Professional Documents

Culture Documents

Building Electrical Installation Level III Teacher Guide

Uploaded by

Mulugeta GebrieOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Building Electrical Installation Level III Teacher Guide

Uploaded by

Mulugeta GebrieCopyright:

Available Formats

KIRKOS MANUFACTURING COLLEGE

Building Electrical Installation Level III

TEACHER GUIDE

TTLM Code:- EIS BEI3 M11 112021v1

Prepared by: - Soresa Tamene

Introduction

his Teacher’s Guide is developed to assist trainers in delivering the BEI Level III training

program. It is usually designed as a resource to support the learning activity.

The BEI III Training is developed to equip the trainees with the required competences in use

The Program is consists of fifteen (15) learning modules covering the fifteen units of

competence The expected outputs of this program are the learners’ acquisition and implementation

of the following competence in Building Electrical Installation L –III. Prepare Working Drawing

(CAD) Select Wiring Systems and Cables for Low Voltage General Electrical Installations,

Install Electrical System Protection, and Install and Maintain Cabling for Multiple Access to

Telecommunication Services. Trouble- Shoot and Repair Faults in Low Voltage Electrical

Apparatus and Circuits , Perform Maintenance of Electrical Equipment , Inspect and

Commission Electrical Installation ,Work Safely in the Construction Industry , Identity OHS

Hazards and Risk Monitor Implementation of Work Plan/Activities ,Apply Quality Control Lead

Workplace Communication , Lead Small Teams , Improve Business Practice

This teacher’s guide covers all the fifteen (15) learning modules and it will assist trainers in

delivering the said program and achieving its learning objectives and outcomes. It also provides

information in the organization of the learning guides and assessment packets. The learning

guides are aid to the trainees by telling them what need to do, when and how to do it and the

expectations once the learning activities are completed. While the assessment packet guide you

in developing the tools or instruments to measure trainee’s overall achievement of the stated

competence. Thus it is important for trainer to understand the design of this program and the

mechanics in which it shall be delivered.

Trainer role as the teacher is to provide opportunities aimed at helping the trainees develop and

improve their competences. You are expected to guide and assist them as they go through the

learning activities and actual work.

Learning Guide BEI

Date: april 2013 E.C

Level III 1

Version: 1 Revision: 1

Author: soresa tamene

Learning Module

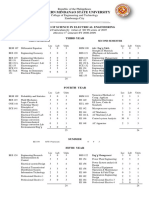

Unit of Competence Module Learning Outcomes D

Code &

Title

EIS BEI3 01 Prepare Working EIS BEI3 01 1118 PreparingWorking

1118 Drawing (CAD) Drawing (CAD) Determine drawing requirements Standa

3S.

Produce drawings in third angle projectio

including auxiliary views, sections and asse

EIS BEI3 02 Select Wiring EIS BEI3 02 1118 Selecting Wiring

1118 Systems and Cables Systems and Cables Prepare to select wiring systems and cab

for Low Voltage for Low Voltage general electrical installations

General Electrical General Electrical Select wiring systems and cables for gen

Installations Installations electrical installations

EIS BEI3 03 Install Electrical EIS BEI3 03 1118 Installing Electrical

1118 System Protection System Protection

Notify completion of work

EIS BEI3 04 Install and EIS BEI3 04 1118 Installing and

1118 Maintain Cabling Maintain Cabling Prepare to install and maintain cabling.

for Multiple Access for Multiple Access

Telecommunication to to

Services Telecommunication Complete cabling work, records and repo

Services

EIS BEI3 05 1118 Trouble- Shoot and EIS BEI3 05 1118 Troubling- Shoot and

Repair Faults in Low Repairing Faults in Prepare to

Voltage Electrical Low Voltage trouble-shoot and

Apparatus and Electrical Apparatus rectify faults

Circuits and Circuits Trouble-shoot

and repair faults.

Completion and

report trouble-

shoot and repair

Learning Guide BEI

Date: april 2013 E.C

Level III 2

Version: 1 Revision: 1

Author: soresa tamene

activities

EIS BEI3 06 1118 Perform Maintenance EIS BEI3 06 1118 Performing

of Electrical Maintenance of

Equipment Electrical Equipment for maintenance of

electrical

equipment

Maintain

electrical

equipment and

associated circuits

and document

results of

Maintenance of

electrical

equipment.

EIS BEI3 07 1118 Inspect and EIS BEI3 07 1118 Inspecting and

Commission Commission Plan and

Electrical Installation Electrical Installation prepare to

commission

electrical system

electrical system

EIS BEI3 08 1118 Work Safely in the EIS BEI3 08 1118 Working Safely in

Construction the Construction

Industry Industry legislative

requirements.

construction hazards

and control

Measures

communication

and reporting

processes.

incident response

Learning Guide BEI

Date: april 2013 E.C

Level III 3

Version: 1 Revision: 1

Author: soresa tamene

procedures.

