Professional Documents

Culture Documents

National Structural Code of The Philippines - Section 204205

Uploaded by

ADRIAN EMMANUEL CLEMENTEOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

National Structural Code of The Philippines - Section 204205

Uploaded by

ADRIAN EMMANUEL CLEMENTECopyright:

Available Formats

2-4 MINIMUM DES IGN LOADS

permitted in allowable stresses for all combinations, SECTION 204 - DEAD LOADS

includ ing W or E ,

D + L +I., (203-12)

IJ + L +W (203- 13)

Dead loads consist of the weight of a ll materials and fixed

D + I. + - " '"

1,4

(203-14) equipment incorpor ated into the building or other structure,

including but not limited to walls, floors, roofs, ceilings,

stairways, built-in partitions. finishes, cladding and other

EXCEPTIONS, similarly incorporated architectural a nd structural items,

and fixed service equipment, including the weight of

Crane hook toad s need nol he combined with roof live loud cranes.

or with more than one half(if the wind load.

203.4.3 Olhu load s. Where l-, H . P or T arc to be 204.1 W EIGHTS OF ~IATERIALS AI'D

considered in design, each applicable load sha ll be added 10 COl'O ST R UCTIO I'

the co mbinations specified in Sections 203 4 .1 and 203.4.2.

When using the alternate load co mbinations specified in The actual weights of materials and constructions shall be

Sectio n 203.4 .2, a one-third increase shall be permitted in used in determi ning dead loads fo r purposes of design. In

allowable stresses for all combinations including W or ,~. the absence of definite informatio n, it shall be permitted 10

use the minimum values in Tables 204- 1 and 204-2.

203.5 SPECIAL SEISM IC LOAD

COMBINATIONS

For both Allowable Stress Design and Strength Design, the

following special load co mbinations for seismic design

shall he used as spccitic ally required by Section 208, or by

Chapters 3 through 7.

1,2 J) + it I. + 1.0 1':", (203- 17)

O. 9 /J ± I 0 I~'", (20J -18)

W hel"c:

fi = 1,0 for floors in places of public assembly. for live

loads in excess of 4,8 kpa, and for garage live

load.

= 0.5 for other live loads.

A ss oc iat io n of Structura l En g ineers of t he Ph ilippines

DEAD LOADS

2-5

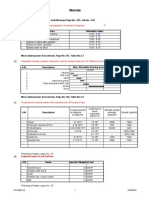

TABLE 204-1 Minimum Densities fo r Design Loads from Mat erials (kNlm3 )

Aluminum 26 7 E ARTII (not submerged) Masonry grout 22 .0

Clay, dry . 9.9

BITUMINOUS PROOUcrS Clay, dam p . 17.3 MASONRY , RUB BLE STONE

Asphaltum . 12.7 Clay and grave l, dry 15,7 Granite _._ 24 ,0

Graphite 21.2 Silt, moist. loose . 12.3 L imestone. crystalline 23 .1

Paraffin 88 Silt, mo ist, packe d 15. 1 Limestone, oo litic "". ". 2 1 7

Petroleum, crude 86 Silt, flow ing ... 17.0 M arble ,,,. 24.5

Petroleum, refined 7.9 Sand and g ravel, dry, loo se 15.7 Sa ndst one 21 5

Petroleum. benzine 7.2 Sand and gravel. dry. pac ked . 17.3 Morta r, cement or lime 20.4

Petroleum, gasol ine 6.6 Sand and gr avel, wet . 18.9

Pitch . 10.8 Parti cleboard . 7.1

Tar . 11.8 EARTH (submerged) Plywood . 5.7

Clay .... . . 12.6

Brass . . 82 6 So il . 11.0 RlPRAP (no t subm erged )

Bronze . 86 .7 Rive r mud . 14 . 1 Limest one 13.0

Cast-stone masonry (ce ment, Sand or gr avel _.__._ . 9.4 Sandsto ne 14.1

stone, sand) . 22.6 Sand o r gravel and clay 102

Cement, portland, loose 14.1 SAA D

Ceramic tile 23,6 Glass 25. 1 Clean and dry 14 . 1

Charcoal 1.9 Gravel, dry 16.3 R iver, dry 16,7

Cinder fill 9.0 Gy psum, loose .." .... 1\. 0

Cinders, dry, in bulk 7.1 Gy psum, wallboard 7.9 SLAG

I" 9.0 Bank . 11.0

COAL Bank scree nings 17.0

Anthracite, piled 8.2 IR ON Mac hine 15. 1

Bituminous, piled 7.4 Cast _ 70 .7 Sand _ 8.2

Lignite, piled ..... 7.4 Wrou ght _ 75 .4

Peat, dry, piled 36 Slate .. 27.0

Lead 111.5 Stee l. cold-drawn 77.3

CONCRETE, PLAIN

Cinder 17.0 LLME STONE, Q UARRIED. PI LE D

Exparded-slag aggregate .; 15.7 Hydrated , loo se 5.0 Basalt, granite . gneiss 15.1

