Professional Documents

Culture Documents

Exp-4 Speed Control

Uploaded by

Vamsi RamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exp-4 Speed Control

Uploaded by

Vamsi RamCopyright:

Available Formats

BEE LAB OBSERVATION

EXPERIMENT-4

SPEED CONTROL OF D.C. SHUNT MOTOR

BVCITS EEE PAGE NO-

BEE LAB OBSERVATION

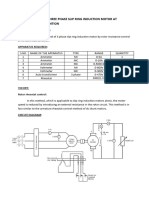

CIRCUIT DIAGRAM

CIRCUIT DIAGRAM FOR SPEED CONTROL OF D.C. SHUNT MOTOR:

BVCITS EEE PAGE NO-

BEE LAB OBSERVATION

EXPT NO: 4 DATE:

SPEED CONTROL OF D.C. SHUNT MOTOR

AIM: To control the speed of the D.C. Shunt Motor by means of Field and Armature control

methods and to draw their corresponding speed characteristics.

APPARATUS REQUIRED

S.No Name of the Type Range Qty.

Equipment

1 Ammeter M.C 0–2A 1No.

2 Voltmeter M.C 0 – 300V 1No.

3 Rheostat Wire 50 Ω/ 5A 1No.

wound

4 Rheostat Wire 360 Ω/ 1.2A 1No.

wound

5. Tachometer Digital 0 – 10,000 1No

rpm

6. Connecting wires - - -.

THEORY:

In Shunt Motor, as speed is inversely proportional to flux, speed can be increased by

decreasing the flux, hence the name flux control method, the speed of a D.C Motor can be changed

by changing I sh is relatively small, shunt field current rheostat has to carry a small current which

measures I2 R losses which is small. So that rheostat is small in size. This method is thereby very

efficient. In interpose machine the speed can be Increased in ratio 6: 1. In interpose machine it

can be adjusted in 2: 1 ratio. Armature control method is used when speed is below rated speed.

As supply voltage is normally constant the voltage across the armature is constant the voltage

across the armature is varied by inserting a variable rheostat at a resistance in series with armature

as controller resistance is increased the potential difference across the armature is decreased

thereby decreasing the armature speed.

BVCITS EEE PAGE NO-

BEE LAB OBSERVATION

TABULATION:

FLUX CONTROL METHOD: ARMATURE CONTROL METHOD:

S.No Speed in Field current S.No Speed in Back emf Eb

RPM in Amperes RPM in Volts

1 1

2 2

3 3

4 4

5 5

6 6

MODEL GRAPHS:

FLUX CONTROL METHOD: ARMATURE CONTROL METHOD:

BVCITS EEE PAGE NO-

BEE LAB OBSERVATION

PROCEDURE:

1.ARMATURE CONTROL METHOD:

1. Make the connections as per the circuit diagram

2. Apply 220V DC supply to the motor by closing DPST switch.

3. Start the motor with the help of 3 –point starter.

4. Check the speed of the motor by using tachometer and adjust the motor to it rated value(1500rpm) by varying

armature rheostat (from max to min), field rheostat from min to max, note down the speed and voltage value

5. By keeping the field current as constant, reduce the armature rheostat(1450rpm) note down the corresponding

armature voltage.

6. Repeat the steps for different speeds like 1400rpm ,1350rpm,1300rpm etc and tabulate the readings

2.FIELD CONTROL METHOD:

1. Make the connections as per the circuit diagram

2. Apply 220V DC supply to the motor by closing DPST switch

3. Start the motor with the help of 3 –point starter

4. Check the speed of the motor by using tachometer and adjust the motor to it rated value (1500rpm) by varying

armature rheostat (from max to min), field rheostat from min to max Note down the speed and field current.

5. By keeping the armature voltage and constant value, adjust the field rheostat such a way that speed is increased

to 1550rpm and note down the corresponding field current.

6. Repeat the steps for different speeds like 1600rpm, 1650 rpm, 1700rpm, 1750rpm, etc and tabulate the readings.

PRECAUTIONS:

1. Connections should be tight.

2. Take the readings without parallax error.

3. Fuses should be properly rated.

4. The operation of the 3 –Point starter should be slow and uniform.

5. Armature rheostat should be connected in maximum position initially.

6. Field rheostat should be minimum resistance position.

RESULT:

Hence, Speed Control of the D.C. Shunt Motor by means of Field and Armature control methods are done

and plotted their corresponding speed characteristics.

