Professional Documents

Culture Documents

Att 11 - Launching and Receiving Procedure

Uploaded by

Avdhesh YadavOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Att 11 - Launching and Receiving Procedure

Uploaded by

Avdhesh YadavCopyright:

Available Formats

LIN SCAN

ADVANCED PIPELINE AND TANK SERVICES

P.O. Box 62159, Dubai, UAE

Launching & Receiving Procedures

1.1 Launching Procedures:

LIN SCAN will be completely in charge of handling of all, valves, doors, connections …etc., to

ensure safe and successful operations.

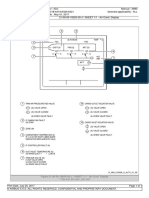

C2

C1 A

C3

P1 H P1 H

P1 H

E G1

G2

F

B

A - Main line valve

D Balance Line B - Main isolating valve

C1 - Kicker valve

D - Drain valve

E - Vent valve

F - Door

Figure 1. Typical Launcher G1, G2 - Pig alerts (pig sigs)

H - Pressure gauge

I - Pres. equalizing valve

1. Ensure kicker valves (C1+C2+C3) and isolation valves (B) are closed. *

2. Open drain valve (D) and vent valve (E) to drain and depressurize the launcher barrel.

Confirm zero pressure. Unseat bleed screw on door.*

Note 1: If no fluid flows through the bleed screw, remove bleed screw. Airflow into trap

Indicates that fluid is still flowing from the trap via the drain. When the airflow stops the traps is

fully drained and the door may be opened.

Note 2: A number of older doors may not be fitted with bleed screws. In these cases additional

precautions shall be taken before opening the door, .e.g. confirm by visual observation that

draining has stopped.

3. Open door (F) in accordance with manufacturer's procedure.*

LIN SCAN

ADVANCED PIPELINE AND TANK SERVICES

P.O. Box 62159, Dubai, UAE

Launching & Receiving Procedures

4. Load pig into barrel, ensuring that the front driving cups are in contact with the reducing portion

of the barrel.

5. Check door seal, clean and lightly oil mating surfaces, close door. Close drain valve (D), ensure

that door is securely locked in accordance with the manufacturer's procedure.*

6. Open the pressure equalizing valve (I), if fitted across the barrel eccentric reducer in order to

prevent the pig coming into contact with the main isolation valve whilst pressuring up the

barrel.

7. Open kicker valve (C2) then slowly crack valve (C3) open.

8. As oil/gas enters air will be displaced from the barrel through the vent valve (E).*

9. When barrel is full of product, close vent valve (E) and allow the barrel to pressurize fully.

10. In the case of a gaseous product air will be replaced by gas. Continuous reading shall be taken

until 100% gas is detected at the vent valve (E).*

Note 1:

Ignition sources shall be removed from the area and continuous atmospheric monitoring within the

area shall be carried out.

Note 2:

In H2S designated areas the procedures for entering and working in an H2S area must be followed.

As a minimum each LIN SCAN employee needs to carry a personal H2S detector at all times.

11. Check all pressure gauges give the same reading. Close kicker valve (C2) and (C3).*

12. Close pressure equalizing valve (I).*

13. Set the pig signaler (G1) and (G2) open main isolating valve (B) fully. *

14. Open kicker valve (C1) fully.*

15. Slowly close main line valve (A) to force product flow through the launcher until pig signaler

(G1) trips showing that the pig has left the barrel and its traveling through the pipeline.

16. Reset the pig signaler.*

17. Open main line valve (A).*

18. Close kicker valve (C1).*

19. Close main isolating valve (B) and vent valve (E).*

20. Drain and depressurized as mentioned above.*

21. Close drain valve (D) and vent valve (E) clean and empty drain pit.*

LIN SCAN

ADVANCED PIPELINE AND TANK SERVICES

P.O. Box 62159, Dubai, UAE

Launching & Receiving Procedures

1.2 Receiving Procedures:

LIN SCAN will be completely in charge of handling of all valves, doors, connections …etc., to

ensure safe and successful operations.

