Professional Documents

Culture Documents

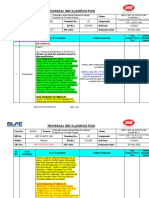

Appendix B - HAZOP Worksheet

Uploaded by

Muhammad SalmanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Appendix B - HAZOP Worksheet

Uploaded by

Muhammad SalmanCopyright:

Available Formats

Risk Ranking

Node No. Node Deviation Cause Consequence Effective Safeguards Recommendations Responsibility

S L RR

1 Blowdown degassing vessel X89-D- 1. No Flow 1. Inadvertent closure of 6'' manual 1. Over pressurization of the upstream 1. Existing system has available protection for 5 1 5 1. 6-inch manual isolation valve SLFE

0038A and degassing pumps X89-P- isolation valve (line 6"-BD-XXX2- condensate surge drum/other sources blocked flow (Line 6"-BD-XXX2-1CA1P) to be

0016A/B 1CA1P) connected to common blowdown header CSO

leading to LOC, fire & explosion causing

multiple fatalities

2. Loss of level in the degassing drum (X89-D- 1. LIC-1001 will stop the pump (X89-G- 5 2 8

0038A), more fuel gas flow & possible gas 0016A/B) on low level

blowby to the pump (X89-G-0016A/B), pump 2. LALL-1003 will trip the pump (X89-G-

cavitation, pump damage, LOC, fire/explosion 0016A/B) on LL level

causing multiple fatalities

2. Stuck closure of NRV (line 6"-BD- 1. Over pressurization of the upstream 1. Existing system has available protection for 5 1 5 2. Evaluate removing NRV (line 6"- SLFE

XXX2-1CA1P) condensate surge drum/other sources blocked flow BD-XXX2-1CA1P) on inlet line to

connected to common blowdown header Blowdown degassing vessel X89-

leading to LOC, fire & explosion causing D-0038A

multiple fatalities

2. Loss of level in the degassing drum (X89-D- 1. LIC-1001 will stop the pump (X89-G- 5 2 8

0038A), More fuel gas flow & possible gas 0016A/B) on low level

blowby to the pump (X89-G-0016A/B), pump 2. LALL-1003 will trip the pump (X89-G-

cavitation, pump damage, LOC, fire/explosion 0016A/B) on LL level

causing multiple fatalities

3. Spurious closure of ZV-1002 (6"-BD- 1. Over pressurization of the upstream 1. Existing system has available protection for 5 1 5

XXX2-1CA1P) condensate surge drum/other sources blocked flow

connected to common blowdown header

leading to LOC, fire & explosion causing

multiple fatalities

2. Loss of level in the degassing drum (X89-D- 1. LIC-1001 will stop the pump (X89-G- 5 2 8

0038A), More fuel gas flow & possible gas 0016A/B) on low level

blowby to the pump (X89-G-0016A/B), pump 2. LALL-1003 will trip the pump (X89-G-

cavitation, pump damage, LOC, fire/explosion 0016A/B) on LL level

causing multiple fatalities

4. Inadvertent closure of MOV-1005 (6"- 1. Over pressurization of the upstream 1. Existing system has available protection for 5 1 5

BD-XXX2-1CA1P) condensate surge drum/other sources blocked flow

connected to common blowdown header

leading to LOC, fire & explosion causing

multiple fatalities

2. Loss of level in the degassing drum (X89-D- 1. LIC-1001 will stop the pump (X89-G- 5 2 8

0038A), More fuel gas flow & possible gas 0016A/B) at low level

blowby to the pump (X89-G-0016A/B), pump 2. LALL-1003 will trip the pump (X89-G-

cavitation, pump damage, LOC, fire/explosion 0016A/B) at LL level

causing multiple fatalities

5. PIC-1001A malfunction causing PCV- 1. Level buildup in the degassing drum (X89-D- 1. LAHH-1003 will close the ZV-1002 and cut 5 1 5

1001A closure 0038A) overfilling and vessel over feed to degassing vessel

pressurization, & liquid carryover to the Flare, 2. PAHH-1010

damage to the flare header and flare

package, LOC, fire, and explosion with 3. PZV-1001/1002

possible multiple fatalities

6. PIC-1001A malfunction causing PCV- 1. Over pressurization, LOC, fire, and explosion 1. PAHH-1010 will open the ZV-1001 5 1 5 3. PCV-1001B (2"-RL-XX24- SLFE

1001B closure with possible multiple fatalities 2. PZV-1001/1002 1CA1P) to flare KO drum shall be

AFO

7. Inadvertent closure of 4'' manual 1. Level buildup in the degassing drum (X89-D- 1. LAHH-1003 will close the ZV-1002 and cut 5 1 5 4. 4-inch manual isolation valve (at SLFE

isolation valve at Degassing Tank 0038A) overfilling and vessel over feed to degassing vessel Degassing Tank outlet

outlet condensate line pressurization, & liquid carryover to the Flare, 2. PAHH-1010 condensate line 4"-BD-XXX3-

damage to the flare header and flare 1CA1P) to be CSO

package, LOC, fire, and explosion with 3. PZV-1001/1002

possible multiple fatalities

2. Possible pump (X89-G-0016A/B), cavitation 1. PALL-1030 will trip the pump on LL Suction 5 1 5 5. Configure low suction pressure SLFE

and damage, LOC, fire, and single fatality Pressure alarm on PIT-1022/1024 for

blowdown degassing vessel

pumps X89-P-0016A/B

8. Spurious closure of ZV-1003/1005 1. Level buildup in the degassing drum (X89-D- 1. LAHH-1003 will close the ZV-1002 and cut 5 1 5

