Professional Documents

Culture Documents

NWV BRZ 001 Modified

Uploaded by

Harmish mewada0 ratings0% found this document useful (0 votes)

16 views2 pagesThis document outlines the results of a brazing procedure qualification test conducted by Niowave, Inc. The test qualified the brazing of niobium to 304 stainless steel using an automatic vacuum furnace brazing process with 35% gold and 65% copper filler metal in the form of a 0.040 inch diameter wire. Mechanical tests on the brazed joint specimens showed a tensile strength of 20.1 ksi and compliance with other Code requirements. Niowave certifies that the brazing procedure qualification test was conducted in accordance with the applicable ASME Boiler and Pressure Vessel Code.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document outlines the results of a brazing procedure qualification test conducted by Niowave, Inc. The test qualified the brazing of niobium to 304 stainless steel using an automatic vacuum furnace brazing process with 35% gold and 65% copper filler metal in the form of a 0.040 inch diameter wire. Mechanical tests on the brazed joint specimens showed a tensile strength of 20.1 ksi and compliance with other Code requirements. Niowave certifies that the brazing procedure qualification test was conducted in accordance with the applicable ASME Boiler and Pressure Vessel Code.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views2 pagesNWV BRZ 001 Modified

Uploaded by

Harmish mewadaThis document outlines the results of a brazing procedure qualification test conducted by Niowave, Inc. The test qualified the brazing of niobium to 304 stainless steel using an automatic vacuum furnace brazing process with 35% gold and 65% copper filler metal in the form of a 0.040 inch diameter wire. Mechanical tests on the brazed joint specimens showed a tensile strength of 20.1 ksi and compliance with other Code requirements. Niowave certifies that the brazing procedure qualification test was conducted in accordance with the applicable ASME Boiler and Pressure Vessel Code.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

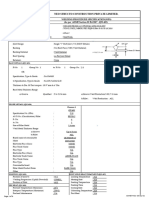

Niowave Proprietary

1012 North Walnut Street

Lansing, MI 48906

Phone: (517) 999-3475

Fax: (517) 999-3626

www.niowaveinc.com

Performance

Brazing Procedure Qualification (BPQ)

_____________________ – Niobium to Stainless Steel

Brazing Operator’s Name: __________ ID Number: NWV-BRZ-001

Testing Conditions and Ranges Qualified

Identification of BPS Followed During Brazing of Test Coupon: NWV-BPS-001

Specification of First Test Coupon Base Metal: Niobium

Specification of Second Test Coupon Base Metal: 304 Stainless Steel

Brazing Variables (QB-350) Actual Values Range Qualified

Brazing Process(es) Vacuum Furnace Vacuum Furnace

Type of Brazing (Manual, Semi-Automatic,

Automatic Automatic

Automatic,Machine)

Vacuum Brazing: Vacuum Level 10-5 10-5

Base Metal: P-Number (N/A) Niobium

to P-Number (102) Stainless Steel 304

N/A N/A

Plate Pipe (Enter diameter)

Base Metal Thickness 0.110” 0.06 in. to 1.00 in.

Joint Type (Butt, Lap, Scarf, Socket, etc.) Lap Lap, Butt

If Lap or Socket, Overlap Length 0.44” 0.25 in. to 1.00 in.

Joint Clearance 0.001” 0.0005 in. to 0.005 in.

Filler Metal (SFA) Specification(s) (info 35 Au / 65 Cu;

35 Au / 65 Cu

only) MFR. Part No. 1007

Filler Metal Classification(s) (info only) N/A N/A

Filler Metal/F-Number N/A N/A

Filler Metal Product Form Φ 0.040 in. Wire Φ 0.040 in. Wire

Flat Flow, Vertical

Brazing Flow Positions Horizontal Flow

Downflow; ± 45°

Page 1 of 2 August 18, 2010

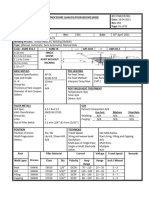

Niowave Proprietary

Niowave Proprietary

Testing and Results

Visual Examination of Completed Joint: Conforms Date of Test: 8-13-2010

Peel(QB-462.3) Section (QB-462.4) Tension (QB-462.1)

Mechanical Test

Transverse Bends(QB-462.2a) Longitudinal Bends(QB-462.2b)

Test Result

Tension Tensile Strength: 20.1 KSI

Peel Conforms

Mechanical Tests Conducted By: Company: Laboratory Testing, Inc.

