Professional Documents

Culture Documents

Gas Cutting Risk Assessment

Uploaded by

chemjesuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gas Cutting Risk Assessment

Uploaded by

chemjesuCopyright:

Available Formats

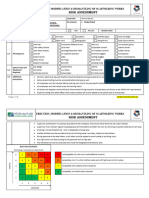

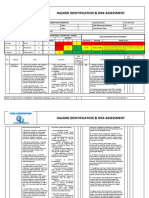

RISK ASSESSMENT FILE REFERENCE: RA#018

GAS CUTTING (OXY-PROPANE)

ASSESSORS: HSEQ Department ASSESSMENT DATE: MAR 2020

Hard Hat Hi-Vis Vest Safety Boots (BS Gloves Safety Glasses Ear Protection Face Mask Overalls Seat Belts Harness

(EN397) (EN471) EN 345 -1) (BS EN 388) (EN 166) (EN 352-1) Flam retardent

GENERIC CONTROL MEASURES

• Operatives to be competent, having both practical & theoretical training. • Toolbox Talks and adequate information to be provided by management.

Applicable • Daily equipment inspections to be carried out and serious defects reported immediately. • Utilise task lighting when applicable.

to all the • Comply with safe systems of work, i.e. RAMS, permits and traffic management plans • Provide and maintain suitable haulage routes.

hazards (provided by Collins or Principal Contractor) • Adequate signs to be in place.

• Plant and equipment to be used and maintained in accordance with manufacturer’s • Failure in the employees’ duties will result in disciplinary action.

below instructions. • Appropriate PPE to be worn at all times as seen above.

• Drug and alcohol testing to be carried out periodically at random and with cause on Collins • Any defective equipment must be taken out of operation until it has been repaired by a competent

operatives. person.

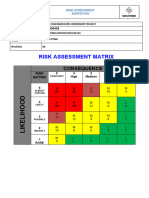

STEP1 Identify the Likelihood rating of the risk materialising, using the table below: STEP 2Identify the Consequence rating if the risk should materialise, using the table below:

Numerical Probability Description Numerical Consequence

Rating Rating

0 Impossible i.e. cannot happen under any circumstances 0 No Injury

1 Almost impossible i.e. possible only under extreme conditions 1 Minor First Aid Injury

2 Highly Unlikely i.e. though conceivable 2 Break Bone or Minor Illness (Temporary)

3 Unlikely i.e. but could happen 3 Break Bone or Minor Illness (Permanent)

4 Possible i.e. but unusual 4 Loss of a limb, eye, serious illness

5 Fatality

5 Even Chance i.e. could happen

STEP 3 the Likelihood and Consequence ratings together to give the risk rating. Using the risk rating and the action table detailed below, determine what further action needs to be taken to

reduce the risk to an acceptable level.

Risk Rating Action to be Taken

16-25 Stop work until control measures reduce the risk rating to an acceptable level

6-15 Introduce control measures to reduce risk as low as reasonably practicable

0-5 No action required risk broadly acceptable

Uncontrolled when printed Version 1 Page 1 of 3

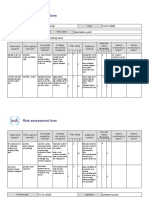

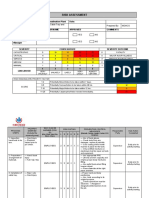

RISK ASSESSMENT FILE REFERENCE: RA#018

GAS CUTTING (OXY-PROPANE)

ASSESSORS: HSEQ Department ASSESSMENT DATE: MAR 2020

RISK RESIDUAL RISK

PERSONS AFFECTED &

HAZARDS ADDITIONAL CONTROL MEASURES

LIKELY HARM L S R L S R

• There are to be no other contractors in the area.

• Flash back arresters are to be fitted to the equipment and checked as part of the daily inspection.

