Professional Documents

Culture Documents

Suiga WC 12co

Uploaded by

Suiga TechnologiesOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Suiga WC 12co

Uploaded by

Suiga TechnologiesCopyright:

Available Formats

India Office:

1701, D Block, Raheja Vistas,

Raheja Vihar, Chandivili, Andheri (East)

MUMBAI - 400072 INDIA

suiga.advancedtechnologies@gmail.com

shashi.bhushan@suigatech.com

Cell: +91 9833 698872

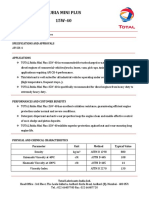

WC-12Co Thermal Spraying Powder

WC-12Co is a tungsten carbide cobalt powder specifically designed for HVOF systems to produce very dense, well-

bonded coatings. These coatings provide excellent resistance against most forms of wear with a service environment

up to 500°C (930°F). The materials contain fine-grained carbides for resistance against abrasive grains, hard

surfaces, particle erosion , sliding and fretting wear mechanisms. High chrome like finishes can be obtained by

typical grinding or lapping techniques.

Product Introduction

Product WC - Base

Composition 88% WC -12%Co

Manufacturing Process Agglomerated & Sintered

Morphology Spherical

Purpose Wear resistance

AD 4.4 – 5.2 g/cm3

Flowability Free flowing powder The metallography section Electron microscopy morphology

Specification & Application

Specifications Composition

Grade Features/ Applications

µm % wt

SGP-12 - 45 / +15 W : Bal. • High abrasion, erosion and sliding wear resistance

Co: 11.0 -13.0% • Excellent bond strength & impact toughness

SGP12-1 - 53 / +15

C : 5.2 – 5.7% • Applications include Hydel power runners and

SGP12-2 - 38 / +15 Fe: ≤ 0.5% buckets, wire drawing drums, fan blades, dies,

O : ≤ 0.1% valve seats, oil field components, paper making

SGP12-16 - 25 / +5 rollers, drawing cone, etc.

Coating Characteristics

Product WC - Base

Spraying system HVOF/HVAF/APS

Hardness (HV0.3) 950 - 1350

Bonding strength ≤ 70MPa

Porosity ≤ 1%

Deposition efficiency 45-65%

Max Service temperature 500°C

Note: Other grades and types of powder canbe made uponcustomer’s specific requirements.

Mumbai Kolkata Jakarta Surabaya Durban

You might also like

- 200-DR Datasheet PDFDocument4 pages200-DR Datasheet PDFKumarRam100% (2)

- SUIGA VARIHARD SteelCase TC RodDocument4 pagesSUIGA VARIHARD SteelCase TC RodSuiga TechnologiesNo ratings yet

- MAK Garonex R 250 GreaseDocument1 pageMAK Garonex R 250 GreaseVardhman SalesNo ratings yet

- Molykote Cu7439 PasteDocument1 pageMolykote Cu7439 PasteProject Sales CorpNo ratings yet

- Servo System 32 46 68Document1 pageServo System 32 46 68ramu naik malothNo ratings yet

- SUIGA VARIHARD Flexi TC WireDocument4 pagesSUIGA VARIHARD Flexi TC WireSuiga TechnologiesNo ratings yet

- Co2 Laser Cutting Machine 4 X 8Document4 pagesCo2 Laser Cutting Machine 4 X 8NAVEEN KUMAR SHARMANo ratings yet

- Everlube 9002 TDSDocument2 pagesEverlube 9002 TDSValentinNo ratings yet

- MAK Graphite Grease SpecialDocument1 pageMAK Graphite Grease SpecialVardhman SalesNo ratings yet

- Marfak 00, 0, 1Document2 pagesMarfak 00, 0, 1Hector IbarraNo ratings yet

- Ultratack Mill Grease SG 4001Document1 pageUltratack Mill Grease SG 4001arkpNo ratings yet

- Product Information Sheet: Description: ApplicationDocument2 pagesProduct Information Sheet: Description: ApplicationgalaxiprinceNo ratings yet

- Ficha Tecnica GrasaDocument2 pagesFicha Tecnica GrasaSergio Torres VeraNo ratings yet

- 7P-700 C-THANE S700 HB: High Built Glossy Polyurethane EnamelDocument4 pages7P-700 C-THANE S700 HB: High Built Glossy Polyurethane EnamelDavid RodriguesNo ratings yet

