Professional Documents

Culture Documents

RT RPGGRT

Uploaded by

ZaidiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

RT RPGGRT

Uploaded by

ZaidiCopyright:

Available Formats

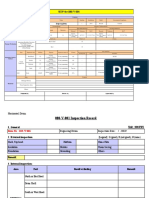

INSPECTION & TEST RECORD-WELDING

ITR No: JI-2045-W-0111X

RADIOGRAPHY REPORT

W-0111X

Plant/Unit: Project No.: Record No.: W-111X-0043

Drawing No.: Rev. No.: System/Sub-system No.:

Source Type: Source Strength: RT Technique : Film Type & Brand Name: Pb Screen Thickness:

(Isotope / X Ray) ______Ci or _______KV (SWSI, DWSI, DWDI, Panoramic, other) Film Processing: (Manual/Automatic) (1) Front _____(mm) (2) Back_____mm

Maximum Source Size / Focal Spot: (mm) SFD: inch Maximum Geometric Unsharpness (Ug): mm Film Density:

Material Grade: Penetrometer Type & No.: Location of Penetrometer: Wire/Hole RT Procedure No. & Rev. No.:

(Source Side / Film Side) Acceptance Criteria & Edition:

Required: Achieved:

Welder ID per Weld Pass

Penetration

Penetration

Slag or El.

Concavity

Undercut

Concave

Result

Through

Porosity

Surface

Lack of

Lack of

Excess

Fusion

Defect

Crack

Size &

Other

Burn

Root

SI N° Drawing No. WELD No. Film Location (Accept / Remarks

Thick.

ROOT HOT FILL 1 FILL 2 CAP Reject)

SAR-W09 SAR-W09 SAR-W09 SAR-W05 SAR-W05 16" x 11.78

1 0302

SAR-W15 SAR-W15 SAR-W15 SAR-W04 SAR-W04 mm

SAR-W09 SAR-W09 SAR-W08 SAR-W08 SAR-W08 16" x 11.78

2 0303

SAR-W15 SAR-W15 SAR-W12 SAR-W12 SAR-W12 mm

SAR-W09 SAR-W09 SAR-W05 SAR-W05 SAR-W08 16" x 11.78

3 0304

SAR-W15 SAR-W15 SAR-W04 SAR-W04 SAR-W12 mm

SAR-W09 SAR-W09 SAR-W05 SAR-W05 SAR-W05 16" x 11.78

4 0305

SAR-W15 SAR-W15 SAR-W04 SAR-W04 SAR-W04 mm

SAR-W09 SAR-W09 SAR-W09 SAR-W04 SAR-W04 16" x 11.78

5 0306

SAR-W15 SAR-W15 SAR-W15 SAR-W12 SAR-W12 mm

SAR-W05 SAR-W08 SAR-W08 SAR-W08 SAR-W04 16" x 11.78

6 0307

SAR-W09 SAR-W15 SAR-W15 SAR-W15 SAR-W12 mm

SAR-W05 SAR-W05 SAR-W08 SAR-W08 SAR-W04 16" x 11.78

7 0308

SAR-W09 SAR-W09 SAR-W15 SAR-W15 SAR-W12 mm

SAR-W05 SAR-W05 SAR-W08 SAR-W08 SAR-W04 16" x 11.78

8 0309

SAR-W09 SAR-W09 SAR-W15 SAR-W15 SAR-W12 mm

SAR-W05 SAR-W05 SAR-W08 SAR-W08 SAR-W04 16" x 11.78

9 0310

SAR-W09 SAR-W09 SAR-W15 SAR-W15 SAR-W12 mm

SAR-W05 SAR-W05 SAR-W05 SAR-W08 SAR-W04 16" x 11.78

10 0311

SAR-W09 SAR-W09 SAR-W09 SAR-W15 SAR-W12 mm

Company Signature: Applicable Not Applicable

WELDTEST SARPI QC PIUL GIS

Name :

Signature :

Date :

Ref. ITP No. B-QAC-PLN-210-39174

RT-W-111X-0043

INSPECTION & TEST RECORD-WELDING

ITR No: JI-2045-W-0111X

RADIOGRAPHY REPORT

W-0111X

Plant/Unit: Project No.: Record No.: W-111X-0043

Drawing No.: Rev. No.: System/Sub-system No.:

Source Type: Source Strength: RT Technique : Film Type & Brand Name: Pb Screen Thickness:

(Isotope / X Ray) ______Ci or _______KV (SWSI, DWSI, DWDI, Panoramic, other) Film Processing: (Manual/Automatic) (1) Front _____(mm) (2) Back_____mm

Maximum Source Size / Focal Spot: (mm) SFD: inch Maximum Geometric Unsharpness (Ug): mm Film Density:

Material Grade: Penetrometer Type & No.: Location of Penetrometer: Wire/Hole RT Procedure No. & Rev. No.:

(Source Side / Film Side) Acceptance Criteria & Edition:

Required: Achieved:

Welder ID per Weld Pass

Penetration

Penetration

Slag or El.

