Professional Documents

Culture Documents

Assist and Assure Step Card

Assist and Assure Step Card

Uploaded by

khushbu Hasan0 ratings0% found this document useful (0 votes)

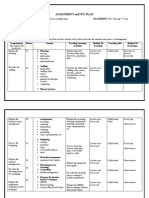

47 views2 pagesThe document outlines safety procedures for transitioning to work and lifting operations. It emphasizes planning, communication, equipment checks, area preparation, energy control, and final checks before starting work. Key steps include verifying competency and understanding, discussing hazards and controls, checking lifting points and equipment, preparing the work area, isolating energy sources, and having emergency plans in place. Hand and lifting safety rules are also described, such as keeping hands free of loads, only touching equipment with handles, and getting permission before touching loads over 20kg. The document stresses taking time to plan and prepare work thoroughly to ensure safety.

Original Description:

Original Title

assist-and-assure-step-card (1)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document outlines safety procedures for transitioning to work and lifting operations. It emphasizes planning, communication, equipment checks, area preparation, energy control, and final checks before starting work. Key steps include verifying competency and understanding, discussing hazards and controls, checking lifting points and equipment, preparing the work area, isolating energy sources, and having emergency plans in place. Hand and lifting safety rules are also described, such as keeping hands free of loads, only touching equipment with handles, and getting permission before touching loads over 20kg. The document stresses taking time to plan and prepare work thoroughly to ensure safety.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

47 views2 pagesAssist and Assure Step Card

Assist and Assure Step Card

Uploaded by

khushbu HasanThe document outlines safety procedures for transitioning to work and lifting operations. It emphasizes planning, communication, equipment checks, area preparation, energy control, and final checks before starting work. Key steps include verifying competency and understanding, discussing hazards and controls, checking lifting points and equipment, preparing the work area, isolating energy sources, and having emergency plans in place. Hand and lifting safety rules are also described, such as keeping hands free of loads, only touching equipment with handles, and getting permission before touching loads over 20kg. The document stresses taking time to plan and prepare work thoroughly to ensure safety.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

TRANSITION TO WORK

“SWITCHING ON - FOR MY TOP 4.”

❑ Fit to Drive

❑ Current LAAR + Weed Hygiene

❑ Journey Plan – hazards / Controls

DRIVING ❑ Positive communications /JMC

❑ Step 7 → Plan, Communicate,

Check Equipment, Area & Energy then

Final Check. 360° walkaround

❑ Competency and FFW checks done

❑ Pre job briefing

❑ Lessons Learnt shared with crew

❑ Weight/center of gravity verified

❑ Lifting procedure/plan checked

❑ Positive and certified lifting points

❑ SIMOPS Hazards verified

Lifting and ❑ Area barricaded to prevent people

Hoisting entering drop zone

❑ Weather and ground conditions

checked

❑ Lifting equipment checked

❑ Positive communications in place

❑ Emergency plan in place and verified

Final Check controls are in place

❑ No Hands on Loads

❑ Hands on Handles Only

HANDS FREE ❑ Permission to Touch (20kg)

RULES ❑ Hands Off ….Energy On

❑ Safe Cargo Loading

Gloves (mandatory)

Whether working alone or in a team we must

ENGAGE: THINK, FOCUS, LEARN

STEP 7 SAFE WORK PROCESS

“STARTING WORK IS NOT STEP # 1”

Work Instruction & Hazard Assessment

1 PLAN Verify Understanding / Competency /

LAAR

Transition to Work – Ask Open Qs

2 COMMUNICATE Personal & Process Safety

Radios / Hand Signals / Signage

Certified / Tested / Rated

CHECK

3 Fit for Purpose / Calibrated

EQUIPMENT No Damage / Backup Ready

Flat and Level / Housekeeping

4 PREPARE AREA Red Zone & NO GO Zones

SIMOPS - Above / Below / Beside

Isolate (Lock-out, Tag-out, and Test)

CONTROL

5 Drain Stored Energy (Gauge?)

ENERGY Line of Fire / Escape Route

100% Ready to Go

6 FINAL CHECK Contingencies in Place / ER

Walk the Line with P&ID

Comply / Intervene / Respect

Follow the Life Saving Rules

7 START WORK Well Barriers / DROPS / Hands Free

PAUSE when things change

AFTER ACTION REVIEW

STARTING WORK IS STEP #7

When things are NOT going as planned, stuck or jammed

STOP, Think and make another Plan

Why rush when the minute you save may be your last?

