Professional Documents

Culture Documents

Is 1865 - 9

Uploaded by

Svapnesh ParikhOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is 1865 - 9

Uploaded by

Svapnesh ParikhCopyright:

Available Formats

13 TESTS 13.2.

1 Tbe test shall be carried out on the test

13.1 Tensile Test samples at one or scwxal points on the castings in

8eCOrdanCewith the agreement between the manu-

The tensile test shall be carried out in accordance facturer and the purchaser. If the measuring

with IS 1608 : 1972 unless otherwise agreed to points are not the subject to an agreement, this

between the purchaser and the manufacturer. The shall be selected by the manufacturer.

test piece shall have a gauge diameter of 14 mm NOTE -In case the grades are specified on the

and a gauge length of 70 mm ( see Fig. 5 ). In c8se basis of the hardness, a reference may be made to

of test-sample of 12 mm size ( i. e. Type I given Annex A fur the requirements.

in Fig. 1 and 2 ) the test piece shall have a gauge

diameter of 8 mm apd a gauge length of 40 mm. 13.3 impact Test

13.1.1 During each tensile test the following pro- The impact test shall be carried out on a V-notch

perties shall be determined and reported: charpy test piece in accordance with IS 1757 : 1988.

The dimensions 6f the V-notch test piece shall be

a) Ultimate tensile strength, as given in Fig. 6.

b) 0’2 percent proof stress ( only if specified by

the purchaser at the time of ordering ), 13.3.1 Unless spccikd the impact test shall be

conducted on the teat pieces at the temperature

c) elongation, and specified, in Table 3 or Table 4.

d) any additional information mutually agreed

upon by the purchaser and the manufacturer. 14 VALIDITY OF TESTS

In absence of facility to accurately measure 14.1 A test may be disregarded if poor results

0’2 percent proof stress to determine compliance are obtained and are not due to the quality of the

with proof stress requirements, the material tested iron itself, but due to any of the following

shall be considered to have passed the test if it reasons:

does not undergo an elongation exceeding the a) Faulty mounting of the test piece or defec-

specified percentage value when subjected to the tive operation of test machine;

specified minimum stress for a period of 15

b) Defective casting or machining of the test

seconds and after removal of that load stress.

piece;

13.2 Hardness Test c) Fracture of tensile test piece beyond middle

When specified by the purchaser, the Brine11 hard- i/3rd of the gauge length; and

ness test shall be done in accordance with IS 1500 : d) Casting defects in the test-piece, evident

1983. after fracture.

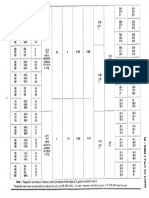

Table 4 Minimum Impact V8lues h!Ie8snred In Test Pieces from Cast-MITest SU@~S

( CIauses 12.2.2 and 13.3.1 )

Grade Typical Minimum Impact Values in Joules on V-Notch Test Pieces at Ambicat

Thickness, Temperature of

mm F--- A-- --------_5

(23AS)“C Mea(n- 20 f 2 1°C. ( - 40 f 2 )‘C

Mean Indivi- Indivi- Mean Indivi-

Value dual Value dual Value dual

from Value from Value from Value

3 Tests 3 Tests 3 Tests

._..-..

SC; 400/18A 30 to 60 14 11

61 to 200 12 9

SG 400/18AL 30 to 60 12 9

61 to 200 10 7

SG 350,‘22A 30 to 60 17 14

61 to 200 15 12

SG 350i22AL 30 to 60 12 9

61 to 200 10 7

You might also like

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Method FOR V-Erification of Rockwell Superficial Hardness Testing Machines (Scales 15N, 30N, 45N, 15T, 30T AND 45T) (Document5 pagesMethod FOR V-Erification of Rockwell Superficial Hardness Testing Machines (Scales 15N, 30N, 45N, 15T, 30T AND 45T) (Pushpendra ChouhanNo ratings yet