C2

C1 A

C3

P1 H P1 H

P1 H

E G1

G2

F

B

A - Main line valve

D Balance Line B - Main isolating valve

C1 - Kicker valve

D - Drain valve

E - Vent valve

F - Door

Figure 2. Typical Receiver G1, G2 - Pig alerts (pigsigs)

H - Pressure gauge

I - Pres. equalizing valve

1. At the start main line valve (A) is open, main isolating valve (B) and kicker valves (C1, C2 and C3)

are closed.*

2. Ensure that drain valve (D) is closed and that the door (F) is secured as per manufacturer

procedure and that the pressure equalizing valve (I) is open.*

3. Open vent valve(s) (E).*

4. Open (C2) crack open (C3) and fill the barrel while air is being vented via (E).*

5. In the case of a gas pipeline air will be replaced by gas, continuous reading shall be taken until

100% gas is detected at the vent valve.*

6. When the barrel is filled with product, close vent valves (E) and allow the barrel to pressurize

fully. Check that the barrel pressure gauge shows the same values as the line pressure gauge.*

LIN SCAN

ADVANCED PIPELINE AND TANK SERVICES

P.O. Box 62159, Dubai, UAE

Launching & Receiving Procedures

7. Open kicker valve (C1) fully and open main isolating valve (B). This allows fluid to flow through

the receiver.*

8. Close the main line valve (A) completely.*

9. Confirm there is no leakage from the door seal and fittings before leaving the site.*

10. Arrival of the pig is shown initially by pig alert (G1) being activated. Pig alert (G2) should activate

shortly afterwards to show that the pig has entered the barrel.

11. Once pig is the receiver barrel, open main line valve (A) fully.*

12. Close main isolating valve (B).*

13. Close kicker valve (C1, C2 and C3).*

14. Drain and de-pressure through drain valve (D) and vent valve(s) (E). Ensure that the pressure

equalizing line (I), if fitted across the reducer, is open. Confirm that pressure is zero. Unseat

bleed screw on door.*

15. If no fluid flows through the bleed screw, removed bleed screw, airflow into the trap indicates

that fluid is still flowing from the trap via the drain. When the airflow stops the trap is fully

drained and the door may be opened.*

Note: A number of older doors may not be fitted with bleed screws. In this case additional

precautions shall be taken before opening the door, e.g. confirm by visual observation that drain

had stopped.

16. Open door (F) and remove pig. */**

17. Clean out receiver barrel and take sample of debris, if specially required. A sample sheet shall be

completed and sent with the sample to the appropriate laboratory. Check door seal clean and

lightly oil mating surfaces.*

18. Close door (F) drain valve (D) and vent valve (E). Ensure door (F) is secured as per manufacturer

procedure.*

19. Empty and clean the drain pit and cross check the valve positions before leaving the site.*

Note:

* Operations performed by Client

** Operations performed by LIN SCAN

You might also like

- Projects Launching & Receiving ProcedureDocument11 pagesProjects Launching & Receiving ProcedureAtif QamarNo ratings yet

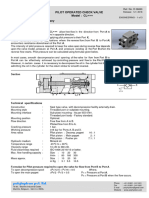

- Sofis Netherlocks InterlocksDocument12 pagesSofis Netherlocks InterlockscesarNo ratings yet

- Filtration Unit Manual BookDocument6 pagesFiltration Unit Manual Bookf4CHNo ratings yet

- Rxq6Ary1 Rxq8Ary1 RXQ10ARY1 RXQ12ARY1 RXQ14ARY1 RXQ16ARY1 RXQ18ARY1 RXQ20ARY1Document44 pagesRxq6Ary1 Rxq8Ary1 RXQ10ARY1 RXQ12ARY1 RXQ14ARY1 RXQ16ARY1 RXQ18ARY1 RXQ20ARY1Tangtang SatangNo ratings yet

- Figure 21-00-00-18200-00-J / SHEET 1/1 - Air Cond. Display ON A/C 201-201, 207-207Document1 pageFigure 21-00-00-18200-00-J / SHEET 1/1 - Air Cond. Display ON A/C 201-201, 207-207chinna_jetNo ratings yet

- Ducto y Vacios-93040632Document11 pagesDucto y Vacios-93040632Nicolás CastiblancoNo ratings yet

- External Pilot Type, Dual 2-Port Solenoid Valve and Manifold SY5A2R-X10 SS5Y5-20P-X688Document5 pagesExternal Pilot Type, Dual 2-Port Solenoid Valve and Manifold SY5A2R-X10 SS5Y5-20P-X688Ade AdeNo ratings yet

- DCV Series VALVES Data SheetDocument11 pagesDCV Series VALVES Data SheetGabriel LeonoriNo ratings yet

