Professional Documents

Culture Documents

2.9 Borescope Inspection

Uploaded by

BILAL FAROOQUIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2.9 Borescope Inspection

Uploaded by

BILAL FAROOQUICopyright:

Available Formats

Part: 2

SHOP PROCEDURE MANUAL (SPM)

Chapter: 2.9

Issue: 05

BORESCOPE INSPECTION (BSI) Revision: 00

Date: 22-Nov-2021

2.9. BORESCOPE INSPECTION..................................................................................................................................... 2

2.9.1. PURPOSE..................................................................................................................................................................2

2.9.2. RESPONSIBILITY....................................................................................................................................................... 2

2.9.3. SCOPE:..................................................................................................................................................................... 2

2.9.4. BSI GENERAL PROCEDURE OF WORK PROCESS........................................................................................................2

2.9.4.1. INCOMING/OUTGOING, LEASE RETURN, SHOP VISIT ENGINE BSI PROCEDURE..............................................3

2.9.5. FORMS IN USE:........................................................................................................................................................ 4

2.9.6. RECORDS OF WORK ACCOMPLISHMENT.................................................................................................................4

Serene Engineering Services (Pvt.) Ltd. Page 1 of 6

Part: 2

SHOP PROCEDURE MANUAL (SPM)

Chapter: 2.9

Issue: 05

BORESCOPE INSPECTION (BSI) Revision: 00

Date: 22-Nov-2021

2.9. BORESCOPE INSPECTION

Documents Referred: Forms: SES-SHOP-3201, SES-SHOP-3203, SES-SHOP-3202, SES-SSPC-1110

2.9.1. PURPOSE

The purpose of this chapter is to define procedure undertaken by Boroscopic Inspection

authorization holder(s) as specialized activity as per scope defined in MOE 1.9.6.

2.9.2. RESPONSIBILITY

1. Prime responsibility for control of these procedure lies with the DDE (Form-04 Holder)

whereas, BSI authorization holder(s) are equally responsible for managing and keeping these

procedures updated.

2. BSI authorization holder(s) is responsible to ensure no work shall be carried out outside

the scope unless approved.

3. Any unapproved procedure must not be adopted unless specified otherwise.

4. BSI authorization holder(s) is responsible to ensure no minor or major changes are

allowed unless brought in knowledge of the DDE and approved by CE &TQA.

2.9.3. SCOPE:

BSI authorization holder(s) shall be responsible for keeping updated the scope of approval as

defined in MOE section 1.9.6.

2.9.4. BSI GENERAL PROCEDURE OF WORK PROCESS

1. Ensure receiving of ARO/WO/UWO along with task card from SSPC office or receiving of

FWO from concern department.

2. Evaluate the given task according to shop capability & scope. If does not fall within shop

capability/scope inform to SSPC office immediately.

3. If the task found within shop capability/scope, then enter the task on shop

incoming/outgoing register (SES-SHOP-3201).

4. Check availability of adequate tools/equipment in shop for respective task. If found

anomaly anything, inform to SSPC office immediately for further action.

5. Study the task card for proper execution of inspection on specified area.

6. Ensure proper access to the inspection area before commencing for the inspection as

per applicable manual.

7. Make sure to follow the procedure in the AMM/EMM when remove BSI plugs and

cranking pad.

8. Ensure proper N1 and N2 indexing by manually rotate the engine.

9. For APU inspection ensure to rotate starter motor in the correct direction as per AMM.

10. Make proper video of the inspection for its record and evaluation.

11. During inspection monitor all previous findings (if any) and do the measurement of

findings wherever possible/necessary.

Serene Engineering Services (Pvt.) Ltd. Page 2 of 6

Part: 2

SHOP PROCEDURE MANUAL (SPM)

Chapter: 2.9

Issue: 05

BORESCOPE INSPECTION (BSI) Revision: 00

Date: 22-Nov-2021

12. Check the updated AMM/EMM for the limitations of findings.

13. When re-installing BSI plugs, be ensure to apply recommended lubricant to the thread

and carefully follow the torqueing procedures in the AMM by authorized personnel.