0038A) overfilling and vessel over feed to degassing vessel

pressurization, & liquid carryover to the Flare, 2. PAHH-1010

damage to the flare header and flare

package, LOC, fire, and explosion with 3. PZV-1001/1002

possible multiple fatalities

2. Possible pump (X89-G-0016A/B), cavitation 1. PALL-1030 will trip the pump on LL Suction 5 1 5 5. Configure low suction pressure SLFE

and damage, LOC, fire, and single fatality Pressure alarm on PIT-1022/1024 for

2. Standby pump available based on auto blowdown degassing vessel

selector pumps X89-P-0016A/B

File Name: S22452-SLF HAZOP 1 of 6

Risk Ranking

Node No. Node Deviation Cause Consequence Effective Safeguards Recommendations Responsibility

S L RR

9. Inadvertent closure of 4'' manual 1. Level buildup in the degassing drum (X89-D- 1. LAHH-1003 will close the ZV-1002 and cut 5 1 5

isolation valve at pump (X89-G- 0038A) overfilling and vessel over feed to degassing vessel

0016A/B) suction line pressurization, & liquid carryover to the Flare, 2. PAHH-1010

damage to the flare header and flare

package, LOC, fire, and explosion with 3. PZV-1001/1002

possible multiple fatalities

2. Possible pump (X89-G-0016A/B), cavitation 1. PALL-1030 4 1 4 5. Configure low suction pressure SLFE

and damage, LOC, fire, and single fatality 2. Standby pump available based on auto alarm on PIT-1022/1024 for

selector blowdown degassing vessel

pumps X89-P-0016A/B

10. Running Pump trip (X89-G-0016A/B) 1. Level buildup in the degassing drum (X89-D- 1. LAHH-1003 will close the ZV-1002 and cut 5 1 5

0038A) overfilling and vessel over feed to degassing vessel

pressurization, & liquid carryover to the Flare, 2. PAHH-1010

damage to the flare header and flare

package, LOC, fire, and explosion with 3. PZV-1001/1002

possible multiple fatalities 4. Standby degassing drum pump available

based on auto selector

11. Stuck closure of NRV at pump (X89- 1. Level buildup in the degassing drum (X89-D- 1. LAHH-1003 will close the ZV-1002 and cut 5 1 5

G-0016A/B discharge 0038A) overfilling and vessel over feed to degassing vessel

pressurization, & liquid carryover to the Flare, 2. PAHH-1010

damage to the flare header and flare

package, LOC, fire, and explosion with 3. PZV-1001/1002

possible multiple fatalities

2. Pump blocked discharge, over pressurization 1. Standby pump available based on auto 4 1 4 6. Relocate NRV to downstream of SLFE

of the discharge line, LOC, fire, and possible selector PIT-1023/1025 (PAHH) for

single fatality blowdown degassing vessel

pumps X89-P-0016A/B

7. Configure high discharge SLFE

pressure alarm on PIT-1002/1003

for blowdown degassing pumps

X89-P-0016A/B

12. Inadvertent closure of 3'' manual 1. Level buildup in the degassing drum (X89-D- 1. LAHH-1003 will close the ZV-1002 and cut 5 1 5

isolation valve at pump (X89-G- 0038A) overfilling and vessel over feed to degassing vessel

0016A/B) discharge line pressurization, & liquid carryover to the Flare, 2. PAHH-1010

damage to the flare header and flare

package, LOC, fire, and explosion with 3. PZV-1001/1002

possible multiple fatalities

2. Pump blocked discharge, over pressurization 1. PAHH-1023 will trip the pump on HH 4 1 4 7. Configure high discharge SLFE

of the discharge line, LOC, fire, and possible Discharge Pressure pressure alarm on PIT-1002/1003

single fatality 2. Standby pump available based on auto for blowdown degassing pumps

selector X89-P-0016A/B

13. Spurious closure of ZV-1004/1006 1. Level buildup in the degassing drum (X89-D- 1. LAHH-1003 will close the ZV-1002 and cut 5 1 5

0038A) overfilling and vessel over feed to degassing vessel

pressurization, & liquid carryover to the Flare, 2. PAHH-1010

damage to the flare header and flare

package, LOC, fire, and explosion with 3. PZV-1001/1002

possible multiple fatalities

2. Pump blocked discharge, over pressurization 1. PAHH-1023 will trip the pump on HH 4 1 4 7. Configure high discharge SLFE

of the discharge line, LOC, fire, and possible Discharge Pressure pressure alarm on PIT-1002/1003

single fatality 2. Standby pump available based on auto for blowdown degassing pumps

selector X89-P-0016A/B

14. FCV-1001 stuck closed 1. Possible pump cavitation and damage, LOC, 1. LIC-1001 will stop the pump (X89-G- 4 1 4 5. Configure low suction pressure SLFE

fire, and possible single fatality 0016A/B) on low level alarm on PIT-1022/1024 for

