Professional Documents

Culture Documents

Balanced Cantilever Method in Bridge Construction (14) ..

Uploaded by

Dhanush S100%(1)100% found this document useful (1 vote)

18 views3 pagesOriginal Title

BALANCED CANTILEVER METHOD IN BRIDGE CONSTRUCTION (14)..

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

18 views3 pagesBalanced Cantilever Method in Bridge Construction (14) ..

Uploaded by

Dhanush SCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

ASSIGNMENT NO : 02 DESIGN OF BRIDGES S.

JAYA HARISH

DATE : 13/06/22 RA2112001010014

1. WHAT IS BALANCED CANTILEVER METHOD IN BRIDGE

CONSTRUCTION ?

The Balanced Cantilever Method refers to a construction method that does

not install scaffolding systems under the bridge and completes the

superstructure of the bridge by sequentially joining the segments to form a

span by post-tensioning and balancing them left and right from each pier

using special erection equipment.

The balanced cantilever method of bridge construction used for bridges

with few spans ranging from 50 to 250m.

The bridge can be either cast-in-place or precast. Moreover, the basic

concept of balanced cantilever construction method is to attach the

segments in an alternate manner at opposite ends of cantilevers supported

by piers.

Furthermore, this method is easily adaptable to irregular and long span

lengths, congested project sites, rough and water terrain, rail crossings, and

environmentally sensitive areas.

Additionally, it is highly suitable for building cable-stayed bridges. This is

because once segments are placed, they will be supported by new cable-

stays in each erection stage.

Therefore, no auxiliary supports are required, and hence it is both

economical and practical method for long cable-stayed bridges.

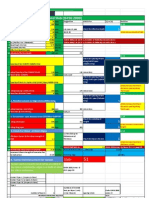

OVERVIEW OF CONSTRUCTION PHASE

CONSTRUCTION PROCESS FOR BALANCED CANTILEVER

METHOD

1. Once the construction of lower infrastructure of the bridge is finished, the

construction of bridge is started at each pier. After that, special formwork is

arranged and cast-in-situ pier segment is provided. The entire pier segment is then

applied as an fabrication platform to support a form traveler for cast-in-place

segments.

2. Then, soffit shuttering, shuttering for web & deck shuttering is settled on both

sides of pier.

3. After that, concreting is accomplished on both sides of the pier. The segment

production rate for form travelers normally remains one segment each 5 days per

traveler.

4. Cast-in-situ segments vary from 3m to 5m in length with formwork driving in

combination with each segment. Segment construction is sustained unless a

joining midpoint is attained where a balanced pair is stopped.

PROGRESSION OF BALANCED CANTILEVER METHOD OF

PRECAST BRIDGE CONSTRUCTION

1. Initially, the construction is done for foundations and pier shafts of all

permanent piers in the primary unit.

2. As soon as the piers are constructed, they are applied as an erection platform

for precast segments.

3. Compile and set up lifting frame.

4. Arrange first pair of precast segments.

5. Build wet joints.

6. Cure the wet joints.

7. After that, set up next pair of precast segments. Then, construct and cure joints.

This method should go on unless the construction process is finished.

You might also like

- Paper Bridge Construction MethodDocument10 pagesPaper Bridge Construction MethodAsep ArdiantoNo ratings yet

- 4 Design of Slab Bridges PDFDocument6 pages4 Design of Slab Bridges PDFsohanpmeharwadeNo ratings yet

- Pre Stressed Precast Concrete Compound WallDocument26 pagesPre Stressed Precast Concrete Compound WallAkhilesh Kumar SinghNo ratings yet

- Cipl MJB 1+055.734 DGN 007Document63 pagesCipl MJB 1+055.734 DGN 007rao shoaibNo ratings yet

- Lecture 01 - Construction EngineeringDocument18 pagesLecture 01 - Construction EngineeringKw TseNo ratings yet

- Review On Reinforced Concrete Skew SlabDocument4 pagesReview On Reinforced Concrete Skew SlabAscanio MarchionneNo ratings yet

- Consultant Expert DR Mohamed Seif Al Den TahaDocument228 pagesConsultant Expert DR Mohamed Seif Al Den Tahaconsultant expert dr mohamed seif al den tahaNo ratings yet

- 05-17 QCS 2014Document8 pages05-17 QCS 2014Raja Ahmed Hassan100% (2)