BVCITS EEE PAGE NO-

You might also like

- Dr. Assad Abu-Jasser, ECE-iugaza: Electrical Machines (EELE 4350)Document37 pagesDr. Assad Abu-Jasser, ECE-iugaza: Electrical Machines (EELE 4350)MohammedSaadaniHassani67% (6)

- Measuring Mosfet Curve Tracer PDFDocument11 pagesMeasuring Mosfet Curve Tracer PDFEugene Chew100% (2)

- HVP 90 Manual EnglishDocument22 pagesHVP 90 Manual EnglishLuis Caba Ramirez88% (16)

- (EM 2) - Lab Manual 4th SemDocument43 pages(EM 2) - Lab Manual 4th SemTime LapserNo ratings yet

- Electrical Machine LabDocument23 pagesElectrical Machine LabAmit kumar singhNo ratings yet

- Adobe Scan 17-Oct-2023Document5 pagesAdobe Scan 17-Oct-2023mehra familyNo ratings yet

- Exp-5 Sep of LossesDocument5 pagesExp-5 Sep of LossesVamsi RamNo ratings yet

- DC Shunt Motor - Field Control MethodDocument4 pagesDC Shunt Motor - Field Control MethodNandha KashwaranNo ratings yet

- Suraj GahalyanDocument6 pagesSuraj GahalyanSuraj GahalyanNo ratings yet

- 9 Speed Control of DC Shunt MotorDocument4 pages9 Speed Control of DC Shunt MotormanishNo ratings yet

- PS Lab ManualDocument25 pagesPS Lab ManualPRAVEEN KUMAR SINGHNo ratings yet

- 9 Speed Control of DC Shunt MotorDocument4 pages9 Speed Control of DC Shunt MotorVaibhavNo ratings yet

- Exp-2 Brake Test On Shunt MotorDocument5 pagesExp-2 Brake Test On Shunt MotorVamsi RamNo ratings yet

- Kushal SoftDocument6 pagesKushal SoftKushal SharmaNo ratings yet

- Speed ControlDocument3 pagesSpeed ControlRadha Krishnan PNo ratings yet

- Speed Control of DC Shunt Motor: A) Field Current Control B) Armature Voltage ControlDocument8 pagesSpeed Control of DC Shunt Motor: A) Field Current Control B) Armature Voltage ControlAkshit VSNo ratings yet

- Exp-6 Load Test On DC Series GenDocument5 pagesExp-6 Load Test On DC Series GenVamsi RamNo ratings yet

- DC Shunt Motor Speed ControlDocument7 pagesDC Shunt Motor Speed Controleric wahomeNo ratings yet

- Rotating Electrical Machine Lab: B.E. 5 SemesterDocument33 pagesRotating Electrical Machine Lab: B.E. 5 SemesterSuma Rani GNo ratings yet

- Original Exp 1 2Document8 pagesOriginal Exp 1 2Kushal SharmaNo ratings yet

- Experiment 3Document10 pagesExperiment 3عبدالعزيز شقحانNo ratings yet

- Control System Lab ManualDocument52 pagesControl System Lab ManualMohammad Umar RehmanNo ratings yet

- Manual EEE2003Document64 pagesManual EEE2003rishanNo ratings yet

- Ac Servo MotorDocument14 pagesAc Servo MotorJeyanthNo ratings yet

- Jawaharlal Nehru Engineering College: Laboratory ManualDocument36 pagesJawaharlal Nehru Engineering College: Laboratory Manualprathap kumarNo ratings yet

- Exp-9 Reg of Alternator - RemovedDocument6 pagesExp-9 Reg of Alternator - RemovedVamsi RamNo ratings yet

- 3 Speed Control of DC Shunt Motor PDFDocument2 pages3 Speed Control of DC Shunt Motor PDFRedwan Ahmad MuidNo ratings yet