- 4650 and 4850 Section 70Document58 pages4650 and 4850 Section 70josephmw0308No ratings yet

- IWCF Equipment اسئله Sep 18 MaerskDocument56 pagesIWCF Equipment اسئله Sep 18 MaerskAboZaidNo ratings yet

- ROC L Hydr Valve Blocks - V2Document11 pagesROC L Hydr Valve Blocks - V2ApeksNo ratings yet

- Water Bath Instruction ManualDocument2 pagesWater Bath Instruction ManualLoreto CarrascoNo ratings yet

- S001-13 Installation SchemeDocument4 pagesS001-13 Installation SchemeJoe JohnsonNo ratings yet

- D-241 Dilution & FlushingDocument1 pageD-241 Dilution & FlushingHammad HussainNo ratings yet

- Vertu Inverter Multi Service ManualDocument32 pagesVertu Inverter Multi Service ManualLas YsigNo ratings yet

- Service InformationDocument2 pagesService InformationMarcelo GiussaniNo ratings yet

- Kitchen Faucet InstructionsDocument10 pagesKitchen Faucet Instructionsmember1000No ratings yet

- Yfick IomDocument21 pagesYfick IomJericho EstrellaNo ratings yet

- 345b Excavator Electrical System Schematic Used in Service Manual Renr1900 - Caterpillar Machinery Repair & TroubleshootingDocument5 pages345b Excavator Electrical System Schematic Used in Service Manual Renr1900 - Caterpillar Machinery Repair & TroubleshootingWilliams Burgos67% (3)

- Impact Valve Block (COPROD) : Qds-A QDS-J Pilot ValveDocument11 pagesImpact Valve Block (COPROD) : Qds-A QDS-J Pilot ValveFrancisco Alvarado HuenquiaoNo ratings yet

- Chapter 10 Steering SystemDocument17 pagesChapter 10 Steering SystemPepe AlNo ratings yet

- Service Manual 12 18 24K Light CommercialDocument70 pagesService Manual 12 18 24K Light CommercialUseköl Electromecánica y HVACNo ratings yet

- Caractéristiques Clapet AS25Document2 pagesCaractéristiques Clapet AS25Erwan Le GuenNo ratings yet

- Technical Information Series C: Slip-In Cartridge Valve CoversDocument11 pagesTechnical Information Series C: Slip-In Cartridge Valve CoversezeizabarrenaNo ratings yet

- Pressure Balancing Techniques To Control Spontaneous CombustionDocument26 pagesPressure Balancing Techniques To Control Spontaneous CombustionpablomilanezNo ratings yet

- Sigurnosni Ventili Hidraulike 7 I 7aDocument11 pagesSigurnosni Ventili Hidraulike 7 I 7aDraganNo ratings yet

- H6-Sany 135 PDFDocument17 pagesH6-Sany 135 PDFHector bustosNo ratings yet

- Series 100 ValvesDocument36 pagesSeries 100 ValvesCarlos Rovello GandoNo ratings yet

- X1 BASE Plus ManuelDocument8 pagesX1 BASE Plus ManuelTyler BergstromNo ratings yet

- A Polyhydron Group Company: Pilot Operated Check Valve Model: CLDocument3 pagesA Polyhydron Group Company: Pilot Operated Check Valve Model: CLDaniel Sandoval FernándezNo ratings yet

- FlufloDocument9 pagesFlufloDiego MoralesNo ratings yet

- LTS PlantDocument2 pagesLTS PlantAhmed NahrawyNo ratings yet

- AC1215 70 Philips User ManualDocument66 pagesAC1215 70 Philips User ManualJosephNo ratings yet

- A) B) C) D) E) : InstallationDocument27 pagesA) B) C) D) E) : InstallationPatrick MarcaidaNo ratings yet

- Pigging: Describe The Main Reasons For Launching A PigDocument6 pagesPigging: Describe The Main Reasons For Launching A PigImmanuelNo ratings yet

- Skema Utilitas TerbaruDocument1 pageSkema Utilitas TerbaruAnas SubkhanNo ratings yet

- Section 5 Work EquipmentDocument8 pagesSection 5 Work EquipmentTaha RdmanNo ratings yet

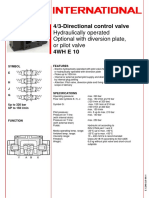

- Directional Control ValvesDocument16 pagesDirectional Control ValvesSamad A BakarNo ratings yet