- FEM Design-Manual CONTENTSDocument18 pagesFEM Design-Manual CONTENTSLocal UserNo ratings yet

- Prepared By: 1 - Mohammad Ismail 2 - Moutasem Muhaisen Submitted To: Professor Samih QaqishDocument44 pagesPrepared By: 1 - Mohammad Ismail 2 - Moutasem Muhaisen Submitted To: Professor Samih Qaqishanon_30048258No ratings yet

- UNIT-3 (Lecture-3) Bridge BearingsDocument27 pagesUNIT-3 (Lecture-3) Bridge BearingsSabbir hossain100% (1)

- Fabrication Work For The Construction of Chenab Bridge Part IDocument2 pagesFabrication Work For The Construction of Chenab Bridge Part IIndra Mishra100% (2)

- Presentationfinal 181109153810 PDFDocument46 pagesPresentationfinal 181109153810 PDFZohaibShoukatBalochNo ratings yet

- Double Composite Bridges The Main Concept and Examples of Its ImplementationDocument8 pagesDouble Composite Bridges The Main Concept and Examples of Its ImplementationDiego Cobo del ArcoNo ratings yet

- Comparative Study of Balance Cantilever Bridge and Extradosed BridgeDocument13 pagesComparative Study of Balance Cantilever Bridge and Extradosed BridgeIJRASETPublicationsNo ratings yet

- Construction Engineering of Phu My Cable-Stayed Bridge, VietnamDocument15 pagesConstruction Engineering of Phu My Cable-Stayed Bridge, VietnamSravanthi MeharNo ratings yet

- PLATE LOAD TEST RESULTSDocument11 pagesPLATE LOAD TEST RESULTSabdul samadNo ratings yet

- Prestressing InfoDocument30 pagesPrestressing InfoDinesh JangraNo ratings yet

- Unit 2 Be NotesDocument30 pagesUnit 2 Be NotesFahd Abdul RahmanNo ratings yet

- Type of Construction JointsDocument11 pagesType of Construction JointsHossam KamalNo ratings yet

- Department of Civil Engineering: Guide:Prof. Vishal SapateDocument21 pagesDepartment of Civil Engineering: Guide:Prof. Vishal SapateshrikantharleNo ratings yet

- The Books On The BottomDocument53 pagesThe Books On The BottomJr BongabongNo ratings yet

- Rehabilitation of Bridge at AgarwadaDocument57 pagesRehabilitation of Bridge at AgarwadaBalan-Nogi DanNo ratings yet

- Literature Review of Cable Stayed BridgeDocument8 pagesLiterature Review of Cable Stayed Bridgeea53sm5wNo ratings yet

- Design of PSC Bridge: Prestressed (Post-Tensioned) Reinforced ConcreteDocument24 pagesDesign of PSC Bridge: Prestressed (Post-Tensioned) Reinforced ConcreteAashish GhimireNo ratings yet

- BRIDGES - PPT by VASUMATHIDocument48 pagesBRIDGES - PPT by VASUMATHIVASUMATHINo ratings yet

- Bridge Bearings PDFDocument6 pagesBridge Bearings PDFsidiq7No ratings yet

- 087 Assessment of A Bridge Pier Pile PDFDocument8 pages087 Assessment of A Bridge Pier Pile PDFVardhanNo ratings yet

- Bridge Engineer in 01 WaddDocument1,228 pagesBridge Engineer in 01 WaddManoranjan KhamariNo ratings yet

- Ashok Kumar Bridge EngineerDocument12 pagesAshok Kumar Bridge EngineerabhilashNo ratings yet

- Materials and Construction Methods for BridgesDocument74 pagesMaterials and Construction Methods for Bridgessanusi69No ratings yet

- Horizontal Construction JointsDocument18 pagesHorizontal Construction JointsPremasiri KarunarathnaNo ratings yet

- Construction CETINA Arch BridgeDocument6 pagesConstruction CETINA Arch BridgeVIDAL MAMANINo ratings yet

- Performance-Based Standard Specifications For Maintenance and Repair of Concrete Structures in JapanDocument18 pagesPerformance-Based Standard Specifications For Maintenance and Repair of Concrete Structures in JapanMatheus AlmeidaNo ratings yet

