratings yet

- Daf Cf65 Cf75 Cf85 To Chassis 0e621376 Electrical Wiring DiagramDocument20 pagesDaf Cf65 Cf75 Cf85 To Chassis 0e621376 Electrical Wiring Diagraminez100% (39)

- Citycom.300: Service ManualDocument271 pagesCitycom.300: Service ManualAlvaro Goncalves Albornoz0% (1)

- Manual Spare Parts - English 3178049001 PDFDocument799 pagesManual Spare Parts - English 3178049001 PDFYoseth Jose Vasquez Parra100% (2)

- Spare Part CatalougeDocument452 pagesSpare Part Catalougejohn100% (1)

- Trening Bagera 7 I 7aDocument134 pagesTrening Bagera 7 I 7aDraganNo ratings yet

- Manual de Taller S2 125 FIDocument222 pagesManual de Taller S2 125 FIyisusyisusNo ratings yet

- Chery A19 SQR477F+EMISSION+CONTROL+SYSTEMDocument14 pagesChery A19 SQR477F+EMISSION+CONTROL+SYSTEMSuckmytickNo ratings yet

- Technical Service Information: Dodge 68rfeDocument10 pagesTechnical Service Information: Dodge 68rfePlanta Damiana2No ratings yet

- CFA901Document135 pagesCFA901Moussa DialloNo ratings yet

- Operator'S Manual CL0409A91XXXXXXXDocument8 pagesOperator'S Manual CL0409A91XXXXXXXtaller.copiapoNo ratings yet

- Specifications: Vehicle Emission Vacuum RoutingDocument4 pagesSpecifications: Vehicle Emission Vacuum RoutingCarlos VelázquezNo ratings yet

- Cable MotorDocument2 pagesCable MotorAlf NeroNo ratings yet

- M60es44 P449y Man 001Document23 pagesM60es44 P449y Man 001Riski Kurniawan100% (1)

- Catalogue TrailerbrakekitsDocument60 pagesCatalogue TrailerbrakekitsAaron GilmourNo ratings yet

- R&I Intake ManifoldDocument4 pagesR&I Intake ManifoldmagetszNo ratings yet

- Punch List: - Çöpler Gold MineDocument2 pagesPunch List: - Çöpler Gold MineademgsNo ratings yet

- Cleveland Nose Wheel 199-126 KitDocument31 pagesCleveland Nose Wheel 199-126 KitMichael MitchellNo ratings yet

- Engineered To Ride, Built To LastDocument12 pagesEngineered To Ride, Built To LastTouch ChannyNo ratings yet

- Tid 0000049 01 PDFDocument4 pagesTid 0000049 01 PDFjoaojitoNo ratings yet

- Omvl Reparaturanleitung R89e Verdampfer EngDocument16 pagesOmvl Reparaturanleitung R89e Verdampfer EngMarcosArt SilvaNo ratings yet

- CSB19-01A Fuel (Primer) Diverter Valve AssemblyDocument12 pagesCSB19-01A Fuel (Primer) Diverter Valve AssemblyFranco PugaNo ratings yet

- 3.06 ES 10K DUAL BOP ManDocument15 pages3.06 ES 10K DUAL BOP ManRafael BolivarNo ratings yet

- Radiator Assembly S3.8-G4andG6Document13 pagesRadiator Assembly S3.8-G4andG6mohsen_cumminsNo ratings yet

- A13 055Document6 pagesA13 055AgustinNo ratings yet

- Capri 1984-1994 - Fuel Charging and Controls - 1.6LDocument17 pagesCapri 1984-1994 - Fuel Charging and Controls - 1.6Ljanuar1983No ratings yet

- VSP 267Document11 pagesVSP 267JS VivasNo ratings yet

- Parts Catalogue - 621 ESDocument32 pagesParts Catalogue - 621 ESnobinmendezNo ratings yet

- DRAFT Vendor Directory VER 10. - For CommentsDocument47 pagesDRAFT Vendor Directory VER 10. - For CommentsRohit0% (1)

- Maintenance Handbook of Pantograpgh AM12 & Similar DesignDocument46 pagesMaintenance Handbook of Pantograpgh AM12 & Similar DesignMaddi vasuNo ratings yet