You might also like

- Safe Work Method Statement: Collbrook Pty LTD Atfmarschall Family Trust Trading AsDocument15 pagesSafe Work Method Statement: Collbrook Pty LTD Atfmarschall Family Trust Trading AsAvinash100% (2)

- Planned Job Observation: ChecklistDocument2 pagesPlanned Job Observation: ChecklistMOHAMMED RIYAN TNo ratings yet

- 2014-03-12 - G.R. No. 150326: First Division Decision Bersamin, J.Document12 pages2014-03-12 - G.R. No. 150326: First Division Decision Bersamin, J.Nunugom SonNo ratings yet

- A Schlumberger Guide To The OSDU Data PlatformDocument12 pagesA Schlumberger Guide To The OSDU Data Platformkhushbu HasanNo ratings yet

- Traditional GrammarDocument4 pagesTraditional GrammarAsha MathewNo ratings yet

- Squeeze Cementing JobDocument64 pagesSqueeze Cementing Jobkhushbu Hasan100% (2)

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplatemahmoudmakladNo ratings yet

- Complicated Lifting Operation Plan: Non Routine Complicated MAX With Lifting Gear Actual or Estimated Crane RegistrationDocument1 pageComplicated Lifting Operation Plan: Non Routine Complicated MAX With Lifting Gear Actual or Estimated Crane RegistrationAva GhaziNo ratings yet

- GSR3 Ergonomics & Manual HandlingDocument14 pagesGSR3 Ergonomics & Manual HandlingEngr Najam U SaqibNo ratings yet

- Pre Job Hazard Assessment (PJHA) FORM: CAN-EHS-F-05 Revision: 15/09/17Document3 pagesPre Job Hazard Assessment (PJHA) FORM: CAN-EHS-F-05 Revision: 15/09/17Dharma Nayak0% (1)

- Robbery Complaint Ate GinaDocument6 pagesRobbery Complaint Ate GinaJameson UyNo ratings yet

- Conductor StringingDocument5 pagesConductor Stringingisaacwabbi100% (1)

- Jsa CraneDocument3 pagesJsa Cranenattwa201075% (24)

- Work Method Statement PDFDocument8 pagesWork Method Statement PDFUsiwo Abed Soteria Otowa100% (4)

- Brand Awareness QuestionnaireDocument3 pagesBrand Awareness QuestionnaireAjit Shadambi40% (10)

- NPV and IRR, Payback Period, ImportantDocument5 pagesNPV and IRR, Payback Period, Important朱潇妤No ratings yet

- Working Heights Risk Assessment TemplateDocument8 pagesWorking Heights Risk Assessment TemplateJUAN NICANOR ALIAGA GIRONNo ratings yet

- REPORT Specpro (Canezo Vs RojasDocument2 pagesREPORT Specpro (Canezo Vs RojasporeoticsarmyNo ratings yet

- Design Thinking in UXDocument20 pagesDesign Thinking in UXIzuagbe27No ratings yet

- Hazard Analysis Webinar PSS PDFDocument57 pagesHazard Analysis Webinar PSS PDFvengielNo ratings yet

- "Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessDocument2 pages"Red" High (1) "Yellow" Medium (2) "Green" Low (3) : IllnessBarb O'NeillNo ratings yet

- Lifting Plan For Erection of 2nd To 6th r.1Document10 pagesLifting Plan For Erection of 2nd To 6th r.1Rhannie GarciaNo ratings yet

- Day 1 - JHADocument20 pagesDay 1 - JHAoshc caragaNo ratings yet

- Zwischenfach - A Distinct Voice TypeDocument100 pagesZwischenfach - A Distinct Voice TyperairochadelNo ratings yet

- TBA NA: Lifting and Hoisting PlanDocument4 pagesTBA NA: Lifting and Hoisting Planikponmwonsa67% (3)

- ASA Form-Lifting Immersion 2Document2 pagesASA Form-Lifting Immersion 2Mostafa KhalifaNo ratings yet

- Mohon Dikembalikan Formulir Yang Sudah Dilengkapi Ke Atasan Anda Sebelum Memulai BekerjaDocument2 pagesMohon Dikembalikan Formulir Yang Sudah Dilengkapi Ke Atasan Anda Sebelum Memulai BekerjamunawarNo ratings yet

- Behavior Based Safety: Date: Project: Observer's Name: Observer's Designation: Description of ObservationDocument2 pagesBehavior Based Safety: Date: Project: Observer's Name: Observer's Designation: Description of ObservationMd. Ashraful IslamaNo ratings yet

- P12 - CHEAC - New Camp - STA - Installation of Fence - 23 Mar 2023Document3 pagesP12 - CHEAC - New Camp - STA - Installation of Fence - 23 Mar 2023imranNo ratings yet

- Activity 5Document6 pagesActivity 5pl.christianmailomNo ratings yet

- g1-s1 Practical Assessment.v1.2Document10 pagesg1-s1 Practical Assessment.v1.2albertabdul-rahmanNo ratings yet