2. LALL-1003 will trip the pump (X89-G- blowdown degassing vessel

0016A/B) on LL level pumps X89-P-0016A/B

3. PALL-1030 will trip the pump on LL Suction

Pressure

2. Less Flow 1. Partial chocking of degassing drum 1. Possible pump damage 1. Standby pump available based on auto 2 3 6 5. Configure low suction pressure SLFE

pump suction strainer selector alarm on PIT-1022/1024 for

blowdown degassing vessel

pumps X89-P-0016A/B

8. Provide high differential pressure SLFE

alarm across suction strainer of

degassing vessel pump X89-G-

016A/B

9. Update P&ID (VA-PP1061-001 SLFE

Rev. A) to include suction strainer

for degassing drum pump X89-G-

0016B

3. More Flow 1. Refer to No Flow Deviation

File Name: S22452-SLF HAZOP 2 of 6

Risk Ranking

Node No. Node Deviation Cause Consequence Effective Safeguards Recommendations Responsibility

S L RR

(More fuel gas flow & gas blowby

scenario)

2. Both degassing drum pumps running 1. Loss of level in the degassing drum (X89-D- 1. LIC-1001 will stop the pump (X89-G- 5 2 8

0038A), More fuel gas flow & possible gas 0016A/B) at low level

blowby to the pump (X89-G-0016A/B), pump 2. LALL-1003 will trip the pump (X89-G-

cavitation, pump damage, LOC, fire/explosion 0016A/B) at LL level

causing multiple fatalities

2. High level in the condensate surge drum (D- 1. FCV-0001A/B draining the condensate surge 5 2 8 10. Provide level control on LIT- SLFE

0002), overfilling, liquid carryover to the Flare, drum based on the high level of LIT-0027 0027 to stop degassing drum

damage to the flare header and flare pump G89-0016A/B on high

package, LOC, fire/explosion causing level of Condensate Surge drum

multiple fatalities D-0002

3. FCV-1001 fail open 1. Level buildup in the degassing drum (X89-D- 1. LAHH-1003 will close the ZV-1002 and cut 5 1 5

0038A) overfilling and vessel over feed to degassing vessel

pressurization, & liquid carryover to the Flare, 2. PAHH-1010

damage to the flare header and flare

package, LOC, fire, and explosion with 3. PZV-1001/1002

possible multiple fatalities

4. PIC-1001A malfunction causing PCV- 1. Level buildup in the degassing drum (X89-D- 1. LAHH-1003 will close the ZV-1002 and cut 5 1 5

1001B opening 0038A) overfilling & liquid carryover to the feed to degassing vessel

Flare, damage to the flare header and flare

package, LOC, fire, and explosion with

possible multiple fatalities

4. Misdirected Flow 1. Refer to No Flow Deviation

(More fuel gas flow & possible gas

blowby scenario)

5. Reverse Flow 1. No Credible Cause identified

6. More pressure 1. Refer to No Flow Deviation

7. Less Pressure 1. Refer to No Flow Deviation

8. More Temperature 1. Not applicable

9. Less Temperature 1. Not applicable

10. More Level 1. Refer to No Flow Deviation

11. Less Level 1. Refer to No Flow Deviation

12. Isolation/ Maintenance 1. No concerns

13. Corrosion 1. No concerns

14. Composition 1. No concerns

15. Human Factor 1. Refer to above Inadvertent valve

operation

16. Startup /Shutdown issues 1. No concerns

2 Produced Water Pumps X89-G- 1. No Flow 1. Inadvertent closure of 3'' manual 1. Less suction pressure for pump, cavitation, 1. PALL-1036 1 2 2 11. Configure low suction pressure SLFE

XXX3A/B isolation valve at pump (X89-G- and possible pump damage alarm on PAL-1034/1039 for

XXX3A/B) suction line Produced Water Pumps X89-G-

XXX3A/B

2. Running Pump trip (X89-G-XXX3A/B) 1. Level buildup in the degassing drum water 1. Standby pump available based on operator 3 1 3 12. Configure high level alarm on SLFE

boot & carry over to the condensate line selector LIT-1007 for degassing drum

leading to off spec product 2. Water stripping available in the subsequent water boot

equipment

3. Stuck closure of 2'' NRV 1. Pump blocked discharge & possible pump 1. None 1 3 3 13. Relocate NRV to downstream of SLFE

damage PIT-1038 for Produced Water

Pumps X89-G-XXX3A/B

14. Configure high pressure alarm SLFE

on PIT-1038 for Produced

Water Pumps X89-G-XXX3A/B

2. Level buildup in the degassing drum water 1. Standby pump available based on operator 3 1 3 12. Configure high level alarm on SLFE

boot & carry over to the condensate line selector LIT-1007 for degassing drum

leading to off spec product 2. Water stripping available in the subsequent water boot

equipment

4. Inadvertent closure of 2'' manual 1. Pump blocked discharge & possible pump 1. None 1 3 3 14. Configure high pressure alarm SLFE

isolation valve at pump (X89-G- damage on PIT-1038 for Produced

XXX3A/B) discharge line Water Pumps X89-G-XXX3A/B

2. Level buildup in the degassing drum water 1. Standby pump available based on operator 3 1 3 12. Configure high level alarm on SLFE

boot & carry over to the condensate line selector LIT-1007 for degassing drum

leading to off spec product 2. Water stripping available in the subsequent water boot

