Professional Documents

Culture Documents

OCP 09 F03 JSA Format

OCP 09 F03 JSA Format

Uploaded by

Bibin JacobOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

OCP 09 F03 JSA Format

OCP 09 F03 JSA Format

Uploaded by

Bibin JacobCopyright:

Available Formats

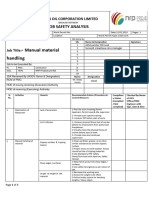

Document Number: OCP 09 F03

EMBASSY REIT Issued Date: 01/06/2021

Integrated Management System Rev.00

Job Safety Analysis (JSA)

Revision Date: NA

Job Safety Analysis (JSA): Emergency Tel. No. 022-25777049 DATE:

JSA Prepared by JSA Approved by

Location: Assessment Team Leader: PTW No.

Job Steps Hazard & Consequence Control Measures

Break the activity down into logical job steps Controls & Recovery Measures Required

1.Lack of awareness of site/work leads Before:

1 Mobilization of manpower 2. Inexperienced, untrained & unidentified worker 1. Induction training for new workers at site

3. Workmen without medical fitness should be carried out

4.Damaged/ substandard PPE worn by worker 2. Entry in the influence of alcohol or drugs

5.Worker under influence of alcohol. strictly prohibited.

6. Worker without valid Photo-Identity card 3. Smoking is not allowed at site.

7.Child labor 4. Checking of IDs for age related matter

During:

1. TBT to be carried before start to work

2. Adequate supervision should be available at

site.

3.Supervisor shall inspect work area for any

prevailing risks.

4.Use of PPES safety helmet, goggle, reflective

vest, hand gloves, safety shoes

5.Mobile phone use is strictly prohibited during

the work, instruct all workers in induction as

well in TBT

After:

1.Housekeeping shall be done after work

completion of work on daily basis.

2.Unwanted lights & Electrical supply shall be

Turnoff.

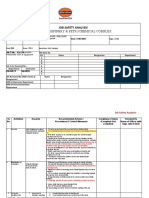

Document Number: OCP 09 F03

EMBASSY REIT Issued Date: 01/06/2021

Integrated Management System Rev.00

Job Safety Analysis (JSA)

Revision Date: NA

1.Usage of defective/improper tools leading to accident. Before:

2 Deployment of Tools & Tackles 2.Wrong selection of Tools & Tackles. 1.Pre-Inspection of all Tool & Tackles as per

3.Use of Tools & Tackles without inspection. checklist.

4.Poor storage of Tools & Tackles. 2.Shelf life shall be considered during inspection.

5.Sharp Edges. 3.SWL should be written on all lifting tools.

4.All lifting tools & tackles third party inspection

certificate by competent person.

5.Inspection Tag shall be provided on Power

Tools.

During:

1.Physical inspection of tools for its healthiness.

2.Selection of tools as per job requirement.

3.The lifting tackles made of polyester and Nylon

if put in use, shall not exceed 5 years from the

date of manufacturing.

4.Work area shall be barricaded.

5.PPES shall be use as per PPE Matrix.

After:

1.All tools shall be properly stored inside

designated area.

2.Any damage tools shall be segregated &

removed from work location.

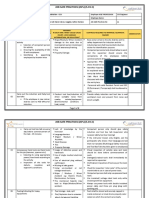

Document Number: OCP 09 F03

EMBASSY REIT Issued Date: 01/06/2021

Integrated Management System Rev.00

Job Safety Analysis (JSA)

Revision Date: NA

Shifting of Material-Manual by lift/Manually 1.Slip, Trip or Fall hazards Before:

3 2. Cut & Bruises 1. Job briefing training should be provided

2. General work permit should be issued before

work start 3.

Provide Proper PPE Helmet Reflective jacket and

safety shoes, goggle, hand gloves, shoulder pad

should be provided

4. Maximum load for Male-55kg & for women-

40kg

During:

1. Ensure no worker lift weight more than the

prescribe weight

2. Effective supervision should be there

3. Provide PPE Hand gloves, shoulder pad, Cut

Resistance hand gloves be provided.