14. After inspection enter all the observations and finding on the work sheet i.e. WO/

ARO/UWO/FWO and Borescope Inspection Record forms.

15. Ensure work sheet or task card is dully filled and all respective column are properly

signed by the authorize personnel as per procedure defined in MEP 05.1.9.

16. Record the results on Borescope Inspection Record and BSI Job record (SES-SHOP-3202).

17. Authorized BSI personnel and LAME ensure to make an entry after every BSI inspection

in Aircraft technical log book.

18. Record the outgoing date on incoming/outgoing register before dispatching the task

card to concern department.

19. Send an Email to MCC or SSPC/PPC after the completion of task on aircraft and in case of

any special health monitoring interval must send an email to customer’s CAMO department

for proper follow up.

20. Prepare a BSI report (SES-SHOP-3203) either general or comparative report according to

the valued customer’s recommendations.

21. During BSI inspection anything found beyond AMM limits inform to CE line maintenance

and LAME.

22. All BSI videos recording shall be maintained on SES Server or in external HDD for backup

(All BSI recording is control through Engine ESN and inspection date).

23. Keep the record of the completed work package (worksheet, WO/UWO/FWO & Form 01

etc.) along with supporting documents in soft or hard copy for 3 years.

24. Completed Work Package Forwarded to SSPC office for further necessary action at their

end.

Serene Engineering Services (Pvt.) Ltd. Page 3 of 6

Part: 2

SHOP PROCEDURE MANUAL (SPM)

Chapter: 2.9

Issue: 05

BORESCOPE INSPECTION (BSI) Revision: 00

Date: 22-Nov-2021

2.9.4.1. WORK FLOW DIAGRAM OF GENERAL PROCEDURE FOR BSI SHOP

INCOMING WO/ARO/UWO/FWO

ASCERTAINING OF WORK

REQUIRED NO

EVALUATE REQUIREMENTS AS PER

APPLICABLE MAINTENANCE DATA

ANALYSIS OF TOLLS

& EQUIPMENT FOR

NO

WORK

ENTER IN INCOMING OUTGOING

RECORD PREPARATION OF

INSTRUMENT

JOB PERFORM AS PER AMM/OEM

RECOMMENDED DATA

JOB FINDING

UNSATISFACTORY

(SATISFACTORY)

INFORM SSPC

FINALIZE DOCUMENTS

(WORK ORDER. TASK CARD, ETC.)

UPDATE

INCOMING OUTGOING RECORD

Serene Engineering Services (Pvt.) Ltd. Page 4 of 6

Part: 2

SHOP PROCEDURE MANUAL (SPM)

Chapter: 2.9

Issue: 05

BORESCOPE INSPECTION (BSI) Revision: 00

Date: 22-Nov-2021

2.9.4.2. INCOMING/OUTGOING, LEASE RETURN, SHOP VISIT ENGINE BSI PROCEDURE

Whenever required, for any Engine & APU used or on loan basis, it may be necessary to

perform complete BSI of engine and/or APU, however for that purpose previous operator’s

documents including ARC shall be required for history and trend monitoring.

Whenever Engine/ APU shall be sent for repair to engine shop or returned back to its owner

a BSI may also be performed on request of operator.

PREPARATION FOR INSPECTION

1. Move handset from the storage box with insertion tube and carry out it according to

requirements.

2. Ensure that the battery is fully charge by pressing the battery symbol on the front of the

battery.

3. Insert the battery into the handset then turn the power on by long pressing the power.

4. Button on the handset.

5. Touch the menu button which provides access to several features including Setup,

File Manager, Profile, Record, Shut down etc. by the use of joy stick.

6. By the use of menu button and select the operating language.

7. Verify that the optical tip is proper installed onto the probe by gentle turn the tip

clockwise with finger tight, to prevent from falling into the inspection area.