Concavity

Undercut

Concave

Result

Through

Porosity

Surface

Lack of

Lack of

Excess

Fusion

Defect

Crack

Size &

Other

Burn

Root

SI N° Drawing No. WELD No. Film Location (Accept / Remarks

Thick.

ROOT HOT FILL 1 FILL 2 CAP Reject)

SAR-W05 SAR-W08 SAR-W08 SAR-W08 SAR-W04 16" x 11.78

11 0312

SAR-W09 SAR-W15 SAR-W15 SAR-W15 SAR-W12 mm

Company Signature: Applicable Not Applicable

WELDTEST SARPI QC PIUL GIS

Name :

Signature :

Date :

Ref. ITP No. B-QAC-PLN-210-39174

RT-W-111X-0043

You might also like

- RT RPRTDocument2 pagesRT RPRTZaidiNo ratings yet

- GCB RT 00Document1 pageGCB RT 00csc EXPERTISENo ratings yet

- Radiography Examination Report: PT. Rekayasa Penta AsiaDocument2 pagesRadiography Examination Report: PT. Rekayasa Penta AsiaSyafi'i SongoNo ratings yet

- STD-QD-009C RT New ReportDocument1 pageSTD-QD-009C RT New ReportmichaelNo ratings yet

- Ultrasonic Testing of Welds Report: Wisconsin Department of Transportation DT2104 2004 (Replaces EM771)Document2 pagesUltrasonic Testing of Welds Report: Wisconsin Department of Transportation DT2104 2004 (Replaces EM771)Abdul GhafoorNo ratings yet

- WPS MatrixDocument4 pagesWPS MatrixHarshaVeeragandham50% (2)

- Radiography Examination Procedure For WeldDocument21 pagesRadiography Examination Procedure For Weldeka prasetya siregarNo ratings yet

- FE VENTURY 1002-21 Straight Pipe 2Document3 pagesFE VENTURY 1002-21 Straight Pipe 2aditya kokoNo ratings yet

- Piping DetailsDocument16 pagesPiping DetailsSasi MesthiriNo ratings yet

- SondirDocument1 pageSondirAli suhendraNo ratings yet

- Submittal: J-96-20 - 215 East Fordham Road ToDocument2 pagesSubmittal: J-96-20 - 215 East Fordham Road Tokashi vishwanathNo ratings yet

- Company Welder & Welding Operator Register Based On Aws D1.5 2015Document1 pageCompany Welder & Welding Operator Register Based On Aws D1.5 2015REZKINo ratings yet

- Inspection Report For Drilling SubsDocument1 pageInspection Report For Drilling SubsERDNo ratings yet

- DVM Chiller Install Im 05937a-00 en 160115Document1 pageDVM Chiller Install Im 05937a-00 en 160115Tsamis IoannisNo ratings yet

- Cable CalculationsDocument9 pagesCable CalculationsFasil ENo ratings yet

- Cable CalculationsDocument9 pagesCable CalculationsMohamed Mostafa0% (1)

- 03 HWDP Spiral 3 1-2 New ReportDocument2 pages03 HWDP Spiral 3 1-2 New ReportKhalil ChabbouhNo ratings yet

- E6 Servo Full Manual PDFDocument2 pagesE6 Servo Full Manual PDFRomain JRNo ratings yet

- DVR Hikvision 7200Document1 pageDVR Hikvision 7200MITMA RA FANo ratings yet

- Breeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableDocument2 pagesBreeze V-Band Clamps: High-Strength Joining With Positive Sealing Integrity Three Latch Styles AvailableMuhammad SyaqirinNo ratings yet

- Technical Information: Display Console SpecificationsDocument1 pageTechnical Information: Display Console SpecificationsamitNo ratings yet

- Ultrasonic Test ReportDocument4 pagesUltrasonic Test ReportBalkishan DyavanapellyNo ratings yet

- SiC Activities 2022 - v8MADocument1 pageSiC Activities 2022 - v8MAKonstantinos ZekentesNo ratings yet

