Professional Documents

Culture Documents

Is.814.2004 16

Uploaded by

Anonymous vwbLPTpjOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is.814.2004 16

Uploaded by

Anonymous vwbLPTpjCopyright:

Available Formats

IS 814: 1004

The computedaveragevalueof the three valuesshall 9.3 RunalDIPerformaaee Test (for ElectrodeSizes

be equalto or greaterthan 47 joules. Up to and IneludIDI2.! mID)

9.1.3.3 For classification EXX4XX. EXX5XX and Thistest is to be camed out for electrodes of 2.5 mm

EXX6XX. two of the three remaining valuesshall be sizeandbelowto usess theweldingperfonnance. The

greater than the specified 27 joules; one of the three testshallbeconducted usingthreeelectrodes as perthe

values may be lowerbutshallnot belessthan23joules. detailsgiven in AnnexH. The bead should be visually

The computedaveragevalue of the three valuesshall inspected and should be free from porosities, slag

be equalto or greaterthan 27joules. inclusions, cracks,etc, in the main portionof the bead

9.2 Butt Weld Bend Test as liven in Annex H. The bead shall be reasonably

straight andevenlyrippled. Theslagshouldberemoved

Butt weld assemblies shan be prepared in different withlittleeffort.

welding positions for the various electrode

classifications as per the recommendations given in 9.4 Increased Metal RecoveryTest

Table 7 and the procedures given in AnnexG. If2.S The metal recovery shall be determined for the

mm size electrodeis manufactured then thissize shall electrodes classified under EXXXXXJ. EXXXXXK

be used for the root run for the butt weld assembly and EXXXXXL or EXXXXXHJ, EXXXXXHK and

whereveroptionof2.5 or 3.15mmis giveninTable7. EXXXXXHL on the largest size electrode

9.2.1 From each butt weld assembly two bend tests. manufactured butnotlowerthan4.0mminaccordance

one with face and one with root in tension shall be withthemethodgivenin IS 13043. Thevalueobtained

carried out. The test specimens shall be bent through by the method shall be rounded off to the nearest

1800 over a mandrelhavinga diameter equalto three multiple of S.

timesthethickness ofthe specimen inaccordance with The rounded recovery figure shall conform to

IS 1599. The electrode shall be deemed to be the requirements of 5.1.2(b) for the respective

satisfactory. if on completion of the test no crack or classification.

defectattheoutersurfaceofthetestspecimen isgreater

than 3 mm measured across the test specimen or I.S 9.5 Dlrrullble Hydroae. Evaluation Test

mm measured along the lengthof the test specimen.

Premature failureat comersof the test specimen shall Thistestshallbecarriedoutforallelectrodes clusified

not be considered as a case for rejection. underEXXXXXH and EXXXXXHL preferably using

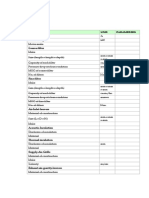

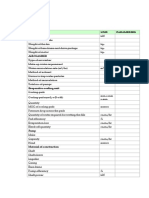

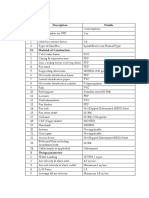

Table 6 Mechanical Properties of Weld Metal

(Clauses 9.1.2 and 9.1.3)

Classificatloa VUII.ateTenuit Yirld Peree.la.e Tempenture I .. pu'

Strealtll SlreB Eloa.ado. lor I.pact. e(! Stren....

oa Gaule

Lelil" 5.65 {i;

MPa MPa.Min Min JIMiII

(I) (2) (3) (4) (5) (6)

EX40XX 410-540 330 16 No impactrequirement

EX41XX 410-540 330 20 +27 47

EX42XX 410-'40 330 22 0 47

EX43XX 410-540 330 24 -20 47

EX44XX 410.'40 330 24 ·30 27

EXSOXX '10-610 360 16 NoImpact requirement

EXSIXX 5U)-610 360 18 +27 47

EXS2XX 510·610 360 18 0 47

EX53XX 510-610 360 20 ·20 47

EXS4XX .510-610 360 20 ·JO 27

EX55XX SIG-610 360 20 ...0 27

EXS6XX SI0-610 360 20 -46 27

NOTE - In view or the pouible scatter in weldin, and lestina. the upperlimit of ultimale tensile strenaths may be exceeded

by 40 MP•.