8. Add the folder with respect to aircraft type and position of engine where all the data

regarding the inspection will be save.

9. Now instrument is fully prepared for the inspection while insert the probe gently inside

the respective ports to inspect for any damages, flaws and defects.

10. Record the video where ever it is necessary or save images.

11. If any damage is found measure the entire damages dimension using measurement

option.

12. Record all the damages in specific folder in the form of images and videos.

13. Now turn off the instrument and secure as prescribed by the OEM

CAUTIONS:

1. Ensure that flexible probe should not be bend by force.

2. Ensure HOME button must be pressed before pulling out the flexible probe.

2.9.5. FORMS IN USE:

All list of controlled forms used in BSI section shall be maintained by SSPC office on SES-SSPC-

1110.

2.9.6. RECORDS OF WORK ACCOMPLISHMENT

Serene Engineering Services (Pvt.) Ltd. Page 5 of 6

Part: 2

SHOP PROCEDURE MANUAL (SPM)

Chapter: 2.9

Issue: 05

BORESCOPE INSPECTION (BSI) Revision: 00

Date: 22-Nov-2021

ALL procedure defined on SPM part 01 regarding filling of work sheet, WO, ARO, UWO and

FWO shall be applicable to complete the work package and keep the all work

accomplishment documents in records for 3 years.

Serene Engineering Services (Pvt.) Ltd. Page 6 of 6

You might also like

- Computer Aided Process Planning (CAPP): 2nd EditionFrom EverandComputer Aided Process Planning (CAPP): 2nd EditionNo ratings yet

- 2.6 Battery Shop (c05)Document6 pages2.6 Battery Shop (c05)BILAL FAROOQUINo ratings yet

- 2.5 Electrical & Avionics Shop (c03, c05 & c06)Document5 pages2.5 Electrical & Avionics Shop (c03, c05 & c06)BILAL FAROOQUINo ratings yet

- 2.7 Galley Equipment Shop (c06)Document5 pages2.7 Galley Equipment Shop (c06)BILAL FAROOQUINo ratings yet

- 2.8 NDT Bsi ShopDocument5 pages2.8 NDT Bsi ShopBILAL FAROOQUINo ratings yet

- 1 3 Engineering Business PlanningDocument2 pages1 3 Engineering Business PlanningBILAL FAROOQUINo ratings yet

- 016calibration ProcedurDocument21 pages016calibration ProcedurYudha Andrie Sasi ZenNo ratings yet

- A HandBook On Finacle Work Flow Process 1st EditionDocument79 pagesA HandBook On Finacle Work Flow Process 1st EditionSpos Udupi100% (2)

- ATMS MDCBP Method Statement For Masonry Works CHB Laying Plastering TB OnlyDocument8 pagesATMS MDCBP Method Statement For Masonry Works CHB Laying Plastering TB OnlycuanicochorielynjuviNo ratings yet

- Bsn-Ip-13 - Eot Crane ProcedureDocument14 pagesBsn-Ip-13 - Eot Crane Procedureragesh r nairNo ratings yet

- PSM-COM 2 Internal AuditDocument8 pagesPSM-COM 2 Internal AuditThich LikeNo ratings yet

- Unit Test / Integration Test Script TEST SCRIPT: Release Budgeting Scenario Module: Ps PROCESS: Release Budgeting ScenarioDocument6 pagesUnit Test / Integration Test Script TEST SCRIPT: Release Budgeting Scenario Module: Ps PROCESS: Release Budgeting ScenarioDanielpremassisNo ratings yet

- 200.1.03.02.preventive Maintenance v0.7Document28 pages200.1.03.02.preventive Maintenance v0.7Neeraj TiwariNo ratings yet

- June09release Teststrategy v2.0Document21 pagesJune09release Teststrategy v2.0livy loveNo ratings yet