- P10 AK MullickDocument11 pagesP10 AK MullickSony JsdNo ratings yet

- Comparative Study of Waffle Slab With Bracing System and Conventional Slabs Without Bracing SystemDocument8 pagesComparative Study of Waffle Slab With Bracing System and Conventional Slabs Without Bracing SystemIJRASETPublicationsNo ratings yet

- Can_Tho_Bridge_VietnamDocument2 pagesCan_Tho_Bridge_VietnamIndra Nath MishraNo ratings yet

- Extradosed Bridges - State of The Art: Indian Association of Structural EngineersDocument2 pagesExtradosed Bridges - State of The Art: Indian Association of Structural EngineersIndra MishraNo ratings yet

- Irb M UpdatedDocument398 pagesIrb M UpdatedAnonymous cYcLLOmmk8No ratings yet

- Bridge Launching Girder - Lecture NotesDocument6 pagesBridge Launching Girder - Lecture NotesVivek G. Abhyankar0% (1)

- MasterbuilderDocument4 pagesMasterbuildermahakNo ratings yet

- Box Pushing Technology PresentationDocument13 pagesBox Pushing Technology PresentationVirendra Kumar PareekNo ratings yet

- 345-001071-1009 - R0 Beam & Slab Formworks First Aid Bldg.17Document1 page345-001071-1009 - R0 Beam & Slab Formworks First Aid Bldg.17Satya kaliprasad vangaraNo ratings yet

- Chapter 10 Design of Prestressed 761661594169023Document15 pagesChapter 10 Design of Prestressed 761661594169023Puzzle ArtsNo ratings yet

- Suhas P KhedkarDocument114 pagesSuhas P KhedkarAndresendeNo ratings yet

- Cable Force TuningDocument23 pagesCable Force TuningBarben Group CorpNo ratings yet

- Technical Journal: Plan Design EnableDocument107 pagesTechnical Journal: Plan Design EnablegullipalliNo ratings yet

- Box Culvert ExtensionDocument4 pagesBox Culvert ExtensionRonak ShahNo ratings yet

- GP E Prestressing Basic AASHTODocument101 pagesGP E Prestressing Basic AASHTOrammirisNo ratings yet

- Incremental Launching of Composite Bridge Deck Ch198Document6 pagesIncremental Launching of Composite Bridge Deck Ch198Miguel PerezNo ratings yet

- Shinso Pile - APMDocument9 pagesShinso Pile - APMHimang Jain100% (1)

- $the Formwork To The Millau ViaductDocument104 pages$the Formwork To The Millau ViaductPopa AndreiNo ratings yet

- UHPFRC - Portfolio EnglishDocument67 pagesUHPFRC - Portfolio EnglishRaylane Castoldi100% (1)

- 18m Simple Span RC T-Girder Bridge DesignDocument72 pages18m Simple Span RC T-Girder Bridge DesignAbera Mamo JaletaNo ratings yet

- Gabion Walls Presentation FijiDocument38 pagesGabion Walls Presentation FijiHuy ChungNo ratings yet

- Different Bridge Construction MethodsDocument25 pagesDifferent Bridge Construction MethodsMuhammad FarooqNo ratings yet

- Different Methods of Bridge Construction 1Document65 pagesDifferent Methods of Bridge Construction 1Jonh Vincent Dedoro100% (1)

- Methods of Bridge Construction: Cast-in-Situ, Precast, Balanced Cantilever & MoreDocument11 pagesMethods of Bridge Construction: Cast-in-Situ, Precast, Balanced Cantilever & MorekarthiksampNo ratings yet

- Balanced Cantilever Method of Bridge ConstructionDocument7 pagesBalanced Cantilever Method of Bridge ConstructionyyingmunNo ratings yet

- SyllabusDocument1 pageSyllabusDhanush SNo ratings yet

- Patenting Flowchart: Steps for Securing Patent ProtectionDocument11 pagesPatenting Flowchart: Steps for Securing Patent ProtectionDhanush SNo ratings yet

- STRUCTURAL ANALYSIS METHODSDocument81 pagesSTRUCTURAL ANALYSIS METHODSDhanush SNo ratings yet

- Bridge - Pier AssignmentDocument5 pagesBridge - Pier AssignmentDhanush SNo ratings yet

- Shear ConnectorDocument2 pagesShear ConnectorDhanush SNo ratings yet

- Eron S Ve-Ts Econ.: BrldeDocument6 pagesEron S Ve-Ts Econ.: BrldeDhanush SNo ratings yet