Damage to eyes

Operatives, other contractors - 20 • Welding mask with correct grade lens must be worn when carrying out this activity. 4

from welding 5 4 1 4

damage to vision, possible blindness HIGH • Where practical, suitable partitions to be placed around work area LOW

flash

• Safety glasses to be worn

• Other persons inside work area must wear similar eye protection

• The work area be free of obstructions.

• Ground to be checked for any grease or liquid spills.

Operatives - bruises and 20 • Safety footwear to be worn and care taken to prevent slips and trips. 5

Slip hazard 4 5 1 5

fractures HIGH • Work area to be clear of any obstructions which will might cause interruptions to welding LOW

operation.

• Any other work participants to follow same requirements.

• Gloves to be worn to prevent burns to hands and lower arm.

Operatives, other workers,

• Long sleeve flame retardant clothing is to be worn when carrying this work activity.

sub-contractors, visitors, general 16 4

Burns injuries 4 4 • Burning/cutting material/equipment are to be allowed to cool down before handling. 1 4

public - serious impact injuries, burns HIGH LOW

possibly leading to death. • Any other work participants to follow same requirements.

• Burns kits are to be available and first aiders aware of the location they are stored in.

• Operator to ensure that work pieces are to be free of any oils or other flammable materials before

welding occurs.

• No flammable materials or liquids are to be near the cutting operation.

• Gas hoses are to be checked for any damage before starting the works.

Operator, other workers, sub- • DO NOT USE IF ANY SUSPICIOUS DAMAGE IS EVIDENT.

Noxious fumes contractors - respiratory 20 • ENSURE FLINT LIGHTER IS READY TO USE PRIOR TO TURNING ON GAS. 5

4 5 1 5

or flames Illness / occupational disease HIGH • TURN ON ACETYLENE GAS FIRST AND LIGHT IT BEFORE TURNING OXYGEN ON (refer to LOW

possibly leading to death operating instructions).

• Gas hoses to be well clear of cutting or shoot material (splatter) at all times.

• Ensure the area been worked has good ventilation.

• ENSURE CUTTING TORCH VALVES AND GAS REGULATORS ARE CORRECTLY CLOSED

WHEN CUTTING COMPLETED.

Collins operatives, other workers, • Good housekeeping is to be maintained on the site at all times.

Unintentional sub-contractors, visitors, general 20 • No flammable liquids/materials are to be present in the area the cutting work activity is to 5

fire public - serious impact injuries, burns

4 5 1 5

HIGH commence. LOW

possibly leading to death. • Hot works permit is to be issued and managed by the Principal Contractor.

Uncontrolled when printed Version 1 Page 2 of 3

RISK ASSESSMENT FILE REFERENCE: RA#018

GAS CUTTING (OXY-PROPANE)

ASSESSORS: HSEQ Department ASSESSMENT DATE: MAR 2020

• No hot works are to be carried out within a minimum of an hour before the end of the working day;

the area is to be visually checked for any smouldering material or signs of fire.

• The relevant fire extinguishers are to be available and all operatives aware of where they are

located.

Uncontrolled when printed Version 1 Page 3 of 3

You might also like

- Operations Risk: Managing a Key Component of Operational RiskFrom EverandOperations Risk: Managing a Key Component of Operational RiskRating: 4 out of 5 stars4/5 (2)

- JSA-003 Fence InstallationDocument5 pagesJSA-003 Fence InstallationMoaatazz Nouisri50% (2)

- 4.1.2 Covid-19 Risk AssessmentDocument41 pages4.1.2 Covid-19 Risk AssessmentaceNo ratings yet

- ERECTION, MODIFICATION & DISMANTLING OF SCAFFOLDING WORKS - Risk Assessment - REV01Document10 pagesERECTION, MODIFICATION & DISMANTLING OF SCAFFOLDING WORKS - Risk Assessment - REV01SolimanNo ratings yet

- Jsa-046 Highway Crossing and Steel CasingDocument11 pagesJsa-046 Highway Crossing and Steel CasingMajdiSahnounNo ratings yet