You might also like

- Midterm Exam Model Answer NOV2016 REV01 M PDFDocument12 pagesMidterm Exam Model Answer NOV2016 REV01 M PDFGeorge IskanderNo ratings yet

- Rebar Coupler Test StandartDocument6 pagesRebar Coupler Test StandartSaurav KumarNo ratings yet

- Low Alloy Steel Creep PropertiesDocument3 pagesLow Alloy Steel Creep Propertiesqueno1No ratings yet

- Carbon Steel Electrodes Specification for Submerged Arc WeldingDocument22 pagesCarbon Steel Electrodes Specification for Submerged Arc WeldingafarmaiaNo ratings yet

- SMiRT-23 Paper 093Document10 pagesSMiRT-23 Paper 093MAT-LIONNo ratings yet

- Testing Seam Concepts For Advanced Multilayer Insulation Rev4Document20 pagesTesting Seam Concepts For Advanced Multilayer Insulation Rev4imredaveNo ratings yet

- Desin Project StructuralDocument3 pagesDesin Project Structuralsteve njugunaNo ratings yet

- XEL Siemens Price ListDocument5 pagesXEL Siemens Price Listমোঃ মোমিনুল ইসলাম শোভনNo ratings yet

- Impact Resistance of Materials for Guards on Cutting Machine Tools Requirements in Future European Safety StandardsDocument15 pagesImpact Resistance of Materials for Guards on Cutting Machine Tools Requirements in Future European Safety Standardsptah1987No ratings yet

- Dissimilar Arc Stud Welding AISI 304/AISI 1008:mechanical PropertiesDocument16 pagesDissimilar Arc Stud Welding AISI 304/AISI 1008:mechanical PropertiesMary martenNo ratings yet

- Steel Module 7Document5 pagesSteel Module 7dash1991No ratings yet

- Lab 2: Nodal Analysis and Mesh Analysis Techniques: V V I V Ia V V I V Ib V I V V IDocument5 pagesLab 2: Nodal Analysis and Mesh Analysis Techniques: V V I V Ia V V I V Ib V I V V Igurdian skyNo ratings yet

- Fatigue Test (Project Report)Document15 pagesFatigue Test (Project Report)Ahmad Fraz0% (1)

- CAT 3E-6477 Relay TestDocument5 pagesCAT 3E-6477 Relay TestmkNo ratings yet

- Anchor and Base Plate CalculationDocument6 pagesAnchor and Base Plate Calculationselahattin_erturk06No ratings yet

- LA Type Test ReportDocument35 pagesLA Type Test Reportashwani2101No ratings yet

- A Comparative Study of Live Loads For A Bridge Deck With Irc and Aashto Codes-Ijaerdv05i0290468 PDFDocument6 pagesA Comparative Study of Live Loads For A Bridge Deck With Irc and Aashto Codes-Ijaerdv05i0290468 PDFJuan Cantillano Tejada IIINo ratings yet

- Jis G3444Document12 pagesJis G3444yapsguanNo ratings yet

- Fracture AnalysisDocument5 pagesFracture Analysisoussama mimouniNo ratings yet

- Uncoated, Weldless, 2-And 3-Wire Steel Strand For Prestressed ConcreteDocument4 pagesUncoated, Weldless, 2-And 3-Wire Steel Strand For Prestressed ConcreteGustavo SuarezNo ratings yet

- TOPSIS - GRA Approach to Optimize Friction Stir Welded Aluminum 6061 Pipes ParametersDocument17 pagesTOPSIS - GRA Approach to Optimize Friction Stir Welded Aluminum 6061 Pipes Parametersdinu thomasNo ratings yet

- Steel PlatesDocument10 pagesSteel PlateshassanNo ratings yet

- Figuras MotopropulsorDocument7 pagesFiguras MotopropulsorMarcelo GutierrezNo ratings yet

- Is 15560 - 2005Document12 pagesIs 15560 - 2005kalpanaadhiNo ratings yet

- A/SA 333 Spec Sheet A333 Pipe Specifications: ScopeDocument8 pagesA/SA 333 Spec Sheet A333 Pipe Specifications: ScopeAdrian EspinosaNo ratings yet

- Chapter Four Experimental Results: 4.1 GeneralDocument67 pagesChapter Four Experimental Results: 4.1 Generalhayfaa Al-AbboodiNo ratings yet

- Experiment No: THE Ex PerimentDocument9 pagesExperiment No: THE Ex PerimentBhanu MacharlaNo ratings yet

- 1 HSS 590 Strain Life FatigueDocument8 pages1 HSS 590 Strain Life FatigueAdisa TutusicNo ratings yet