- Electrical Machines Lab 1 Electrical MacDocument153 pagesElectrical Machines Lab 1 Electrical MacOladimeji OluwaseunNo ratings yet

- Speed Control of Three Phase Slip Ring Induction Motor at Variable Load ConditionDocument3 pagesSpeed Control of Three Phase Slip Ring Induction Motor at Variable Load Conditionhi100% (1)

- Eee206 DC Motor p1bDocument3 pagesEee206 DC Motor p1bAhad AhadNo ratings yet

- Electromechanical Energy Conversion Lab ManualDocument61 pagesElectromechanical Energy Conversion Lab Manualprathyush srinivasanNo ratings yet

- Benn Machine Lab ManualDocument14 pagesBenn Machine Lab ManualRahatullah Khan100% (1)

- EE3411 EM-II Lab Manual FinalDocument71 pagesEE3411 EM-II Lab Manual FinalManoj KumarNo ratings yet

- Swinburns'S Test On D.C Shunt MachineDocument15 pagesSwinburns'S Test On D.C Shunt MachineharimadhavareddyNo ratings yet

- Ec-I Lab MannualDocument30 pagesEc-I Lab Mannualsmaran247017No ratings yet

- ECE 5570 - Lab 8: Brushless DC Motor Control With 6-Step CommutationDocument6 pagesECE 5570 - Lab 8: Brushless DC Motor Control With 6-Step CommutationAnimesh GhoshNo ratings yet

- Em-2 Lab ManualDocument9 pagesEm-2 Lab Manualsomnath banerjeeNo ratings yet

- Experiment No. 3: 1.0 TITLEDocument7 pagesExperiment No. 3: 1.0 TITLEWaseem WasiNo ratings yet

- Speed Control of 3 Phase Slip Ring Induction MotorDocument2 pagesSpeed Control of 3 Phase Slip Ring Induction Motoraditya aryaNo ratings yet

- Exp 1 N 2Document16 pagesExp 1 N 2mallikarjunbpatilNo ratings yet

- Circuit Diagram For Brake Test On D.C.Shunt Motor: EM1 LAB, BVCR, RAJAHMUNDRY Prepared by K. Nagesh & V.D.NeelimaDocument4 pagesCircuit Diagram For Brake Test On D.C.Shunt Motor: EM1 LAB, BVCR, RAJAHMUNDRY Prepared by K. Nagesh & V.D.NeelimaPrabhu MoorthyNo ratings yet

- Electric Drive Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, UttarakhandDocument15 pagesElectric Drive Lab Laboratory Manual: Dev Bhoomi Institute Chakrata Road, Navgaoun Manduwala, Uttarakhandjaya mishraNo ratings yet

- Machine Lab CombineDocument38 pagesMachine Lab Combinelakha ramNo ratings yet

- AVR444: Sensorless Control of 3-Phase Brushless DC Motors 8-Bit Microcontrollers Application NoteDocument14 pagesAVR444: Sensorless Control of 3-Phase Brushless DC Motors 8-Bit Microcontrollers Application Noteantonio carlos soares da silvaNo ratings yet

- Speed Control of DC Shunt MotorDocument7 pagesSpeed Control of DC Shunt MotorAakash0% (1)

- 1 Introduction 2. TheoryDocument33 pages1 Introduction 2. TheorychikulenkaNo ratings yet

- Lab 11 (Hardware Practice) PDFDocument7 pagesLab 11 (Hardware Practice) PDFzeeshan shaukatNo ratings yet

- PMSM Electrical Parameters Measurement: Application NoteDocument16 pagesPMSM Electrical Parameters Measurement: Application NotebrabandmNo ratings yet

- Lab 3Document14 pagesLab 3simran goelNo ratings yet

- Electrical and Electronics Engineering Laboratory ManualDocument36 pagesElectrical and Electronics Engineering Laboratory Manualjith16No ratings yet

- BE8161-Basic Electrical Electronics and Instrumentation Engineering Lab Manual FINAL PDFDocument82 pagesBE8161-Basic Electrical Electronics and Instrumentation Engineering Lab Manual FINAL PDFBHUVANA ARUMUGAMNo ratings yet

- Drives Manual Final EeeDocument60 pagesDrives Manual Final EeenandhakumarmeNo ratings yet