- GL XX Mobilgear SHC SeriesDocument3 pagesGL XX Mobilgear SHC SeriesHenry UntirtaNo ratings yet

- AffcvDocument2 pagesAffcvValentinNo ratings yet

- MAK Hitemp Xtra SM GreaseDocument1 pageMAK Hitemp Xtra SM GreaseAnand PadhiyarNo ratings yet

- ERABOMDocument2 pagesERABOMAlberto Alfaro CerdaNo ratings yet

- MAK Lanthax EP GreaseDocument2 pagesMAK Lanthax EP GreaseshobhaNo ratings yet

- Puma HD Drive Train 10W 30 40 50 TDSDocument2 pagesPuma HD Drive Train 10W 30 40 50 TDSHakim AmmorNo ratings yet

- Super HDB 10W: Automotive Diesel EnginesDocument1 pageSuper HDB 10W: Automotive Diesel EnginesizzybjNo ratings yet

- ISO 12944 5 C5 Paint System WilkoDocument5 pagesISO 12944 5 C5 Paint System Wilkojayakumar100% (3)

- 1040 Stangard (ST) Epoxy Mastic-ImpDocument6 pages1040 Stangard (ST) Epoxy Mastic-ImpThenamudhan sakthivelNo ratings yet

- Rubia Fleet HD 400 15W 40Document2 pagesRubia Fleet HD 400 15W 40سالم دريديNo ratings yet

- Interface Value GradesDocument16 pagesInterface Value Gradesvagner boldiNo ratings yet

- Moly GreaseDocument2 pagesMoly GreaseDivyanshu SharmaNo ratings yet

- MFG 460 - 3M - TDS - 2 - 12.10.22Document1 pageMFG 460 - 3M - TDS - 2 - 12.10.22RUTA TLAXCALA (SHELL)No ratings yet

- Sher-Tile HS - SHERWIN WILLIAMSDocument4 pagesSher-Tile HS - SHERWIN WILLIAMSJoão Gilberto Vedana JúniorNo ratings yet

- FT - Longtime PD RangeDocument2 pagesFT - Longtime PD RangeRonald Mario Kupa AnticonaNo ratings yet

- GL XX Mobilgear SHC SeriesDocument3 pagesGL XX Mobilgear SHC Seriesanibal_rios_rivasNo ratings yet

- Rubia Mini Plus 15w-40 Pds PDFDocument2 pagesRubia Mini Plus 15w-40 Pds PDFAmal AleyasNo ratings yet

- Everlube 620 ATDSDocument2 pagesEverlube 620 ATDSValentinNo ratings yet

- Gadus S5 V220 2Document2 pagesGadus S5 V220 2Luqman Cuopreakt'zNo ratings yet

- Quotation Co2 Laser Machine-1410-110WDocument2 pagesQuotation Co2 Laser Machine-1410-110Wdpradhan.admNo ratings yet

- Servo Product Data - Industrial GradesDocument23 pagesServo Product Data - Industrial GradesUtkarsh100% (1)

- Gre Pipe Technical Documents PDFDocument64 pagesGre Pipe Technical Documents PDFSunriseNo ratings yet

- 1482407553balmerol Ropelube 1000 PdsDocument2 pages1482407553balmerol Ropelube 1000 PdsKapil GoyalNo ratings yet

- Total Rubia Tir 8800 10w 40Document3 pagesTotal Rubia Tir 8800 10w 40Marko MinicNo ratings yet

- Performance Thickness Ratio at Its BestDocument2 pagesPerformance Thickness Ratio at Its BestmshNo ratings yet

- 985 000 693,4,5,6Document3 pages985 000 693,4,5,6IventNo ratings yet

- MAK Hydrol HVLPDocument3 pagesMAK Hydrol HVLPadheesNo ratings yet

- Rubia Fleet HD 500 15w-40Document2 pagesRubia Fleet HD 500 15w-40Sami KahtaniNo ratings yet

- 3751 QD Almagard®Vari PurposeLubricant3751Document4 pages3751 QD Almagard®Vari PurposeLubricant3751Celular Oil Control 05No ratings yet

- Product Description: Mobilube HD 80W-90, 85W-140Document3 pagesProduct Description: Mobilube HD 80W-90, 85W-140windiNo ratings yet

- Shalifloor M DH: DescriptionDocument2 pagesShalifloor M DH: Descriptionsiddhartha kumar SinghNo ratings yet