Haydite (burned-day Hydrated , co mpacted 7. 1 Limes tone. marb le, quart z 14 .9

aggregate) 14.1 Sandstone 12 ,9

Slag . 20,7 MA SONRY, ASHLA R STO NE Shale 14.5

Stone. 22,6 Granite ....."". " .. 25 .9 Gree nstone, horn blende 16.8

Vermiculite and perlite Lime stone, cryst alline 25 .9

aggregate, nonload- Limeston e, oolit ic 2 1.2 T ERRA corrA, Architectural

bearing _.. ..... 3_9-7.9 Marble 27 .2 Voids filled . 18.9

Other light aggregate, load Sands to ne 22 6 Voids u nfilled . 11.3

bearing 11.0- 16.5

MASONRY, BRICK Tin ..... 72.1

CONCRETE, REINFORCED Hard (lo w abso rptio n) 20.4

Cinder . 17.4 Med ium (med iu m WA TER

Slag . 2 1.7 absorption) . 18.1 Fres h . 9.8

Stone, (Including gra vel) 23.6 So ft (high absorption) 15.7 Sea . 10. 1

Copper 87.3 M A SONR Y, CONCRE TE (solid Wood (sec Ta ble 6,2 for relative

Cork, compressed 2.2 port ion) densities fo r Philippi ne wood)

Lightw eight un its [6.5

Med ium we ight units 19 ,6 Zinc. ro lled sheet . . ..." 70 .5

Normal w eight units 21.2

Nationa l Structural Code of the Philippines, Vo lume 1

2-6 MINIMUM DESIGN LOA DS

Tab le 204 ·2 Mini m um Desi g n Dead Loa ds (kPa) (Use actual loads when available)

Component Load Compo nent Load Component Load

CEIl..INGS Wa terpro ofing membra nes: F RA '\-tE PA RTITI O NS

Acoustica l Fiber B oar d 0 .05 Bitu minous. gravel-cover ed 026 Mo vable st eel partition'> _ 0. 19

Gypsum Board (pe r mm Bitum inous. smooth surface 0.07 Wood or steel studs. 13 mm

thickness) 0 .008 Liquid. ap plied __ 0.05 gyps um board each side 0 38

Mechanical duct allowance . ... 0.20 Single-p ly. sheet 0 ,03 Wood studs. 50 x 100,

Plaster on rile or concrete 02 4 Wood Sheathing (per mm unplastc red 0 .19

Plaster on wood lath 0.38 thickness) 0.005 7 Wood studs 50 x 100. plastered

Suspended steel channel Wood shingles _ _ 0_14 o nc side _. __ _0 .57

system ,... 010 Woo d studs 50 x I00 , plastered

Su spended meta l lath and FLOO R FIL L two side . .. .. ... 096

cement plaster 0.72 Cinder concret e. per mm 0 .0 17

Su spend ed metal lath and Lightweight concrete, per mm 0 .015 FRA~n: WALLS

gypsum plaste r 0.48 Sand. per mm 0 .0 15 Exterior stud walls :

Wood furri ng suspension Stone conc rete. per mm .. .. 0.023 5Ox l00 mm @ 400 mm, 15

system __ _._ _.__ _.. 0.12 mm gypsum, insulated, 10

FLOOR AND FLOOR FIN ISHES mm siding _ 0 .53

COVERINGS, ROOF AND Asphalt block (50 mm), 13 mm 5Ox 150 mm @ 400 mm. 15

WALL mortar 1.44 mm gypsum. insulat ed. 10

Asphalt shing les 0. 10 Cement finish (25 mm) on mm sid ing 057

Ce ment tile __ __ _ 0 .77 sto ne-concrete fill 1.53 Exterior stud wall wit h brick

Clay tile (for morta r add 0 .48 kPa) Ceram ic o r quarry tile (20 mm) venee r 2 .30

Boo k tile, 50 mm 0.57 on 13 mm mortar bed 0.77 Window s. g lass. fram e and

Boo k tile, 75 mm 0.96 Ceramic or quarry tile (20 rom) sash __ 0 ,38

Ludowici , 0.48 on 25 mm mortar bed 1.10 Clay brick wythes:

Roma n __ __ 0 .57 Co ncrete fill finish (pe r mm 100 mm 1.87

Spanis h _ 0.9 1 thickness) _ 0.023 200 mm 3.80

Composition: Hardwood floo ring. 22 mm 0. 19 300 mm __ 5.50

Three-ply ready roofin g 0.05 Linoleum or as phalt tile. 6mm .". 005 400 mm 7.42

Four-ply felt and gravel 026 Marble and mortar on sto ne- Hollow Concrete Masonry units

Five- ply felt and gra vel O.29 co ncrete fill _ _ 1.58 (Unplastc red, add 0 24 kPa for each

Co pper or tin 0 .05 Slat e (pe r mm thickness) 0 ,028 face plastered)

Corrugated asbesto s-ce ment Solid flat tile on 25 mm mort ar G rout Wvthe thickness mm

roofing 0. 19 base " " 1.10 Soacinll. I 100 I 150 I 200

Deck, metal 20 gagc O. 12 Subflooring, 19 mm O. 14 _ 1£ 5..10 ' m' p e/./: Ht)-.'.Y[ Un!i-r;_ _

Deck, metal, 18 gage . _ _ 0.14 Terrazzo (38 mm) direct ly on

slab _ _0 .9 1

y o grou t ' 1 05

800

i I 53 I 15R:}'..:l ~

20 1

Fiberboard , 13 mm _ _ 0 04 I ,

Gypsum sheathing, 13 mm 0.10 Terrazzo (25 mm) o n stone- 690 : 1 1 63 _2.20 _

Insulation. roof boards (per nun thickness)

Cellular g lass 0 .00 13

con crete fill "

Terrazzo (25 mm), 50 mm stone

" 1.53

" :~~ --~ , --_

. T~-:f=r ;t~·-~

Fibrous glass 00021 concrete _ __._ _ 1.53 19.6 l;N :;? lJensifJ'.!J.f.C/nit

Fiberboard _......... 0 .0028 Wood block (76 mm) on masti c, y o grout ! 1.24 ~' ~.}~1 1 . 72_