- Experiment 8Document3 pagesExperiment 8buhbabfNo ratings yet

- Ism LabDocument67 pagesIsm LabpadmavathiNo ratings yet

- ElecDocument31 pagesElecdeepanshumehalawat07No ratings yet

- 142 No Load and Block Rotor Test 3 PH Ind Motor Dol PDFDocument15 pages142 No Load and Block Rotor Test 3 PH Ind Motor Dol PDFGopinath B L NaiduNo ratings yet

- Voltage Regulation of alternator-EMF, MMF - ZPF-Expt-7Document7 pagesVoltage Regulation of alternator-EMF, MMF - ZPF-Expt-7Gingka HaganeNo ratings yet

- Speed Control of DC MotorDocument4 pagesSpeed Control of DC MotorsanjuNo ratings yet

- Control System Lab EE-324-FDocument45 pagesControl System Lab EE-324-FBalraj SinghNo ratings yet

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- 9.1 CentralDocument6 pages9.1 CentralVamsi RamNo ratings yet

- Individuals 2023Document7 pagesIndividuals 2023Vamsi RamNo ratings yet

- Geo Tagged Class Rooms: Bonam Venkata Chalamayya Institute of Technology & ScienceDocument4 pagesGeo Tagged Class Rooms: Bonam Venkata Chalamayya Institute of Technology & ScienceVamsi RamNo ratings yet

- 22 Batch 2 Sem TimetableDocument4 pages22 Batch 2 Sem TimetableVamsi RamNo ratings yet

- Skill CourseDocument1 pageSkill CourseVamsi RamNo ratings yet

- UdaysopsDocument6 pagesUdaysopsVamsi RamNo ratings yet

- S. No. Name of The Experiment Page No. Sig of Faculty Cycle-IDocument1 pageS. No. Name of The Experiment Page No. Sig of Faculty Cycle-IVamsi RamNo ratings yet

- Bonam Venkata Chalamayya Institute of Technology & Science Library & Information Centre Consolidated ReportDocument1 pageBonam Venkata Chalamayya Institute of Technology & Science Library & Information Centre Consolidated ReportVamsi RamNo ratings yet

- Exp-2 Brake Test On Shunt MotorDocument5 pagesExp-2 Brake Test On Shunt MotorVamsi RamNo ratings yet

- Exp-1 Mag CharDocument5 pagesExp-1 Mag CharVamsi RamNo ratings yet

- Exp-6 Load Test On DC Series GenDocument5 pagesExp-6 Load Test On DC Series GenVamsi RamNo ratings yet

- Iii Eee TTDocument1 pageIii Eee TTVamsi RamNo ratings yet

- Exp-8 Sump TestDocument7 pagesExp-8 Sump TestVamsi RamNo ratings yet

- Exp-9 Reg of Alternator - RemovedDocument6 pagesExp-9 Reg of Alternator - RemovedVamsi RamNo ratings yet

- Exp-3 Swinburns TestDocument5 pagesExp-3 Swinburns TestVamsi RamNo ratings yet

- Exp-7 OC & SC TestDocument7 pagesExp-7 OC & SC TestVamsi RamNo ratings yet

- Transmission LineDocument9 pagesTransmission LineVamsi RamNo ratings yet

- Exp-10 Brake Test On IMDocument8 pagesExp-10 Brake Test On IMVamsi RamNo ratings yet

- Individual Time TableDocument8 pagesIndividual Time TableVamsi RamNo ratings yet

- Work Load 2021-22 IDocument7 pagesWork Load 2021-22 IVamsi RamNo ratings yet

- Bee Cover PageDocument12 pagesBee Cover PageVamsi RamNo ratings yet

- L U N C H: B V C Institute of Technology and Science::AmalapuramDocument1 pageL U N C H: B V C Institute of Technology and Science::AmalapuramVamsi RamNo ratings yet

- L U N C H: B V C Institute of Technology and Science: AmalapuramDocument4 pagesL U N C H: B V C Institute of Technology and Science: AmalapuramVamsi RamNo ratings yet

- III Yr Time Tables NewDocument1 pageIII Yr Time Tables NewVamsi RamNo ratings yet