- QC-A-F86 Rev0 J FormDocument12 pagesQC-A-F86 Rev0 J FormMohd Soufian KamarudinNo ratings yet

- Product CatalogueDocument2 pagesProduct CatalogueBharath YemireddyNo ratings yet

- Installation Instructions For A2Frc Conduit GlandDocument2 pagesInstallation Instructions For A2Frc Conduit GlandPT INDORAD MEGA BINTANGNo ratings yet

- OML 58 Phase 1 Project Welders Qualification Log: Candiate IdDocument9 pagesOML 58 Phase 1 Project Welders Qualification Log: Candiate IdTheophilus OrupaboNo ratings yet

- Electrical Certificate of Test Business Trading Name: - ABNDocument1 pageElectrical Certificate of Test Business Trading Name: - ABNCarmina AlmiñeNo ratings yet

- (PM) งานวิทยุสื่อสารลูกข่าย ZPQDocument6 pages(PM) งานวิทยุสื่อสารลูกข่าย ZPQਪੰਜਾਬਐਕਟ ਤੀਰਅੰਦਾਜ਼No ratings yet

- Liquid Penetrant Quality Control and Inspection Report Form 1Document1 pageLiquid Penetrant Quality Control and Inspection Report Form 1Ricardo MachadoNo ratings yet

- Water Chamber-Rs (016019A01000) :: WCHT WBHT + Wcepht - WBFWDocument11 pagesWater Chamber-Rs (016019A01000) :: WCHT WBHT + Wcepht - WBFWAyush ChoudharyNo ratings yet

- 07 HWDP 5Document2 pages07 HWDP 5khalilNo ratings yet

- RT Report Imran ShahzadDocument1 pageRT Report Imran ShahzadthehitechmultanNo ratings yet

- Ydr DMSC LDocument2 pagesYdr DMSC Lsf wNo ratings yet

- D155 Idler Installation Checksheet - Rev1Document5 pagesD155 Idler Installation Checksheet - Rev1miswansabani86No ratings yet

- Muhammad WaqasDocument1 pageMuhammad WaqasthehitechmultanNo ratings yet

- SEIP For 080-V-001: Degassing DrumDocument6 pagesSEIP For 080-V-001: Degassing DrumThinh NguyenNo ratings yet

- BS 7671 TemplateDocument1 pageBS 7671 TemplateKarim AmerNo ratings yet

- Xs1059-02 - Connection, Exhaust OutletDocument1 pageXs1059-02 - Connection, Exhaust OutletBoBoMilovanovicNo ratings yet

- Ajay Industrial Corporation LTD: ISO 9001:2015, EN ISO 14001:2015, OHSAS 18001:2007Document2 pagesAjay Industrial Corporation LTD: ISO 9001:2015, EN ISO 14001:2015, OHSAS 18001:2007Ankit SandhuNo ratings yet

- Pocket Guide: IQI - DIN EN ISO 19232-1/5 Conformity IQI - DIN EN ISO 17636 ApplicationDocument2 pagesPocket Guide: IQI - DIN EN ISO 19232-1/5 Conformity IQI - DIN EN ISO 17636 ApplicationAhmed LepdaNo ratings yet

- WEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTDocument2 pagesWEG 10004278046 13617810 r01 CFW700 Adenddum H1as1 en Es PTLuanNo ratings yet

- Installation Instructions: Max Barrier PressureDocument2 pagesInstallation Instructions: Max Barrier PressureRaul V MaqNo ratings yet

- Suction Head Calculation: Local Factors of FittingsDocument1 pageSuction Head Calculation: Local Factors of Fittingsmohamad azipNo ratings yet

- 5-EM-A2.1-D-DFEMA-001-D 电气原理图Schematic Diagrams for GovernorDocument65 pages5-EM-A2.1-D-DFEMA-001-D 电气原理图Schematic Diagrams for Governorayisheshimgetinet05No ratings yet

- Form PAUTDocument1 pageForm PAUTLuong Ho VuNo ratings yet

- Smart Studio (Logic Program)Document2 pagesSmart Studio (Logic Program)purwantoandi99No ratings yet

- Electrical ScheduleDocument5 pagesElectrical Schedulerizwan266No ratings yet

- Daily Welding Progress ReportDocument1 pageDaily Welding Progress ReportManoj KumarNo ratings yet

- RME Data Sheet - RUSSELL Mill Relining MachineDocument1 pageRME Data Sheet - RUSSELL Mill Relining MachineСергейNo ratings yet

- Phased Array Probes Application MatrixDocument1 pagePhased Array Probes Application MatrixFethi BELOUISNo ratings yet