4. Ensure a good hold on the load

5. Keep the load close to the waist

6. Do not bend your back when lifting. Use

proper lifting manual technique

After:

1. Area should be barricade properly

2. Material should be stack as per standards and

shouldn't stack above 2m heights

Document Number: OCP 09 F03

EMBASSY REIT Issued Date: 01/06/2021

Integrated Management System Rev.00

Job Safety Analysis (JSA)

Revision Date: NA

Grinding/Cutting/Drilling work 1.Electric Shock Before:

4 2. Use of faulty grinding machine/Drilling/Cutting machine 1. Ensure hot work permit should be issue

3. Improper power connection given before start to work

4. Non-standard or damaged cutting/grinding wheel. 2. Job briefing TBT should be provided

(Rpm of cutting wheel less than machine rpm. 3. Provide Proper PPE Helmet Reflective jacket

5.Working nearby flammable materials and safety shoes, goggle and hand gloves.

4. Adequate supervision should be provided

5. Area should be barricade with signages.

6.Ensure that all Power connections shall be

routed through 30mA trip ELCB/RCCB.

7.The power cable is to be connected using

industrial plug-socket.

8.No tapping shall be allowed in the power

cable.

9.RPM rating of the wheel to be above the max

RPM of the machine.

10.The blade and other rotating parts must have

mechanical guards

During:

1. Cable shall not be twisted and pinched.

2.Power cable shall be kept 2 meter above

ground to avoid trip hazards.

3. Wear all personal protective equipment's

4.The worker shall use proper face shield while

operating machines

After:

1.Work place shall be free from any flammable

or combustible materials. The adjacent area

where the grinding flash may fall shall also be

made free of such materials.

2.Keep a suitable Fire Extinguisher in the work

area always 3.Used

Cutting/grinding wheels are to be disposed to

avoid re-uses

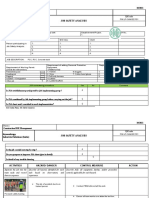

Document Number: OCP 09 F03

EMBASSY REIT Issued Date: 01/06/2021

Integrated Management System Rev.00

Job Safety Analysis (JSA)

Revision Date: NA

Extended hours work (night work). Inadequate lighting 1.Ensure valid night PTW

5 2.Adequate Illumination to be Ensured i.e. 80 to

100 lux lightning

3.Ensure emergency contact number available

all the time with permit receiver

4.Display of emergency contact no.

Site Emergencies 1.Fire Hazards 1.Ensure Adequate Illumination available at site

6 2.Snake bite (Day & Night. And carry torch during night shifts.

2.Workman should not continue work duties

more than 12hrs.in a day should take breaks in

frequents intervals.

3.Immediately inform snake catcher in case of

snake witness at site. DO NOT KILL SNAKE.

4.Use of PPES all the time at work

5. In case of any emergency call on project

Emergency phone number.

Permit Holder Permit Issuer EHS/ICS

Sign

Name

Designation

Date

You might also like

- Unit IG2: Risk AssessmentDocument11 pagesUnit IG2: Risk Assessmentshaukat80% (100)

- JSA Underwater WeldingDocument2 pagesJSA Underwater WeldingCristina Rican77% (13)

- Risk Assessment MicrotunnelingDocument7 pagesRisk Assessment Microtunnelingmohamed ghalyNo ratings yet

- Copy (2) of JSA For Removal of MS Sheet For E&P ShedDocument12 pagesCopy (2) of JSA For Removal of MS Sheet For E&P Shedmidozoty50% (2)

- JSA For Foundation Concrete RepairDocument6 pagesJSA For Foundation Concrete RepairOvais FarooqNo ratings yet

- Job Safety Analysis (JSA) - Rebar Installation/steel Fixing DateDocument1 pageJob Safety Analysis (JSA) - Rebar Installation/steel Fixing DatenabeelNo ratings yet

- JSa For Operation of Jack HammeringDocument3 pagesJSa For Operation of Jack Hammeringyc safety0% (1)

- FSO Personnel ResponsibilitiesDocument41 pagesFSO Personnel ResponsibilitieshaitacvietnamNo ratings yet

- JSA-Steel Structure Erection-NDocument4 pagesJSA-Steel Structure Erection-NVivek Naik100% (2)

- JSA For Soil ImprovementDocument4 pagesJSA For Soil ImprovementHilbrecht De Pedro100% (1)