- Documento 5Document53 pagesDocumento 5JuancarlosNo ratings yet

- UT2.WBS Release and Auc CreationDocument6 pagesUT2.WBS Release and Auc CreationDanielpremassisNo ratings yet

- Operations & Maintenance Engineering RCM Handbook: Eni S.p.A. Exploration & Production DivisionDocument124 pagesOperations & Maintenance Engineering RCM Handbook: Eni S.p.A. Exploration & Production DivisionGlad BlazNo ratings yet

- 26071-100-VSC-BD4-00028 - 00A - Work Method Statement For Bituminous Coating Rev.00A (R)Document13 pages26071-100-VSC-BD4-00028 - 00A - Work Method Statement For Bituminous Coating Rev.00A (R)rony_lesbtNo ratings yet

- ABB-GEN-CNS-MOS-GPS-16015-00002-U-00 - Earth Work For Off Loading FaciliDocument10 pagesABB-GEN-CNS-MOS-GPS-16015-00002-U-00 - Earth Work For Off Loading Facilisaravana.bNo ratings yet

- Ujvnl PM Calibration Maintenance User ManualDocument40 pagesUjvnl PM Calibration Maintenance User ManualSiva Thunga50% (2)

- Mobis Isir ManualDocument17 pagesMobis Isir ManualGabriel MolinaNo ratings yet

- IMP206 PipelinesDocument11 pagesIMP206 PipelinesMurali KumaraguruNo ratings yet

- TECHOP - ODP - 16 - (P) - Part - 2 - (DP SME PRACTITIONER COMPETENCY ELEMENTS) - INTERIM - Ver1 - 03201921 PDFDocument45 pagesTECHOP - ODP - 16 - (P) - Part - 2 - (DP SME PRACTITIONER COMPETENCY ELEMENTS) - INTERIM - Ver1 - 03201921 PDFDouglas BemficaNo ratings yet

- Maintenance Management System Guideline For Maintenance Operating Procedures Global Maintenance Service ManagementDocument43 pagesMaintenance Management System Guideline For Maintenance Operating Procedures Global Maintenance Service ManagementGlad BlazNo ratings yet

- Maintenance Management System Guideline For Maintenance Operating Procedures Corrective MaintenanceDocument22 pagesMaintenance Management System Guideline For Maintenance Operating Procedures Corrective MaintenanceGlad BlazNo ratings yet

- 2-Table of ContentsDocument4 pages2-Table of ContentsAmyNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- Control of Non-ConformanceDocument6 pagesControl of Non-ConformanceLawzy Elsadig Seddig100% (1)

- QA ProcessDocument4 pagesQA Processmadhu krishnaNo ratings yet

- D-p5-Bv-pd-006 - Tofd, Issue 01, Rev 00 - Time of Flight Diffraction InspectionDocument33 pagesD-p5-Bv-pd-006 - Tofd, Issue 01, Rev 00 - Time of Flight Diffraction InspectionThinh NguyenNo ratings yet

- 000-ZA-E-09413 Construction Progress Meas ProcDocument12 pages000-ZA-E-09413 Construction Progress Meas Procalinor_tnNo ratings yet

- RP2 - Findings Matrix - Aspac Worldwide Logistics, Inc, Superhawk Logistics Inc. & Aspac International Inc. - QE-1SA-7&8 Jul 2022 (ACCOMPLISHED)Document1 pageRP2 - Findings Matrix - Aspac Worldwide Logistics, Inc, Superhawk Logistics Inc. & Aspac International Inc. - QE-1SA-7&8 Jul 2022 (ACCOMPLISHED)Amado LobitosNo ratings yet

- QMP-10 New Product DevelopmentDocument15 pagesQMP-10 New Product Developmentom cnc100% (1)

- M270H1 L01 PDFDocument27 pagesM270H1 L01 PDFIrwantoirwanNo ratings yet

- Checklist GuidelinesDocument11 pagesChecklist GuidelinesCMDT-59 GeraldoNo ratings yet