Perlite

polystyrene foam

0001 5

0.0004

no fill

Wood block (76 mm) on 13 mm

0.48

,·-t~ . _-..,1·_·.. . ---,. ~ :·~~·- l}·~1--

Urethane foam with skin ... 0 ,0009 mortar base 0_77 --. 00-- T =l ~:i l':J)i2--

Plyw ood (per mm thickness) .. 0 .0060 Full ; ! 2 ,82 ) 3.88

Rigid Insulation, 13 mm 0 .04 FLOORS, WOOD-JOIST (no plasla)

2 /.2. kM-",J Dem-ilJ:..0! lfnit

Sky light, metal fram e, 10 mm

wire glass 0.38

~~~:s }-t%~t ~£.al··l:t~"-'[('OO -- ··~&o~<l.Ut·:tTI~f---tfJt=r,~,j~ .

(mm) i mm r mm l mm

Slate, 5 nun ._ __ 0.34

I 0.25 600 ~6 ! 2.59

Slate, 6 mm 0 .48 5Oxl50

50x200

0.30

0.30

0.25

0.30 i 0.25 400 ! f-=J=2 .92__

2..

Full [ 2 97 : 3.97

50x250,,_

"

0.35

_-, __

.. _

0.30

.., _.. i 0.30-_

" . _. - . . _.

sooro I 0.40 i 0.35 i 0.30

Associat ion of St ru ctural Engineers of t he Ph ili ppines

DEAD LOA DS & LIVE LOADS ,.,

20·1.3 PARTITION WADS SECTION 205 - LIVE LOADS

Floors in office buildings and ot her buildings where 205.1 GENERAL

partition locations are subject to change shall be designed to

support, in addition to all other loads, a unifonnly Live loads shall be the maximu m loads expected by the

distributed dead load equal to 1.0 kPa o f tloor are a, intended use or occupancy but in no case shall be less than

the loads required by this secti on,

EXCEPTION:

Access floor systems shall be designed to support, in

205.2 CRITICAL DISTR IBUT ION O F LIVE

addition to all other loads, a uniformly distributed dead

load 1101 less sban0.5 !cPa offloor area. LOADS

Where structural members are arra nged to create co ntinuity ,

mem ber s shall be designed usin g the loading conditions.

which woul d cause maximum shear and bending momen ts ,

Thi s requ irement may be satisfied in accordance with the

provision s of Sect ion 205.3.2 or 205 .4.2. where applicable.

205.3 FLOO R LIVE LOADS

205.3, t General Floors shall be designed for the unit live

loads as set fort h in Table 205- 1. These loads shall he taken

as the minimu m live loads in kilo newton per square meter

of horizontal projection to be used in the design of

buildings for the occupancies listed, and loads at least equal

shall be assumed for uses not listed in this section but that

create Of acco mmodate similar loading s.

Where it ca n be det ermined in designing floors that the

actual live load will be greater than the value shown in

Table 205 - 1, the actual live load sha ll be used in the des ign

of such buildings or portions thereo f Specia l provisio ns

shall be made for machi ne and ap parat us loads

205.3.2 Distrib uti on of uniform Floor load s. Where

unifor m floor loads are involved, considerat ion may be

limited to full dead load on all spa ns in combination with

full live load on adjace nt spans and alternate spans

205.3.3 C onu n tra tffi load s Provision shall be made in

designi ng floo rs fo r a conce ntrated load. L, as set fo rth in

Table 205 ·1 placed upon any space 760 mm squa re.

wherever this load upon an otherwise unloaded floor 'Would

produce stresse s greater than those caused by the unifo rm

load required therefore.

Provision shall be made in areas where vehicles are used or

stored for concentrated loads, J., consist ing of two or more

loads spaced 1.5 meter s nominally on cen ter without

uniform live loads Each load shall be 40 percent or the

gross weig ht of the maximum size vehicle \0 be

accomm odated Parking garages for the stora ge o f private

or pleasu re-type motor vehicles wit h no repair or refuel ing

shall have a floor system designed for a concen trated load

2

of not tess than 89 kN act ing o n an are a of 0 .0 13 m

Nationat Structural Code of the Philippines, VollJf1\f! 1

2-8 MIN IMU M DES IG N L OADS

wrthout uniform live loads. The co ndit ion of concentrated TA BLE 205-1 (conti nued ) - MINIMUM UNIFORM

o r un iform live load. combined in accordance with Section AND CONCENTRA TED UVE LOADS

203 3 o r 203 ,4 as appropriate. producing the greatest Concen-

Uniform

stresses sha ll govern. USE OR OCCUPANCY Load I trated

Load

-----

f---

205.3.4 Special load s. Provision shall be made fo r the Category Description kPo kN

special vert ical and lateralloads as set forth in Table 205-2 ,

Basic fl oor aTell 19 0'

Exteri or 4

ba lcon ies

2.9 0

TABLE 205·1 MINIMUM UNIFORM AND 13. Residential !! 4

CONCENTRATED LIVE LOADS D,"" 1.9 0

COlleen-

Uniform Sl.oruge 19 0

USE OR OCCUPANCY Load I trated

Load

rc-c -- - -- -- -- -

14 . Rcstrooms l) - - -

Catcf:Ol)' Description kPa kN 15. Reviewing

stands, grandstands,

()fiice usc 2.4 9.0 J Bleachers , -- 4.8 0

I. Access I1<x< "d

syste ms

Computer usc 4.8 9.0'

folding ,,'"

telesccome sceue e

Same as .~

2. Armor ies .- 7.2 0 16. Roof decks served or .. ..