EIS BEI3 09 1118 Identity OHS EIS BEI3 09 1118 Identitying OHS

Hazards and Risk Hazards and Risk

workplace hazard

Identification

information about

workplace

Hazards

OHS risk

assessment

EIS BEI3 10 1118 Monitor EIS BEI3 10 1118 Monitoring Monitor and

Implementation of Implementation of improve

Work Plan/Activities Work Plan/Activities workplace

operations

organize workflow

Maintain

workplace records

and make decisions

EIS BEI3 11 1118 Apply Quality EIS BEI3 11 1118 Applying Quality

Control Control lity

standards

service delivered.

information

quality deviations

documentation

Learning Guide BEI

Date: april 2013 E.C

Level III 4

Version: 1 Revision: 1

Author: soresa tamene

EIS BEI3 12 1118 Lead Workplace EIS BEI3 12 1118 Leading Workplace

Communication Communication icate

information about

workplace processes

discussion

Identify and

communicate

issues arising in

the workplace

EIS BEI3 13 1118 Lead Small Teams EIS BEI3 13 1118 Leading Small Teams Provide team

Leadership

vidual

and organizational

growth

evaluate workplace

learning

Develop team

commitment and

Cooperation

accomplishment of

organizational

goals

EIS BEI3 14 1118 Improve Business EIS BEI2 M14 Improving

Practice 0919 Business Practice Diagnose the

business

business

Learning Guide BEI

Date: april 2013 E.C

Level III 5

Version: 1 Revision: 1

Author: soresa tamene

Learning Outcomes and Assessment Criteria

Unit of Competence Apply Quality Control

Module- Title Applying Quality Control

Establish quality standards

LO1

Quality standard procedures for masonry work are

developed and agreed upon

Quality standard procedures are documented in accordance

Assessment Criteria with the organization policy

Standard procedures are introduced to organizational staff /

personnel

Standard procedures are revised / updated when necessary

LO2 Assess quality of service delivered

Services delivered are checked against organization quality

standards and specifications

Service delivered are evaluated using the appropriate

evaluation parameters and in accordance with organization

Assessment Criteria standards

Causes of any identified faults are identified and corrective

actions are taken in accordance with organization policies

and procedures

LO3 record information

Basic information on the quality performance is recorded in

accordance with organization procedures

Assessment Criteria

Records of work quality are maintained according to the

requirements of the organization

LO4: Study causes of quality deviations

Assessment Criteria Causes of deviations from final outputs or services are

investigated and reported in accordance with organization

procedures

Suitable preventive action is recommended based on

organization quality standards and identified causes of

deviation from specified quality standards of final service or

output

LO5: Complete documentation

Learning Guide BEI

Date: april 2013 E.C

Level III 6

Version: 1 Revision: 1

Author: soresa tamene

Assessment Criteria Information on quality and other indicators of service

performance is recorded

All service processes and outcomes are recorded

Learning Guide BEI

Date: april 2013 E.C

Level III 7

Version: 1 Revision: 1

Author: soresa tamene

Training Mechanics

The Outcome-Based Training is one form of an independent learning approach. This approach

enables trainees to be master of their own environment and in charge of their learning. It is also

characterized by the integration of theory and application as two dimensions of an effective

learning process. In this program, the outcome-based system is consists of a combination of

lecture-discussion, individualized learning activities, mentoring, field immersion and feedback.

In this program the trainees will be given individual learning guide to go through and

accomplish. They will be instructed through this learning guide to accomplish learning

activities as part of the mechanism for transfer of learning from the training situation to the job

situation. For each competence area, trainees will formulate a specific learning plan as a guide

for applying their learning to work setting and for their own continuing self-development. At

this point, your role as the teacher/facilitator is to guide the trainee in preparing and

accomplishing their plan.

Lecture and discussion of the topics outlined in the session plan should be performed first before

the trainees are instructed to go to the workshop. You are also required to demonstrate the

correct steps/procedures and techniques to your trainees before you let them practice. Insure

that they are practicing safely.

Most part of the training activities will be conducted in the workshop for better development of

specific skills. Aside from motivating them to relate concepts and skills to their own work

situations, make sure to provide the necessary opportunity for competence practice and better

internalization of such concepts and techniques. The trainees should also be provided the

opportunity to blend with the actual working unit in the industry.

In this system, it is important to develop a sustained relationship with the trainees through a

continued involvement, where you are to offer support, guidance and assistance as the trainee go

through the learning activities and actual work.