- Generator voltage faults testing formDocument4 pagesGenerator voltage faults testing formUdi AsulinNo ratings yet

- AISC DG02 Example 002 PDFDocument6 pagesAISC DG02 Example 002 PDFMohamed Abo-ZaidNo ratings yet

- Experimental Study of Prestressed Concrete Under Combined Torsion, Bending and ShearDocument16 pagesExperimental Study of Prestressed Concrete Under Combined Torsion, Bending and ShearTooma DavidNo ratings yet

- 13 Tests for Cast Iron ComponentsDocument1 page13 Tests for Cast Iron ComponentsSvapnesh ParikhNo ratings yet

- D I Il I: Ma4Hine D6FlfrnDocument3 pagesD I Il I: Ma4Hine D6FlfrnMostafaNo ratings yet

- ASTM A992: Output Calculations & FormulasDocument1 pageASTM A992: Output Calculations & FormulasAddrien DanielNo ratings yet

- Miniature Size: 7Mml 85, Standard CDocument1 pageMiniature Size: 7Mml 85, Standard CbehzadNo ratings yet

- CIGRE Vol2Document64 pagesCIGRE Vol2reinscNo ratings yet

- Shear TransferDocument21 pagesShear Transfergene_sparcNo ratings yet

- Kubota DC 68gDocument11 pagesKubota DC 68gGjg GjruruNo ratings yet

- Determination of The Winding Inductances of A Two-Phase MachineDocument7 pagesDetermination of The Winding Inductances of A Two-Phase MachineIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalNo ratings yet

- Application Guide: ISM Bus ArrangementDocument27 pagesApplication Guide: ISM Bus ArrangementMohamed MagedNo ratings yet

- Tutorial sheet 03 211111003Document18 pagesTutorial sheet 03 211111003thegreatnitianabhiNo ratings yet

- Failure Analysis of SA-213TP347H High-TemperatureDocument6 pagesFailure Analysis of SA-213TP347H High-TemperatureLakshminarayanNo ratings yet

- Pavement Microtexture and Its Relation To Skid ResistanceDocument14 pagesPavement Microtexture and Its Relation To Skid ResistanceMuslim mazarNo ratings yet

- Unbound MaterialsDocument3 pagesUnbound Materialsmadhav choudharyNo ratings yet

- Industrial Leaflet 2009Document2 pagesIndustrial Leaflet 2009stefancuandreiNo ratings yet

- Some Structural: Results of Compression OFDocument19 pagesSome Structural: Results of Compression OFZdravko VidakovicNo ratings yet

- Columns Short and Slender2Document45 pagesColumns Short and Slender2Anwar Jabar QadersheenNo ratings yet

- KUAT & Lentur Pengendalian mutu pipa uPVCDocument6 pagesKUAT & Lentur Pengendalian mutu pipa uPVCkuat jaya karyaNo ratings yet

- Fusing Equipment: ELX Full Range Current-Limiting FuseDocument4 pagesFusing Equipment: ELX Full Range Current-Limiting FusehrsciberNo ratings yet

- KOKS 24 (25) - 1VLC000511 Rev. 3, enDocument5 pagesKOKS 24 (25) - 1VLC000511 Rev. 3, enTetianaNo ratings yet

- Question 1 of 25Document7 pagesQuestion 1 of 25antonio larotta100% (1)

- 2.double Shear Conversion Table LBFDocument1 page2.double Shear Conversion Table LBFaxis inspection solutionsNo ratings yet

- Railway Ministry rubber buffer spring specificationDocument14 pagesRailway Ministry rubber buffer spring specificationmailbkraoNo ratings yet

- List Acceptance Criteria For Mechanical Test (03032017)Document7 pagesList Acceptance Criteria For Mechanical Test (03032017)Alfian Imaduddin100% (1)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Friction Stir Welding of High Strength 7XXX Aluminum AlloysFrom EverandFriction Stir Welding of High Strength 7XXX Aluminum AlloysNo ratings yet

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- S. No Description Value Unit Remarks: 10 Effluentpit - Ii Water Transfer Pump (CT Area) Head and Flow CalculationsDocument1 pageS. No Description Value Unit Remarks: 10 Effluentpit - Ii Water Transfer Pump (CT Area) Head and Flow CalculationsAnonymous vwbLPTpjNo ratings yet

- NSPCL Steamblowing Procedure (1) 5Document1 pageNSPCL Steamblowing Procedure (1) 5Anonymous vwbLPTpjNo ratings yet

