Professional Documents

Culture Documents

Exp-2 Brake Test On Shunt Motor

Uploaded by

Vamsi RamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Exp-2 Brake Test On Shunt Motor

Uploaded by

Vamsi RamCopyright:

Available Formats

BEE LAB OBSERVATION

EXPERIMENT-2

BRAKE TEST ON D.C. SHUNT MOTOR

BVCITS EEE PAGE NO-

BEE LAB OBSERVATION

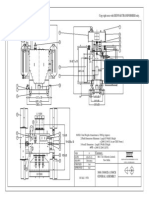

CIRCUIT DIAGRAM:

CIRCUIT DIAGRAM FOR BRAKE TEST ON D.C. SHUNT MOTOR

BVCITS EEE PAGE NO-

BEE LAB OBSERVATION

EXPT NO: 2 DATE:

BRAKE TEST ON D.C. SHUNT MOTOR

AIM: To conduct brake test on D.C. Shunt Motor and to draw its performance curves.

APPARATUS REQUIRED:

S. No Name of Range Type Quantity

apparatus

1. Voltmeter 0-300 v MC 1 No.

2. Ammeter 0-20 A MC 2 No.

3. Rheostat 360ohms/1.2A Wire Wound 1 No.

4. Tacho meter 0-10000 rpm Digital 1 No.

5. Connecting - - -

wires

THEORY:

It is a direct method and consists of applying a brake to a water – cooled pulley mounted

on the motor shaft. The brake band is fixed with the help of wooden blocks gripping the pulley.

The sample brake test described above can be used for small motors only. Because in the

case of large motors. It is difficult to dissipate the large amount of heat generated at the brake.

BVCITS EEE PAGE NO-

BEE LAB OBSERVATION

TABULATION:

Spring Net Torque = Power

Line

Voltag Field N Balance Balance S x r x 9.81 (O/P) Power %Efficien

Curre e Curren (rpm) (kg’s) S1 – S2 N-M = (I/P) cy

S.No nt (v ) t S1 S2 (kg’s) 2πNT VIL = O/P*100

IL ( A ) If (A) 60 watts I/ P

watts

MODEL GRAPH:

BVCITS EEE PAGE NO-

BEE LAB OBSERVATION

PROCEDURE:

1. Make the connections as per the circuit.

2. Keep the armature rheostat in maximum position and field rheostat in minimum

position.

3. Give 220v D.C Supply to the motor by closing DPST switch.

4. Start the motor with the help of 3- Point starter.

5. Check the speed of the motor using tachometer and bring it to rated speed (1500 rpm)

by adjusting the armature rheostat (from maximum to minimum position) and field rheostat

(from minimum to maximum position)

6. Note down the V, N, S1, S2, Load current, Field current readings under no-load

conditions.

7. Now gradually applying the mechanical load i.e., by using tightening the belt on the

brake drum until the load current reaches rated value note down the readings of the V, N,

S1, S2, Load current, Field current.

8. Remove the mechanical load stop the motor in reverse procedure i.e. bring back the

armature and field rheostats two there original position.

PRECAUTIONS:

➢ The pulley of the brake drum must be filled with cool water.

➢ Before stop the motor, load should be removed.

➢ Connections must be tight.

➢ Readings must be noted without any parallax error.

➢ Fuses should be properly rated.

➢ The operation of the 3-Point starter. Should be slow and uniform.

➢ Armature rheostat should be connected in maximum position initially.

➢ Field rheostat should be minimum resistance position.

RESULT:

Brake Test on D.C Shunt Motor is conducted and its performance curves were drawn.