With the mentoring approach, the trainees are grouped in learning teams with one facilitator-

mentor per team. Before learning session or workshop start in the morning, each team and

mentor meets to give feedback regarding their work, or how the group improves, acquire set of

skills for the members to become more effective trainees. You are also to asses them at the end

of each module. However, they have to be ready before the assessment and it should be them to

request for it.

Learning Guide BEI

Date: april 2013 E.C

Level III 8

Version: 1 Revision: 1

Author: soresa tamene

Session Plans

Session Plan-1 (M11-LO1)

Unit of Competence Apply Quality Control

Module Title Applying Quality Control

LO1 Establish quality standards

At the end of this session the trainees will be able to –

Session Objectives

.

Developing and implementing quality standards, policies and

procedures

Documenting quality standards, policies and procedures

Update quality standards, policies and procedures

Nominal

Activities Contents Method

Duration

Sessions Developing policies and procedures

2 hrs Lecture

2 hrs Implementing quality standards, lecture ,Observation

1 hrs Documenting quality standards, policies Lecture, Observation

1 hrs Prepare work area Demonstration

Update quality standards, policies and

5 hrs lecture ,

procedures

2 hrs Update policies and procedures lecture ,

Evaluation 30 min Oral, written & lap test Individual,

Summary 30 min Wrap-up and feedback Lecture

Resources

learning guide#34

Session Plan-2 (M11-LO2)

Unit of Competence Apply Quality Control

Module Title Applying Quality Control

LO2 Assess quality of service delivered

Session Objectives At the end of this session the trainees shall be able to –

Learning Guide BEI

Date: april 2013 E.C

Level III 9

Version: 1 Revision: 1

Author: soresa tamene

Evaluation techniques

Quality checking procedures

Applying corrective actions

Nominal

Activities Contents Method

Duration

Sessions Evaluation techniques

5 hrs Lecture

Quality checking procedures

3 hrs Demonstration

Applying corrective actions

4 hrs Demonstration

Evaluation 40 min Oral, written & Lap test Individual, group

Summary 20 min Wrap-up and Feedback Lecture

Resources Learning guide#35

Unit of Competence Apply Quality Control

Module Title Applying Quality Control

LO3 record information

At the end of this session the trainees will be able to –

Session Objectives

Recording quality performance

Maintain records

Nominal

Activities Contents Method

Duration

Sessions 1 hrs Discuses previous class Demonstration

3 hrs

Recording quality performance Lecture

4 hrs

Maintain records Lecture

Evaluation 40 min Oral, written & Lap test Individual ,group

Summary 20 min Wrap-up and Feedback Demonstration

Resources Learning guide#36

Learning Guide BEI

Date: april 2013 E.C

Level III 10

Version: 1 Revision: 1

Author: soresa tamene

Session Plan-4 (M11-LO4)

Unit of Competence Apply Quality Control

Module Title Applying Quality Control

LO 4 Study causes of quality deviations

At the end of this session the trainees shall be able to –

Session Objectives

Identifying faulty or poor service

Identifying Causes of deviations

Identifying and applying corrective actions

Nominal

Activities Contents Method

Duration

Sessions Identifying faulty or poor service Lecture-

4 hrs

discussion

Identifying Causes of deviations Group and

5 hrs individual

assignment

Identifying and applying corrective actions Practical

4 hrs

exercise

Evaluation 40 min Oral, written & Lap test Individual ,group

Summary 20 min Wrap-up and Feedback Demonstration

Resources Learning guide#37

Learning Guide BEI

Date: april 2013 E.C

Level III 11

Version: 1 Revision: 1

Author: soresa tamene

Session Plan-5 (M11-LO5)

Unit of Competence Apply Quality Control

Module Title Applying Quality Control

LO 5

Complete documentation

At the end of this session the trainees shall be able to –

Session Objectives

Recording information on quality and other

indicators

Reporting procedures

Nominal

Activities Contents Method

Duration

Sessions Recording information on quality Lecture-

1 hrs

discussion

Reporting procedures Group and

2 hrs individual

assignment

Documentation Practical

1 hrs

exercise

Evaluation 40 min Oral, written & Lap test Individual ,group

Summary 20 min Wrap-up and Feedback Demonstration

Resources Learning guide#38

Learning Guide BEI

Date: april 2013 E.C

Level III 12

Version: 1 Revision: 1

Author: soresa tamene

Assessment Context

There are two types of evaluation used in determining the extent to which learning outcomes are

achieved. The specific learning outcomes are stated in the modules. In assessing them,

verifiable and observable indicators and standards shall be used.