- Instructions For Using OHS Risk Assessment Template: Only Complete The Unshaded Cells All Others Are Locked 1. 2Document4 pagesInstructions For Using OHS Risk Assessment Template: Only Complete The Unshaded Cells All Others Are Locked 1. 2Abdelrahman N. AliNo ratings yet

- Method Statement For Anti Termite TreatmentDocument7 pagesMethod Statement For Anti Termite TreatmentSagar Aliasjackey100% (2)

- Risk Assessment ErectionDocument9 pagesRisk Assessment Erectionelizabethmaseko16No ratings yet

- JSA-018 Lifting With Mobile CraneDocument5 pagesJSA-018 Lifting With Mobile CraneOmar Dhieb100% (1)

- Excavation Permmit To WorkDocument3 pagesExcavation Permmit To WorkWilson Wambua0% (1)

- Safetyra-527 Fal EgyDocument6 pagesSafetyra-527 Fal EgymujuburrNo ratings yet

- Hirarc & Aspect ImpactDocument21 pagesHirarc & Aspect ImpactHazru NazriNo ratings yet

- Hazard Identification and Risk AssessmentDocument11 pagesHazard Identification and Risk Assessmentgiridhar225No ratings yet

- DSM-FRM-0001-27-0, HDPE PE-100 Pipe InstallationDocument4 pagesDSM-FRM-0001-27-0, HDPE PE-100 Pipe Installationkadir tanzaniaNo ratings yet

- Hazard Identification & Risk AssessmentDocument9 pagesHazard Identification & Risk AssessmentLathakula RajashekharNo ratings yet

- JSA-020 Fence InstallationDocument4 pagesJSA-020 Fence InstallationMoaatazz Nouisri75% (4)

- Risk Assessment FormDocument50 pagesRisk Assessment FormAndre Porles100% (1)

- Job Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdDocument3 pagesJob Hazard Analysis (JHA) Worksheet: Sungchang & Al-Shaikh Contracting Co.,LtdTeodoro EsquilloNo ratings yet

- Risk Assessment: By: Satendra SinghDocument13 pagesRisk Assessment: By: Satendra SinghVishwash GoyalNo ratings yet

- Risk AssessmentDocument12 pagesRisk AssessmentmubarakhembarakNo ratings yet

- Risk Assessment and Jop Safety Practice JSPDocument20 pagesRisk Assessment and Jop Safety Practice JSPShafie ZubierNo ratings yet

- Condenser Hotwell Conductivity HIRACDocument1 pageCondenser Hotwell Conductivity HIRACKent Martin D. CartagenaNo ratings yet

- JSA-055 Hydro-TestDocument24 pagesJSA-055 Hydro-TestOmar Dhieb100% (7)

- Safety at OffshoreDocument51 pagesSafety at OffshoreRavi Kant TripathiNo ratings yet

- HIRA For Work at HeightDocument4 pagesHIRA For Work at Heightdinesattri100% (1)

- RA For Sump PumpsDocument9 pagesRA For Sump PumpsAnonymous ubta67y6eNo ratings yet

- Abrasive Wheels Risk AssessmentDocument4 pagesAbrasive Wheels Risk AssessmentAhmed El-sherpiniNo ratings yet

- Baseline Risk Assessment 2014 Construction Regulations (Rev 2)Document26 pagesBaseline Risk Assessment 2014 Construction Regulations (Rev 2)preciousphooko50No ratings yet

- 10 - Lift Car ElectricalDocument8 pages10 - Lift Car Electricalyoen_anNo ratings yet

- HIRACDocument2 pagesHIRACWilliam Bautista100% (1)

- 073 - R.A - Tank CleaningDocument3 pages073 - R.A - Tank Cleaningbappy s.hNo ratings yet

- Baseline Risk Assessment (Bra)Document8 pagesBaseline Risk Assessment (Bra)aceNo ratings yet

- Construction COVID-19 Risk Assessment: Siemens - Co.ukDocument17 pagesConstruction COVID-19 Risk Assessment: Siemens - Co.ukMd Jawed AnsariNo ratings yet