BVCITS EEE PAGE NO-

You might also like

- Circuit Diagram For Brake Test On D.C.Shunt Motor: EM1 LAB, BVCR, RAJAHMUNDRY Prepared by K. Nagesh & V.D.NeelimaDocument4 pagesCircuit Diagram For Brake Test On D.C.Shunt Motor: EM1 LAB, BVCR, RAJAHMUNDRY Prepared by K. Nagesh & V.D.NeelimaPrabhu MoorthyNo ratings yet

- Exp-10 Brake Test On IMDocument8 pagesExp-10 Brake Test On IMVamsi RamNo ratings yet

- Exp-6 Load Test On DC Series GenDocument5 pagesExp-6 Load Test On DC Series GenVamsi RamNo ratings yet

- Brake Test On DC Shunt MotorDocument4 pagesBrake Test On DC Shunt Motorkudupudinagesh87% (31)

- Em Lab InsideDocument54 pagesEm Lab InsideSeema MotagiNo ratings yet

- Final Consolidated Expts-18eel46Document55 pagesFinal Consolidated Expts-18eel46AshwiniNo ratings yet

- Load Test of DC Shunt Motor: (Hardware)Document10 pagesLoad Test of DC Shunt Motor: (Hardware)ABHISHEKNo ratings yet

- Brake Test DC Series MotorDocument3 pagesBrake Test DC Series MotorVARAPRASADNo ratings yet

- 2 Machine LabDocument4 pages2 Machine LabManoj GuptaNo ratings yet

- Exp 2 (Load Test On Three Phase Im)Document6 pagesExp 2 (Load Test On Three Phase Im)Adarsh Singh100% (1)

- Exp-1 Mag CharDocument5 pagesExp-1 Mag CharVamsi RamNo ratings yet

- Control System Lab EE-324-FDocument45 pagesControl System Lab EE-324-FBalraj SinghNo ratings yet

- Exp-4 Speed ControlDocument5 pagesExp-4 Speed ControlVamsi RamNo ratings yet

- Swinburns'S Test On D.C Shunt MachineDocument15 pagesSwinburns'S Test On D.C Shunt MachineharimadhavareddyNo ratings yet

- Control System Lab ManualDocument52 pagesControl System Lab ManualMohammad Umar RehmanNo ratings yet

- Exp-5 Sep of LossesDocument5 pagesExp-5 Sep of LossesVamsi RamNo ratings yet

- Jawaharlal Nehru Engineering College: Laboratory ManualDocument36 pagesJawaharlal Nehru Engineering College: Laboratory Manualprathap kumarNo ratings yet

- Eee206 DC Motor p1bDocument3 pagesEee206 DC Motor p1bAhad AhadNo ratings yet

- Load Test On DC Shunt MotorDocument6 pagesLoad Test On DC Shunt Motorsanju0% (1)

- Brake Test On DC Shunt MotorDocument5 pagesBrake Test On DC Shunt MotorkudupudinageshNo ratings yet

- EE6512-Electrical Machines Laboratory - II-1000431998-EM II Lab Manual 2018Document122 pagesEE6512-Electrical Machines Laboratory - II-1000431998-EM II Lab Manual 2018dinesh jNo ratings yet

- Exp-9 Reg of Alternator - RemovedDocument6 pagesExp-9 Reg of Alternator - RemovedVamsi RamNo ratings yet

- Anna University Practical Lab Manuals For Engineering StudentsDocument13 pagesAnna University Practical Lab Manuals For Engineering StudentsTinku RathoreNo ratings yet

- DCM Lab Manual - 0 PDFDocument45 pagesDCM Lab Manual - 0 PDFVenkata HemanthNo ratings yet

- Brake Test DC Shunt MotorDocument3 pagesBrake Test DC Shunt MotorVARAPRASADNo ratings yet

- Experiment - No.10 Load Test On DC Shunt Motor: DATE:10/12/2021Document6 pagesExperiment - No.10 Load Test On DC Shunt Motor: DATE:10/12/2021Baba YagaNo ratings yet

- Machines1 Exp 5Document6 pagesMachines1 Exp 5Lover BoyNo ratings yet

- s5 Lab Manual Full FinalDocument45 pagess5 Lab Manual Full FinalananyadeviashokkumarNo ratings yet

- List of Experiments: Sno Name of The Experiment Date SignatureDocument41 pagesList of Experiments: Sno Name of The Experiment Date SignatureRajeshKanchanaNo ratings yet

- Electrical and Electronics Engineering Laboratory ManualDocument36 pagesElectrical and Electronics Engineering Laboratory Manualjith16No ratings yet

- EECS Lab Manual For IV ECE R2013Document66 pagesEECS Lab Manual For IV ECE R2013keshav315No ratings yet