- STA ElectricalDocument3 pagesSTA ElectricalimranNo ratings yet

- Risk AssessmentDocument4 pagesRisk AssessmentThoufeer NETTERYNo ratings yet

- Internal Training Traning Conducted By: B.A Mohamed Ibrahim Topic: Safety in LiftingDocument4 pagesInternal Training Traning Conducted By: B.A Mohamed Ibrahim Topic: Safety in LiftingibrahimNo ratings yet

- Vennsys Media Take 5 Meter Reader BookletDocument8 pagesVennsys Media Take 5 Meter Reader BookletgabguarseNo ratings yet

- CPG - Co-Op15gn121Document4 pagesCPG - Co-Op15gn121azNo ratings yet

- Field Level Risk AssessmentDocument23 pagesField Level Risk AssessmentTammyNo ratings yet

- JSA 173 - CRT RIG UP - Updated 21.10.2019Document11 pagesJSA 173 - CRT RIG UP - Updated 21.10.2019tafhim rashidNo ratings yet

- Job Hazard Analysis Rev. BDocument28 pagesJob Hazard Analysis Rev. BAldrien CabinteNo ratings yet

- Observation CardDocument2 pagesObservation Cardm.auzanfebrianoshazaNo ratings yet

- RPI Job Briefing - LlanoDocument1 pageRPI Job Briefing - LlanoShogun1stNo ratings yet

- DSTIDocument3 pagesDSTIMalefane Cortez TlatlaneNo ratings yet

- Supervisor: Job/Location: Date: Work To Be Done: Task LocationDocument1 pageSupervisor: Job/Location: Date: Work To Be Done: Task LocationBala SingamNo ratings yet

- RefuellingDocument4 pagesRefuellingAnish ThampiNo ratings yet

- Dewatering 2016 VersionDocument2 pagesDewatering 2016 VersionAmeerHamzaWarraichNo ratings yet

- Take 5Document9 pagesTake 5aaqibfarhanNo ratings yet

- HE Vietnam Induction - Offshore HSE Induction For Contractors - ENG - April2023Document69 pagesHE Vietnam Induction - Offshore HSE Induction For Contractors - ENG - April2023Bien MLNo ratings yet

- 9 Golden RulesDocument39 pages9 Golden RuleskhurramNo ratings yet

- Contact Information: Date Job ReferenceDocument5 pagesContact Information: Date Job ReferenceMukeshLagadhirNo ratings yet

- Lifting Plan For Erection of 2nd To 6th Rev.3Document11 pagesLifting Plan For Erection of 2nd To 6th Rev.3Rhannie GarciaNo ratings yet

- JCA Full Set PDFDocument68 pagesJCA Full Set PDFaymenmoatazNo ratings yet

- Genie Australia Operating Telescopic HandlerDocument10 pagesGenie Australia Operating Telescopic Handlerahmed ibNo ratings yet

- Omn01ard - Jsa-Loading and Unloading of Weight Drop With Hi-AbDocument3 pagesOmn01ard - Jsa-Loading and Unloading of Weight Drop With Hi-Abhechame TamerhouletNo ratings yet

- Form Take 5 - ENG - R01Document4 pagesForm Take 5 - ENG - R01arnoldNo ratings yet

- Incident Details: Construction - Event Report (Near Miss)Document2 pagesIncident Details: Construction - Event Report (Near Miss)deepak bhagatNo ratings yet

- 002 433 Vibratingcompactorplates 1458731120Document2 pages002 433 Vibratingcompactorplates 1458731120Jose PrabhuNo ratings yet

- 002 433 Vibratingcompactorplates 1458731120Document2 pages002 433 Vibratingcompactorplates 1458731120Abrar AbbasiNo ratings yet

- JHA Align Towers & Torque All NutsDocument5 pagesJHA Align Towers & Torque All NutsGord BullNo ratings yet

- BULLDOZER - C52JSA-037 - Dozer Clearing of Existing Tracks in Jebel - 18-Mar-14Document6 pagesBULLDOZER - C52JSA-037 - Dozer Clearing of Existing Tracks in Jebel - 18-Mar-14hechame TamerhouletNo ratings yet

- 20220730-20220801 - Prestart NP Dayshift Tuesday 020523Document6 pages20220730-20220801 - Prestart NP Dayshift Tuesday 020523nigelNo ratings yet

- Field Service Jsa: Prepare Yes / No / NADocument2 pagesField Service Jsa: Prepare Yes / No / NADeba RinaNo ratings yet

- JSA Elevator MaintenancDocument6 pagesJSA Elevator MaintenancHSE fahadNo ratings yet

- LifeSavingRules AnIntroductionDocument18 pagesLifeSavingRules AnIntroductionsoumya19800000000100% (1)