File Name: S22452-SLF HAZOP 3 of 6

Risk Ranking

Node No. Node Deviation Cause Consequence Effective Safeguards Recommendations Responsibility

S L RR

equipment

5. FCV-1003 stuck closed (not available 1. Less flow to the pump, resulting pump 1. PALL-1036 1 2 2 11. Configure low suction pressure SLFE

on demand) cavitation and possible pump damage alarm on PAL-1034/1039 for

Produced Water Pumps X89-G-

XXX3A/B

6. Downstream Causes (2'' existing 1. Pump blocked discharge & possible pump 1. FCV-1003 at recycle line 1 3 3 14. Configure high pressure alarm SLFE

manual isolation valve at line 2"-PW- damage 2. FALL-1003B will trip pump on LL flow on PIT-1038 for Produced

0001-3CS2P) Water Pumps X89-G-XXX3A/B

2. Less Flow 1. Partial chocking of pump suction 1. Less suction pressure for pump, cavitation, 1. PALL-1036 1 2 2 11. Configure low suction pressure SLFE

strainer and possible pump damage alarm on PAL-1034/1039 for

Produced Water Pumps X89-G-

XXX3A/B

3. More Flow 1. Both pumps running due to Inadvertent 1. Loss of level in water boot, possible 1. LALL-1009 will trip the pump at LL level 1 2 2

operation condensate carryover to the produced water 2. LAL-1007 will stop the pump at low level

side leading to more flaring

4. Misdirected Flow 1. No Credible Cause identified

5. Reverse Flow 1. No Credible Cause identified

6. More pressure 1. Refer to No Flow Deviation

7. Less Pressure 1. Refer to No Flow Deviation

8. More Temperature 1. No concerns

9. Less Temperature 1. No concerns

10. More Level 1. Refer to No Flow Deviation

11. Less Level 1. Refer to No Flow Deviation

12. Isolation/ Maintenance 1. No concerns

13. Corrosion 1. No concerns

14. Composition 1. Both pumps running due to Inadvertent 1. Loss of level in water boot, possible 1. LALL-1009 will trip the pump at LL level 1 2 2

operation condensate carryover to the produced water 2. LAL-1007 will stop the pump at low level

side leading to more flaring

2. Inadvertent closure of 2'' manual 1. Level buildup in the degassing drum water 1. Standby pump available based on operator 3 1 3 12. Configure high level alarm on SLFE

isolation valve at pump (X89-G- boot & carry over to the condensate line selector LIT-1007 for degassing drum

XXX3A/B) discharge line leading to off spec product 2. Water stripping available in the subsequent water boot

equipment

15. Human Factor 1. Refer to above Inadvertent valve

operation

16. Startup /Shutdown issues 1. No concerns

3 New Flare Package 1. No/ Less Flow 1. Closure of any single or multiple 1. Over pressurization of the Flare Header 1. BPV (pressure switch) provided which will 5 2 8

staging Valves due to loop malfunction leading to LOC, fire & explosion causing pop-up in case staging valve does not

(PIT-101/102/103) multiple fatalities function

2. XV closure on One stage while 1. Loss of smoke less operation of flare 1. BPV (pressure switch) provided which will 3 1 3

multiple staging lines are open pop-up in case staging valve does not

function

3. PCV-301 fail closed (Fuel Gas Line) 1. Flame out condition 1. Backup fuel supply in form of LPG 2 2 3

2. TE at burner tip for operator action to

activate FFG manually

3. TE at burner tip for automatic action by PLC

to activate HEI automatically

4. PCV-301 fail closed (Instrument Air 1. Loss of FFG ignition capability 1. HEI can provide ignition in case of loss of 2 2 3

Line) FFG ignition

2. More Flow 1. PCV-301 fail open (Fuel Gas Line) 1. Loss of FFG ignition capability 1. HEI can provide ignition in case of loss of 2 2 3 15. For permanent flare, ensure Zeeco

FFG ignition flame stability in the pilot in case

when PCV on the fuel gas line is

fully open

2. Possible Flame out condition with minor 1. TE at burner tip for operator action to 2 2 3 16. Evaluate cutting fuel gas supply Zeeco

environmental impact activate FFG manually to pilot in order to avoid

2. TE at burner tip for automatic action by PLC formation flammable gas cloud

to activate HEI automatically within enclosed flare

2. PCV-301 fail open (Instrument Air 1. Loss of FFG ignition capability 1. HEI can provide ignition in case of loss of 2 2 3 15. For permanent flare, ensure Zeeco

Line) FFG ignition flame stability in the pilot in case

when PCV on the fuel gas line is

fully open

3. Misdirected Flow 1. No Credible Cause identified

File Name: S22452-SLF HAZOP 4 of 6

Risk Ranking

Node No. Node Deviation Cause Consequence Effective Safeguards Recommendations Responsibility

S L RR

4. Reverse Flow 1. No Credible Cause identified

5. More pressure 1. Closure of any single or multiple 1. Over pressurization of the Flare Header 1. BPV (pressure switch) provided which will 5 2 8

staging Valves due to loop malfunction leading to LOC, fire & explosion causing pop-up in case staging valve does not