Occepancv

Fixed seating 2.9 0 17. Schools C la,,,moms 19 4.5

2

3. Assembly arcus J Mova ble

4.8 0 18. Sidewalks a nd Public access 12.0 --

,

and auditorium seatmg dn vewa vs

"d

therewith

balconies Lo hb ies

platform&

,,' 4.8 0

19. Storage

Ligh t 6.0 --

Sta!l-L':l"rea~ 1.2 0 Heavy 12.0 --

4. Corn ices

marquees

,,'" - 3 6" 0

20 51"",

Retal] 4.8 4 ,5

2

6.0 13.4 1

5. Dining rooms and

restaurants ,- 48 0

21 Pedestrian

WboI=k

6. Exit facilities ~ - 4.8 0' bridges

walk w avs

~d -- 4.8 -

General slora fl"

aml/e>r rc p" ir

48 -- - NOTES FOR TABLE 205-1

See Section 205.5 for live load red uctions.

Prj~-atc ,

7. Garages

pleu. urc-typc '"

--

, See Section 205.3.3, first paragraph, for area of load

mot or "chicle

2.4 , application.

Assembly areas include such occupancies as dance halls,

sroraac

drill rooms, gymnasiums, playgrounds, plazas, terraces and

, Hospi tals

1,J,'ards

w.'" '-~

."" 1.9 4 _5 ~ similar occupancies that are generally accessible 10 the

pubhc.

Labordlori "" &

29 4.5 ~

• For special-purpose roofs, see section 205.• .• .

0l":rating rooms EJrit facilities shal include such uses as corridors serving

an occupant loa d of 10 or ffiOI" e persons, exterior ell it

Reac.hnj!. " ... lffi!I 2.9 4.5 2 balconies . stairwa ys, fTe escapes and similar uses.

9. Libraries Individual stair treads shan be designed to support a 1.3 kN

Stack ro um .' 1.2 6.7 2 conce ntrated load placed in a position that woul d caus e

maximum stress. Sla ir stJingers may be designed lor the

10. Man ufacturing

Li ght 6.0 i 9 0' uniform load sel lorth in the lable.

See Section 205.3 .3, second paragraph, IOf concentrated

He avy 12.0 13.4 2 loads. See Table 205-2 for vehicle barr ers.

Residential occupancies include private dwelling s,

2 apartments and hotel guest rooms.

I I Offices -- 2.4 9.0 •

Restroom loads sha ll not be less than the load for the

occupancy with which they are associated, but need not

I"rt:"" ""lIl1" 1.2 11.0 ] exceed 2 ,4 kPa.

12. Printing plants

C~inlland 2

4.8

! Iinol.~ l'" mom.,

9. 0

Association of Structural Eng inee rs of the Phili pp ines

lIVE LOADS ,-,

TABLE 205-2 - SPECIAL LOA DS'

Vertical Lateral

NOTES FOR TABLE 2Ofr2

USE The tabulated loads Me minimum loads, Where other verlie~1 by

Load Lood_

this code Of requ" ed by the design would cause greater stresses ,

CalC1!""Y Description

"'" "'" they shaUbe used. Loads are in kPa unless otherwise indicated

in the table.

I. Construction, Wnll,.-way 7.2 -- Units is kNlm .

public access

site (live lo ad) " Canopy 72 --

, Lateral sway bracing loads of 350 Nfm parallel and 145 Nlm

perpendicular to seat and footboards.

2. Grandstands, .. Does not apply to ceilings that have sufficient total access from

reviewing, stands below, such that access is not required within the space above

bleachers, sese 1.75 &, the ceiling, Does not apply to ceilings if the attic areas above the

"d and

ceiling are not provided with access. This live load need not be

folding and foofboards kN/m ! Noll,' )

considered as actin g simultaneousl y wit h other live loads

telescoping imposed upon the ceiling framing or its supporting structure.

scatina(hve load) e The impact teete rs included are tor cranes with steel wheels

riding on steel ra ils . They may be modified it substantiating

Cal"alh 1.9 -- technical data acceptable to the building official is submrtted. Live

3 Stage accessories

Followspot, load s on crane sup port girders and ther connections shal be

[live load)

~oction

control rooms

,,'" 24 - taken as the maximum crane wheel loads. For pendant-operated

traveling crane support girders and their connections, the impact

factors shaN be 1.10.

O\-er stages 1.0 -- 8 This applies in lhe eeecncn parallel 10 the runway rais

4. Ceil ing framin g (longitudina l). The factor for forces perpendic ular to the rail is

(1i\'Cload) All uses cxc~'f'l- 0.20 x the transverse traveling loads (lrolley , cab , hooks and

" vcr stages

05 " -- lifted lo ads). Forces shall be applied at top of rail and may be

5. Partitions and disturb ed among rails of multiple rail cranes and shall be

interior walls, -- -- 025 distributed with due regard lor lateral stiffness of the structures

supporting these rails.

6. Elevators and A load per lineal meter (kN/m) to be applied horizon tally at right

2 x total

durnbwnucrstdcad l"ud, - angles to the top rail.

andlive load~) • Intermediate rails, panel fillers and their connectio ns shall be

Total 1 25 x 0.10 x capable of withstanding a load of 1.2 kPa applied horizontany at

s Cranes (dead and

live loads)

incl~ ''' ' ' """ ""'I

right angles o ver the entire tributary area , including openngs and

spaces between fai ls. Reactions due to this loading need not be