- Planned Task Observation Report: Manual ScalingDocument4 pagesPlanned Task Observation Report: Manual ScalingAnonymous CKxHJmwRiiNo ratings yet

- WSWP For Hamisa Installation of Lift FramesDocument6 pagesWSWP For Hamisa Installation of Lift FramesVictor Thembinkosi MakhubeleNo ratings yet

- JSA ReportDocument2 pagesJSA ReportVinod GuptaNo ratings yet

- Health and Saftey PowerpointDocument55 pagesHealth and Saftey PowerpointKobby BrineNo ratings yet

- VFD Ac Blower Belt ChangeDocument2 pagesVFD Ac Blower Belt Changeshams surveNo ratings yet

- Rayad's Resume - PE PDFDocument1 pageRayad's Resume - PE PDFkhushbu HasanNo ratings yet

- TAO - SSW - Assessment - PATEL - HARSH - 20211001 - Rev0.1Document186 pagesTAO - SSW - Assessment - PATEL - HARSH - 20211001 - Rev0.1khushbu HasanNo ratings yet

- Evo-RED Bridge Plug - H010742-DSDocument2 pagesEvo-RED Bridge Plug - H010742-DSkhushbu HasanNo ratings yet

- My Questions 1Document26 pagesMy Questions 1vk.maddali6256No ratings yet

- B. Glo Bal Maxima/MinimaDocument15 pagesB. Glo Bal Maxima/MinimalucasNo ratings yet

- Ocampo Vs OmbDocument4 pagesOcampo Vs OmbLindsay MillsNo ratings yet

- Grief TherapyDocument15 pagesGrief TherapyDaniel CanoNo ratings yet

- 4.3 - Concept of Political Obligation and Civil DisobedienceDocument12 pages4.3 - Concept of Political Obligation and Civil DisobedienceSàúrábh JaíswãlNo ratings yet

- Background and Origin of The Christian, The - Dikran Y. Hadidian PDFDocument11 pagesBackground and Origin of The Christian, The - Dikran Y. Hadidian PDFMonachus IgnotusNo ratings yet

- Assignment Onunit Plan: Course Titel: PLACEMENT-B.Sc. Nursing 4 Unit Titel: Unit No.: HoursDocument2 pagesAssignment Onunit Plan: Course Titel: PLACEMENT-B.Sc. Nursing 4 Unit Titel: Unit No.: HoursPriyaNo ratings yet

- PB Claim FormDocument2 pagesPB Claim Formmhaseeb35100% (1)

- Introduction To Management and Organizations: Stephen P. Robbins Mary CoulterDocument26 pagesIntroduction To Management and Organizations: Stephen P. Robbins Mary CoulternidamahNo ratings yet

- MOdule 4 Unders CulDocument2 pagesMOdule 4 Unders CulQuinto Grace IreneNo ratings yet

- TestDocument13 pagesTestmani kandanNo ratings yet

- LyricsDocument51 pagesLyricsKen ShinNo ratings yet

- SUAOKI IntercomDocument1 pageSUAOKI IntercomAlberto MagallónNo ratings yet

- PT 6.3 Business StrategiesDocument6 pagesPT 6.3 Business StrategiesPaula de TorresNo ratings yet

- Required Texts:: Hanoi Foreign Trade University Faculty of Banking and Finance TCHE321 Corporate FinanceDocument2 pagesRequired Texts:: Hanoi Foreign Trade University Faculty of Banking and Finance TCHE321 Corporate Financegenius_2No ratings yet

- Melanie Phillips and IranDocument5 pagesMelanie Phillips and IranBinamAryaniNo ratings yet

- Shrinking CitiesDocument38 pagesShrinking CitiessalminaNo ratings yet

- Summary of ReportDocument13 pagesSummary of ReportCindy Mae CamohoyNo ratings yet

- Benjamin 1-Grade 5 Mathematical Logic: Choose Correct Answer(s) From The Given ChoicesDocument3 pagesBenjamin 1-Grade 5 Mathematical Logic: Choose Correct Answer(s) From The Given ChoiceskingnachiNo ratings yet

- User Usable Experience - A Three-Dimensional Approach On Usability in Tourism Websites and A Model For Its EvaluationDocument13 pagesUser Usable Experience - A Three-Dimensional Approach On Usability in Tourism Websites and A Model For Its EvaluationfiziNo ratings yet

- NS1000 v1.1-PC Programming ManualDocument968 pagesNS1000 v1.1-PC Programming ManualJulioNo ratings yet

- A Movie Analysis of Jose Rizal Movie (1998)Document7 pagesA Movie Analysis of Jose Rizal Movie (1998)Kate TomaganNo ratings yet