(PIT-101/102/103) multiple fatalities function

6. Less Pressure 1. No Credible Cause identified

7. More Temperature 1. No Credible Cause identified

8. Less Temperature 1. No Credible Cause identified

9. More Level 1. Not applicable

10. Less Level 1. Not applicable

11. Isolation/ Maintenance 1. Malfunction of XV on the nitrogen 1. Trapped gas in staging line, possible fire & 1. None 3 3 7 17. Evaluate provision of protection Zeeco

purge line in closed position flame reaching back up to closed XV causing measures for flame flash back

asset damage to flare piping

2. 1. 18. Provide isolation valve on (line SLFE

24"-RL-XX39-1CA1P) to new

flare and this valve shall be

marked as CSO when new

permanent flare is operational

19. Evaluate selection of valve type SLFE/ Zeeco

within flare package to ensure

reliable and positive isolation

12. Corrosion 1. No concerns

13. Composition 1. No concerns

14. Human Factor 1. No concerns

15. Startup /Shutdown issues 1. Refer to isolation

4 Mobile Flare (Temporary) 1. No/ Less Flow 1. PCV-001 fail closed (IA line) 1. Loss of FFG ignition capability 1. HEI can provide ignition in case of loss of 2 2 3

FFG ignition

2. Blocked strainer on IA Line 1. Loss of FFG ignition capability 1. HEI can provide ignition in case of loss of 2 2 3

FFG ignition

3. PCV-002 fail closed (Fuel Gas Line) 1. Loss of FFG ignition capability 1. HEI can provide ignition in case of loss of 2 2 3 20. Evaluate provision of back-up John Zink

FFG ignition fuel supply to pilot in case the

main fuel gas supply is

interrupted

4. Blocked strainer on the FG line 1. Loss of FFG ignition capability 1. HEI can provide ignition in case of loss of 2 2 3 20. Evaluate provision of back-up John Zink

FFG ignition fuel supply to pilot in case the

main fuel gas supply is

interrupted

5. PCV-003 closure 1. Pilot Flame loss 1. HEI can provide ignition in case of loss of 2 2 3 21. Fuel gas supply PCV-003 John Zink

FFG ignition isolation valves shall be CSO

2. PCV bypass line

2. More Flow 1. PCV-001 fail open (IA line) 1. Loss of FFG ignition capability 1. HEI can provide ignition in case of loss of 2 2 3

FFG ignition

2. PCV-002 fail open (Fuel Gas Line) 1. Loss of FFG ignition capability 1. HEI can provide ignition in case of loss of 2 2 3

FFG ignition

3. PCV-003 fail open 1. Pilot Flame loss 1. HEI can provide ignition in case of loss of 2 2 3 22. For temporary mobile flare, John Zink

FFG ignition ensure flame stability in the pilot

2. PCV bypass line in case when PCV-003 on the

fuel gas line is fully open

3. Misdirected Flow 1. No Credible Cause identified

4. Reverse Flow 1. No Credible Cause identified

5. More pressure 1. No Credible Cause identified

6. Less Pressure 1. No Credible Cause identified

7. More Temperature 1. No Credible Cause identified

8. Less Temperature 1. No Credible Cause identified

9. More Level 1. Not applicable

10. Less Level 1. Not applicable

11. Isolation/ Maintenance 1. 1. 23. Provide isolation valve on fuel SLFE

gas line (1"-FG-XX40-1CS1P)

to permanent flare & this should

be marked as CSO when new

File Name: S22452-SLF HAZOP 5 of 6

Risk Ranking

Node No. Node Deviation Cause Consequence Effective Safeguards Recommendations Responsibility

S L RR

flare is in operation

12. Corrosion 1. No concerns

13. Composition 1. No concerns

14. Human Factor 1. No concerns

15. Startup /Shutdown issues 1. Refer to isolation

File Name: S22452-SLF HAZOP 6 of 6

You might also like

- BasedictDocument6,070 pagesBasedictTeguh Setiadi100% (2)

- Mitsubishi Fault Codes PDFDocument38 pagesMitsubishi Fault Codes PDFMislav Perin100% (2)

- Institution Registration Number Name Course Unit Name Unit Code LecturerDocument9 pagesInstitution Registration Number Name Course Unit Name Unit Code LecturerJosline MuriikiNo ratings yet

- 05 - Andersen - Choke Collapse SimulationsDocument13 pages05 - Andersen - Choke Collapse Simulations903352No ratings yet

- 000 5Document185 pages000 5fahad jamilNo ratings yet

- NG7-40.5 Z Isatallation GuideDocument27 pagesNG7-40.5 Z Isatallation GuideWenceslao EscorzaNo ratings yet

- Daftar Harga Pompa Grunfos Terbaru Juni 2021Document158 pagesDaftar Harga Pompa Grunfos Terbaru Juni 2021lukmanNo ratings yet

- Water Hammer ReportDocument16 pagesWater Hammer Reportahemdmohi88% (8)

- Transient Drainage Processes in Storage ReservoirsDocument2 pagesTransient Drainage Processes in Storage ReservoirsshmomenyNo ratings yet

- Wandfluh Pre ControlDocument3 pagesWandfluh Pre Controlfrancis_15inNo ratings yet

- HAZOP TG Sekong DraftDocument51 pagesHAZOP TG Sekong DraftAnonymous akyLdkCB4FNo ratings yet

- CPU Trip Limit 1Document2 pagesCPU Trip Limit 1Bikash Kumar SahooNo ratings yet

- Features: 899 - 1A - F - C EDocument3 pagesFeatures: 899 - 1A - F - C EiskarupNo ratings yet