llI1pltd: increa...,

h il fuc ililN:s "'"'" """"

0.75

combined wit h those of Footnote 7,

P A horizontal load in kilonewtons applied at right angles to the

~"' >-,'" -- 1

vehicle barrier at a height of 450 mm above the parking surface .

occupant kN/m The force may be distribut ed over a 300- m~limeter-square area .

tcr than 50

'0 The mounting of hallltails shall be such that the completed

9 Balcony railings

Oth"r than cxn 0.30 handrail and supporting structure are capable of withstanding a

and guardrails

facilities - kN /m 1 load of at least 890 N applied in any direction at any point on the

ran. These loads shall not be assum ed to act cumulatively w ith

Item 9.

Components -- J2 X

" Verti cal members of storage racks shall be protected from impact

forces of operating equipment, or racks shall be designed so that

10. Vehicle barriers -- -- 27 kN Y failure of one vertical member will no cause colla pse of more than

the bay or bays diredly supported by that member.

II . Handrails

Su: See ' ~The 1.1 kN load is 10 be applied 10 any single fire sprinkler

,VOlt' /0 Nolt' JO Sl4Iport point but not simultaneously to all support joi nts .

12. Storage racks

(},l.... 2,4 m eter r"", ~II

Set' Tab/t"

Iti~l ]fJ8-.-J2

II kN

~~

lJ. Firc sprinkler

- weight or :it't' Tal>1t"

structural support "al.....- 2M - /1

ftlled

i""/!

National Structural Code 01 the Philip pines, Volume 1

2-10 MINIMUM DESIG N LOADS

205.4 ROOF LIVE LOADS whenever this loading creates greater stresses than

tho se caused by the uniform live lo ad. The

205.4. 1 Gfoorral Roofs shall be designed for the un it conce ntrated load shall be placed on the mem ber

live loads, L .. set forth in T able 205-3 . The live loads shall over a length of 750 mm along the span The

be assumed to act vertically upo n the ar ea proj ected on a concentrated load need not be ap plied to more than

horizon tal plane. one span sim ulta neously.

3. Water accumulation as prescribed in Section 206.7.

205.4.2 Dis tri b ution o f loads . Where uniform roo f loads

are invo lved in th e design of struct ural me mbers arr anged 205.4.3 Unbala nced loa ding. Unbalanced loads shall be

to create co ntinuity, consideration may be limited to full used where such loading w ill resu lt in larger members or

dead loads o n all spa ns in co mbinatio n with full roo f live co nnec tions . Trus ses and arches shall be designed to resist

loa ds o n adjacent spans and on alternate spans. the stresses cause d by u nit live loads on one half of the spa n

if such load ing resu lts in reverse stres ses, or stress es greater

EXCEPTION: in any port ion than the stresses pro duc ed by the require d

unit live load on the ent ire span. For roo fs wh ose str uctures

Alternate span loading need not he considered where the are composed of a stresse d shell, framed or solid, wherein

uniform roo! live load is J kPa or more. stre sses caused by any point loading are dist ribu ted

througho ut the area of the shell, the requ irements for

Fo r those co nditio ns where light-gage meta l prefo nncd unbal anced unit live load des ign may be reduced 50

structural shee ts serv e as the su ppo rt and finish o f roofs, percent.

roof structural members arranged to create con tinuity shall

be co nsidered adequate if designed for full dead loads on all 205.4.4 Spec ial roof Iead s, Roofs to be used for spec ial

spans in co mbi nation with the most critica l one of th e purpo ses shall be designed for ap propriate loads as

followi ng su perim posed loads: approved by the bui lding official.

1. The uniform roof Jive load, L.. set forth in Table

205-3 on all spans Green house roo f bars, purl ins an d rafters shall be designed

2. A co ncentrated gravity load, Lr, of 9 kN placed o n to carry a 0 .45 kN concentrated load, L.-. in add ition to the

anI span supporti ng a tributary area greater than 18.5 uniform live load .

m to create max imu m stresses in the member,

Table 205-3 Minimum Roof Live Loads I

MEmOD 1 METHOD 2

Tributarv Area m Rate of Maximum

ROOF SLOPE Uniform

o 10 :20 :20 to 60 (N~ 60

Load' Reduction, Reduction

Uniform Load (kl'lI) r R

(kP lI) ( n lTC e nla lle )

I. Flat or rise less than 4 units vertical. in 12

units horizontal (33.3% Sl (~~t Arch and 1.00 0.75 0.60 1.00 0 .08 40

dome with rise less than onc-e t of soan.

2. Rise 4 units vertical to less than 12 units

vertical in 12 units horizontal (33% to less

than HXJOA. slope). Arch and domes with rise 0 .75 0.70 0.60 0 .75 0.06 25

one-e ight of span to less than three-eights of

soan

3 Rise 12 units vertical in 12 units horizontal

(100% slope) and greater. Arch Of dome 0 60 0.60 0.60 0.60

with rise three eigh~ of STl!lll or ereate-