Specimens Evaluated By: Sherri L. Scheifele Company: Laboratory Testing, Inc.

Lab Test Number: BNL001-10-08-25591-1

We certify that the statements in this record are correct and that the test coupons were prepared, brazed, and tested in

accordance with the requirements of Section IX of the ASME BOILER AND PRSSURE VESSEL CODE.

Manufacturer: Niowave, Inc.

Certified By: Matt Winowski Date: 8-18-2010

Page 2 of 2 August 18, 2010

Niowave Proprietary

You might also like

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Computer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Document1 pageComputer Engineering, Inc.: WPQ D1.1 - C - 5.2.0 Form 2000 Rev. 0Erick GoyesNo ratings yet

- BPQ Welder LoaizaDocument1 pageBPQ Welder LoaizaCARLOS ROMERONo ratings yet

- PWPS 102Document2 pagesPWPS 102Cyril J PadiyathNo ratings yet

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- HHHHHHHHJJJJJJ: O O O ODocument1 pageHHHHHHHHJJJJJJ: O O O OAli MoosaviNo ratings yet

- WPS For Carbon Steel THK 7.11 GTAWDocument1 pageWPS For Carbon Steel THK 7.11 GTAWAli Moosavi100% (1)

- Wps For Carbon Steel THK 7.11 GtawDocument1 pageWps For Carbon Steel THK 7.11 GtawAli MoosaviNo ratings yet

- PQR Acero Al CarbonoDocument2 pagesPQR Acero Al CarbonoROBERTO QUESADANo ratings yet

- Manufacturer's Welding Procedure (WPS) N.: Issued atDocument7 pagesManufacturer's Welding Procedure (WPS) N.: Issued atBelin InversoNo ratings yet

- Vind Flow Data CompressDocument5 pagesVind Flow Data CompressMohan BabuNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- 1108-DES-005 Rev02Document1 page1108-DES-005 Rev02Omar TocmoNo ratings yet

- (P1) NSC-1020-TR-0102-1.1-WPS-06Document6 pages(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaNo ratings yet

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Document2 pagesTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNo ratings yet

- Swathi Industries: JOINT (QW 402)Document10 pagesSwathi Industries: JOINT (QW 402)Mustu AkolawalaNo ratings yet

- WPS 7018+70S2Document8 pagesWPS 7018+70S2rajuNo ratings yet

- Welding Procedure Specification According To EN ISO 15609, 2004Document2 pagesWelding Procedure Specification According To EN ISO 15609, 2004Dimitris NikouNo ratings yet

- R UPERTY - Second API Line Pipe Basics QA QC Inspection and Testing 2011Document156 pagesR UPERTY - Second API Line Pipe Basics QA QC Inspection and Testing 2011Abdul Wajid AliNo ratings yet

- PQR GmawDocument4 pagesPQR GmawEr Sumant Kumar Singh0% (1)

- Visual Examination ReportDocument47 pagesVisual Examination ReportalouisNo ratings yet

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- Welder WQTDocument85 pagesWelder WQTKy100% (1)

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- KP WPS PQR GTAW FCAWDocument1 pageKP WPS PQR GTAW FCAWwahyuNo ratings yet

- Welding Procedure Specification "WPS": O O O ODocument1 pageWelding Procedure Specification "WPS": O O O OAli MoosaviNo ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- WPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0Document1 pageWPQ Ix - C - WPW 7.0.4 Form 2007 Rev. 0คุณพ่อน้อง บิ๊กบอส100% (1)

- KKJV WPS PP01Document2 pagesKKJV WPS PP01serbay tuncaNo ratings yet

- WPS A36 For PipesDocument3 pagesWPS A36 For PipesJuan AvellaNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- En Iso 9606 1 ADocument2 pagesEn Iso 9606 1 AvitharvanNo ratings yet