- Data Sheet 5.01 Issue C: Wet Alarm Valve Model B, D, EDocument1 pageData Sheet 5.01 Issue C: Wet Alarm Valve Model B, D, EpitigoiNo ratings yet

- RecommendationsDocument1 pageRecommendationsMuhammad SalmanNo ratings yet

- Hose Inflation Kit Sales SheetDocument2 pagesHose Inflation Kit Sales SheetForum PompieriiNo ratings yet

- Model SW-20 and SW-24 - 11.2 K-Factor Extended Coverage Ordinary Hazard Horizontal Sidewall Sprinklers (Standard Response)Document6 pagesModel SW-20 and SW-24 - 11.2 K-Factor Extended Coverage Ordinary Hazard Horizontal Sidewall Sprinklers (Standard Response)Mohammad IsmailNo ratings yet

- Model Back-To-Back Check/shuttle Valve With Signal at Port 2Document2 pagesModel Back-To-Back Check/shuttle Valve With Signal at Port 2Erasmo LimaNo ratings yet

- CSAD Full en Us LetterDocument2 pagesCSAD Full en Us LetterService - Anda Hydraulics Asia Pte LtdNo ratings yet

- Model Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Open Check Valve With Standard Pilot: Series 1 / Capacity: 15 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- High TAN Study SummuaryDocument3 pagesHigh TAN Study Summuary00083583rfNo ratings yet

- Arrestor ListDocument4 pagesArrestor ListHassan GDOURANo ratings yet

- Techniical DetailDocument42 pagesTechniical DetailAhmed AbdelgawadNo ratings yet

- Model SW-20 and SW-24 - 11.2 K-Factor Extended Coverage Ordinary Hazard Horizontal Sidewall Sprinklers (Standard Response) General DescriptionDocument6 pagesModel SW-20 and SW-24 - 11.2 K-Factor Extended Coverage Ordinary Hazard Horizontal Sidewall Sprinklers (Standard Response) General DescriptionAr JunNo ratings yet

- Series TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard Coverage General DescriptionDocument10 pagesSeries TY-B - 2.8, 5.6, and 8.0 K-Factor Upright, Pendent, and Recessed Pendent Sprinklers Standard Response, Standard Coverage General DescriptionJennifer SalamancaNo ratings yet

- 8 - C - NRL QachieverDocument4 pages8 - C - NRL Qachieverkaabach80No ratings yet

- LOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterDocument2 pagesLOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterHassan KhattabNo ratings yet

- 4857-59 Cable Schedule Sending End Switchyard Bay1Document1 page4857-59 Cable Schedule Sending End Switchyard Bay1Dev Dutt DwivediNo ratings yet

- Magnetrol TD2-8D00-032 + Tma-A210-007Document1 pageMagnetrol TD2-8D00-032 + Tma-A210-007BRUNONo ratings yet

- MC7900 ONSemiconductorDocument15 pagesMC7900 ONSemiconductorMansoor AsifNo ratings yet

- D D D D D D: A78L00 Series Positive-Voltage RegulatorsDocument14 pagesD D D D D D: A78L00 Series Positive-Voltage RegulatorsbaixadocNo ratings yet

- DFCB Es Us LetterDocument1 pageDFCB Es Us LetterLe HaiNo ratings yet

- TFP151 07 2018Document8 pagesTFP151 07 2018Mónica BaqueNo ratings yet

- GB088 2013 200 HS RP 003 - 1 PDFDocument225 pagesGB088 2013 200 HS RP 003 - 1 PDFMohammed AbdallaNo ratings yet

- CD74AC14E-U4 Datasheet ElectronicaDocument12 pagesCD74AC14E-U4 Datasheet ElectronicaYvàn Renato Vigil LozanoNo ratings yet

- 59 270001 Relay 793Document5 pages59 270001 Relay 793Ethan JanusNo ratings yet

- D D D D D D D D D: Description/ordering InformationDocument13 pagesD D D D D D D D D: Description/ordering InformationAdilson ToledoNo ratings yet

- Transformer Protection: Presented by MR. D G Pattanayak Dy MGR (Electrical)Document41 pagesTransformer Protection: Presented by MR. D G Pattanayak Dy MGR (Electrical)DUVASU UPNo ratings yet

- UL Listed 42 Bar FK 1230 (FK-5-1-12) Clean Agent SystemDocument7 pagesUL Listed 42 Bar FK 1230 (FK-5-1-12) Clean Agent SystemtanchoNo ratings yet

- FQCA Full Es Metric A4Document2 pagesFQCA Full Es Metric A4Sara SaritaNo ratings yet

- Contactor PDFDocument83 pagesContactor PDFjhamilcarNo ratings yet

- data-sheet-HLSA25G-255-4-0-10 465-EnDocument3 pagesdata-sheet-HLSA25G-255-4-0-10 465-EnThe Anh NguyenNo ratings yet

- Bisat C Sif ListDocument6 pagesBisat C Sif ListShamsuddin SoomroNo ratings yet

- Buchholz Relay NotesDocument7 pagesBuchholz Relay NotesjameelahmadNo ratings yet

- Type 1 and 2 Cooling Tower Nozzles, Crossflow General DescriptionDocument4 pagesType 1 and 2 Cooling Tower Nozzles, Crossflow General DescriptionhungNo ratings yet