4. A\\-nings except cloth covered. I 0.25 0.25 0.25 0.25 No reduction permitted

5. Greenhouses, lath houses and Agricultural

buildings."

0.50

. 0.50 0.50 0.50

For special-purpose roofs, see Section 205.4.4 J A nat roo f IS any roof WIth a slo pe less than 114 un it vertcar

f See Sections 205 .5 and 205 .6 lor Iive-load reductions The in 12 units horiZontal (2% slope). The live load for nat roofs

rate of reduction I in Equation 205- 1 Shall be as indicated in is in additionto the pond ing load required by Section 206 .7.

lhe table. Tile maximum reduction, R, shaM not exceed the I See definition in Section 202.

value indicated in the table. ~ See Section 205.4.4 for concentrated load requirements fOl"

greenhouse roof members.

Associat i on of Structural Engin eers of the Philip pines

You might also like

- Chapter 2 PDFDocument35 pagesChapter 2 PDFJeisther Timothy Galano0% (1)

- Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresDocument42 pagesCode of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresSalin ShresthaNo ratings yet

- ARUP - Tải trọng tác độngDocument4 pagesARUP - Tải trọng tác độngThành Vương XuânNo ratings yet

- 875 - 1 DLDocument39 pages875 - 1 DLSudhakaran PilicodeNo ratings yet

- Standard Specifications Code of Practice Construction Oe Concrete RoadsDocument72 pagesStandard Specifications Code of Practice Construction Oe Concrete Roadsshankarswaminathan100% (1)

- 875 - 1 Design LoadDocument39 pages875 - 1 Design LoadSandeep GuptaNo ratings yet

- Code of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresDocument39 pagesCode of Practice For Design Loads (Other Than Earthquake) For Buildings and StructuresIshor ThapaNo ratings yet

- General Spec For Water Main Construction (JKR Sarawak 2011) PDFDocument64 pagesGeneral Spec For Water Main Construction (JKR Sarawak 2011) PDFmakhsmyNo ratings yet

- BNBC Chapter 2 6Document67 pagesBNBC Chapter 2 6Faisal Ahmed100% (1)

- Table 1.1. Representative Values of K Hydraulic Conductivity (After Morris andDocument3 pagesTable 1.1. Representative Values of K Hydraulic Conductivity (After Morris andSavaSintyaNo ratings yet

- Pile CalcDocument11 pagesPile CalcADHAM HAMZANo ratings yet

- NSCP Design LoadsDocument10 pagesNSCP Design LoadsShem Barro88% (33)

- Section 203 Combinations of Loads: Chapter 2Document10 pagesSection 203 Combinations of Loads: Chapter 2FishonthestreetNo ratings yet

- NPWD Sor 2010Document269 pagesNPWD Sor 2010jaxen101No ratings yet

- Irc Codes - Bridge - For MST PDFDocument59 pagesIrc Codes - Bridge - For MST PDFMehakpreet SinghNo ratings yet

- SJVN Sor 2012Document168 pagesSJVN Sor 2012Pallavi Negi ThakurNo ratings yet

- Dharwad SOR PDFDocument510 pagesDharwad SOR PDFArthanareeswaran0% (1)

- Unit Price Check Sheet: Formwork For ConcretingDocument3 pagesUnit Price Check Sheet: Formwork For ConcretingAbenezerNo ratings yet

- PDF Combined Nov 2016Document3 pagesPDF Combined Nov 2016albertoNo ratings yet

- Kyenjojo Materials Schedule PDFDocument19 pagesKyenjojo Materials Schedule PDFIsaac WamalaNo ratings yet

- Data Geoteknik (Perancangan Keairan) (Recovered)Document14 pagesData Geoteknik (Perancangan Keairan) (Recovered)Wingky PratamaNo ratings yet

- Road Note 29: A Guide To The Structural Design of Pavements For New RoadsDocument43 pagesRoad Note 29: A Guide To The Structural Design of Pavements For New Roads7d5b3373100% (7)

- Use RCA in Construction P1Document22 pagesUse RCA in Construction P1Hung LeNo ratings yet

- Estimate of Box Culvert - at KM 24.890Document11 pagesEstimate of Box Culvert - at KM 24.890SUSHEEL KUMAR KANAUJIYANo ratings yet

- NOL B H Qty Unit Rate AmountDocument2 pagesNOL B H Qty Unit Rate AmountsonofalexanderNo ratings yet

- Ghar Expert EstimateDocument15 pagesGhar Expert Estimatekim ko laNo ratings yet

- Take Off SheetDocument4 pagesTake Off SheetGuyo TunaNo ratings yet

- Properties of Soils: AppendixDocument32 pagesProperties of Soils: AppendixMd. Nahid HossainNo ratings yet

- M&D Foundations & Building Services Limited: SHOREHAM - 79-81 Brighton Road, BN43 6RHDocument10 pagesM&D Foundations & Building Services Limited: SHOREHAM - 79-81 Brighton Road, BN43 6RHNitaiGauranga108No ratings yet

- DSR Analizer Ver.16Document5 pagesDSR Analizer Ver.16Anoop GeorgeNo ratings yet

- 2007CoolingCheong PDFDocument13 pages2007CoolingCheong PDFMed El Hadi AbidiNo ratings yet

- Geotechnical Engineering - 1: Course Instructor Dr. Trudeep N. DaveDocument28 pagesGeotechnical Engineering - 1: Course Instructor Dr. Trudeep N. DaveDeep ShahNo ratings yet

- S.O.R For Building Ahmedabad District 2015-16 Above 5 CroreDocument399 pagesS.O.R For Building Ahmedabad District 2015-16 Above 5 CroreKunal MandalaywalaNo ratings yet