- CIE Exam Notice 7th and 9th April 2022Document1 pageCIE Exam Notice 7th and 9th April 2022Sunny SharmaNo ratings yet

- MS 092 Bidirectional Cell Rev.0Document83 pagesMS 092 Bidirectional Cell Rev.0jibeesh cmNo ratings yet

- User Manual ENG ESPDocument90 pagesUser Manual ENG ESPjorge_t_71No ratings yet

- AMO Procedure Manual Issue Dt-14 Aug 2022Document1,084 pagesAMO Procedure Manual Issue Dt-14 Aug 2022Benzeer TanhaNo ratings yet

- Maintenance Management System Guideline For Maintenance Operating Procedures Preventive MaintenanceDocument22 pagesMaintenance Management System Guideline For Maintenance Operating Procedures Preventive MaintenanceGlad BlazNo ratings yet

- Pacs Analysis Corrections Tsr-195396 v1.0Document6 pagesPacs Analysis Corrections Tsr-195396 v1.0Shaqif Hasan SajibNo ratings yet

- TECHOP (P-01 - Rev1 - Jan21) PART 2 - COMPETENCY FOR DP PROFESSIONALS - DP SMEsDocument44 pagesTECHOP (P-01 - Rev1 - Jan21) PART 2 - COMPETENCY FOR DP PROFESSIONALS - DP SMEsGMNo ratings yet

- Ims-Sop-F02-Ehv Tower Erection StringingDocument7 pagesIms-Sop-F02-Ehv Tower Erection StringingAnonymous cj7JdRbDbNo ratings yet

- KrisEnergy (Gulf of Thailand) - CoatingDocument21 pagesKrisEnergy (Gulf of Thailand) - CoatingsuriyaNo ratings yet

- Qatif Method Statement GroutingDocument13 pagesQatif Method Statement GroutingelbaraniNo ratings yet

- WSM-PSFP-01 Piping Spool Fabrication Procedure PDFDocument14 pagesWSM-PSFP-01 Piping Spool Fabrication Procedure PDFMiky AndreanNo ratings yet

- Piping Spool Fabrication ProcedureDocument14 pagesPiping Spool Fabrication ProcedureMiky Andrean100% (6)

- R&D Procedure - Control of Drawing Engg Specification P2Document1 pageR&D Procedure - Control of Drawing Engg Specification P2sumanNo ratings yet

- It 03 00 03 Rev002 Sonar Op in RovDocument4 pagesIt 03 00 03 Rev002 Sonar Op in RovJoão Leandro LimaNo ratings yet

- AVU Operating Manual Rev. 07Document965 pagesAVU Operating Manual Rev. 0700083583rfNo ratings yet

- BST7A - Test 2 BMFG4043 - Feb 2021Document12 pagesBST7A - Test 2 BMFG4043 - Feb 2021luqman malayNo ratings yet

- Internship Report of M.Shahzad PDFDocument64 pagesInternship Report of M.Shahzad PDFinzamamalam515No ratings yet

- ABAP SkillsDocument183 pagesABAP SkillsAnil KumarNo ratings yet

- IMee Report (1) - MergedDocument62 pagesIMee Report (1) - MergedRaiden mathewNo ratings yet

- Lube Oil Console Functional Test ProcedureDocument10 pagesLube Oil Console Functional Test Proceduremohamedsaib438No ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)Document6 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level)bubbles82No ratings yet

- En-7825101 MAF Palletizer 2007 Standard V1.1Document121 pagesEn-7825101 MAF Palletizer 2007 Standard V1.1gabrielpasut5No ratings yet

- ABAP Program Tips v3Document159 pagesABAP Program Tips v3avijeet negelNo ratings yet

- Nde ProceduresDocument66 pagesNde Proceduressoumaya yahyaouiNo ratings yet

- LDAR TemplateDocument56 pagesLDAR TemplateJohnNo ratings yet

- ATS NED Project-BilalDocument17 pagesATS NED Project-BilalBILAL FAROOQUINo ratings yet