- Practical Manual: Electrical Machine - I LabDocument4 pagesPractical Manual: Electrical Machine - I LabHinaNo ratings yet

- EE6365-Electrical Engineering Lab ManualDocument95 pagesEE6365-Electrical Engineering Lab ManualAishwayaNo ratings yet

- Electrical Machine-Ii Lab ManualDocument33 pagesElectrical Machine-Ii Lab ManualTauhidul Haque100% (1)

- Electrical Machines Lab 1 Electrical MacDocument153 pagesElectrical Machines Lab 1 Electrical MacOladimeji OluwaseunNo ratings yet

- EM-I LAB-finalDocument114 pagesEM-I LAB-finalHarimadhavareddy YenireddyNo ratings yet

- Machine Lab CombineDocument38 pagesMachine Lab Combinelakha ramNo ratings yet

- Exp-7 OC & SC TestDocument7 pagesExp-7 OC & SC TestVamsi RamNo ratings yet

- (EM 2) - Lab Manual 4th SemDocument43 pages(EM 2) - Lab Manual 4th SemTime LapserNo ratings yet

- Control System Lab EE-324-FDocument45 pagesControl System Lab EE-324-FDheeraj KumarNo ratings yet

- Experiment No.6 The DC Shunt Motor RatingDocument7 pagesExperiment No.6 The DC Shunt Motor RatingMounta1n DewNo ratings yet

- Electrical Machine-II Laboratory Manual B.Tech, 3 Yr, 5 Semester, Electrical Engg. DeptDocument28 pagesElectrical Machine-II Laboratory Manual B.Tech, 3 Yr, 5 Semester, Electrical Engg. DeptMoumi PanditNo ratings yet

- Expt 6 The Cage Rotor Induction MotorDocument5 pagesExpt 6 The Cage Rotor Induction MotorRyan De GuzmanNo ratings yet

- Circuit Diagram: Kprient/Eee/Ee8361 Electrical Engineering LaboratoryDocument6 pagesCircuit Diagram: Kprient/Eee/Ee8361 Electrical Engineering LaboratorykavineshNo ratings yet

- Date: Experiment - 2 To Study The Operation of Controlled Rectifier Fed Separately Excited DC Motor DriveDocument5 pagesDate: Experiment - 2 To Study The Operation of Controlled Rectifier Fed Separately Excited DC Motor DriveDaksh SharmaNo ratings yet

- Exercises On Electric Motors.Document11 pagesExercises On Electric Motors.Salman Muneer AhmedNo ratings yet

- 142 No Load and Block Rotor Test 3 PH Ind Motor Dol PDFDocument15 pages142 No Load and Block Rotor Test 3 PH Ind Motor Dol PDFGopinath B L NaiduNo ratings yet

- Me 2209 Electrical Engineering LaboratoryDocument63 pagesMe 2209 Electrical Engineering LaboratoryRaja SekarNo ratings yet

- Bersabal - Experiment 25 - Ee435alDocument8 pagesBersabal - Experiment 25 - Ee435alCegrow Ber BersabalNo ratings yet

- EM-1 LabDocument49 pagesEM-1 LabApoorvNo ratings yet

- Exp - 4. Determination of Series & Shunt Motor Characteristic CurveDocument5 pagesExp - 4. Determination of Series & Shunt Motor Characteristic CurveMd KaziNo ratings yet

- EE6512-Electrical Machines LaboratoryDocument82 pagesEE6512-Electrical Machines LaboratoryGopinath B L NaiduNo ratings yet

- Practical Manual: Electrical Machine-I LabDocument5 pagesPractical Manual: Electrical Machine-I LabHinaNo ratings yet

- Bee Lab Manual R19Document25 pagesBee Lab Manual R19Sudharshan ChennupalliNo ratings yet

- Machine - Lab Manual Merged PDFDocument14 pagesMachine - Lab Manual Merged PDFMubin LikhonNo ratings yet

- Exp-3 Swinburns TestDocument5 pagesExp-3 Swinburns TestVamsi RamNo ratings yet

- m2 (6) The DC Shunt Motor Report DataDocument8 pagesm2 (6) The DC Shunt Motor Report DataEric CalejaNo ratings yet