- Norms: Coefficient of Friction For The Investigation of Penstock SupportsDocument11 pagesNorms: Coefficient of Friction For The Investigation of Penstock SupportsAsmita KoiralaNo ratings yet

- Khani AB No. 05Document11 pagesKhani AB No. 05Asmita KoiralaNo ratings yet

- Co2 Absorbing Concrete BlockDocument5 pagesCo2 Absorbing Concrete BlockHai HaNo ratings yet

- 8 Compacted Fill: Jack W. Hilf, Ph.D. P.E. Consulting Engineer Aurora, ColoradoDocument68 pages8 Compacted Fill: Jack W. Hilf, Ph.D. P.E. Consulting Engineer Aurora, ColoradoVicente ManuelNo ratings yet

- Is 875 Part I & II - CombinedDocument66 pagesIs 875 Part I & II - CombinedHarsh RanaNo ratings yet

- Is 875 1 1987Document43 pagesIs 875 1 1987thoidangquangNo ratings yet

- Design of Prestressed Concrete Pile PDFDocument14 pagesDesign of Prestressed Concrete Pile PDFvindyavNo ratings yet

- Feela LSGD Project HelperDocument25 pagesFeela LSGD Project HelperVishnu P SudhakaranNo ratings yet

- Soil Investigation ReportDocument20 pagesSoil Investigation ReportEngr qazi sayyed waqarNo ratings yet

- 1 Bore Pile Design D 800-57M - HK12Document3 pages1 Bore Pile Design D 800-57M - HK12mdalgamouniNo ratings yet

- Bore Pile Design Bs 8004Document2 pagesBore Pile Design Bs 8004Nabil YassarNo ratings yet

- Brick CalculationsDocument13 pagesBrick CalculationsMirza Mustansir BaigNo ratings yet

- Bore Pile Design Bs 8004Document2 pagesBore Pile Design Bs 8004Uý ĐạiNo ratings yet

- 29154269Document66 pages29154269hassan hidaNo ratings yet

- Img 0001Document11 pagesImg 0001Christopher ThomasNo ratings yet

- Durability, Strength, and Stiffness of Green Stabilized SandDocument10 pagesDurability, Strength, and Stiffness of Green Stabilized SandHelena LeonNo ratings yet

- L7 تخمينDocument12 pagesL7 تخمينMohammed O IbrahimNo ratings yet

- A Double Hyperbolic ModelDocument10 pagesA Double Hyperbolic Modelshachen2014No ratings yet

- Bore Pile Design Bs 8004Document2 pagesBore Pile Design Bs 8004nabeel hameedNo ratings yet

- UntitledDocument15 pagesUntitledSakthi VeeraNo ratings yet

- Cone Penetration Testing: Methods and InterpretationFrom EverandCone Penetration Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (3)

- Semiconducting III–V Compounds: International Series of Monographs on SemiconductorsFrom EverandSemiconducting III–V Compounds: International Series of Monographs on SemiconductorsNo ratings yet

- Geotechnical Engineering: Unsaturated and Saturated SoilsFrom EverandGeotechnical Engineering: Unsaturated and Saturated SoilsRating: 5 out of 5 stars5/5 (1)

- Superseded Safety StandardsDocument28 pagesSuperseded Safety StandardsADRIAN EMMANUEL CLEMENTENo ratings yet

- AS REcitDocument7 pagesAS REcitADRIAN EMMANUEL CLEMENTENo ratings yet

- The Econmienda System ReadingDocument2 pagesThe Econmienda System ReadingADRIAN EMMANUEL CLEMENTENo ratings yet

- SunEarthTools SunPath 1694091455102Document5 pagesSunEarthTools SunPath 1694091455102ADRIAN EMMANUEL CLEMENTENo ratings yet

- STS Activity3Document1 pageSTS Activity3ADRIAN EMMANUEL CLEMENTENo ratings yet

- AD Model RefDocument3 pagesAD Model RefADRIAN EMMANUEL CLEMENTENo ratings yet

- Abstract GGEZ With TitleDocument1 pageAbstract GGEZ With TitleADRIAN EMMANUEL CLEMENTENo ratings yet

- Ao 013-1977Document63 pagesAo 013-1977ADRIAN EMMANUEL CLEMENTENo ratings yet

- Global Street Design GuideDocument115 pagesGlobal Street Design GuideADRIAN EMMANUEL CLEMENTENo ratings yet

- Ben Kenobi Roleplay ExampleDocument3 pagesBen Kenobi Roleplay ExampleADRIAN EMMANUEL CLEMENTENo ratings yet

- Ra 9266Document20 pagesRa 9266ADRIAN EMMANUEL CLEMENTENo ratings yet

- Activity 2 Topic SupportDocument6 pagesActivity 2 Topic SupportADRIAN EMMANUEL CLEMENTENo ratings yet

- BU 2 1.3 Worksheet - InstructionDocument1 pageBU 2 1.3 Worksheet - InstructionADRIAN EMMANUEL CLEMENTENo ratings yet

- Minimum Design Loads For Buildings and Other Structures ASCE SEI 07 - Chap24Document9 pagesMinimum Design Loads For Buildings and Other Structures ASCE SEI 07 - Chap24ADRIAN EMMANUEL CLEMENTENo ratings yet

- Makati 10.2017aDocument23 pagesMakati 10.2017aADRIAN EMMANUEL CLEMENTENo ratings yet

- Mtian, 8081 Production Final GalleyDocument6 pagesMtian, 8081 Production Final GalleyADRIAN EMMANUEL CLEMENTENo ratings yet

- ASDA 2023 Product List 17 AugDocument5 pagesASDA 2023 Product List 17 AugADRIAN EMMANUEL CLEMENTENo ratings yet

- RICHSep 2016Document9 pagesRICHSep 2016ADRIAN EMMANUEL CLEMENTENo ratings yet

- Density of Commom Building MaterialsDocument3 pagesDensity of Commom Building MaterialsADRIAN EMMANUEL CLEMENTENo ratings yet

- 001 Iee enDocument347 pages001 Iee enADRIAN EMMANUEL CLEMENTENo ratings yet

- Nat VentDocument23 pagesNat VentADRIAN EMMANUEL CLEMENTENo ratings yet