The formative assessment is incorporated in the learning modules and form part of the learning

process. Formative evaluation provides the trainee with feedback regarding success or failure in

attaining learning outcomes. It identifies the specific learning errors that need to be corrected,

and provides reinforcement for successful performance as well. For the trainer/facilitator,

formative evaluation provides information for making instruction and remedial work more

effective. In this program the LAP Test serves as the formative assessment.

Summative Evaluation the other form of evaluation is given when all the modules of the

program have been accomplished. It determines the extent to which competence have been

achieved. This will be given in the form of written test for the underpinning knowledge and

demonstration for the attitudes and skills portion. And, the result of the assessment decision

shall be expressed in the term ‘competent or not yet competent’. In this program the summative

assessment shall also serves as the final examination.

These two types of evaluation form part of the training and they are considered as institutional

assessment.

Evaluation Tools

a) Formative Assessment

Written

Practical

Reading and presentation

b) Summative Evaluation

Written test

Learning Guide BEI

Date: april 2013 E.C

Level III 13

Version: 1 Revision: 1

Author: soresa tamene

Self-check

Choose the Best answer

1._______________ includes all the activities that organizations use to direct,

control, and coordinate quality

A.Standard

B.Strategy

C.Quality policy

D.Quality management

2. _________is a document. It is a set of rules that control how people develop and

manage materials, products, services, technologies, processes, and systems.

A.Standard

B.Strategy

C.Quality policy

D.Quality management

3. ____________defines top management’s commitment to quality

A.Standard

B.Strategy

C.Quality policy

D.Quality management

4. --------------- is a logically structured plan or method for achieving long term goals.

A,Standard

B,Strategy

C,Quality policy

D,Quality management

5. What will be Quality improvement?

A.Refers to anything that enhances an organization's ability to meet quality

requirements

B.A set of activities intended to ensure that quality requirements are actually

being met.

C.A set of activities that an organization carries out in order to enhance its ability

to meet requirements

Learning Guide BEI

Date: april 2013 E.C

Level III 14

Version: 1 Revision: 1

Author: soresa tamene

D.A set of activities intended to establish confidence that quality requirements

will be met

6. What will be Quality control?

A. Refers to anything that enhances an organization's ability to meet quality

requirements

B.A set of activities intended to ensure that quality requirements are actually

being met.

C.A set of activities that an organization carries out in order to enhance its ability

to meet requirements

D.A set of activities intended to establish confidence that quality requirements

will be met

7. What will be Continual improvement?

A.Refers to anything that enhances an organization's ability to meet quality

requirements

B.A set of activities intended to ensure that quality requirements are actually

being met.

C.A set of activities that an organization carries out in order to enhance its ability

to meet requirements

D.A set of activities intended to establish confidence that quality requirements

will be met

8. What will be Quality assurance (QA)?

A. Refers to anything that enhances an organization's ability to meet quality

requirements

B. A set of activities intended to ensure that quality requirements are actually

being met.

C. A set of activities that an organization carries out in order to enhance its ability

to meet requirements

D. set of activities intended to establish confidence that quality requirements will

be met

Learning Guide BEI

Date: april 2013 E.C

Level III 15

Version: 1 Revision: 1

Author: soresa tamene

Evidence Plan

TVET Program Building Electrical Installation level III

Learning Modules Applying Quality Control

Ways in which evidence will be collected:

Demonstration

Written Test

Discussion

The evidence must show that the trainee…

Develop and implementing quality standards

Document quality standards

Update quality standards

Identify Organizations should interrelated processes and

treat them as a system.

Improve Organizations should make a permanent

commitment to continually their overall performance

Maintain Organizations should a mutually beneficial

relationship with their suppliers

Manage Organizations should use a process approach to

activities and related resources

Evaluate techniques

Check Quality procedures

Apply corrective actions

plan A strategy is a logically structured or method for

achieving long term goals

Define An organization’s quality policy top management’s

commitment to quality.

Learning Guide BEI

Date: april 2013 E.C

Level III 16

Version: 1 Revision: 1

Author: soresa tamene

generate Quality policies should be used quality objectives

and should serve as a general framework for action

Record quality performance

Record information on quality and other indicators

Report procedures on quality and other indicators

Understand and improve operational processes

Identify faulty or poor service

Identify Causes of deviations

Identify and applying corrective actions

Prepared by: Soresa Tamene Date: 16/04/2021

Learning Guide BEI

Date: april 2013 E.C

Level III 17

Version: 1 Revision: 1

Author: soresa tamene

Summative Assessment

KIRKOS MANUFACTURING COLLEGE

TRAINEE TEST GUIDE

PERFORMANCE TEST

Level

BEI IIIIII

Level

Learning Modules

APPLY QUALITY CONTROL

covered

Learning Guide BEI

Date: april 2013 E.C

Level III 18

Version: 1 Revision: 1

Author: soresa tamene

Rating Sheet for PRACTICAL EXAM

Student’s Name:

Teacher’s Name:

Learning Module Title: Applying Quality Control

Learning Outcome covered: Lo1-Lo5

Batch Class:

Date of assessment:

Time of assessment:

Instructions for demonstration

Circuit breakers/Fuses Pilot lamps

Magnetic Contactors Selector Switches

Relays Din rail

Distribution board Wire Strap

Terminal Blocks/Lugs Push buttons

Wire Markers Câble Glands/Grommet

OBSERVATION

During the demonstration of skills, did the trainee: Yes No N/A

Check all lugs are properly crimped or soldered, and

connections are tight.

Measure voltage at motor terminals while motor

starting

Identify Overload or circuit breaker incorrectly set or

sized.

Perform Fit new fuses, reset circuit breakers, etc.

Check load performance data against motor

performance data.

Correct setting of overload or breaker or change.

Obtain Motor does not reach full speed or takes a

long time to accelerate.

The trainee’s demonstration was:

Satisfactory Not Satisfactory

Learning Guide BEI

Date: april 2013 E.C

Level III 19

Version: 1 Revision: 1

Author: soresa tamene

Questions Satisfactory

response

The trainee should answer the following questions: Yes No

1. What are the five Quality Performance in Production

Management?

2. Explain the Six-Factor Model of Personality in the

Workplace.

3. Explain the 5S in Increase Performance in the Workplace.

4. What is the use of finalizing product against workplace?

5. What is Quality?

The trainee’s underpinning knowledge was:

Satisfactory Not Satisfactory

Feedback to trainee:

The trainee’s overall performance was:

Satisfactory Not Satisfactory

Student signature: Date:

Teacher signature: Date:

Learning Guide BEI

Date: april 2013 E.C

Level III 20

Version: 1 Revision: 1

Author: soresa tamene

KEY ANSWERS

TEST ITEM ANSWER MARK

Multiple Choice

1 Answer: D

2 Answer: A

3 Answer: B

4 Answer: C

5 Answer: D

6 Answer: D

7 Answer: C

8 Answer: B

TEST ITEM ANSWER MARK

Short Answer Questions

1 Set direction and meet customers’ expectations

Improve process control

Reduce wastage

Lower costs

improved product value,

improved quality,

2 increased productivity (reduced waste),

reduced cycle time,

increased customer satisfaction

3 Laundry washing machine

Presses, compressor

Water pumps, fans

Wood working machines, wood planers

4 (DOL) starter is the simplest and the most inexpensive of all

starting methods and is usually used for squirrel cage induction

motors.

5 the quality of something can be determined by comparing a set

of inherent characteristics with a set of requirements

(Short Answer Questions) Total points

Learning Guide BEI

Date: april 2013 E.C

Level III 21

Version: 1 Revision: 1

Author: soresa tamene

Assessment Summary Results

Student’s Name

Teacher’s Name

TVET Program Title Building Electrical Installation level III

Batch Class

Module Title Applying Quality Control

Date of Assessment

The performance of the trainee is – Satisfactory Not Satisfactory

A. Demonstration with Oral questioning

B. Written Test

Did the trainee’s overall performance meet

Yes No

the required evidences / standards?

OVERALL EVALUATION COMPETENT NOT YET COMPETENT

General Comments [Strengths / Improvements needed]

Student's signature: Date:

Teacher’s signature: Date:

Learning Guide BEI

Date: april 2013 E.C

Level III 22

Version: 1 Revision: 1

Author: soresa tamene

TERMINAL REPORT

Batch Class: _______________

FINAL MARK

REGISTRATION

NO. Student’s Name

NUMBER [Competent / Not Yet Competent]

Legend: NYC – Not Yet Competent C – Competent

Learning Guide BEI

Date: april 2013 E.C

Level III 23

Version: 1 Revision: 1

Author: soresa tamene

Learning Guide BEI

Date: april 2013 E.C

Level III 24

Version: 1 Revision: 1

Author: soresa tamene

You might also like

- Teacher Guide: Kirkos Manufacturing CollegeDocument23 pagesTeacher Guide: Kirkos Manufacturing CollegeMulugeta GebrieNo ratings yet

- Electrical/Electronic Equipment Servicing Level - II: TVET Institution Training TheoryDocument4 pagesElectrical/Electronic Equipment Servicing Level - II: TVET Institution Training Theorybelacheweshetu222100% (1)

- Building Electrical Installation: NTQF Level I, Ii, Iii, Iv and VDocument248 pagesBuilding Electrical Installation: NTQF Level I, Ii, Iii, Iv and VBewuketu Alemayehu75% (4)