- TSRA9-Replacement of SwitchgearDocument3 pagesTSRA9-Replacement of SwitchgearGraeme WinterburnNo ratings yet

- Risk Assessment:: Corresponding Permit To Work NoDocument4 pagesRisk Assessment:: Corresponding Permit To Work NoNaseemandson TeamNo ratings yet

- Risk Assessment Project Iosh - MsDocument2 pagesRisk Assessment Project Iosh - MsSanjeev Kumar75% (32)

- AV-SWP-08 Risk Assessment Iss 1Document4 pagesAV-SWP-08 Risk Assessment Iss 1Kevin DeLimaNo ratings yet

- Drilling and Milling Machine HIRARCDocument1 pageDrilling and Milling Machine HIRARCMahendren Jayapalan0% (1)

- HIRADocument14 pagesHIRAGobindaSahu100% (2)

- HIRAC Sample and PresentationDocument14 pagesHIRAC Sample and PresentationEric Valenzuela100% (2)

- JOB SAFETY ANALYSIS - Topographic SurveyDocument3 pagesJOB SAFETY ANALYSIS - Topographic SurveyMoaatazz Nouisri86% (7)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRyanNo ratings yet

- TIP-HSE-P02-01-F01 Risk Assessment R0Document10 pagesTIP-HSE-P02-01-F01 Risk Assessment R0Vijayakumar KarunanidhiNo ratings yet

- 04 Hazards Identification, Assessment and Controls (Participant Rev1)Document31 pages04 Hazards Identification, Assessment and Controls (Participant Rev1)ᜇᜒᜌᜓᜈᜎ᜔ᜇ᜔ ᜊᜒᜇᜓᜌ᜔No ratings yet

- Shear Wall Jumping Platform R A - 50Document6 pagesShear Wall Jumping Platform R A - 50Saranlal M0% (1)

- Ra 04 - SurveyingDocument4 pagesRa 04 - SurveyingHafiz M WaqasNo ratings yet

- Sewer Plant Management and Operation Risk-AssessmentDocument33 pagesSewer Plant Management and Operation Risk-AssessmentvalveworkshseNo ratings yet

- IOSH Project 34/38 MarksDocument7 pagesIOSH Project 34/38 MarksSaleem Shahzad KhanNo ratings yet

- Generic RA FSDocument5 pagesGeneric RA FSStephenNo ratings yet

- Method Statement For Anti Termite TreatmentDocument6 pagesMethod Statement For Anti Termite TreatmentSagar Aliasjackey0% (1)

- HIRARC Building Work-Roof and Rainwater SystemDocument4 pagesHIRARC Building Work-Roof and Rainwater SystemSarah Liyana100% (1)

- RA Existing Asphalt Milling WorksDocument8 pagesRA Existing Asphalt Milling WorksSolimanNo ratings yet

- Spray Booth Risk AssessmentDocument3 pagesSpray Booth Risk AssessmentJohn Geddes100% (1)

- Occupational Health & Safety-HazardsDocument36 pagesOccupational Health & Safety-HazardsSandaruwanNo ratings yet

- Rotek Valves Risk Assessment - Process: If You Have Any Questions, Please Contact The ManagerDocument3 pagesRotek Valves Risk Assessment - Process: If You Have Any Questions, Please Contact The ManagerPieter BezuidenhoutNo ratings yet

- 11 - Commission Inspection ModeDocument10 pages11 - Commission Inspection Modeyoen_anNo ratings yet

- Risk Assesment @ro, WTP & STP PremDocument6 pagesRisk Assesment @ro, WTP & STP PremvarunthalariNo ratings yet

- Risk Management PlanDocument46 pagesRisk Management PlanJohn Oo100% (4)

- Cable Tray InstallationDocument3 pagesCable Tray InstallationIzzy TudtudNo ratings yet

- EI Mobile Phone UsingDocument16 pagesEI Mobile Phone Usingchemjesu100% (1)