- CBT Questions: (2) Peel TestDocument18 pagesCBT Questions: (2) Peel TestMOHAMEDNo ratings yet

- A 106/A 106M - 06a: 12. Flattening Tests 14. Nondestructive Electric TestDocument1 pageA 106/A 106M - 06a: 12. Flattening Tests 14. Nondestructive Electric TestAGnes Stephani MuntheNo ratings yet

- Gridmesh Anchor Test Report ANSI Z359.18Document14 pagesGridmesh Anchor Test Report ANSI Z359.18IMIXCINo ratings yet

- Api 107Document14 pagesApi 107Yersin Hernandez AldanNo ratings yet

- API 510 Close Book (Sec Ix & Sec V) - 20Document20 pagesAPI 510 Close Book (Sec Ix & Sec V) - 20walid walidNo ratings yet

- Fall-of-Potential Ground Testing, Clamp-On Ground Testing ComparisonDocument4 pagesFall-of-Potential Ground Testing, Clamp-On Ground Testing ComparisonRicky Respondo TindocNo ratings yet

- En1170-5 1997Document4 pagesEn1170-5 1997Abdullah Talha TuranNo ratings yet

- Tensile Stress-Strain of Carbon and Graphite: Standard Test Method ForDocument12 pagesTensile Stress-Strain of Carbon and Graphite: Standard Test Method Forsj19330No ratings yet

- API 510 Open Book Q&ADocument138 pagesAPI 510 Open Book Q&AMohammed Shakil25% (4)

- Wi - Hardness TestingDocument8 pagesWi - Hardness Testingvipulsharma655No ratings yet

- Cast Aluminum Alloy Railing Posts: Standard Specification ForDocument2 pagesCast Aluminum Alloy Railing Posts: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Concrete Durability Requirement in QCS 2014Document1 pageConcrete Durability Requirement in QCS 2014Zohaib Sattar NagraNo ratings yet

- Canuipan Bridge PDADocument11 pagesCanuipan Bridge PDAeddmari.engineeringNo ratings yet

- Report On Vertical Load Test On 500Mm Dia, 7.30 Meters Deep Initial Pile Tp-2, BangaloreDocument15 pagesReport On Vertical Load Test On 500Mm Dia, 7.30 Meters Deep Initial Pile Tp-2, BangaloreRavi BojankiNo ratings yet

- Procedure For WQTDocument13 pagesProcedure For WQTdevikar8umNo ratings yet

- Welder Qualification Procedure PDFDocument13 pagesWelder Qualification Procedure PDFEngineersEDGE Coimbatore0% (1)

- Offshore Mooring Chain Cables and AccessoriesDocument8 pagesOffshore Mooring Chain Cables and Accessoriesscofiel1No ratings yet

- Steel Screw Spikes: Standard Specification ForDocument3 pagesSteel Screw Spikes: Standard Specification ForVivi VargasNo ratings yet

- API 510 PC 20 31 Aug05 Mid Session OpenDocument7 pagesAPI 510 PC 20 31 Aug05 Mid Session OpenCss SfaxienNo ratings yet

- Final Draft ACS No. 4 To IRS-T-12-2009Document27 pagesFinal Draft ACS No. 4 To IRS-T-12-2009NILADRI SEKHAR ROYNo ratings yet

- En 60889Document3 pagesEn 60889Pankaj Goyal0% (1)

- Compressive Strength TestDocument8 pagesCompressive Strength TestBeaver CaraNo ratings yet

- Note 7 - Welder Test - Mechanical Test and X-RayDocument29 pagesNote 7 - Welder Test - Mechanical Test and X-RayMohamad Yusuf HelmiNo ratings yet

- 60 KV and 20 KV SA Factory Test ReportsDocument2 pages60 KV and 20 KV SA Factory Test Reportsvinoth madhavanNo ratings yet