- Ip9183 R1Document4 pagesIp9183 R1jeffinNo ratings yet

- Shell Gadus S5 V220 2: Performance, Features & Benefits Main ApplicationsDocument2 pagesShell Gadus S5 V220 2: Performance, Features & Benefits Main ApplicationsWawanDarmawanNo ratings yet

- Servo Coat 120Document1 pageServo Coat 120BhaveshBalasNo ratings yet

- Sheet CM RD 215 GGG HRDocument2 pagesSheet CM RD 215 GGG HRSea Man MktNo ratings yet

- Gem EPDocument1 pageGem EPAnanda Shankar SahuNo ratings yet

- Variable Resistive Inks (Vri) : Technical Data SheetDocument2 pagesVariable Resistive Inks (Vri) : Technical Data SheetDebidas KunduNo ratings yet

- GreasesDocument11 pagesGreasesRamakrishnan NatarajanNo ratings yet

- LaminateDocument68 pagesLaminatedesignNo ratings yet

- Rocol Sapphire® Hi-Power Range 22Document7 pagesRocol Sapphire® Hi-Power Range 22Luz Angela GuerreroNo ratings yet

- Omega 85Document1 pageOmega 85Kelly RobertsNo ratings yet

- A Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessFrom EverandA Study of the Supply Chain and Financial Parameters of a Small Manufacturing BusinessNo ratings yet

- Advanced Level of Dental Resins - Material Science & Technology: 2nd Edtion / 2nd VersionFrom EverandAdvanced Level of Dental Resins - Material Science & Technology: 2nd Edtion / 2nd VersionNo ratings yet

- Suiga WC 12niDocument1 pageSuiga WC 12niSuiga TechnologiesNo ratings yet

- SUIGA TriboHARD PipesDocument3 pagesSUIGA TriboHARD PipesSuiga TechnologiesNo ratings yet

- SUIGA VARIHARD Flexible TC CordDocument4 pagesSUIGA VARIHARD Flexible TC CordSuiga TechnologiesNo ratings yet

- SUIGA VARIHARD Flexi TC WireDocument4 pagesSUIGA VARIHARD Flexi TC WireSuiga TechnologiesNo ratings yet

- Power Sector Developments in India: Industry Information Insights 2014Document17 pagesPower Sector Developments in India: Industry Information Insights 2014Suiga TechnologiesNo ratings yet

- Cast-O-Glide Brochure - R13Document6 pagesCast-O-Glide Brochure - R13Suiga TechnologiesNo ratings yet

- L&T Hydrocarbon Presentation September 2015Document27 pagesL&T Hydrocarbon Presentation September 2015Suiga TechnologiesNo ratings yet

- LTHE - Overview - Presentation 05-10-2015Document70 pagesLTHE - Overview - Presentation 05-10-2015Suiga TechnologiesNo ratings yet

- Indonesia Oil, Gas, and Mining News - PetromindoDocument1 pageIndonesia Oil, Gas, and Mining News - PetromindoSuiga TechnologiesNo ratings yet

- SUIGA Brochure AFP (L)Document4 pagesSUIGA Brochure AFP (L)Suiga TechnologiesNo ratings yet

- SUIGA - TC Solution For - Decanter CentrifugeDocument33 pagesSUIGA - TC Solution For - Decanter CentrifugeSuiga TechnologiesNo ratings yet

- SUIGA - AFP - UpdatedDocument25 pagesSUIGA - AFP - UpdatedSuiga TechnologiesNo ratings yet

- SUIGA - Heavy Engg - Capability N Experience (Low Res)Document50 pagesSUIGA - Heavy Engg - Capability N Experience (Low Res)Suiga TechnologiesNo ratings yet

- Kershner - Decanter Centrifuge Presentation PDFDocument23 pagesKershner - Decanter Centrifuge Presentation PDFSuiga TechnologiesNo ratings yet

- Examination Board of Boilers: Instructions To Candidates.Document9 pagesExamination Board of Boilers: Instructions To Candidates.9766224189No ratings yet

- Acikbas Alfa Beta SialonDocument7 pagesAcikbas Alfa Beta SialonBabcsánné Kiss JuditNo ratings yet

- 14 - Inorganic and Organic Uv Filters Their Role and Efficacy in 2007Document9 pages14 - Inorganic and Organic Uv Filters Their Role and Efficacy in 2007Trần Duy TânNo ratings yet

- Water Logging and Salinity ControlDocument13 pagesWater Logging and Salinity Controlpik MeNo ratings yet