- Air Powered Internal SWDDocument2 pagesAir Powered Internal SWDchemjesuNo ratings yet

- Lessons From Fatal Tyre Maintenance Incidents - ToolboxDocument5 pagesLessons From Fatal Tyre Maintenance Incidents - ToolboxchemjesuNo ratings yet

- TID 1 Microbial Monitoring Strategies Oct 2015 V1.1Document21 pagesTID 1 Microbial Monitoring Strategies Oct 2015 V1.1chemjesuNo ratings yet

- Bulletin 144 Future Changes To JIG Checklist 07 2022 1Document7 pagesBulletin 144 Future Changes To JIG Checklist 07 2022 1chemjesuNo ratings yet

- Boundary WallDocument1 pageBoundary WallchemjesuNo ratings yet

- Business Continuity Plan Covid 19Document9 pagesBusiness Continuity Plan Covid 19chemjesuNo ratings yet

- Electrostatic Ignition Resulted in Flash Fire During Road Tanker Unloading - ToolboxDocument4 pagesElectrostatic Ignition Resulted in Flash Fire During Road Tanker Unloading - ToolboxchemjesuNo ratings yet

- Thesis Mazaris TUDDocument245 pagesThesis Mazaris TUDchemjesuNo ratings yet

- Bulletin 139 Life Saving RulesDocument2 pagesBulletin 139 Life Saving RuleschemjesuNo ratings yet

- IP Code 1089 (Water Cooling System)Document3 pagesIP Code 1089 (Water Cooling System)chemjesuNo ratings yet

- AIGA TP 31 - 22 - Recent - H2 - of - 2021 - Incidents - in - Gas - Industry - in - AsiaDocument52 pagesAIGA TP 31 - 22 - Recent - H2 - of - 2021 - Incidents - in - Gas - Industry - in - AsiachemjesuNo ratings yet

- Unidentified Thermal Expansion Hazard Causes Oil Spill To Secondary Containment - ToolboxDocument4 pagesUnidentified Thermal Expansion Hazard Causes Oil Spill To Secondary Containment - ToolboxchemjesuNo ratings yet

- Worker Enters Kerosene Tank During Cleaning Without Authorisation - ToolboxDocument4 pagesWorker Enters Kerosene Tank During Cleaning Without Authorisation - ToolboxchemjesuNo ratings yet

- SSSP Form 2 - Site or Job Hazard and Risk RegisterDocument2 pagesSSSP Form 2 - Site or Job Hazard and Risk RegisterchemjesuNo ratings yet

- TN Electricity Bills Press Release 23mar21Document3 pagesTN Electricity Bills Press Release 23mar21chemjesuNo ratings yet

- 57-0000-S-90-04-O-0254-00-E Appendix 5Document3 pages57-0000-S-90-04-O-0254-00-E Appendix 5chemjesuNo ratings yet

- Fuel Unloading, Storage and Dispatching Facility, KwinanaDocument21 pagesFuel Unloading, Storage and Dispatching Facility, KwinanachemjesuNo ratings yet

- Model Code of Safe Practice: 4th EditionDocument14 pagesModel Code of Safe Practice: 4th EditionchemjesuNo ratings yet

- Bs en 858-1-2002 Separator Systems For Light Liquids 1 1pdf PDF FreeDocument1 pageBs en 858-1-2002 Separator Systems For Light Liquids 1 1pdf PDF FreechemjesuNo ratings yet

- Soil Mechanics - Chapter 2 ExamplesDocument12 pagesSoil Mechanics - Chapter 2 ExamplesSelino CruzNo ratings yet

- Sailor Moon Vol 1 - Naoko TakeuchiDocument204 pagesSailor Moon Vol 1 - Naoko TakeuchiKate Yati100% (4)

- CV Emil SatriaDocument1 pageCV Emil SatriaazmiazfarNo ratings yet

- Discrete Time Random ProcessDocument35 pagesDiscrete Time Random ProcessSundarRajanNo ratings yet