- 1917307-Design of BridgesDocument15 pages1917307-Design of BridgesDhanush SNo ratings yet

- Two-way Restrained Slab Design CheckDocument3 pagesTwo-way Restrained Slab Design CheckBasandharaAdhikariNo ratings yet

- HOOD CalculationDocument3 pagesHOOD CalculationhimajcpNo ratings yet

- Is 456 Code Clausewise Detailed Explanation PART: - 42: Ashish VermaDocument46 pagesIs 456 Code Clausewise Detailed Explanation PART: - 42: Ashish VermaAshish VermaNo ratings yet

- Setting of Cement Chemistry Project Class 12Document18 pagesSetting of Cement Chemistry Project Class 12Hari KrishnanNo ratings yet

- Trafford Council Plans List 15 July 2013Document6 pagesTrafford Council Plans List 15 July 2013SophieCorlessNo ratings yet

- The Arup Journal Issue 2 1987Document20 pagesThe Arup Journal Issue 2 1987Lip Bing YongNo ratings yet

- JSRG - Mom - DRM - 04 (13.12.2018) PDFDocument3 pagesJSRG - Mom - DRM - 04 (13.12.2018) PDFNithyanandhan TranzionNo ratings yet

- Romanticism PDFDocument85 pagesRomanticism PDFSriLaxmi BulusuNo ratings yet

- Types of Formwork GuideDocument10 pagesTypes of Formwork GuideEngrdens Dela CruzNo ratings yet

- Redefining Humanitarian Architecture with Complexity in MindDocument6 pagesRedefining Humanitarian Architecture with Complexity in MindAneta Mudronja PletenacNo ratings yet

- Stainless Steel Composition Chart: TP304 TP304H TP304L TP310S TP316Document4 pagesStainless Steel Composition Chart: TP304 TP304H TP304L TP310S TP316Gonzalo MazaNo ratings yet

- Property For Sale - The Berwyn MillDocument12 pagesProperty For Sale - The Berwyn MillNicola AitkinNo ratings yet

- Steps in English 1 Unit 3 Test BDocument2 pagesSteps in English 1 Unit 3 Test BAlina SkybukNo ratings yet

- Wardha District Tourism Plan1Document34 pagesWardha District Tourism Plan1Joint Chief Officer, MB MHADANo ratings yet

- Production RatesDocument29 pagesProduction RatesSam Monte0% (1)

- Methods of Construction of Prestressed MembersDocument20 pagesMethods of Construction of Prestressed Membersofreneo_joshua4437No ratings yet

- Single-View Systems Cannot Handle Modern Communications CustomersDocument6 pagesSingle-View Systems Cannot Handle Modern Communications Customersprathamesh gawliNo ratings yet

- Gewan Island Qatar concrete BOQDocument7 pagesGewan Island Qatar concrete BOQabid hamzaNo ratings yet

- Experimental Study On Behaviour of Composite Column CFTDocument7 pagesExperimental Study On Behaviour of Composite Column CFTnilkanthNo ratings yet

- India Expo CentreDocument11 pagesIndia Expo CentreMudit DuaNo ratings yet

- ConantDocument232 pagesConanthelenaanjosNo ratings yet

- Guide Specification Aluminum Composite Wall PanelsDocument9 pagesGuide Specification Aluminum Composite Wall PanelsJosielyn100% (1)

- Reinforced Concrete Column: ConditionDocument3 pagesReinforced Concrete Column: ConditionJheo TorresNo ratings yet

- Basic Components of A BuildingDocument7 pagesBasic Components of A Buildingrahimmulla100% (3)

- Wirand Application Re3 ValuesDocument2 pagesWirand Application Re3 ValuesSerbanDragosNo ratings yet

- Hand Rail Details: NotesDocument1 pageHand Rail Details: NotesManthan HingooNo ratings yet

- Assignment On Conceptual Design of Earthquake Resistant BuildingsDocument11 pagesAssignment On Conceptual Design of Earthquake Resistant BuildingsShaijal KmNo ratings yet

- Foundation ProjectDocument8 pagesFoundation ProjectLee Chong JengNo ratings yet

- ArticlesDocument2 pagesArticlesNielfranz MaderazoNo ratings yet

- Assignment 2Document1 pageAssignment 2Dale MalazzabNo ratings yet