- Fundamentals of Material Science and Engineering ExamDocument23 pagesFundamentals of Material Science and Engineering ExamJesimie OriasNo ratings yet

- Pump Tutorial 2Document19 pagesPump Tutorial 210teste10No ratings yet

- Photos of Defects Found in RadiographyDocument14 pagesPhotos of Defects Found in RadiographyKavipriyan KaviNo ratings yet

- Effect of Calcium Carbonate Replacement On Workability and Mechanical Strength of Portland Cement ConcreteDocument7 pagesEffect of Calcium Carbonate Replacement On Workability and Mechanical Strength of Portland Cement ConcreteThuan Nguyen Thi NhuNo ratings yet

- F and Q Project Heera PDFDocument8 pagesF and Q Project Heera PDFSherry HenryNo ratings yet

- SyllabusDocument40 pagesSyllabusArangaNo ratings yet

- MPSC Civil (Mes) Main Exam Subjectwise Previous Year Question Paper With Detail ExplanationDocument29 pagesMPSC Civil (Mes) Main Exam Subjectwise Previous Year Question Paper With Detail ExplanationvishalNo ratings yet

- Assigning and Using Oxidation Numbers in Biochemistry Lecture CoursesDocument5 pagesAssigning and Using Oxidation Numbers in Biochemistry Lecture CoursesFederico PiñeyroNo ratings yet

- Bhartiya Vidya Bhavan Vidyashram: Chemistry Investigatory ProjectDocument23 pagesBhartiya Vidya Bhavan Vidyashram: Chemistry Investigatory ProjectMudit MangalNo ratings yet

- So, Hello Everyone, This Is The Final Lecture On The NPTEL Course Mechanical Characterization of Bituminous MaterialDocument41 pagesSo, Hello Everyone, This Is The Final Lecture On The NPTEL Course Mechanical Characterization of Bituminous MaterialNabanita RoyNo ratings yet

- Shear PlateDocument5 pagesShear Platezakk1003No ratings yet

- Covalent CompoundsDocument4 pagesCovalent Compoundsrayan.ashroffNo ratings yet

- Bio-Medical Engineering: Dr. Pinku RanjanDocument39 pagesBio-Medical Engineering: Dr. Pinku RanjanAakansh ShrivastavaNo ratings yet

- About Titanium Dioxide: WWW - Tdma.infoDocument6 pagesAbout Titanium Dioxide: WWW - Tdma.infoWill TohallinoNo ratings yet

- LiquefactionDocument3 pagesLiquefactionjayanta_1989No ratings yet

- Manual: Flammable Gas SensorDocument7 pagesManual: Flammable Gas SensorWerliock MorlorumNo ratings yet

- UG-100 Pneumatic TestDocument2 pagesUG-100 Pneumatic TestInaamNo ratings yet

- Paul 2010Document18 pagesPaul 2010DianaMarcelaBurbanoNo ratings yet

- 9A14403 Fluid Mechanics & Heat TransferDocument8 pages9A14403 Fluid Mechanics & Heat TransfersivabharathamurthyNo ratings yet

- State of The Art - Geopolymer ConcreteDocument23 pagesState of The Art - Geopolymer ConcreteAYYAPPAN PILLAINo ratings yet

- Devalopment and Validation of Stability Indicating Quantitative Estimation of Dapagliflozin in Bulk and Pharmaceutical Dosage Form by RP-HPLCDocument6 pagesDevalopment and Validation of Stability Indicating Quantitative Estimation of Dapagliflozin in Bulk and Pharmaceutical Dosage Form by RP-HPLCBaru Chandrasekhar RaoNo ratings yet

- Grignard Reagent Q.B.Document12 pagesGrignard Reagent Q.B.Aariya KumariNo ratings yet

- Soal ProductionDocument4 pagesSoal Productionshabila gadisNo ratings yet

- Nsport Phenomena in Materials Engineering PDF Book - Mediafile Free File SharingDocument3 pagesNsport Phenomena in Materials Engineering PDF Book - Mediafile Free File SharingSanjeev Sahu0% (1)

- IPCC Special Report On Carbon Dioxide Capture and StorageDocument443 pagesIPCC Special Report On Carbon Dioxide Capture and StorageJonty Parkin100% (1)

- Dokumen - Tips Physics STPM Past Year Questions With Answer 2006Document18 pagesDokumen - Tips Physics STPM Past Year Questions With Answer 2006lllNo ratings yet