- OS II-V ElectronicsDocument202 pagesOS II-V ElectronicsSha Tu BolaNo ratings yet

- 232 Syllabus Flyer UEE30811 Certificate III in Electrotechnology Electrician V7 16032020 A.1Document13 pages232 Syllabus Flyer UEE30811 Certificate III in Electrotechnology Electrician V7 16032020 A.1Oyelowo SamuelNo ratings yet

- CV2201Document12 pagesCV2201abhijit satramwarNo ratings yet

- CBLM Rogh-In PDFDocument64 pagesCBLM Rogh-In PDFmyco saura80% (5)

- Ueeneeh119a R1Document13 pagesUeeneeh119a R1Sajid AliNo ratings yet

- Building Electrical InstallationDocument77 pagesBuilding Electrical Installationmengistu Addis100% (2)

- Electrical Short Courses BrochureDocument20 pagesElectrical Short Courses BrochureAbdullah JadNo ratings yet

- Abebe EMT CurriculemDocument31 pagesAbebe EMT CurriculemFantahun MucheNo ratings yet

- Learning Competencies Code Days Topics: First WeekDocument3 pagesLearning Competencies Code Days Topics: First WeekZeen DeeNo ratings yet

- EE4533 Power Apparatus and System Protection - OBTLDocument6 pagesEE4533 Power Apparatus and System Protection - OBTLAaron TanNo ratings yet

- MyLearning Catalog 2021 - Rev BDocument18 pagesMyLearning Catalog 2021 - Rev BMohamed MahmoudNo ratings yet

- Os Iect Lii-VDocument139 pagesOs Iect Lii-VErmiyas SolomonNo ratings yet

- College of Engineering: S/N Course Title Course Code Unit StatusDocument1 pageCollege of Engineering: S/N Course Title Course Code Unit StatusVictor ImehNo ratings yet

- GEnova FinalsDocument9 pagesGEnova Finalsjoey catotoNo ratings yet

- EE Lab Syllabus: Measure Circuits, Diodes & TransistorsDocument4 pagesEE Lab Syllabus: Measure Circuits, Diodes & TransistorsJannineNo ratings yet

- Basic Lab Equipment and Circuit MeasurementsDocument14 pagesBasic Lab Equipment and Circuit MeasurementsAsma GulzarNo ratings yet

- Contoh CPC DLLDocument9 pagesContoh CPC DLLIzzah ZakiNo ratings yet

- Bei L-IvDocument140 pagesBei L-IvMeried100% (1)

- EE4503 Power Engineering Design - OBTLDocument6 pagesEE4503 Power Engineering Design - OBTLAaron Tan100% (1)

- Design and Implementation of Portable Impedance AnalyzersFrom EverandDesign and Implementation of Portable Impedance AnalyzersNo ratings yet

- Session Plan in Eim11 - 2Document4 pagesSession Plan in Eim11 - 2EMELITO COLENTUMNo ratings yet

- EIM-SSLM-week5Document4 pagesEIM-SSLM-week5Ivy Jean Ybera-PapasinNo ratings yet

- NAAC AQAR Academic Year (2021-22)Document193 pagesNAAC AQAR Academic Year (2021-22)Kavishree RNo ratings yet

- Form 1.3 Comparing and Cross MatchingDocument2 pagesForm 1.3 Comparing and Cross MatchingMat Domdom SansanoNo ratings yet

- Tem 5025eDocument14 pagesTem 5025eĐồng Công QuốcNo ratings yet

- Assistant Electrician PDFDocument169 pagesAssistant Electrician PDFRajat SharmaNo ratings yet

- UEENEEI113A Setup and Configure Human-Machine Interface (HMI) and Industrial NetworksDocument14 pagesUEENEEI113A Setup and Configure Human-Machine Interface (HMI) and Industrial NetworksmhafizanNo ratings yet

- Ewis Course Note PDFDocument212 pagesEwis Course Note PDFSuman Bajracharya100% (1)

- Electrical TechnicianDocument232 pagesElectrical TechnicianmarcorpbackupNo ratings yet

- Form 1.3Document1 pageForm 1.3Jayson Deocareza Dela TorreNo ratings yet

- X1 Hybrid HV User ManualDocument38 pagesX1 Hybrid HV User ManualPMV DeptNo ratings yet

- Elec Discrimination StudyDocument4 pagesElec Discrimination Studyemoi72No ratings yet

- EE215 Lab 7: Zener & Limiter Circuits ApplicationsDocument5 pagesEE215 Lab 7: Zener & Limiter Circuits ApplicationsSher EjazNo ratings yet

- Short Circuit Guide Example PDFDocument174 pagesShort Circuit Guide Example PDFUlysses OreiroNo ratings yet