- Harolds Real Analysis Cheat Sheet 2022Document54 pagesHarolds Real Analysis Cheat Sheet 2022Boey HeNo ratings yet

- LAS - G11 - Q2 - Week8 - Personal DevelopmentDocument7 pagesLAS - G11 - Q2 - Week8 - Personal DevelopmentRubenNo ratings yet

- Sustainable Habitat: 24 - 28 September 2019Document2 pagesSustainable Habitat: 24 - 28 September 2019sajid khanNo ratings yet

- Spectral Triad (AS7265x) Hookup Guide - SparkFun LearnDocument13 pagesSpectral Triad (AS7265x) Hookup Guide - SparkFun LearnFrancisco BoteroNo ratings yet

- Podcaster Inc Issue 1Document38 pagesPodcaster Inc Issue 1Hubert NomamiukorNo ratings yet

- Getting Things Done With ADHDDocument74 pagesGetting Things Done With ADHDhfuqueneNo ratings yet

- Uav UpdateDocument16 pagesUav UpdateHanif Ahmad Abdul GhofurNo ratings yet

- Crystallisation - Faculty LectureDocument24 pagesCrystallisation - Faculty Lecturesoumitra hazraNo ratings yet

- Brain Computer InterfaceDocument1 pageBrain Computer InterfaceMd Moshiur RahmanNo ratings yet

- ULO2a - Basic Concepts of Crystal StructureDocument14 pagesULO2a - Basic Concepts of Crystal StructureCHARLIE AMOGUIS JRNo ratings yet

- EsssayDocument5 pagesEsssayNuman FarooqiNo ratings yet

- Ea-Inf 01Document24 pagesEa-Inf 01linedalineda2021No ratings yet

- Soal Listrik Statis Dan Kelistrikan Pada Makhluk SedangDocument10 pagesSoal Listrik Statis Dan Kelistrikan Pada Makhluk SedangRifatiMasrurohNo ratings yet

- Unit 6 Test MHF4U - Fatima YahyaDocument2 pagesUnit 6 Test MHF4U - Fatima YahyafatimatumbiNo ratings yet

- Tle InterventionDocument8 pagesTle InterventionNorman T. Regal100% (1)

- Copper Alloy Split Bolt Connectors: Types S and SELDocument2 pagesCopper Alloy Split Bolt Connectors: Types S and SELHalenaBuanNo ratings yet

- RTP-LASG8Q3M5W5Document9 pagesRTP-LASG8Q3M5W5Atheena Johann VillaruelNo ratings yet

- IEC 60793-1-30-2001 Fibre Proof TestDocument12 pagesIEC 60793-1-30-2001 Fibre Proof TestAlfian Firdaus DarmawanNo ratings yet

- Script Fibonacci and Golden RatioDocument3 pagesScript Fibonacci and Golden RatioJenilyn EsposoNo ratings yet

- Continuous Beams (Common But Special Case) : Msc. CourseDocument15 pagesContinuous Beams (Common But Special Case) : Msc. CourseRaffal NejimNo ratings yet

- Palla: Vibrating MillDocument16 pagesPalla: Vibrating MillSanjeev AroraNo ratings yet

- Sub TopicDocument1 pageSub TopicApril AcompaniadoNo ratings yet

- Who Guideline On Use of Ferritin Concentrations To Assess Iron Status in Individuals and PopulationsDocument82 pagesWho Guideline On Use of Ferritin Concentrations To Assess Iron Status in Individuals and PopulationsLima NetNo ratings yet

- Curriculumn CSE Btech AI DSDocument30 pagesCurriculumn CSE Btech AI DSAnonymous tricksNo ratings yet

- Step 5 - DRADocument19 pagesStep 5 - DRACHICKYNo ratings yet

- Chapter 1 Principle of Grain StorageDocument29 pagesChapter 1 Principle of Grain StorageNguyễn Ngọc QuânNo ratings yet