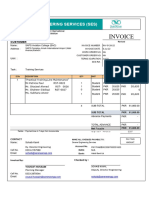

- INV 0141 22 (Air Sial Limited)Document1 pageINV 0141 22 (Air Sial Limited)BILAL FAROOQUINo ratings yet

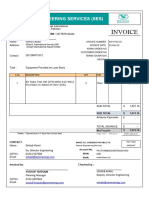

- Inv 0131 22Document1 pageInv 0131 22BILAL FAROOQUINo ratings yet

- INV 0141 22 (Air Sial Limited)Document1 pageINV 0141 22 (Air Sial Limited)BILAL FAROOQUINo ratings yet

- 1204 Ses Shops Arc Form 1 RecordDocument1 page1204 Ses Shops Arc Form 1 RecordBILAL FAROOQUINo ratings yet

- 1201-Ses-Shop Shop Production ReportDocument1 page1201-Ses-Shop Shop Production ReportBILAL FAROOQUINo ratings yet

- Automotive Maintenance - PDF PDF BooksDocument100 pagesAutomotive Maintenance - PDF PDF BooksBILAL FAROOQUINo ratings yet

- Proposal FypDocument2 pagesProposal FypBILAL FAROOQUINo ratings yet

- Inv 0131 22Document1 pageInv 0131 22BILAL FAROOQUINo ratings yet

- Whole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022Document2 pagesWhole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022BILAL FAROOQUINo ratings yet

- Inv 0128 22Document1 pageInv 0128 22BILAL FAROOQUINo ratings yet

- INV 0132 22 (Gerry's Dnata)Document1 pageINV 0132 22 (Gerry's Dnata)BILAL FAROOQUINo ratings yet

- Inv 0131 22Document1 pageInv 0131 22BILAL FAROOQUINo ratings yet

- Whole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022Document2 pagesWhole - Man-hour-SSPC-Man Hour Plan (Planning & EBD) - 2022BILAL FAROOQUINo ratings yet

- DPR 2023Document4 pagesDPR 2023BILAL FAROOQUINo ratings yet

- Repair MaterialDocument4 pagesRepair MaterialBILAL FAROOQUINo ratings yet

- 2.3 ReservedDocument2 pages2.3 ReservedBILAL FAROOQUINo ratings yet

- Shop Production Report 29 March 23Document2 pagesShop Production Report 29 March 23BILAL FAROOQUINo ratings yet

- Ap-Bnf Can List Open Items 21 Dec 22Document1 pageAp-Bnf Can List Open Items 21 Dec 22BILAL FAROOQUINo ratings yet

- Ap-Bnf Can List Open Items 19 Dec 22Document1 pageAp-Bnf Can List Open Items 19 Dec 22BILAL FAROOQUINo ratings yet

- Ses Shop 1201 DPR March 23Document91 pagesSes Shop 1201 DPR March 23BILAL FAROOQUINo ratings yet

- Ses Shop 1201 DPR March 23Document91 pagesSes Shop 1201 DPR March 23BILAL FAROOQUINo ratings yet

- Qa NCR # 03Document1 pageQa NCR # 03BILAL FAROOQUINo ratings yet

- Ap-Bnc Can List Open Items 21 Dec 22Document1 pageAp-Bnc Can List Open Items 21 Dec 22BILAL FAROOQUINo ratings yet

- Tata Steel LTD.: Elements Unit Min Max RemarksDocument2 pagesTata Steel LTD.: Elements Unit Min Max RemarksPavan KumarNo ratings yet

- S.NO. Students Name Contact Number CAP 10TH: Ideal Institute of Pharamacy, Wada SESSION-2020-21Document12 pagesS.NO. Students Name Contact Number CAP 10TH: Ideal Institute of Pharamacy, Wada SESSION-2020-21DAMBALENo ratings yet