- Welder Test 18 December 2018Document1 pageWelder Test 18 December 2018NEMO MEMBUATNo ratings yet

- Hdmi FTV: HDMI Connection System For Harsh EnvironmentDocument10 pagesHdmi FTV: HDMI Connection System For Harsh EnvironmentViet Chau DaoNo ratings yet

- Ard D 01 en Ma Drw171437aa 20171220 He 20171227 PDFDocument1 pageArd D 01 en Ma Drw171437aa 20171220 He 20171227 PDFUus SuhadaNo ratings yet

- Borlog ADocument1 pageBorlog Arifqi bambangNo ratings yet

- Rotating Equipment List: A. ProcessDocument2 pagesRotating Equipment List: A. ProcesshungNo ratings yet

- Eppm-Wps-Jtf-Cs-13 Rev. 0 Gtaw+ FcawDocument18 pagesEppm-Wps-Jtf-Cs-13 Rev. 0 Gtaw+ FcawBassem Ben FrajNo ratings yet

- Hail Surface Facilities: RT Request For Sivert Date 7-Apr-17Document1 pageHail Surface Facilities: RT Request For Sivert Date 7-Apr-17Anonymous AdofXEYAgENo ratings yet

- Quick Data Sheet Magtech Mli en 60296Document3 pagesQuick Data Sheet Magtech Mli en 60296Sanket YewaleNo ratings yet

- IC PMO Charter Document 11223 - WORDDocument15 pagesIC PMO Charter Document 11223 - WORDZaidiNo ratings yet

- Earned Value Analysis ReportDocument2 pagesEarned Value Analysis ReportZaidiNo ratings yet

- P 0200 152 LWQ 01Document1 pageP 0200 152 LWQ 01ZaidiNo ratings yet

- Application of Agile Project Management in Kuwait Oil and Gas Capital ProjectsDocument224 pagesApplication of Agile Project Management in Kuwait Oil and Gas Capital ProjectsHassan Al DahhakNo ratings yet

- Quality Induction ManualDocument79 pagesQuality Induction ManualZaidiNo ratings yet

- RRRRRDWR atDocument3 pagesRRRRRDWR atZaidiNo ratings yet

- RFI atDocument94 pagesRFI atZaidiNo ratings yet

- DRTHRTHHWR atDocument2 pagesDRTHRTHHWR atZaidiNo ratings yet

- RFI LogDocument2 pagesRFI LogZaidiNo ratings yet

- P 0200 152 LHS 01Document2 pagesP 0200 152 LHS 01Zaidi100% (1)

- DRTHRTHHWR atDocument2 pagesDRTHRTHHWR atZaidiNo ratings yet

- RT RPGGRTDocument2 pagesRT RPGGRTZaidiNo ratings yet

- RFI LogDocument1 pageRFI LogZaidiNo ratings yet

- Request For Inspection: Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282Document1 pageRequest For Inspection: Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282ZaidiNo ratings yet

- Chart 1: Runningtotal - RT (Sum) Welding (Sum) Prog - W (Sum) Prog - RT (Sum)Document1 pageChart 1: Runningtotal - RT (Sum) Welding (Sum) Prog - W (Sum) Prog - RT (Sum)ZaidiNo ratings yet

- DWR atDocument1 pageDWR atZaidiNo ratings yet

- Stakeholder RegisterDocument20 pagesStakeholder RegisterZaidiNo ratings yet

- Request For Inspection: Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282Document1 pageRequest For Inspection: Ain Tsila Development Main EPC Contract A-CNT-CON-000-00282ZaidiNo ratings yet

- 5DPM DetailsDocument26 pages5DPM DetailsZaidiNo ratings yet

- DWR At1Document1 pageDWR At1ZaidiNo ratings yet

- Djahid Zaidi CVDocument5 pagesDjahid Zaidi CVZaidiNo ratings yet

- Daily Joint WeldedDocument1 pageDaily Joint WeldedZaidiNo ratings yet

- Print EVM ReportDocument1 pagePrint EVM ReportZaidiNo ratings yet

- EVM ReportDocument1 pageEVM ReportZaidiNo ratings yet

- Daily Joint WeldedDocument1 pageDaily Joint WeldedZaidiNo ratings yet

- Daily Joint WeldedDocument1 pageDaily Joint WeldedZaidiNo ratings yet

- Daily Joint WeldedDocument1 pageDaily Joint WeldedZaidiNo ratings yet

- Daily Joint WeldedDocument1 pageDaily Joint WeldedZaidiNo ratings yet

- 22 - GIS Testing PDFDocument9 pages22 - GIS Testing PDFwaqas_a_shaikh4348No ratings yet