- 4-Burner Gas Grill: ITEM #0097709 Model #Document39 pages4-Burner Gas Grill: ITEM #0097709 Model #urieoNo ratings yet

- Mooney M20R - ChecklistDocument14 pagesMooney M20R - ChecklistJoão SantosNo ratings yet

- Accumulator CatalogueDocument4 pagesAccumulator CatalogueDomingos BarrosNo ratings yet

- WB March 2004Document8 pagesWB March 2004Caterine Jara CeaNo ratings yet

- Asme Bladder Accumulator DatasheetDocument3 pagesAsme Bladder Accumulator DatasheetSamad A BakarNo ratings yet

- ASME Bladder Accumulator DatasheetDocument3 pagesASME Bladder Accumulator DatasheetEng-Mohammed Salem100% (1)

- FX 6Document116 pagesFX 6Jared PérezNo ratings yet

- Cannot Operate All DoorsDocument16 pagesCannot Operate All DoorsDannyDDannyDNo ratings yet

- Guide Lines-: Heavy Storm Water HandlingDocument1 pageGuide Lines-: Heavy Storm Water HandlingAnonymous 5PGSwX5No ratings yet

- Technical Data: The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058Document1 pageTechnical Data: The Viking Corporation, 210 N Industrial Park Drive, Hastings MI 49058Dgh TeriNo ratings yet

- Tcpl-1X63.75 MW Power Plant, Gummidipoondi - 1Document5 pagesTcpl-1X63.75 MW Power Plant, Gummidipoondi - 1SelvaNo ratings yet

- Vmy UkDocument8 pagesVmy UkEdwinNo ratings yet

- Luxfer SOPMPV Manual Rev 3bDocument16 pagesLuxfer SOPMPV Manual Rev 3bandreicarbuneanuNo ratings yet

- Ful Flo A SeriesDocument10 pagesFul Flo A Seriesrodruren01No ratings yet

- DX75控制阀BCV-65 Manual EngDocument27 pagesDX75控制阀BCV-65 Manual EngAimHighNo ratings yet

- Procedures For Pigging OperationsDocument5 pagesProcedures For Pigging Operationsテレブリコ ジェファーソン78% (9)

- Pneumatic Actuator ElementsDocument49 pagesPneumatic Actuator Elementsdk.vermaNo ratings yet

- Water Level GaugeDocument6 pagesWater Level GaugeAlexander BaziotisNo ratings yet

- Water Flow Diagrams: Seawater Cooled Models With An Engine Mounted Seawater PumpDocument2 pagesWater Flow Diagrams: Seawater Cooled Models With An Engine Mounted Seawater PumpJason WilliamNo ratings yet

- Polti Vaporetto 1030-ENGDocument12 pagesPolti Vaporetto 1030-ENGChristian AlbertiniNo ratings yet

- Execution of Pulling Pipeline in Swampy AreaDocument1 pageExecution of Pulling Pipeline in Swampy AreaAvdhesh YadavNo ratings yet

- Laying Arrangement For Push PullDocument1 pageLaying Arrangement For Push PullAvdhesh YadavNo ratings yet

- Push Pull Laying PipelineDocument1 pagePush Pull Laying PipelineAvdhesh YadavNo ratings yet

- Installation in SlopeDocument21 pagesInstallation in SlopeAvdhesh YadavNo ratings yet

- TD31 Datasheet 12 4CC CW Protector NoseDocument3 pagesTD31 Datasheet 12 4CC CW Protector NoseAvdhesh YadavNo ratings yet

- Att 10 - HSE GuidleinesDocument4 pagesAtt 10 - HSE GuidleinesAvdhesh YadavNo ratings yet

- Rabies PresentationDocument23 pagesRabies PresentationAvdhesh YadavNo ratings yet

- 3c. Health & Safety PlanDocument21 pages3c. Health & Safety PlanAvdhesh YadavNo ratings yet

- ASME 31.8-841.1.1-8 Temperature Derature TableDocument1 pageASME 31.8-841.1.1-8 Temperature Derature TableAvdhesh YadavNo ratings yet

- 3b. Process Risk AssessmentDocument33 pages3b. Process Risk AssessmentAvdhesh YadavNo ratings yet

- TP48200A-H15A8 Outdoor Power System Datasheet For Enterprise 01-20130507Document2 pagesTP48200A-H15A8 Outdoor Power System Datasheet For Enterprise 01-20130507Zaheer Ahmed TanoliNo ratings yet