- NSPCL Steamblowing Procedure (1) 4Document1 pageNSPCL Steamblowing Procedure (1) 4Anonymous vwbLPTpjNo ratings yet

- Steamblowing Procedure (1) 2Document1 pageSteamblowing Procedure (1) 2Anonymous vwbLPTpjNo ratings yet

- Steamblowing Procedure (1) 3Document1 pageSteamblowing Procedure (1) 3Anonymous vwbLPTpjNo ratings yet

- ES0203-75990100-DBR-0004 - WORKING FINAl 5Document1 pageES0203-75990100-DBR-0004 - WORKING FINAl 5Anonymous vwbLPTpjNo ratings yet

- S. No Description Value Unit Remarks Flow: 9 CTMWT Pump (Slop Cogen) Head and Flow CalculationsDocument1 pageS. No Description Value Unit Remarks Flow: 9 CTMWT Pump (Slop Cogen) Head and Flow CalculationsAnonymous vwbLPTpjNo ratings yet

- Rev 00 - Pumps 1Document1 pageRev 00 - Pumps 1Anonymous vwbLPTpjNo ratings yet

- ES0203-75990100-DBR-0004 - WORKING FINAl 6Document1 pageES0203-75990100-DBR-0004 - WORKING FINAl 6Anonymous vwbLPTpjNo ratings yet

- Es0128-75570200-Pos-0001 5Document1 pageEs0128-75570200-Pos-0001 5Anonymous vwbLPTpjNo ratings yet

- ES0203-75990100-DBR-0004 - WORKING FINAl 4Document1 pageES0203-75990100-DBR-0004 - WORKING FINAl 4Anonymous vwbLPTpjNo ratings yet

- ES0203-75990100-DBR-0004 - WORKING FINAl 4Document1 pageES0203-75990100-DBR-0004 - WORKING FINAl 4Anonymous vwbLPTpjNo ratings yet

- ES0203-75990100-DBR-0004 - WORKING FINAl 3Document1 pageES0203-75990100-DBR-0004 - WORKING FINAl 3Anonymous vwbLPTpjNo ratings yet

- ES0203-75990100-DBR-0004 - WORKING FINAl 5Document1 pageES0203-75990100-DBR-0004 - WORKING FINAl 5Anonymous vwbLPTpjNo ratings yet

- S. No Spares List QTY: NotesDocument1 pageS. No Spares List QTY: NotesAnonymous vwbLPTpjNo ratings yet

- MCW pump sizing calculationsDocument1 pageMCW pump sizing calculationsAnonymous vwbLPTpjNo ratings yet

- S. No Spares List QTY: 10.0 Three (3) Years O & M SparesDocument1 pageS. No Spares List QTY: 10.0 Three (3) Years O & M SparesAnonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 1 PDFDocument1 pageTechnical Specification For Auxiliary Cooling Tower 1 PDFAnonymous vwbLPTpjNo ratings yet

- Es0128-75570200-Pos-0001 4Document1 pageEs0128-75570200-Pos-0001 4Anonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 7 PDFDocument1 pageTechnical Specification For Auxiliary Cooling Tower 7 PDFAnonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling TowerDocument7 pagesTechnical Specification For Auxiliary Cooling TowerAnonymous vwbLPTpj100% (2)

- 8.0 Vendor List For Major Bought Out ItemsDocument1 page8.0 Vendor List For Major Bought Out ItemsAnonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 3 PDFDocument1 pageTechnical Specification For Auxiliary Cooling Tower 3 PDFAnonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 6Document1 pageTechnical Specification For Auxiliary Cooling Tower 6Anonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 5Document1 pageTechnical Specification For Auxiliary Cooling Tower 5Anonymous vwbLPTpjNo ratings yet

- Technical Specification For Auxiliary Cooling Tower 4Document1 pageTechnical Specification For Auxiliary Cooling Tower 4Anonymous vwbLPTpjNo ratings yet

- Auxiliary Cooling Tower Design BasisDocument1 pageAuxiliary Cooling Tower Design BasisAnonymous vwbLPTpjNo ratings yet

- Pos 2 PDFDocument1 pagePos 2 PDFAnonymous vwbLPTpjNo ratings yet

- Pos 4 PDFDocument1 pagePos 4 PDFAnonymous vwbLPTpjNo ratings yet

- Tag. No 06-PSV-151: Sl. No. Description UnitDocument1 pageTag. No 06-PSV-151: Sl. No. Description UnitAnonymous vwbLPTpjNo ratings yet