- KS31Document1 pageKS31Raúl SerranoNo ratings yet

- Needle Valves: Forged Integral BonnetDocument12 pagesNeedle Valves: Forged Integral Bonnetnnaemeka omekeNo ratings yet

- Expansion Bellow SpecificationDocument1 pageExpansion Bellow SpecificationASHWINI BHOSALENo ratings yet

- Datasheet & Specification For Deluge ValveDocument2 pagesDatasheet & Specification For Deluge ValvechintanNo ratings yet

- O O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Document1 pageO O O O: Illustration: Joint Design, Weld Layers and Bead Sequence 3.5+0.5Ali MoosaviNo ratings yet

- Erosion-Corrosion in Slurry Service - NACE CalgaryDocument17 pagesErosion-Corrosion in Slurry Service - NACE Calgaryzerocool86No ratings yet

- WPS&PQR For PipeDocument5 pagesWPS&PQR For PipeKAMALNo ratings yet

- sdg4 - 9 - STAINLESS STEELDocument3 pagessdg4 - 9 - STAINLESS STEELJian Ming WongNo ratings yet

- Negemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Document3 pagesNegemco For Engineering & Contracting Processing Equipment Welding Procedure Spcifications (Qw-482)Khaled GamalNo ratings yet

- Brazing BPS 107-1 PDocument5 pagesBrazing BPS 107-1 Pmbe josephNo ratings yet

- Sample and Injection Quill CatalogDocument48 pagesSample and Injection Quill Catalogdiego pinedaNo ratings yet

- 123HAN BPS 02 - Rev.2Document1 page123HAN BPS 02 - Rev.2ABDUL RAHMAN ALI MIRNo ratings yet

- Welder Approval CertDocument1 pageWelder Approval Certlee.ramsell1No ratings yet

- WPS-4 ADocument3 pagesWPS-4 AaleventNo ratings yet

- WPS SertipDocument3 pagesWPS SertipMassimo FumarolaNo ratings yet

- SPL - PQR-WPS-SWPS SmawDocument7 pagesSPL - PQR-WPS-SWPS Smawgopuvinu4uNo ratings yet

- Welding Procedure Specification (WPS)Document2 pagesWelding Procedure Specification (WPS)Abdulmecit YetisNo ratings yet

- Phoenix Contact 5452027 enDocument7 pagesPhoenix Contact 5452027 enDGNo ratings yet

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- Diaphragm - Type Diaphragm SealType L990.10Document4 pagesDiaphragm - Type Diaphragm SealType L990.10harglugurNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- Welder'S and Welding Operators Qualification Test Certificate ACCORDING TO ASME IX Edition 2017Document1 pageWelder'S and Welding Operators Qualification Test Certificate ACCORDING TO ASME IX Edition 2017Ahmad Nabil ElsharkawyNo ratings yet

- Jhabua-Sor 20200702 181504Document4 pagesJhabua-Sor 20200702 181504Suaib VCSNo ratings yet

- Madap CertificateDocument1 pageMadap Certificateisrafil mirzaNo ratings yet

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- Catalogue CNA 50Hz Rev.1 Update 6-1Document6 pagesCatalogue CNA 50Hz Rev.1 Update 6-1Rido MardanNo ratings yet

- API 510 ClosedDocument15 pagesAPI 510 ClosedHarmish mewadaNo ratings yet

- Document 20Document32 pagesDocument 20Harmish mewadaNo ratings yet

- API 510 Hydrostatic Head PressureDocument40 pagesAPI 510 Hydrostatic Head PressureHarmish mewadaNo ratings yet

- New Doc 2017-11-29 23.38.58Document8 pagesNew Doc 2017-11-29 23.38.58Harmish mewadaNo ratings yet

- Field Joint Developments and Compatibility Considerations: October 2003Document13 pagesField Joint Developments and Compatibility Considerations: October 2003Harmish mewadaNo ratings yet

- Group 6 ManufacturingDocument15 pagesGroup 6 ManufacturingAli JavedNo ratings yet

- GF-OGF4-J-SP-1008 - Material Specification For Piping and Valves - Rev 1 - CODE AFCDocument159 pagesGF-OGF4-J-SP-1008 - Material Specification For Piping and Valves - Rev 1 - CODE AFCRami Ksida100% (1)