- Concrete Breakina Jsa by Breaker MachineDocument2 pagesConcrete Breakina Jsa by Breaker MachineAKBAR ALINo ratings yet

- Survey ActivityDocument3 pagesSurvey ActivitynrphsebarauniNo ratings yet

- 2.7 Working Near Live SwitchyardDocument3 pages2.7 Working Near Live SwitchyardYusuf Afraz100% (1)

- JSA - Manual Lifting and Installation (Using Chain Block, Sling Belt and Shackle)Document2 pagesJSA - Manual Lifting and Installation (Using Chain Block, Sling Belt and Shackle)muiqbal.workNo ratings yet

- Job Safety Analysis WorksheetDocument3 pagesJob Safety Analysis Worksheetmohammed a hseNo ratings yet

- JSA - Manual Lifting (Using Chain Block, Sling Belt and Shackle)Document2 pagesJSA - Manual Lifting (Using Chain Block, Sling Belt and Shackle)muiqbal.workNo ratings yet

- PTL JSA Maintenance of Cooling Towers - National Cycling Centre - SPORTTDocument7 pagesPTL JSA Maintenance of Cooling Towers - National Cycling Centre - SPORTTShannon MooreNo ratings yet

- Job Safety Analysis Worksheet: Tie - in For Power Cable 33 KVDocument3 pagesJob Safety Analysis Worksheet: Tie - in For Power Cable 33 KVmohammed a hseNo ratings yet

- 5-6. Overhauling of TGS & CGS JSA HADEED MODULE A-BDocument8 pages5-6. Overhauling of TGS & CGS JSA HADEED MODULE A-Bammar mughalNo ratings yet

- StockYard Conveyor System Overhauling JSA HADEED MODULE A-BDocument8 pagesStockYard Conveyor System Overhauling JSA HADEED MODULE A-Bammar mughalNo ratings yet

- PCC Safety Supervisor: CivilDocument4 pagesPCC Safety Supervisor: CivilDwitikrushna RoutNo ratings yet

- Pre Commissioning Electrical EquipmentDocument4 pagesPre Commissioning Electrical Equipmentmohammed a hseNo ratings yet

- Installation of Pannel JSADocument6 pagesInstallation of Pannel JSAOFFSHORE OFFSITENo ratings yet

- JSA Hot Work Indospace RajpuraDocument2 pagesJSA Hot Work Indospace RajpuraGuri PreetNo ratings yet

- 26.RG Cooler Overhauling, Pipe Work and Seal Leg Replacement JSA HADEED MODULE A-BDocument8 pages26.RG Cooler Overhauling, Pipe Work and Seal Leg Replacement JSA HADEED MODULE A-Bammar mughalNo ratings yet

- PTO Project - Reposisi HDPE Di TSF Cell 2 Doc - Rev1Document3 pagesPTO Project - Reposisi HDPE Di TSF Cell 2 Doc - Rev1John NainggolanNo ratings yet

- Hot Work JSADocument6 pagesHot Work JSAMukesh KumarNo ratings yet

- (SWMS) Shaft Work Duct ErectionDocument4 pages(SWMS) Shaft Work Duct Erectionsyed khaja misbhuddinNo ratings yet

- PTO Project - Fire Line Pipe Fabrication at Magazine 10Document3 pagesPTO Project - Fire Line Pipe Fabrication at Magazine 10John NainggolanNo ratings yet

- HVAC SWMS BonfiglioliDocument7 pagesHVAC SWMS BonfiglioliJ JohnsonNo ratings yet

- Manual Material HandlingDocument3 pagesManual Material HandlingnrphsebarauniNo ratings yet

- DEL - 062 Punch List Killing of Switch RoomDocument7 pagesDEL - 062 Punch List Killing of Switch RoomCaminBonNo ratings yet

- Hydro TestDocument8 pagesHydro Testmozzammil saqibNo ratings yet

- JHAP Skidding and Hauling of Power Shunt Reactor to Its New LocationDocument5 pagesJHAP Skidding and Hauling of Power Shunt Reactor to Its New Locationjosepepemanalo6No ratings yet