- Sae Summer KepsDocument6 pagesSae Summer KepsPritesh KumarNo ratings yet

- Physical Science Module 3Document22 pagesPhysical Science Module 3Florence-j Pelayo Tupaz100% (1)

- XT1C 160 TMD 25-450 4p F F: General InformationDocument3 pagesXT1C 160 TMD 25-450 4p F F: General InformationHenrics MayoresNo ratings yet

- Availability Simulation - IsographDocument1 pageAvailability Simulation - IsographsaospieNo ratings yet

- 2.4 GHZ 14 Dbi 90 Degree Vertical Polarized Sector Panel Wireless Lan Antenna - Model: Hg2414Sp-090Document2 pages2.4 GHZ 14 Dbi 90 Degree Vertical Polarized Sector Panel Wireless Lan Antenna - Model: Hg2414Sp-090Giovanni José Huacasi SupoNo ratings yet

- Shell & Tube Heat Exchangers: First Name LAST NAME - Speaker's Job TitleDocument71 pagesShell & Tube Heat Exchangers: First Name LAST NAME - Speaker's Job TitledivakarNo ratings yet

- 07 VariablesDocument3 pages07 VariablesBaneeIshaqueKNo ratings yet

- 1.3 Hydraulic PumpsDocument15 pages1.3 Hydraulic Pumpsdoan lucNo ratings yet

- Présentation AFAME - SESARDocument3 pagesPrésentation AFAME - SESARsystex2No ratings yet

- Fast Web View PDF TomcatDocument2 pagesFast Web View PDF TomcatEddieNo ratings yet

- Python Lab 1Document4 pagesPython Lab 1vaskoreNo ratings yet

- Cambium cmm5 DatasheetDocument2 pagesCambium cmm5 DatasheetSean MarkNo ratings yet

- 3 - Intermetallic Compounds of Ni and Ga As Catalysts For The Synthesis of MethanolDocument12 pages3 - Intermetallic Compounds of Ni and Ga As Catalysts For The Synthesis of Methanoltunganh1110No ratings yet

- Pantron Amplifier ISG-N138 DatasheetDocument7 pagesPantron Amplifier ISG-N138 DatasheetlutfirozaqiNo ratings yet

- Chapter 8 - SynchronousDocument12 pagesChapter 8 - SynchronousLin ChongNo ratings yet

- Harmonic Resonance During Energizing Primary Restorative Transmission SystemsDocument14 pagesHarmonic Resonance During Energizing Primary Restorative Transmission SystemsLuKas21cNo ratings yet

- Tips To Perform Pipette CalibrationDocument9 pagesTips To Perform Pipette CalibrationEdword SimpsonNo ratings yet

- Is Structure AnswerDocument2 pagesIs Structure AnswerJay JayNo ratings yet

- 10385-J UTBI-001 ManualDocument2 pages10385-J UTBI-001 ManualMatias GiammariniNo ratings yet

- BalancesDocument8 pagesBalancescchauling6841No ratings yet

- Weld Acceptance Criteria1Document1 pageWeld Acceptance Criteria1sankarNo ratings yet

- Substance Chemistry Lesson 1Document28 pagesSubstance Chemistry Lesson 1samsonNo ratings yet

- Light: Year 9 Science Semester RevisionDocument4 pagesLight: Year 9 Science Semester Revisionapi-32133818No ratings yet

- An Electronic Control Unit For Reducing Contact Bounce in Electromagnetic ContactorsDocument10 pagesAn Electronic Control Unit For Reducing Contact Bounce in Electromagnetic ContactorsAbirami RajagopalNo ratings yet

- Dossat Principles of RefrigerationDocument554 pagesDossat Principles of RefrigerationJunaid Ameer100% (8)

- Module 1.MMWDocument20 pagesModule 1.MMWJimmy DegayNo ratings yet

- Chenmko Enterprise Co.,Ltd: CHN202UPT Surface MountDocument3 pagesChenmko Enterprise Co.,Ltd: CHN202UPT Surface MountAlberto CardenasNo ratings yet

- Appian Training CurriculumDocument3 pagesAppian Training CurriculumKumarReddy100% (1)

- Unification of Euler and Werner Deconvolution in Three Dimensions Via The Generalized Hilbert TransformDocument6 pagesUnification of Euler and Werner Deconvolution in Three Dimensions Via The Generalized Hilbert TransformMithunNo ratings yet