- Swinburne S Test On DC Shunt MotorDocument5 pagesSwinburne S Test On DC Shunt Motortamann2004No ratings yet

- Geo Tagged Class Rooms: Bonam Venkata Chalamayya Institute of Technology & ScienceDocument4 pagesGeo Tagged Class Rooms: Bonam Venkata Chalamayya Institute of Technology & ScienceVamsi RamNo ratings yet

- 9.1 CentralDocument6 pages9.1 CentralVamsi RamNo ratings yet

- Individuals 2023Document7 pagesIndividuals 2023Vamsi RamNo ratings yet

- UdaysopsDocument6 pagesUdaysopsVamsi RamNo ratings yet

- Skill CourseDocument1 pageSkill CourseVamsi RamNo ratings yet

- 22 Batch 2 Sem TimetableDocument4 pages22 Batch 2 Sem TimetableVamsi RamNo ratings yet

- Bonam Venkata Chalamayya Institute of Technology & Science Library & Information Centre Consolidated ReportDocument1 pageBonam Venkata Chalamayya Institute of Technology & Science Library & Information Centre Consolidated ReportVamsi RamNo ratings yet

- S. No. Name of The Experiment Page No. Sig of Faculty Cycle-IDocument1 pageS. No. Name of The Experiment Page No. Sig of Faculty Cycle-IVamsi RamNo ratings yet

- Exp-4 Speed ControlDocument5 pagesExp-4 Speed ControlVamsi RamNo ratings yet

- Exp-1 Mag CharDocument5 pagesExp-1 Mag CharVamsi RamNo ratings yet

- Exp-5 Sep of LossesDocument5 pagesExp-5 Sep of LossesVamsi RamNo ratings yet

- Exp-3 Swinburns TestDocument5 pagesExp-3 Swinburns TestVamsi RamNo ratings yet

- Exp-8 Sump TestDocument7 pagesExp-8 Sump TestVamsi RamNo ratings yet

- II B.tech Time Tables NewDocument1 pageII B.tech Time Tables NewVamsi RamNo ratings yet

- Exp-7 OC & SC TestDocument7 pagesExp-7 OC & SC TestVamsi RamNo ratings yet

- Iii Eee TTDocument1 pageIii Eee TTVamsi RamNo ratings yet

- L U N C H: B V C Institute of Technology and Science::AmalapuramDocument1 pageL U N C H: B V C Institute of Technology and Science::AmalapuramVamsi RamNo ratings yet

- Exp-9 Reg of Alternator - RemovedDocument6 pagesExp-9 Reg of Alternator - RemovedVamsi RamNo ratings yet

- Transmission LineDocument9 pagesTransmission LineVamsi RamNo ratings yet

- Work Load 2021-22 IDocument7 pagesWork Load 2021-22 IVamsi RamNo ratings yet

- Bee Cover PageDocument12 pagesBee Cover PageVamsi RamNo ratings yet

- Individual Time TableDocument8 pagesIndividual Time TableVamsi RamNo ratings yet

- III Yr Time Tables NewDocument1 pageIII Yr Time Tables NewVamsi RamNo ratings yet

- IAENG Membership 234119Document1 pageIAENG Membership 234119Vamsi RamNo ratings yet

- II B.tech Time Tables NewDocument1 pageII B.tech Time Tables NewVamsi RamNo ratings yet

- L U N C H: B V C Institute of Technology and Science: AmalapuramDocument4 pagesL U N C H: B V C Institute of Technology and Science: AmalapuramVamsi RamNo ratings yet

- Iv B.Tech I Sem Eee Inst Mid IiDocument1 pageIv B.Tech I Sem Eee Inst Mid IiVamsi RamNo ratings yet

- MODULE-3 Single Phase Transformers NOTESDocument11 pagesMODULE-3 Single Phase Transformers NOTESAffan KhanNo ratings yet

- Esd5500E Series Speed Control Tlnit: WarningDocument5 pagesEsd5500E Series Speed Control Tlnit: WarningKarla HolandaNo ratings yet