- Test ReportDocument40 pagesTest ReportMourad BenderradjiNo ratings yet

- Hardness TestingDocument6 pagesHardness TestingRakesh RanjanNo ratings yet

- Tension StiffeningDocument14 pagesTension StiffeningOlesea NesterencoNo ratings yet

- 17568-10-Test ReportDocument16 pages17568-10-Test ReportJuan Rodrigo Mamani PollogueriNo ratings yet

- Hardness Test Procedure: 1 of 8 DE3511.006/EDocument8 pagesHardness Test Procedure: 1 of 8 DE3511.006/Esalman1111aNo ratings yet

- API Recert QuestionsDocument8 pagesAPI Recert Questionsrama77No ratings yet

- 510 IRS Pune Open Book Questions FinalDocument6 pages510 IRS Pune Open Book Questions Finaljaheer1No ratings yet

- QW-483 (Red) PQR No.: Tme 358Document1 pageQW-483 (Red) PQR No.: Tme 358Sudhir KotkarNo ratings yet

- Astm Standart A416.1974Document7 pagesAstm Standart A416.1974SetyasasmitaNo ratings yet

- QW-483 (Green) PQR No.: Tme 356Document1 pageQW-483 (Green) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- QW-483 (BACK) PQR No.: Tme 356Document1 pageQW-483 (BACK) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- Protocolo de Referencia para TC y CalculosDocument23 pagesProtocolo de Referencia para TC y Calculosgonzalo fernandezNo ratings yet

- ASME B31.8 - A 106 GR.B TENSILE STRENGTHDocument1 pageASME B31.8 - A 106 GR.B TENSILE STRENGTHjoaquin torrano veraNo ratings yet

- Informe Ruptura AnchongaDocument9 pagesInforme Ruptura Anchongamunianchonga2023a2026No ratings yet

- API 510 Mid-Session Exam (Open Book) : Instructions: Choose Only One Answer Which You Think Is Most AppropriateDocument6 pagesAPI 510 Mid-Session Exam (Open Book) : Instructions: Choose Only One Answer Which You Think Is Most AppropriatesnamprogNo ratings yet

- QC - 16 Guided Bend Test.Document3 pagesQC - 16 Guided Bend Test.mahendra100% (1)

- Pages From Asme Sec Ix 2017Document1 pagePages From Asme Sec Ix 2017Akhtar Ansari0% (1)

- Satr-P-3208 Rev 8 FinalDocument7 pagesSatr-P-3208 Rev 8 FinalMohamed HaleemNo ratings yet

- Is.814.2004 16Document1 pageIs.814.2004 16Anonymous vwbLPTpjNo ratings yet

- Specific Bendability of Pipeline Coatings: Standard Test Method ForDocument3 pagesSpecific Bendability of Pipeline Coatings: Standard Test Method ForCamilo GuardadoNo ratings yet

- QW-483 (Black) PQR No.: Tme 356Document1 pageQW-483 (Black) PQR No.: Tme 356Sudhir KotkarNo ratings yet

- Iacs W-22 2004Document15 pagesIacs W-22 2004Guilherme de BarrosNo ratings yet

- API 570 DAY 3 BOOK (1 To 108) (PP)Document106 pagesAPI 570 DAY 3 BOOK (1 To 108) (PP)melvinNo ratings yet

- AWS D1.1 - Acceptance Criteria For RTDocument11 pagesAWS D1.1 - Acceptance Criteria For RTHoras Canman67% (3)

- Welder Performance Qualification AsmeDocument14 pagesWelder Performance Qualification AsmeAhmad RizkiNo ratings yet

- Astm A82-79Document5 pagesAstm A82-79jameyconnorNo ratings yet

- Wps 1Document1 pageWps 1Sudhir KotkarNo ratings yet

- ASME Questions and AnswersDocument6 pagesASME Questions and AnswersAshwani DograNo ratings yet

- 2-Asme BPVC Section Ix-2013Document2 pages2-Asme BPVC Section Ix-2013Reda ElsawyNo ratings yet