- Problem 12 - Safety ContingenciesDocument29 pagesProblem 12 - Safety ContingenciesJorge Enciso AcuñaNo ratings yet

- Prs 680140103Document4 pagesPrs 680140103diaNo ratings yet

- 301 1C C D1Document3 pages301 1C C D1ssinokrotNo ratings yet

- Model Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11ADocument2 pagesModel Pilot-To-Close Check Valve: Series 1 / Capacity: 20 GPM / Cavity: T-11AErasmo LimaNo ratings yet

- HAZOP WorksheetDocument8 pagesHAZOP Worksheetxiaoyii9707No ratings yet

- Shut Down DefectsDocument4 pagesShut Down DefectsNIKHIL KSHIRSAGARNo ratings yet

- Shutdown Issue Unit#5 Upto Dec-15 Aux. Shutdown Issue ResponsibilityDocument4 pagesShutdown Issue Unit#5 Upto Dec-15 Aux. Shutdown Issue ResponsibilityNIKHIL KSHIRSAGARNo ratings yet

- MVI Titel Klapps. InhaltDocument14 pagesMVI Titel Klapps. InhaltAdamNo ratings yet

- 3.at Final Draw For P0089Document60 pages3.at Final Draw For P0089FILIN VLADIMIR100% (1)

- CKEB Full en Metric LetterDocument2 pagesCKEB Full en Metric LetterRafalNo ratings yet

- Pc1022-Me-Hdf-021-A1 - Rociador Abierto de EspumaDocument4 pagesPc1022-Me-Hdf-021-A1 - Rociador Abierto de EspumaDanilo ValenzuelaNo ratings yet

- AIC2951Document8 pagesAIC2951Edson ConceicaoNo ratings yet

- Phoenix Contact Termination CarrierDocument8 pagesPhoenix Contact Termination CarrierAndy Kong KingNo ratings yet

- Unisonic Technologies Co., LTD: Low Dropout Voltage RegulatorDocument12 pagesUnisonic Technologies Co., LTD: Low Dropout Voltage RegulatorjicoelhoNo ratings yet

- Ut-1201 Flow MeterDocument12 pagesUt-1201 Flow MeterRam KumarNo ratings yet

- Data Sheet - Rev.0Document4 pagesData Sheet - Rev.0mahesh reddy mNo ratings yet

- TFP 3153Document6 pagesTFP 3153Diego PinedaNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Control Narrative: Gas Facilities Projects Department Northern Area Gas Projects Division (Nagpd)Document27 pagesControl Narrative: Gas Facilities Projects Department Northern Area Gas Projects Division (Nagpd)Muhammad SalmanNo ratings yet

- RDP48052042Document42 pagesRDP48052042Muhammad SalmanNo ratings yet

- TBC - SWTF - SLFE Response - 30th MarchDocument21 pagesTBC - SWTF - SLFE Response - 30th MarchMuhammad SalmanNo ratings yet

- Ecr Ins 005 Sa ResponseDocument1 pageEcr Ins 005 Sa ResponseMuhammad SalmanNo ratings yet

- TBC-Alderlay - SLFE Response 30th Mar 2020Document24 pagesTBC-Alderlay - SLFE Response 30th Mar 2020Muhammad SalmanNo ratings yet

- RecommendationsDocument1 pageRecommendationsMuhammad SalmanNo ratings yet

- Calc Report EMERSONDocument2 pagesCalc Report EMERSONMuhammad SalmanNo ratings yet

- Rap 46001001Document1 pageRap 46001001Muhammad SalmanNo ratings yet

- Esd Tbe MR 011Document1 pageEsd Tbe MR 011Muhammad SalmanNo ratings yet

- Appendix-A: Attendance SheetDocument41 pagesAppendix-A: Attendance SheetMuhammad SalmanNo ratings yet

- CF.19.D032 - TBC-Petronash - SLFE Response-30th MarchDocument30 pagesCF.19.D032 - TBC-Petronash - SLFE Response-30th MarchMuhammad SalmanNo ratings yet

- ID Index File On Class: Saudi Aramco: Company General UseDocument7 pagesID Index File On Class: Saudi Aramco: Company General UseMuhammad SalmanNo ratings yet

- Initial Screening QuestionsDocument4 pagesInitial Screening QuestionsMuhammad SalmanNo ratings yet

- Taking The Control System For Granted - Ensuring The Integrity of Sub-Sil Instrumented FunctionsDocument5 pagesTaking The Control System For Granted - Ensuring The Integrity of Sub-Sil Instrumented FunctionsMuhammad SalmanNo ratings yet

- Componnent Failure ValuesDocument82 pagesComponnent Failure ValuesMuhammad SalmanNo ratings yet

- Et200s Terminalmodule Manual en-USDocument34 pagesEt200s Terminalmodule Manual en-USNimesh VaghelaNo ratings yet

- Solenoid Valves 3 - 2 General Service 327 CAT 80020GBDocument6 pagesSolenoid Valves 3 - 2 General Service 327 CAT 80020GBCecep AtmegaNo ratings yet

- Thursday If Got Out at 9Document2 pagesThursday If Got Out at 9Muhammad SalmanNo ratings yet

- Replace Crude Oil Samplers at Yanbu North TerminalDocument4 pagesReplace Crude Oil Samplers at Yanbu North TerminalMuhammad SalmanNo ratings yet