- Lab 3 (3420)Document12 pagesLab 3 (3420)Ahmed Razi UllahNo ratings yet

- Etn 2023 - Industrial Electronic Equipment TroubleshootingDocument11 pagesEtn 2023 - Industrial Electronic Equipment TroubleshootingpijaazizNo ratings yet

- DLL 14Document1 pageDLL 14Abigail MontesNo ratings yet

- North South University: Lab 5: Delta-Wye ConversionDocument6 pagesNorth South University: Lab 5: Delta-Wye ConversionNazmul Hasan 1911742042No ratings yet

- Coasting & EstimatingSyllDocument13 pagesCoasting & EstimatingSylldamrudharbareth25No ratings yet

- Supplement To Fault CalculationDocument88 pagesSupplement To Fault CalculationCaribNo ratings yet

- Able To Configure Ethernet Cable. Allotted Time 30 MinutesDocument4 pagesAble To Configure Ethernet Cable. Allotted Time 30 MinutesOrlando NajeraNo ratings yet

- IEEE STD C37.41™-2008: Sponsor of TheDocument4 pagesIEEE STD C37.41™-2008: Sponsor of TheHéctor EliasNo ratings yet

- Lab 03Document11 pagesLab 03afnanmirza106No ratings yet

- Electronics Syllabus-VerifiedDocument17 pagesElectronics Syllabus-VerifiedGennyNo ratings yet

- Level - 3 Railway Signaling Work &maintenanceDocument103 pagesLevel - 3 Railway Signaling Work &maintenancekedirNo ratings yet

- Electrical Power System Protection EE 45Document10 pagesElectrical Power System Protection EE 45Hsko TomNo ratings yet

- 1.4 1styr 1stsem ELECTRO 1 Basic ElectricityDocument29 pages1.4 1styr 1stsem ELECTRO 1 Basic ElectricityRYAN PILUETANo ratings yet

- Electrical Construction and MaintenanceDocument3 pagesElectrical Construction and MaintenanceEstudio Del DJNo ratings yet

- Loesungen Photovoltaik en PDFDocument134 pagesLoesungen Photovoltaik en PDFMilica LolićNo ratings yet

- Module 3. Building Installation (New Template) - 8219Document132 pagesModule 3. Building Installation (New Template) - 8219panjoelsNo ratings yet

- ELE202 Lab1 v2.1Document21 pagesELE202 Lab1 v2.1gotseason789No ratings yet

- X1 Hybrid User Manual 614.00184.03 6368850342699030647582506Document38 pagesX1 Hybrid User Manual 614.00184.03 6368850342699030647582506Charlez ManaloNo ratings yet

- Western Mindanao State University: Bachelor of Science in Electrical EngineeringDocument1 pageWestern Mindanao State University: Bachelor of Science in Electrical EngineeringMahpuja JulangNo ratings yet

- BNBC 2020-Vol-3 of 3 Electrical+Document210 pagesBNBC 2020-Vol-3 of 3 Electrical+Shabbir AhmadNo ratings yet

- Basic Electronics: Preparatory Electricity and Electronics Training SystemDocument220 pagesBasic Electronics: Preparatory Electricity and Electronics Training SystemMi LuanaNo ratings yet

- 1 CBLM-ROGH-IN ActivitiesDocument77 pages1 CBLM-ROGH-IN ActivitiesEarl TrinidadNo ratings yet

- The Group BehaviorDocument132 pagesThe Group BehaviorMulugeta GebrieNo ratings yet

- Oromia State University: Organizational Behavior Master of Business Administration CR.H 3Document36 pagesOromia State University: Organizational Behavior Master of Business Administration CR.H 3Mulugeta GebrieNo ratings yet

- Kirkos Manufacturing College: Building Electrical Installation LEVEL IIIDocument19 pagesKirkos Manufacturing College: Building Electrical Installation LEVEL IIIMulugeta GebrieNo ratings yet

- The Organization System and DynamicsDocument101 pagesThe Organization System and DynamicsMulugeta GebrieNo ratings yet

- Individual BehaviorDocument108 pagesIndividual BehaviorMulugeta GebrieNo ratings yet

- Monitor and evaluate workplace learningDocument15 pagesMonitor and evaluate workplace learningMulugeta GebrieNo ratings yet

- TG65Document26 pagesTG65Mulugeta GebrieNo ratings yet

- Ap 65Document14 pagesAp 65Mulugeta GebrieNo ratings yet

- lg#65Document48 pageslg#65Mulugeta GebrieNo ratings yet

- Performance Evaluation of A Five Phase Modular Externa - 2012 - Alexandria EnginDocument13 pagesPerformance Evaluation of A Five Phase Modular Externa - 2012 - Alexandria EnginMulugeta GebrieNo ratings yet