- Module 3 Mohaney - Soni 2018Document6 pagesModule 3 Mohaney - Soni 2018ADRIAN EMMANUEL CLEMENTENo ratings yet

- Unit-I Mathematical Logic: Statements and NotationsDocument24 pagesUnit-I Mathematical Logic: Statements and NotationsADRIAN EMMANUEL CLEMENTENo ratings yet

- The Jeepney Drivers and Their Lived Experiences During The COVID 19 Pandemic A Phenomenological Qualitative Study in The PhilippinesDocument19 pagesThe Jeepney Drivers and Their Lived Experiences During The COVID 19 Pandemic A Phenomenological Qualitative Study in The PhilippinesADRIAN EMMANUEL CLEMENTENo ratings yet

- SLBO Press Kit - 2017Document19 pagesSLBO Press Kit - 2017ADRIAN EMMANUEL CLEMENTENo ratings yet

- RainwaterDocument10 pagesRainwaterADRIAN EMMANUEL CLEMENTENo ratings yet

- Electricity Phenomena Arising From TheDocument6 pagesElectricity Phenomena Arising From TheADRIAN EMMANUEL CLEMENTENo ratings yet

- Subculture and Counterculture - A Christian ResponseDocument14 pagesSubculture and Counterculture - A Christian ResponseADRIAN EMMANUEL CLEMENTENo ratings yet

- MNLSI Banquet CapacityDocument1 pageMNLSI Banquet CapacityADRIAN EMMANUEL CLEMENTENo ratings yet

- Ethics - Module 1Document10 pagesEthics - Module 1ADRIAN EMMANUEL CLEMENTENo ratings yet

- Material Science and Metallurgy: Unit - 9Document24 pagesMaterial Science and Metallurgy: Unit - 9Vivek BajpaiNo ratings yet

- Debye Temperature - The Elements Handbook at KnowledgeDoorDocument7 pagesDebye Temperature - The Elements Handbook at KnowledgeDoorshiferawNo ratings yet

- Differences Between Manganese and MagnesiumDocument2 pagesDifferences Between Manganese and MagnesiumAluruVasuNo ratings yet

- ChemEngineering 07 00054Document17 pagesChemEngineering 07 00054Juan Guzmán SantosNo ratings yet

- 1.06 GasketsDocument4 pages1.06 GasketsKia McNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument16 pagesCambridge International General Certificate of Secondary EducationKiss 002No ratings yet

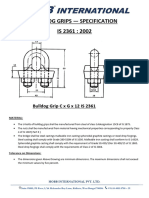

- Bull Dog Clamp - SpecificationDocument2 pagesBull Dog Clamp - SpecificationsanjoyNo ratings yet

- Larson - Ton KartaDocument9 pagesLarson - Ton KartaJelena GraovčevićNo ratings yet

- fLAME TESTDocument6 pagesfLAME TESTkemcanaboNo ratings yet

- ASTM E747-04 - Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used For RadiologyDocument14 pagesASTM E747-04 - Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used For RadiologyMelissa SammyNo ratings yet

- AP 08 Ps em 04 Q A Metals and Non MetalsDocument3 pagesAP 08 Ps em 04 Q A Metals and Non Metalslakkysep16No ratings yet

- Tablas Atkins ImprimirDocument8 pagesTablas Atkins ImprimirbrenmattaloniNo ratings yet

- En1011 7Document44 pagesEn1011 7A. ΒρατσισταNo ratings yet

- S Block ElementsDocument19 pagesS Block ElementsLurkingMangoNo ratings yet

- Heresite Corrosion ProtectionDocument2 pagesHeresite Corrosion ProtectionDANIEL PEREZNo ratings yet

- Perhaps One of You Gentlemen Would Mind Telling Me Just What Is Outside The Window That You Find So Attractive..?Document7 pagesPerhaps One of You Gentlemen Would Mind Telling Me Just What Is Outside The Window That You Find So Attractive..?Seema ChaturvediNo ratings yet

- Foundry Equipments: Casting and ApplicationsDocument5 pagesFoundry Equipments: Casting and ApplicationsvjtiitNo ratings yet

- Extrusion For ClassDocument49 pagesExtrusion For ClassNABIL HUSSAINNo ratings yet

- Chemistry Curriculum Guide Grade 11 CaribbeanDocument14 pagesChemistry Curriculum Guide Grade 11 CaribbeanANGELINA FERGUSONNo ratings yet

- Marlon Malvar SebastianDocument3 pagesMarlon Malvar SebastianMelvin ManzanaresNo ratings yet

- 2015 Task 2 Yr 11mid-Course Chem Exam SolnsDocument14 pages2015 Task 2 Yr 11mid-Course Chem Exam SolnsSid JoonNo ratings yet

- Extractive Metallurgy Pachuca Tank DesignDocument8 pagesExtractive Metallurgy Pachuca Tank DesignXtet AungNo ratings yet

- Steel 1Document25 pagesSteel 1basanthi noorbashaNo ratings yet

- Choke Beans, Stems & SeatsDocument4 pagesChoke Beans, Stems & Seatscrni rokoNo ratings yet

- Magnetic SeparationDocument12 pagesMagnetic SeparationArdhaEriNo ratings yet

- ASTM A 194 A194M 2012a Standard Specification For Carbon and Alloy Steel Nuts For BoltsDocument11 pagesASTM A 194 A194M 2012a Standard Specification For Carbon and Alloy Steel Nuts For BoltsTravis TwaddellNo ratings yet

- 1 4920401554629984258 PDFDocument278 pages1 4920401554629984258 PDFDaniel Janthinus Kristianto100% (1)

- Introduction Letter KsiDocument2 pagesIntroduction Letter KsiKamlesh Steel industriesNo ratings yet

- Aluminum AnodizingDocument7 pagesAluminum Anodizingkarthik venkatachalamNo ratings yet

- Creep-Resistant Steels - TWI PDFDocument6 pagesCreep-Resistant Steels - TWI PDFFarid Ahmed KhwajaNo ratings yet