- Business Plan AssignmentDocument9 pagesBusiness Plan AssignmentIqra UsamaNo ratings yet

- Internship Report - Roopam Kr. RajDocument34 pagesInternship Report - Roopam Kr. RajRoopam Kumar RajNo ratings yet

- Product Description Sheet Nordbak High Temperature Pneu-WearDocument2 pagesProduct Description Sheet Nordbak High Temperature Pneu-WearANDRESMARTESNo ratings yet

- QCS 2014 Section 13 Part 04Document5 pagesQCS 2014 Section 13 Part 04Glexer Dazo CorralesNo ratings yet

- Bill of Quantity: Baner Lifespaes LLPDocument1 pageBill of Quantity: Baner Lifespaes LLPSales AlufacadesNo ratings yet

- Quiz LetDocument25 pagesQuiz LetChristopher Lennon Dela CruzNo ratings yet

- Additive Manufacturing: MIT 2.008xDocument113 pagesAdditive Manufacturing: MIT 2.008xYasir KhanNo ratings yet

- Preparation of Ointments: IncorporationDocument2 pagesPreparation of Ointments: IncorporationIonel DiaconuNo ratings yet

- ORD 5700 Parker O-Ring HandbookDocument292 pagesORD 5700 Parker O-Ring Handbookcalaverilandia100% (1)

- Gearbox Alignment Bolt Change 40-20-42 Sundyne Field Engineering BulletinDocument2 pagesGearbox Alignment Bolt Change 40-20-42 Sundyne Field Engineering Bulletinjamil ahmedNo ratings yet

- Design and Evaluation of Biomass FurnaceDocument18 pagesDesign and Evaluation of Biomass FurnaceChie ChieNo ratings yet

- Ebay Gold RecoveryDocument11 pagesEbay Gold RecoveryAFLAC ............90% (10)

- AD 2000-Merkblatt: Cast Steel W5Document8 pagesAD 2000-Merkblatt: Cast Steel W5Diogo CunhaNo ratings yet

- Quotation of The Chamber Filter Press XY16-450-30U (210824)Document7 pagesQuotation of The Chamber Filter Press XY16-450-30U (210824)Sebastian Sanchez PolancoNo ratings yet

- Clinipak Medical Catalogue 2017Document60 pagesClinipak Medical Catalogue 2017Mosolygó RóbertNo ratings yet

- Extraction of ZincDocument15 pagesExtraction of ZincAmit MishraNo ratings yet

- Specification For FRP Weir and Scum BafflesDocument4 pagesSpecification For FRP Weir and Scum BafflesTS WongNo ratings yet

- WELDINGDocument6 pagesWELDINGDinusha ThirimaduraNo ratings yet

- Abloy Door Closers: Exactly The Right ChoiceDocument24 pagesAbloy Door Closers: Exactly The Right ChoiceTamta ZakarashviliNo ratings yet

- CivilDAR - 2019 Basic RatesDocument118 pagesCivilDAR - 2019 Basic RatesDeepak ChandolaNo ratings yet

- Weld DefectsDocument9 pagesWeld DefectsshankarNo ratings yet

- Construction Supplies For Buildings and FurnituresDocument6 pagesConstruction Supplies For Buildings and FurnituresMarata Steve60% (5)

- Makinda Hollow Block Making MachineDocument117 pagesMakinda Hollow Block Making MachineMuhajir MashuaNo ratings yet

- Gauge Hatches: MODEL 95004Document4 pagesGauge Hatches: MODEL 95004GauravNo ratings yet

- Lab Report Lathe TurningDocument13 pagesLab Report Lathe TurningSohaliaNo ratings yet

- PP34. Rev.1xlsDocument1 pagePP34. Rev.1xlsS GoudaNo ratings yet

- Bill of Material: 103V2 - HSS8X8X5/16 - 17'-1 3/8" - 2 REQ'DDocument1 pageBill of Material: 103V2 - HSS8X8X5/16 - 17'-1 3/8" - 2 REQ'Dai ambaraNo ratings yet

- Plem Design and Analysis - OilfieldWikiDocument4 pagesPlem Design and Analysis - OilfieldWikilsatchithananthanNo ratings yet