- Páginas desdeAISC 358-16 CASTING REQUIREMENTSDocument2 pagesPáginas desdeAISC 358-16 CASTING REQUIREMENTSalejandroNo ratings yet

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryFrom EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryNo ratings yet

- Is 12308-9 - 1993 - 1Document1 pageIs 12308-9 - 1993 - 1Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 3Document1 pageIs 12308-7 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 12308-8 - 1997 - 5Document1 pageIs 12308-8 - 1997 - 5Svapnesh ParikhNo ratings yet

- Is 12308-6 - 1991 - 5Document1 pageIs 12308-6 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 12308-8 - 1997 - 3Document1 pageIs 12308-8 - 1997 - 3Svapnesh ParikhNo ratings yet

- Is 12308-4 - 1988 - 4Document1 pageIs 12308-4 - 1988 - 4Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 5Document1 pageIs 12308-5 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 14Document1 pageIs 10719 (Iso 1302) - 14Svapnesh ParikhNo ratings yet

- Is 12308-3 - 1987 - 1Document1 pageIs 12308-3 - 1987 - 1Svapnesh ParikhNo ratings yet

- Is 12308-7 - 1991 - 5Document1 pageIs 12308-7 - 1991 - 5Svapnesh ParikhNo ratings yet

- Is 12308-5 - 1991 - 3Document1 pageIs 12308-5 - 1991 - 3Svapnesh ParikhNo ratings yet

- Is 11166 - 1993 - 10Document1 pageIs 11166 - 1993 - 10Svapnesh ParikhNo ratings yet

- Is 2102-2 (Iso 2768-2) - 4Document1 pageIs 2102-2 (Iso 2768-2) - 4Svapnesh ParikhNo ratings yet

- Is 8422-2 - 1977 - 6Document1 pageIs 8422-2 - 1977 - 6Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 8Document1 pageIs 10719 (Iso 1302) - 8Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 11Document1 pageIs 10719 (Iso 1302) - 11Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 5Document1 pageIs 10719 (Iso 1302) - 5Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 1Document1 pageIs 8422-3 - 1977 - 1Svapnesh ParikhNo ratings yet

- Is 10719 (Iso 1302) - 1Document1 pageIs 10719 (Iso 1302) - 1Svapnesh ParikhNo ratings yet

- Is 8422-3 - 1977 - 3Document1 pageIs 8422-3 - 1977 - 3Svapnesh ParikhNo ratings yet

- Is 8422-1 - 1977 - 5Document1 pageIs 8422-1 - 1977 - 5Svapnesh ParikhNo ratings yet

- Is 5519 - 6Document1 pageIs 5519 - 6Svapnesh ParikhNo ratings yet

- Is 5519 - 2Document1 pageIs 5519 - 2Svapnesh ParikhNo ratings yet

- Is 2102-1 (Iso 2768-1) - 5Document1 pageIs 2102-1 (Iso 2768-1) - 5Svapnesh ParikhNo ratings yet

- Is 5519 - 3Document1 pageIs 5519 - 3Svapnesh ParikhNo ratings yet

- Is 2102-2 (Iso 2768-2) - 3Document1 pageIs 2102-2 (Iso 2768-2) - 3Svapnesh ParikhNo ratings yet

- Is 2102-2 (Iso 2768-2) - 5Document1 pageIs 2102-2 (Iso 2768-2) - 5Svapnesh ParikhNo ratings yet

- Is 2102-1 (Iso 2768-1) - 4Document1 pageIs 2102-1 (Iso 2768-1) - 4Svapnesh ParikhNo ratings yet

- Is 2102-2 (Iso 2768-2) - 1Document1 pageIs 2102-2 (Iso 2768-2) - 1Svapnesh ParikhNo ratings yet

- Is 2102-2 (Iso 2768-2) - 2Document1 pageIs 2102-2 (Iso 2768-2) - 2Svapnesh ParikhNo ratings yet