- IncarcatorDocument12 pagesIncarcatorMadalin LazarescuNo ratings yet

- Ee 11Document17 pagesEe 11Juphil PletoNo ratings yet

- C & S 3000kVA GA DrgsDocument7 pagesC & S 3000kVA GA DrgsIrshad Khan100% (1)

- What Is The Cause of Generator Overfluxing and Overcxcitation - QuoraDocument2 pagesWhat Is The Cause of Generator Overfluxing and Overcxcitation - QuoraCharles RobiansyahNo ratings yet

- Tiastar and Legacy Motor Control Center Aftermarket Renewal Parts CatalogDocument20 pagesTiastar and Legacy Motor Control Center Aftermarket Renewal Parts CatalogLuis Antonio Chiapas GarciaNo ratings yet

- Asco Series 015 Manual Reset CatalogDocument6 pagesAsco Series 015 Manual Reset Catalogpneuma110No ratings yet

- How Important Is Volts Vs Amps - Endless SphereDocument7 pagesHow Important Is Volts Vs Amps - Endless SphereAri HaranNo ratings yet

- KE's Evaluation & Integration Plan For CTBCM - NEPRA - 271121Document60 pagesKE's Evaluation & Integration Plan For CTBCM - NEPRA - 271121Hunain RazaNo ratings yet

- Specification For Transformer: ANSI C57.12-01Document1 pageSpecification For Transformer: ANSI C57.12-01Charlie MendozaNo ratings yet

- PAT Status:: MobitelDocument20 pagesPAT Status:: Mobiteldumindu1No ratings yet

- Installation and Operational Instructions For Roba - Switch Type 017. - 00.2Document6 pagesInstallation and Operational Instructions For Roba - Switch Type 017. - 00.2Jarosław SkarbekNo ratings yet

- TrafoTech R2Document12 pagesTrafoTech R2krmurali2000No ratings yet

- Master VSG1Document81 pagesMaster VSG1Bình ChuNo ratings yet

- Losses in TransformerDocument15 pagesLosses in TransformerAnkit SrivastavaNo ratings yet

- CTTN121 - DC Motor Resistive EvaluationDocument7 pagesCTTN121 - DC Motor Resistive EvaluationIsmael ValeroNo ratings yet

- 11 TCVN 18-2006Document124 pages11 TCVN 18-2006tung100% (1)

- TNERC-Tariff Order For Wind Energy-2012Document142 pagesTNERC-Tariff Order For Wind Energy-2012Phani KumarNo ratings yet

- 132KV VT Test Report-Jumsouth Ss Updated SIGNEDDocument3 pages132KV VT Test Report-Jumsouth Ss Updated SIGNEDharihara_675292894No ratings yet

- 2 - Transmission Line ParametersDocument83 pages2 - Transmission Line ParametersEshet ShumetNo ratings yet

- Active, Reactive, Apparent and Complex Power. Simple Explanation With FormulasDocument4 pagesActive, Reactive, Apparent and Complex Power. Simple Explanation With FormulasHussam GujjarNo ratings yet

- Electricity Rates or TariffDocument10 pagesElectricity Rates or TariffPVV RAMA RAONo ratings yet

- Earthing Calculation - Open ElectricalDocument11 pagesEarthing Calculation - Open ElectricalChihiya Fitria NurhayatiNo ratings yet

- User Manual: HGM170/170HCDocument11 pagesUser Manual: HGM170/170HCazocarNo ratings yet

- Application of Buck-Boost Converter For Wind Energy ControlDocument5 pagesApplication of Buck-Boost Converter For Wind Energy ControlIJIRST100% (2)

- Standard Features: Model GB-P1250Document4 pagesStandard Features: Model GB-P1250husan shahNo ratings yet

- EE 740 Professor Ali Keyhani Lecture #3: Ideal TransformersDocument11 pagesEE 740 Professor Ali Keyhani Lecture #3: Ideal TransformersMohamed A. HusseinNo ratings yet

- 02 Section 7 PriceScheduleForm BOQDocument3 pages02 Section 7 PriceScheduleForm BOQHayman AhmedNo ratings yet

- AUSTAND CGRSERIES-1000KG-1.75 GHHDocument4 pagesAUSTAND CGRSERIES-1000KG-1.75 GHHTahir Iqbal BalochNo ratings yet