- 11 Intake-Exhaust PDFDocument16 pages11 Intake-Exhaust PDFnadaNo ratings yet

- FSG000030 500 12 8V Eu5Document12 pagesFSG000030 500 12 8V Eu5jorge luis guevara martinezNo ratings yet

- Refcomp Src-S SeriesDocument141 pagesRefcomp Src-S Seriesohsajong71% (7)

- Lincoln Helios (India) Limited: Operation & Maintenance ManualDocument50 pagesLincoln Helios (India) Limited: Operation & Maintenance Manualprem sagarNo ratings yet

- Dga 1000 PartsDocument20 pagesDga 1000 Partswaltech2005No ratings yet

- Engine Control, Fuel & Exhaust Systems SectionDocument8 pagesEngine Control, Fuel & Exhaust Systems Sectionyt2g6wmy4qNo ratings yet

- Technical Service Bulletin: 210-2418 Ed. 4 April 2006 AllDocument7 pagesTechnical Service Bulletin: 210-2418 Ed. 4 April 2006 AllPyro KDNo ratings yet

- TSB 2100306Document13 pagesTSB 2100306ossoskiNo ratings yet

- M (V) - 28 Gas Welding EquipmentDocument69 pagesM (V) - 28 Gas Welding Equipmenterkan aksoyNo ratings yet

- QAWTP 40in GV Actuation SurveyDocument23 pagesQAWTP 40in GV Actuation SurveykarthikNo ratings yet

- Specifications: 2008 Ford Edge SE 2008 Ford Edge SEDocument6 pagesSpecifications: 2008 Ford Edge SE 2008 Ford Edge SECarlos VelázquezNo ratings yet

- Air Cleaner GPDocument2 pagesAir Cleaner GPhayaNo ratings yet

- Number: Group: Date:: Transmission (Sales Code DG6)Document6 pagesNumber: Group: Date:: Transmission (Sales Code DG6)Mohamed AhmedNo ratings yet

- ProductcataloqueknorrDocument60 pagesProductcataloqueknorrIslam ShoukryNo ratings yet

- Intake and ExhaustDocument9 pagesIntake and ExhaustmkNo ratings yet

- Technical Service Information: FORD 4R44E/55E AND 5R44E/55EDocument3 pagesTechnical Service Information: FORD 4R44E/55E AND 5R44E/55EAranza SuNo ratings yet

- Reles EuropeoDocument450 pagesReles EuropeojuanNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- HINO US Chap03Document113 pagesHINO US Chap03Andres GomezNo ratings yet

- US Chamm8997Document46 pagesUS Chamm8997SuckmytickNo ratings yet

- Engine Control Module (ECM)Document4 pagesEngine Control Module (ECM)SuckmytickNo ratings yet

- Section+8A-4 PartsDocument8 pagesSection+8A-4 PartsSuckmytickNo ratings yet

- Section 8A-6Document3 pagesSection 8A-6SuckmytickNo ratings yet

- Bookcover12 PDFDocument1 pageBookcover12 PDFSuckmytickNo ratings yet

- SM 24Document15 pagesSM 24SuckmytickNo ratings yet

- Terminals of Ecm: DiagnosticsDocument6 pagesTerminals of Ecm: DiagnosticsSuckmytickNo ratings yet

- Guy in FindDocument1 pageGuy in FindSuckmytickNo ratings yet

- Guy in FindDocument1 pageGuy in FindSuckmytickNo ratings yet

- ReadMe GVDocument10 pagesReadMe GVLuiz Roberto Tomasi RibeiroNo ratings yet

- List To Man PDFDocument1 pageList To Man PDFSuckmytickNo ratings yet

- RW415 / RW416 / RW420: Service Manual Supplementary Service ManualDocument1 pageRW415 / RW416 / RW420: Service Manual Supplementary Service ManualSuckmytickNo ratings yet

- 4G6 GDI Timing MechanicalDocument38 pages4G6 GDI Timing MechanicalSuckmytickNo ratings yet

- Operating Instruction: Acrobat Reader Screen Display How To Read Manual DataDocument10 pagesOperating Instruction: Acrobat Reader Screen Display How To Read Manual DataSuckmytickNo ratings yet

- 6G72 TimingDocument1 page6G72 TimingSuckmytick100% (1)