- Resume Arun.A: Career ObjectiveDocument2 pagesResume Arun.A: Career ObjectiveajithkumarNo ratings yet

- DSP UPG CU EngDocument1 pageDSP UPG CU EngArtur KwiatkowskiNo ratings yet

- Plot Elements - DisneyDocument23 pagesPlot Elements - DisneyssssssNo ratings yet

- Make - Volume 13 - Volume 13Document212 pagesMake - Volume 13 - Volume 13Pedernal Lisiao100% (2)

- Final Exam Tle Grade 8Document4 pagesFinal Exam Tle Grade 8John leo Claus67% (3)

- Can We Define Ecosystems - On The Confusion Between Definition and Description of Ecological ConceptsDocument15 pagesCan We Define Ecosystems - On The Confusion Between Definition and Description of Ecological ConceptsKionara SarabellaNo ratings yet

- Language - Introduction To The Integrated Language Arts CompetenciesDocument7 pagesLanguage - Introduction To The Integrated Language Arts CompetenciesHari Ng Sablay100% (1)

- Polyethylene PolyamineDocument6 pagesPolyethylene PolyamineAV kayanNo ratings yet

- Aurora National High School: Report On AttendanceDocument2 pagesAurora National High School: Report On AttendanceLimuel CaringalNo ratings yet

- Fire Master Mirine PlusDocument3 pagesFire Master Mirine PlusCarlos BarriosNo ratings yet

- Case Presentation On Management of Depressive Disorders-1Document40 pagesCase Presentation On Management of Depressive Disorders-1Fatima MuhammadNo ratings yet

- Qatar OM PART C PDFDocument796 pagesQatar OM PART C PDFBobi Guau100% (3)

- Portal 2 PresDocument15 pagesPortal 2 Presapi-666608332No ratings yet

- TelemetryDocument8 pagesTelemetryKristin WiseNo ratings yet

- Activity 1.1.2 Simple Machine Practice Problems KeyDocument6 pagesActivity 1.1.2 Simple Machine Practice Problems KeyNehemiah GriffinNo ratings yet

- I J E E: Nternational Ournal of Nergy and NvironmentDocument8 pagesI J E E: Nternational Ournal of Nergy and NvironmentsheilamegumiNo ratings yet

- CREDEDocument10 pagesCREDEDaffodilsNo ratings yet

- Visibility of NursesDocument17 pagesVisibility of NursesLuke ShantiNo ratings yet

- Arduino PDFDocument9 pagesArduino PDFMuhammad HazimNo ratings yet

- A Christmas Memory. Lesson - AnthologyDocument24 pagesA Christmas Memory. Lesson - AnthologySherry CallisonNo ratings yet

- BC Caribou Recovery Program Stakeholders Teleconference MinutesDocument5 pagesBC Caribou Recovery Program Stakeholders Teleconference MinutesRevelstoke MountaineerNo ratings yet

- SIP Debugging Commands Overview - Cisco CommunityDocument5 pagesSIP Debugging Commands Overview - Cisco CommunitysenthilNo ratings yet

- James Bruce, One of Russian Tsar Peter The Great's Key Advisors (1669-1735)Document2 pagesJames Bruce, One of Russian Tsar Peter The Great's Key Advisors (1669-1735)Johanna Granville100% (1)

- Factors Affecting Pakistani English Language LearnersDocument19 pagesFactors Affecting Pakistani English Language LearnersSaima Bint e KarimNo ratings yet

- Sheet - PDF 3Document4 pagesSheet - PDF 3Nazar JabbarNo ratings yet

- Zero Voltage Switching Active Clamp Buck-BoostDocument10 pagesZero Voltage Switching Active Clamp Buck-Boostranjitheee1292No ratings yet

- Kyt KtiDocument13 pagesKyt KtiIbunnaya100% (1)

- Sample CISSP ResumeDocument4 pagesSample CISSP ResumeAskia MappNo ratings yet