- RDSO Secification IRS S 99 2023 Amndt 4 Uploaded in RDSO Website For Comments27 April 2023Document91 pagesRDSO Secification IRS S 99 2023 Amndt 4 Uploaded in RDSO Website For Comments27 April 2023Priya SinghNo ratings yet

- Energy Conserrvation PresentationDocument49 pagesEnergy Conserrvation PresentationshreemantiNo ratings yet

- Torretas y Balizas Schneider Electric PDFDocument52 pagesTorretas y Balizas Schneider Electric PDFFrancisco TellezNo ratings yet

- LR 3410Document11 pagesLR 3410karimNo ratings yet

- 9 D9.35PDocument2 pages9 D9.35Pmanpreetsingh3458417No ratings yet

- Main Panel: Agarwall VillaDocument15 pagesMain Panel: Agarwall VillaEr.AROCKIA STEPHAN VSGNo ratings yet

- Gerber P2C™ 600 User's ManualDocument61 pagesGerber P2C™ 600 User's ManualSHER1303No ratings yet

- Premier Magnetics Inc.: 100watt PFC Universal Off-Line Switching MagneticsDocument2 pagesPremier Magnetics Inc.: 100watt PFC Universal Off-Line Switching Magneticsanon_316469432No ratings yet

- 20181201113141Document28 pages20181201113141Galuh PrambananNo ratings yet

- Cooking Hacks - Let's Cook - Fritzing LibrariesDocument4 pagesCooking Hacks - Let's Cook - Fritzing LibrariesJosephRomeraloNo ratings yet

- OEC R900V1-4J - IR ReceiverDocument9 pagesOEC R900V1-4J - IR Receiverrajaec58No ratings yet

- Manual Newly CS-1600 30Document20 pagesManual Newly CS-1600 30vijaaigNo ratings yet

- Mod. SMK/EV: Solar Energy Mini LaboratoryDocument2 pagesMod. SMK/EV: Solar Energy Mini Laboratoryessam essNo ratings yet

- Iec 60364 4 43 2008Document15 pagesIec 60364 4 43 2008KristofNo ratings yet

- Service Manual: Published in Jul.'02 842DF110Document326 pagesService Manual: Published in Jul.'02 842DF110Soraphong NaknoppakoonNo ratings yet

- Winpower Ge6w2a InstructionsDocument10 pagesWinpower Ge6w2a InstructionsjashmathewwNo ratings yet

- EgyLux Catalog 2021-Final ReducedDocument128 pagesEgyLux Catalog 2021-Final ReducedMichael Badawy100% (1)

- Connection Guide G83 Stage 1Document41 pagesConnection Guide G83 Stage 1JohnWilliamsNo ratings yet

- Measuring Instruments: Learning Activity Sheet For Grade 11Document2 pagesMeasuring Instruments: Learning Activity Sheet For Grade 11wiljhon sunioNo ratings yet

- Explain How Multiplexing Is So Cost-Effective. How Is Interference Avoided by Using Frequency Division Multiplexing?Document3 pagesExplain How Multiplexing Is So Cost-Effective. How Is Interference Avoided by Using Frequency Division Multiplexing?Fahad RuhulNo ratings yet

- Eaton 93PR 25-75 Datasheet ENDocument2 pagesEaton 93PR 25-75 Datasheet ENPhaniNo ratings yet

- CT 2 Answer KeyDocument7 pagesCT 2 Answer KeyAnirudhh RaviNo ratings yet

- Adjustments For CaterpillarDocument2 pagesAdjustments For CaterpillarsportyjoNo ratings yet

- Emcc-Ta-S-B01 Load ScheduleDocument1 pageEmcc-Ta-S-B01 Load SchedulezfrlNo ratings yet

- InterruptsDocument16 pagesInterruptsRajaViriyalaNo ratings yet

- Chapter 1Document21 pagesChapter 1iris33% (3)

- 25NAVAIDS 助航仪器Document8 pages25NAVAIDS 助航仪器Hoài ThanhNo ratings yet

- Computer Essentials - Lecture 1Document6 pagesComputer Essentials - Lecture 1SHKO MAGDIDNo ratings yet