- Molecular Orbital Theory: or When Electrons Don't Like Sitting Between Atoms!Document33 pagesMolecular Orbital Theory: or When Electrons Don't Like Sitting Between Atoms!HeniAnggraeniLestariNo ratings yet

- Silicon Nitride - Synthesis, Properties and Application (2012)Document176 pagesSilicon Nitride - Synthesis, Properties and Application (2012)Daud BabaNo ratings yet

- JMS For INSTRUMENT TUBING AND IMPULSE LINE Pressure Leak TestDocument3 pagesJMS For INSTRUMENT TUBING AND IMPULSE LINE Pressure Leak Testzack zeeartNo ratings yet

- Ball ChargeDocument28 pagesBall ChargeAbul Qasim50% (2)

- How To Make Floating Tensegrity Table: Step 1Document9 pagesHow To Make Floating Tensegrity Table: Step 1Januar EmberNo ratings yet

- Print Double-Sided - Acrobat, ReaderDocument4 pagesPrint Double-Sided - Acrobat, ReaderGustavo Dos Santos AngeliNo ratings yet

- A Paper Sizes - A0, A1, A2, A3, A4, A5, A6, A7, A8, A9, A10Document3 pagesA Paper Sizes - A0, A1, A2, A3, A4, A5, A6, A7, A8, A9, A10RajaKuppanNo ratings yet

- Counting Scale: User InstructionsDocument50 pagesCounting Scale: User InstructionsDexter PoliNo ratings yet

- User Manual - SR 60-80-100kvaDocument59 pagesUser Manual - SR 60-80-100kvaThịnh LêNo ratings yet

- En Katalog NawiewnikowDocument56 pagesEn Katalog NawiewnikowmarioLhrNo ratings yet

- 07 Thermal StressDocument13 pages07 Thermal StressSundaravathanan ChellappanNo ratings yet

- Z Transform 2 of 3Document18 pagesZ Transform 2 of 3Gilbert SigalaNo ratings yet

- Bulk Chemical Facilities ChecklistDocument5 pagesBulk Chemical Facilities ChecklistPerwez21No ratings yet

- Name: Teacher: Date: Score:: Reading Bar GraphsDocument2 pagesName: Teacher: Date: Score:: Reading Bar GraphsLatoyaWatkinsNo ratings yet

- Palm Oil in FryingDocument73 pagesPalm Oil in FryingGenesis Custodio100% (1)

- Reasons, Regulations, and Rules: A Guide To The Validation Master Plan (VMP)Document6 pagesReasons, Regulations, and Rules: A Guide To The Validation Master Plan (VMP)carbouNo ratings yet

- A Consideration On Intermediate Diaphragm Spacing in Steel BoxDocument10 pagesA Consideration On Intermediate Diaphragm Spacing in Steel BoxDhimas Surya NegaraNo ratings yet

- Everydayrailsrspec Sample PDFDocument42 pagesEverydayrailsrspec Sample PDFJustoMtzNo ratings yet

- Assignment VlsiDocument5 pagesAssignment VlsiBk RoyNo ratings yet

- Polyaspartic Webinar Protective and MarineDocument47 pagesPolyaspartic Webinar Protective and MarinequimizaNo ratings yet

- RILEM Report 35 - Casting of Self-Compacting ConcreteDocument41 pagesRILEM Report 35 - Casting of Self-Compacting ConcretegianniorlatiNo ratings yet

- 19xr 6ssDocument206 pages19xr 6ssLouie Dupaya100% (1)

- Reference Guide FTTHDocument116 pagesReference Guide FTTHturbozmejNo ratings yet

- 201505 緑測器カタログ 中国版 0604Document12 pages201505 緑測器カタログ 中国版 0604YiBiauChiouNo ratings yet

- Water DistributionDocument116 pagesWater DistributionJoshua GonzalesNo ratings yet

- Electrical Codes & Standards ListDocument27 pagesElectrical Codes & Standards ListKamalesh SaraswatNo ratings yet

- Curriculam VitaeDocument3 pagesCurriculam Vitaeapi-3708106No ratings yet

- Schedule ADocument46 pagesSchedule ALucian AnghelNo ratings yet

- Material Selection For Screwdriver-Sandeep SikriDocument25 pagesMaterial Selection For Screwdriver-Sandeep SikriSunil Yadav0% (2)