- Project Department Kuwait National Petroleum Company: Daily Welding Inspection ReportDocument1 pageProject Department Kuwait National Petroleum Company: Daily Welding Inspection ReportMuthazhagan SaravananNo ratings yet

- Documentatie Tehnica Tocator ST200Document3 pagesDocumentatie Tehnica Tocator ST200Ionuț CojocariuNo ratings yet

- D38999 Guide - D38999 Mil Spec Connector GuideDocument12 pagesD38999 Guide - D38999 Mil Spec Connector GuideFrederich Bear River100% (1)

- Parts of A Competency-Based Learning Material PackageDocument19 pagesParts of A Competency-Based Learning Material PackageRoedfrey OrtizNo ratings yet

- Metric ThreadsDocument35 pagesMetric ThreadsmihaidelianNo ratings yet

- Tutorial Questions - Answers.ca3703.week 13Document4 pagesTutorial Questions - Answers.ca3703.week 13wilsonNo ratings yet

- Test Certificate: Portland Pozzolana Cement (Fly Ash Based)Document1 pageTest Certificate: Portland Pozzolana Cement (Fly Ash Based)Manash Protim GogoiNo ratings yet

- Design Arc Welding ProcessesDocument2 pagesDesign Arc Welding ProcessesAfthabNo ratings yet

- Imported electronics repair tools and equipmentDocument8 pagesImported electronics repair tools and equipmentHayatNo ratings yet

- FCAW For P91Document11 pagesFCAW For P91Satyendra SinghNo ratings yet

- 4 - ASME IX Exam (61 Q&A)Document10 pages4 - ASME IX Exam (61 Q&A)Dada KhalandarNo ratings yet

- SMAW GTAW Guide Filler Metal SelectionDocument3 pagesSMAW GTAW Guide Filler Metal SelectionBipin SinghNo ratings yet

- AWS 5.15 Cast Iron ElectrodesDocument30 pagesAWS 5.15 Cast Iron ElectrodesMed Ali SmaouiNo ratings yet

- Method Statement - WeldingDocument2 pagesMethod Statement - WeldingsuremessyNo ratings yet

- Welder Qualification Register 01Document3 pagesWelder Qualification Register 01Andrei UrsacheNo ratings yet

- PQR 3G Fcaw SF71Document3 pagesPQR 3G Fcaw SF71long phamNo ratings yet

- SolderingDesoldering 2Document34 pagesSolderingDesoldering 2delfino santosNo ratings yet

- Welding Procedure Specification's (WPS) : Presented by John Lucas Welding Engineer UTI CorporationDocument30 pagesWelding Procedure Specification's (WPS) : Presented by John Lucas Welding Engineer UTI CorporationCris VillapanaNo ratings yet

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 pagesList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSNo ratings yet

- Welding Defects PDFDocument61 pagesWelding Defects PDFمحمد امين شريفNo ratings yet

- SB15 Spare PartsDocument2 pagesSB15 Spare PartsProdajapasaonlineNo ratings yet

- TOYOTA 1HD-FT - 196000-1111 - 22100-17881 - VE6 12F2000RND111 - Shema+cat +testplan TNVDDocument28 pagesTOYOTA 1HD-FT - 196000-1111 - 22100-17881 - VE6 12F2000RND111 - Shema+cat +testplan TNVDДенисКузнецовNo ratings yet

- Consumables CatalogDocument68 pagesConsumables CatalogsiddiqNo ratings yet

- BoltList Weight 12.11.2015Document8 pagesBoltList Weight 12.11.2015Vashish RamrechaNo ratings yet

- HERBERT METZENDORFF & CO. KG Stock List Hamburg Engine PartsDocument2 pagesHERBERT METZENDORFF & CO. KG Stock List Hamburg Engine PartsAymen BriniNo ratings yet

- Dimensions Across Flats and Heights of Hex Nuts According To ISO 4032Document3 pagesDimensions Across Flats and Heights of Hex Nuts According To ISO 4032Reyhan Fanny PratamaNo ratings yet

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- LPS High Tensile Fasteners for Non-Auto IndustryDocument20 pagesLPS High Tensile Fasteners for Non-Auto IndustryPrabhat MishraNo ratings yet

- WPS for Welding ASTM A36 Steel with E7018 ElectrodesDocument1 pageWPS for Welding ASTM A36 Steel with E7018 Electrodeshenry ayalaNo ratings yet

- Welding Inspector Interview QuestionsDocument5 pagesWelding Inspector Interview QuestionsValli Raju91% (23)