- Cpu 410 5h en En-UsDocument380 pagesCpu 410 5h en En-UsSaqib Afaq100% (1)

- AppendixDocument1 pageAppendixMuhammad SalmanNo ratings yet

- Replace Crude Oil Samplers at Yanbu North TerminalDocument4 pagesReplace Crude Oil Samplers at Yanbu North TerminalMuhammad SalmanNo ratings yet

- Remaing NMR ReviewDocument1 pageRemaing NMR ReviewMuhammad SalmanNo ratings yet

- 1-POC Termination 2 - FTA Numbers Were Changed and Assignment Was Changed 3 - Iom NUMBER 4 - Poc LAN CABINET ALARM Pib-1Document1 page1-POC Termination 2 - FTA Numbers Were Changed and Assignment Was Changed 3 - Iom NUMBER 4 - Poc LAN CABINET ALARM Pib-1Muhammad SalmanNo ratings yet

- Project Title: Replace Crude Oil Samplers - Yanbu North TerminalDocument1 pageProject Title: Replace Crude Oil Samplers - Yanbu North TerminalMuhammad SalmanNo ratings yet

- Replace Crude Oil Samplers at Yanbu North TerminalDocument4 pagesReplace Crude Oil Samplers at Yanbu North TerminalMuhammad SalmanNo ratings yet

- FT 205Document1 pageFT 205Muhammad SalmanNo ratings yet

- Workshop Creativity Input WorksheetDocument9 pagesWorkshop Creativity Input WorksheetMuhammad SalmanNo ratings yet

- Design 3, Estimation of The Hydro Power Potential For A Given Water Power Development SchemeDocument10 pagesDesign 3, Estimation of The Hydro Power Potential For A Given Water Power Development SchemeFarah MujahidNo ratings yet

- Surge Tanks - Surge - Pipes - Fluid Mechanics - Engineering Reference With Worked ExamplesDocument15 pagesSurge Tanks - Surge - Pipes - Fluid Mechanics - Engineering Reference With Worked ExamplesPRABHUTIRUPUR100% (2)

- Analysis and Design of A Surge TankDocument7 pagesAnalysis and Design of A Surge TankUchirai Dede100% (3)

- Lecture 4 Water Passages Part - IVDocument65 pagesLecture 4 Water Passages Part - IVAbram KhanNo ratings yet

- A Surge TankDocument23 pagesA Surge TankihllhmNo ratings yet

- !surge Tank Analysis For Water HammerDocument7 pages!surge Tank Analysis For Water HammerPHẠM HỒNG MINHNo ratings yet

- REG NO: F16/42422/2017: Name: Mukabwa Deone LukasiDocument12 pagesREG NO: F16/42422/2017: Name: Mukabwa Deone LukasiLukasi DeoneNo ratings yet

- Fluid Mechanics ReportDocument10 pagesFluid Mechanics ReportLukasi DeoneNo ratings yet

- Transient Flow AnalysisDocument14 pagesTransient Flow Analysiscpsankar100% (1)

- Design of Surge Tank For Water Supply Systems UsinDocument9 pagesDesign of Surge Tank For Water Supply Systems Usinmohamed hindawiNo ratings yet

- Surge Control PDFDocument14 pagesSurge Control PDFMohamed Guezguez100% (1)

- Chapter Four: Water Conveyance Structures: CanalDocument11 pagesChapter Four: Water Conveyance Structures: Canaljebril yusufNo ratings yet

- WH Chapter ExercisesDocument25 pagesWH Chapter ExercisesMegh Raj KCNo ratings yet

- Hydropower WCSDocument36 pagesHydropower WCSKathiravan ParameswaranNo ratings yet

- Function of Components of DamsDocument8 pagesFunction of Components of DamsAmber AliNo ratings yet

- Surge Tanks Surge Pipes Fluid Mechanics Engineering Reference With Worked Examples PDFDocument15 pagesSurge Tanks Surge Pipes Fluid Mechanics Engineering Reference With Worked Examples PDFtunlinooNo ratings yet

- Water Conductor SystemDocument47 pagesWater Conductor Systemsarvannn100% (3)

- WW Massal v9 1Document4 pagesWW Massal v9 1tunlinooNo ratings yet

- Surge Tanks: Presented By:-Vignesh VDocument25 pagesSurge Tanks: Presented By:-Vignesh VVignesh TamilanNo ratings yet

- Storage ReservoirDocument6 pagesStorage Reservoirmaaz hussainNo ratings yet

- Sump DesignDocument4 pagesSump DesignThiru AnanthNo ratings yet

- 06 Hydraulic TransientsDocument58 pages06 Hydraulic TransientsKike VergaraNo ratings yet

- Model Answer 15CE41T PDFDocument14 pagesModel Answer 15CE41T PDFPRAKASHA SNNo ratings yet

- Chapter 4Document22 pagesChapter 4Yasin Mohamed BulqaazNo ratings yet

- EPASurge Users GuideDocument27 pagesEPASurge Users GuideNattasit JiraissarakornNo ratings yet

- Economic Surge Tank DesignDocument6 pagesEconomic Surge Tank DesigncsimsekNo ratings yet

- Components of Hydropower Projects & DesignsDocument127 pagesComponents of Hydropower Projects & Designssharvan10No ratings yet