- RCC Safety Supervisor: CivilDocument7 pagesRCC Safety Supervisor: CivilDwitikrushna RoutNo ratings yet

- SWMS - Replacement of Light BulbsDocument5 pagesSWMS - Replacement of Light BulbsHanindita Widhi PangestiNo ratings yet

- Job Safety Analysis (JSA) - Carpentry Works DateDocument1 pageJob Safety Analysis (JSA) - Carpentry Works DatenabeelNo ratings yet

- HIF Program - 03 Dec To 08 Dec 22 - Area5Document14 pagesHIF Program - 03 Dec To 08 Dec 22 - Area5ManojNo ratings yet

- JSA-002 JSA For TCFDocument4 pagesJSA-002 JSA For TCFRafeeq Ur RahmanNo ratings yet

- Standard Operating Procedure SOP - NO.-01 Joda Date:-19.09.2020Document6 pagesStandard Operating Procedure SOP - NO.-01 Joda Date:-19.09.2020Dwitikrushna Rout50% (2)

- Jsa Welding GrindingDocument5 pagesJsa Welding GrindingWiedz PrastNo ratings yet

- JSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreaDocument8 pagesJSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreaMohammed MinhajNo ratings yet

- JSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreaDocument8 pagesJSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Process AreamarvinNo ratings yet

- JSA For Fence RemovalDocument5 pagesJSA For Fence Removal92qhnqmrhsNo ratings yet

- JSA - Structure Lifting PlanDocument2 pagesJSA - Structure Lifting Planmuiqbal.workNo ratings yet

- Job Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedDocument2 pagesJob Safety Analysis Worksheet: Short Descriptive Title of Task: New Revised ReviewedZulfokar FahdawiNo ratings yet

- JSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Flare Pit AreaDocument8 pagesJSA For Mobilization of Crane, Welding Cutting and Grinding and Air Blowing of Spools in Flare Pit Areanoahlungu96No ratings yet

- 5.19-FO-33-JOB SAFE PRACTICE Hajer-Nujha SS - T-6Document2 pages5.19-FO-33-JOB SAFE PRACTICE Hajer-Nujha SS - T-6Shariq AhmedNo ratings yet

- Scrap Material Handling & Loading Jha - 1Document2 pagesScrap Material Handling & Loading Jha - 1Dwitikrushna Rout100% (1)

- Human Performance ToolsDocument15 pagesHuman Performance Toolswindgust82No ratings yet

- Risk Assesment Project VimalDocument7 pagesRisk Assesment Project VimalHASHIM TKNo ratings yet

- JSA For Scaffolding Erection and Dismentling Inside The Building Room at Accommodation Block CDocument5 pagesJSA For Scaffolding Erection and Dismentling Inside The Building Room at Accommodation Block Cnoahlungu96No ratings yet

- Grinding Work JsaDocument2 pagesGrinding Work JsaAKBAR ALINo ratings yet

- 3 SPS Sop RCC FullDocument14 pages3 SPS Sop RCC FullDwitikrushna RoutNo ratings yet

- High Pressur Hydro Testing JSA 03Document6 pagesHigh Pressur Hydro Testing JSA 03Nikunja mohantyNo ratings yet

- JSA (Loading Arm)Document4 pagesJSA (Loading Arm)Noman AliNo ratings yet

- JHA For Work PermitDocument1 pageJHA For Work PermitShahid RazaNo ratings yet

- Blank JSA For Building WorksDocument5 pagesBlank JSA For Building Worksiftikhar ahmadNo ratings yet

- 18 - Maintenance of Skip HoistDocument5 pages18 - Maintenance of Skip Hoistgiet11aei010No ratings yet

- JSP For AsphaltDocument8 pagesJSP For Asphaltmohammed tofiqNo ratings yet

- SOP For Maintenance & Testing of 6.6KV BET-CETDocument2 pagesSOP For Maintenance & Testing of 6.6KV BET-CETArbind NathNo ratings yet

- C164 JSA Forr Tie On Fire Water Line On South Side of Train 1Document3 pagesC164 JSA Forr Tie On Fire Water Line On South Side of Train 1CaminBonNo ratings yet

- JSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentDocument4 pagesJSA For Operation of Jack Hammer, Dimantalling Batching Plant Fountdation Near Waste Water TreatmentMohammed Minhaj100% (1)