- TG#65Document26 pagesTG#65Mulugeta GebrieNo ratings yet

- Introduction To Outdoor Lighting: and How It Affects Light PollutionDocument48 pagesIntroduction To Outdoor Lighting: and How It Affects Light PollutionAmos KormeNo ratings yet

- 2 Basic Lighting Design PDFDocument4 pages2 Basic Lighting Design PDFzee159No ratings yet

- Application LetterDocument4 pagesApplication LetterMulugeta GebrieNo ratings yet

- HTML MCQDocument22 pagesHTML MCQBuxar Students LifeNo ratings yet

- Crash of Air France ConcordeDocument11 pagesCrash of Air France ConcordeAhmad Aimi SafuanNo ratings yet

- Strategic Management and Municipal Financial ReportingDocument38 pagesStrategic Management and Municipal Financial ReportingMarius BuysNo ratings yet

- Business Letter WritingDocument13 pagesBusiness Letter WritingAlex Alexandru100% (1)

- Lucknow Digital Members Directory 4 Jan22Document84 pagesLucknow Digital Members Directory 4 Jan22B2B InfomediaNo ratings yet

- 01 - Narmada M PhilDocument200 pages01 - Narmada M PhilafaceanNo ratings yet

- Korean Enthusiasm and PatriotismDocument68 pagesKorean Enthusiasm and PatriotismYukino Hera100% (1)

- v16 n3Document219 pagesv16 n3Mark ReinhardtNo ratings yet

- GogikavofobifigukidonDocument2 pagesGogikavofobifigukidonMd. Bepul HossainNo ratings yet

- Ultrasonic Couplant MSDSDocument2 pagesUltrasonic Couplant MSDSAnonymous uhqwokAeU0No ratings yet

- SECURED TRANSACTION BAR CHECKLISTDocument4 pagesSECURED TRANSACTION BAR CHECKLISTatw4377100% (1)

- List of Trigonometric IdentitiesDocument16 pagesList of Trigonometric IdentitiesArnab NandiNo ratings yet

- (MATH1013) (2016) (F) Midterm Wsuab 41338Document9 pages(MATH1013) (2016) (F) Midterm Wsuab 41338陳希程No ratings yet

- Studies of Land Restoration On Spoil Heaps From Brown Coal MiningDocument11 pagesStudies of Land Restoration On Spoil Heaps From Brown Coal MiningeftychidisNo ratings yet

- Serv Manual SM 100 FREEDocument75 pagesServ Manual SM 100 FREEGustavo Vargas Ruiz100% (1)

- WholeDocument397 pagesWholedelbot01No ratings yet

- WEG Low Voltage Motor Control Center ccm03 50044030 Brochure English PDFDocument12 pagesWEG Low Voltage Motor Control Center ccm03 50044030 Brochure English PDFRitaban222No ratings yet

- At GN4Document1 pageAt GN4jazzvivekNo ratings yet

- Metal Expansion Joint 2020 v2 20MBDocument116 pagesMetal Expansion Joint 2020 v2 20MBanni trejoNo ratings yet

- Avago Fiber Optic ComponentsDocument8 pagesAvago Fiber Optic ComponentsGerardo BaltaNo ratings yet

- Safety Data Sheet: Flexa SoftDocument9 pagesSafety Data Sheet: Flexa SoftSercan şahinkayaNo ratings yet

- Main Body Recruitment Process of Human Resource Division in Brac BankDocument55 pagesMain Body Recruitment Process of Human Resource Division in Brac BankAsfia PrantyNo ratings yet

- Collective BargainingDocument18 pagesCollective Bargainingchandni kundel100% (3)

- Document Revision TableDocument11 pagesDocument Revision Tableseva1969No ratings yet

- Lifeboat Equipment ListDocument1 pageLifeboat Equipment Listjosua albertNo ratings yet

- UFD/MMC/SD Controller Flash Support Limitation and Interconnection NoteDocument5 pagesUFD/MMC/SD Controller Flash Support Limitation and Interconnection Noteمہرؤآنہ آبہرآهہيہمہNo ratings yet

- Remove Fuel Sub TankDocument9 pagesRemove Fuel Sub Tankthierry.fifieldoutlook.comNo ratings yet

- Lyrics: Original Songs: - JW BroadcastingDocument56 pagesLyrics: Original Songs: - JW BroadcastingLucky MorenoNo ratings yet

- RSG 303Document196 pagesRSG 303Makinde TimiNo ratings yet

- Sample Resume For HRDocument2 pagesSample Resume For HRnapinnvoNo ratings yet