- Guy in Find PDFDocument1 pageGuy in Find PDFSuckmytickNo ratings yet

- 6G74 GDI TimingDocument1 page6G74 GDI TimingSuckmytickNo ratings yet

- BAW Diagnostics List (Note:For Reference Only) : Menu Connector FunctionsDocument3 pagesBAW Diagnostics List (Note:For Reference Only) : Menu Connector FunctionsSuckmytickNo ratings yet

- Timing MechanicalDocument66 pagesTiming MechanicalSuckmytickNo ratings yet

- HowtoFind PDFDocument7 pagesHowtoFind PDFSuckmytickNo ratings yet

- Hr12de - IpdmDocument1 pageHr12de - IpdmSuckmytickNo ratings yet

- Hr12de - BCMDocument1 pageHr12de - BCMSuckmytickNo ratings yet

- Wiring Diagram Manual Manuel Des Schemas de Cablage Handbuch Für Verkabelung Manual de Diagrama de Conexiones Bedradingsschema-HandboekDocument1 pageWiring Diagram Manual Manuel Des Schemas de Cablage Handbuch Für Verkabelung Manual de Diagrama de Conexiones Bedradingsschema-HandboekSuckmytickNo ratings yet

- Sy 419Document240 pagesSy 419Suckmytick0% (1)

- Manual List PDFDocument3 pagesManual List PDFSuckmytickNo ratings yet

- TopDocument140 pagesTopSuckmytickNo ratings yet

- Presentation Report: The University of LahoreDocument7 pagesPresentation Report: The University of Lahoresarim buttNo ratings yet

- Operacion de Sistemas - Convertidor 924GDocument2 pagesOperacion de Sistemas - Convertidor 924Gguido50% (2)

- OBD Codes MazdaDocument4 pagesOBD Codes MazdaRegisAraújoAbdallaNo ratings yet

- Boiler and Air Compressor MaritimeDocument4 pagesBoiler and Air Compressor MaritimeJulius PampolaNo ratings yet

- A030f464 - I8 - 201605 Manual de Partes GG - Ee. GGPC 45KW - 5.0L GMDocument84 pagesA030f464 - I8 - 201605 Manual de Partes GG - Ee. GGPC 45KW - 5.0L GMjohanNo ratings yet

- Note On Carburetor PDFDocument22 pagesNote On Carburetor PDFRajesh PuhanNo ratings yet

- Cantidad Descripcion Numero de ParteDocument2 pagesCantidad Descripcion Numero de ParteJose Cruz Martinez MedinaNo ratings yet

- Study of Reciprocating Air CompressorDocument4 pagesStudy of Reciprocating Air Compressor01parth100% (5)

- 06 I C EnginesDocument60 pages06 I C Engines1234No ratings yet

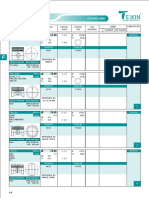

- Teikin Catalog Vol 18-Automotive FiatDocument6 pagesTeikin Catalog Vol 18-Automotive FiatJuan Esteban Ordoñez BonillaNo ratings yet

- How To Read Oil Analysis ReportDocument7 pagesHow To Read Oil Analysis ReportAbdullah BawazirNo ratings yet

- Curva Bs 2400.402 104kw c264 440v Y-D HT InoxDocument1 pageCurva Bs 2400.402 104kw c264 440v Y-D HT InoxIvanNo ratings yet

- 1250AJP Boom FlyerDocument2 pages1250AJP Boom FlyerMohamed AliNo ratings yet

- Engine RemanDocument24 pagesEngine RemanJoshua SimamoraNo ratings yet

- Steyr Marine Engines: MO256H45 I MO256K43Document2 pagesSteyr Marine Engines: MO256H45 I MO256K43Ayegba AchimuguNo ratings yet

- Arstra 1.8 2002.ecu ConectorDocument3 pagesArstra 1.8 2002.ecu Conectorcarlos eli olveraNo ratings yet

- 4BY150Document2 pages4BY150Angga ClevneztNo ratings yet

- Ignition Curve Analysis GuideDocument25 pagesIgnition Curve Analysis GuidePugs ThomasNo ratings yet

- Evo X ECUDocument2 pagesEvo X ECUJustin StarkNo ratings yet

- Performance Testing of An Electrically Assisted Turbocharger On A Heavy Duty Diesel EngineDocument23 pagesPerformance Testing of An Electrically Assisted Turbocharger On A Heavy Duty Diesel EngineZauron Kent TouchitNo ratings yet