- Aj Infratech: Job Hazard AnalysisDocument5 pagesAj Infratech: Job Hazard AnalysisDwitikrushna RoutNo ratings yet

- Resume Brijesh SainiDocument1 pageResume Brijesh SainiBibin JacobNo ratings yet

- ResumeMohammedRahuman PDFDocument1 pageResumeMohammedRahuman PDFBibin JacobNo ratings yet

- Resume Pradyum JhaDocument3 pagesResume Pradyum JhaBibin JacobNo ratings yet

- Manu Construction - Jan-22 NTTDocument4 pagesManu Construction - Jan-22 NTTBibin JacobNo ratings yet

- Neon - Pour Card FormatDocument1 pageNeon - Pour Card FormatBibin JacobNo ratings yet

- Installation of Pannel JSADocument6 pagesInstallation of Pannel JSAOFFSHORE OFFSITENo ratings yet

- MGMT 2 Week 15Document3 pagesMGMT 2 Week 15DarkxeiDNo ratings yet

- Iosh Osha Interveiw Session11Document45 pagesIosh Osha Interveiw Session11Sameer RajuNo ratings yet

- WP056P Rev0Document12 pagesWP056P Rev0Mohamed Reda HusseinNo ratings yet

- Docit - Tips Contoh Manajemen Resikoxls Personal Protective EquipmentDocument12 pagesDocit - Tips Contoh Manajemen Resikoxls Personal Protective EquipmentBambang SumantriNo ratings yet

- Brochure UYC EnglishDocument8 pagesBrochure UYC EnglishAndra SerbanNo ratings yet

- GDN 207Document42 pagesGDN 207VARUN SHARMANo ratings yet

- Chap 01Document17 pagesChap 01Abdelrahman B Abu AmroNo ratings yet

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDocument2 pagesJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiNo ratings yet

- CPCCCM2006 Assessment THEORYDocument32 pagesCPCCCM2006 Assessment THEORYPriyanka DeviNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- Case Study: Flash Fire During Underground Pipeline RepairDocument9 pagesCase Study: Flash Fire During Underground Pipeline RepairManish ChandaniNo ratings yet

- Jsa FormDocument3 pagesJsa Formmiaicarba100% (1)

- Job Safety Analysis Sheet: Erection & Use of ScaffoldingDocument1 pageJob Safety Analysis Sheet: Erection & Use of ScaffoldingHelza RahmanniaNo ratings yet

- Job Safety Analysis Sheet: Pre - WorkDocument2 pagesJob Safety Analysis Sheet: Pre - Workmalimsaidi_160040895100% (1)

- BSEE Safety Alert 445 - Stored Energy in Slings Causes Multiple InjuriessDocument2 pagesBSEE Safety Alert 445 - Stored Energy in Slings Causes Multiple InjuriessmakramNo ratings yet

- 16-070331 JSA For The Tie-In of Chilled Water Lines Behind General OfficeDocument3 pages16-070331 JSA For The Tie-In of Chilled Water Lines Behind General Officeiftikhar ahmadNo ratings yet

- Is18347 2023Document16 pagesIs18347 2023RAVIKANT SINDHENo ratings yet

- Industrial Safety MCQ Ans...Document5 pagesIndustrial Safety MCQ Ans...PANKIT78% (9)

- Scaffolding Method StatementDocument166 pagesScaffolding Method Statementirma100% (6)

- 48 Steam Heating Boiler Daily Checks-JOB PROCEDUREDocument2 pages48 Steam Heating Boiler Daily Checks-JOB PROCEDUREMaximilianoRodrigoCabestreroNo ratings yet

- Accident-Causation ModuleDocument73 pagesAccident-Causation ModuleMadhuri PeriNo ratings yet

- Job Safety Analysis - IntroDocument17 pagesJob Safety Analysis - IntroVanessaa D'muliaputriNo ratings yet

- Job SafetyDocument14 pagesJob SafetyAnto Jacob John.eNo ratings yet

- File - 20200905 - 105458 - Jsa Wind PowerDocument10 pagesFile - 20200905 - 105458 - Jsa Wind PowerMon Trang NguyễnNo ratings yet