- KhanIzh - FGI Life - Offer Letter - V1 - Signed - 20220113154558Document6 pagesKhanIzh - FGI Life - Offer Letter - V1 - Signed - 20220113154558Izharul HaqueNo ratings yet

- Basic Electrical Engineering Mcqs Unit 1Document13 pagesBasic Electrical Engineering Mcqs Unit 1shubha christopherNo ratings yet

- Assignment Nutrition and HydrationDocument17 pagesAssignment Nutrition and Hydrationmelencio olivasNo ratings yet

- MelatoninaDocument32 pagesMelatoninaCodrut GeorgescuNo ratings yet

- Chapter - 7 Materials HandlingDocument14 pagesChapter - 7 Materials HandlingTanaya KambliNo ratings yet

- NCP On DiabetesDocument2 pagesNCP On DiabetesShumaila AlviNo ratings yet

- Post Traumatic Stress DisorderDocument2 pagesPost Traumatic Stress Disorderapi-188978784100% (1)

- ResearchDocument13 pagesResearchCHOYSON RIVERALNo ratings yet

- Cape 2 Biology - Homeostasis &excretionDocument9 pagesCape 2 Biology - Homeostasis &excretionTamicka BonnickNo ratings yet

- Phenotype and GenotypeDocument7 pagesPhenotype and GenotypeIrish Claire Molina TragicoNo ratings yet

- Bulk-Fill Composite RestorationsDocument9 pagesBulk-Fill Composite RestorationssusethNo ratings yet

- Pentacam Four Maps RefractiveDocument4 pagesPentacam Four Maps RefractiveSoma AlshokriNo ratings yet

- Earth As A PlanetDocument60 pagesEarth As A PlanetR AmravatiwalaNo ratings yet

- MAIZEDocument27 pagesMAIZEDr Annie SheronNo ratings yet

- Monitoring AlkesDocument41 pagesMonitoring AlkesEndangMiryaningAstutiNo ratings yet

- Ainsworth, The One-Year-Old Task of The Strange SituationDocument20 pagesAinsworth, The One-Year-Old Task of The Strange SituationliliaNo ratings yet

- Espiritualidad AFPP - 2018 PDFDocument5 pagesEspiritualidad AFPP - 2018 PDFEsteban OrellanaNo ratings yet

- Qi Gong & Meditation - Shaolin Temple UKDocument5 pagesQi Gong & Meditation - Shaolin Temple UKBhuvnesh TenguriaNo ratings yet

- ScienceDocument17 pagesScienceTambong HailyNo ratings yet

- Quinta RuedaDocument20 pagesQuinta RuedaArturo RengifoNo ratings yet

- Wada Defending Cannabis BanDocument18 pagesWada Defending Cannabis Banada UnknownNo ratings yet

- Recipe: Patisserie Method: Eclair Cake RecipeDocument3 pagesRecipe: Patisserie Method: Eclair Cake RecipeEisha BibiNo ratings yet

- Keygene Strengthens Its Patent Portfolio On Keypoint Mutation BreedingDocument1 pageKeygene Strengthens Its Patent Portfolio On Keypoint Mutation Breedingapi-99034713No ratings yet

- AQ-101 Arc Flash ProtectionDocument4 pagesAQ-101 Arc Flash ProtectionYvesNo ratings yet

- Cooling SistemadeRefrigeracion RefroidissementDocument124 pagesCooling SistemadeRefrigeracion RefroidissementPacoNo ratings yet

- RestraintsDocument48 pagesRestraintsLeena Pravil100% (1)

- Assistive TechnologyDocument3 pagesAssistive Technologyapi-547693573No ratings yet

- Cough PDFDocument3 pagesCough PDFKASIA SyNo ratings yet

- A I R P O R T S Construction Program Management 56Document56 pagesA I R P O R T S Construction Program Management 56Carl WilliamsNo ratings yet

- PowderCoatingResins ProductGuide 0Document20 pagesPowderCoatingResins ProductGuide 0zizitroNo ratings yet