Professional Documents

Culture Documents

Calculation Notes of Silo 4M X9M: Description

Uploaded by

ahmed aboyosefOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Calculation Notes of Silo 4M X9M: Description

Uploaded by

ahmed aboyosefCopyright:

Available Formats

CALCULATION NOTES of SILO 4M X9M

Description

Design of SILO 4M X9M 1

ENG.AHMED SAAD

23-05-23

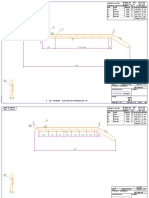

density height pressure on wall

density height pressure on silo wall

ρ

Design of SILO 4M X9M 2

ENG.AHMED SAAD

23-05-23

PV Elite Silo Analysis Program: Input Data

Design of SILO 4M X9M 3

ENG.AHMED SAAD

23-05-23

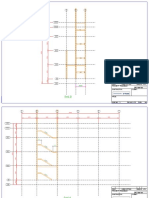

Complete Listing of Silo Elements and Details:

Design of SILO 4M X9M 4

ENG.AHMED SAAD

23-05-23

Design of SILO 4M X9M 5

ENG.AHMED SAAD

23-05-23

Design of SILO 4M X9M 6

ENG.AHMED SAAD

23-05-23

XY Coordinate Calculations:

Element Thickness, Pressure, Diameter and Allowable Stress :

Element Required Thickness and MAWP :

MAWP: 34.283 KPa., limited by: Cone.

Internal Pressure Calculation Results :

ASME Code, Section VIII Division 1, 2017

Conical Section From 10 To 20 SB-209 T651 at 50 °C

Material UNS Number: Alcl6061

Design of SILO 4M X9M 7

ENG.AHMED SAAD

23-05-23

Required Thickness due to Internal Pressure [tr]:

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Maximum Allowable Pressure, New and Cold [MAPNC]:

Actual stress at given pressure and thickness, corroded [Sact]:

Note: The Pressure at the Large Diameter is used in the TR calculation.

Cylindrical Shell From 20 To 30 SB-209 T651 at 50 °C

Material UNS Number: Alcl6061

Required Thickness due to Internal Pressure [tr]:

Note: The thickness required was less than the Code Minimum, therefore

the Code Minimum value of 1.5000 mm. per UG-16 will be used.

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Maximum Allowable Pressure, New and Cold [MAPNC]:

Actual stress at given pressure and thickness, corroded [Sact]:

Cylindrical Shell From 30 To 40 SB-209 T651 at 50 °C

Material UNS Number: Alcl6061

Required Thickness due to Internal Pressure [tr]:

Design of SILO 4M X9M 8

ENG.AHMED SAAD

23-05-23

Note: The thickness required was less than the Code Minimum, therefore

the Code Minimum value of 1.5000 mm. per UG-16 will be used.

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Maximum Allowable Pressure, New and Cold [MAPNC]:

Actual stress at given pressure and thickness, corroded [Sact]:

Cylindrical Shell From 40 To 50 SB-209 T651 at 50 °C

Material UNS Number: Alcl6061

Required Thickness due to Internal Pressure [tr]:

Note: The thickness required was less than the Code Minimum, therefore

the Code Minimum value of 1.5000 mm. per UG-16 will be used.

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Maximum Allowable Pressure, New and Cold [MAPNC]:

Actual stress at given pressure and thickness, corroded [Sact]:

Cylindrical Shell From 50 To 60 SB-209 T651 at 50 °C

Material UNS Number: Alcl6061

Required Thickness due to Internal Pressure [tr]:

Note: The thickness required was less than the Code Minimum, therefore

the Code Minimum value of 1.5000 mm. per UG-16 will be used.

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Design of SILO 4M X9M 9

ENG.AHMED SAAD

23-05-23

Maximum Allowable Pressure, New and Cold [MAPNC]:

Actual stress at given pressure and thickness, corroded [Sact]:

Conical Section From 60 To 70 SB-209 T651 at 50 °C

Material UNS Number: Alcl6061

Max. Allowable Working Pressure at given Thickness, corroded [MAWP]:

Maximum Allowable Pressure, New and Cold [MAPNC]:

Elements Suitable for Internal Pressure.

Element and Detail Weights:

Design of SILO 4M X9M 10

ENG.AHMED SAAD

23-05-23

Weight of Details:

Total Weight of Each Detail Type:

Weight Summation Results: (kg.)

Weight Summary:

Outside Surface Areas of Elements:

Design of SILO 4M X9M 11

ENG.AHMED SAAD

23-05-23

Element and Detail Weights:

Cumulative Silo Weight

Cumulative Silo Moment

Design of SILO 4M X9M 12

ENG.AHMED SAAD

23-05-23

The Natural Frequencies for the Silo have been computed iteratively

by solving a system of matrices. These matrices describe the mass

and the stiffness of the Silo. This is the generalized eigenvalue/

eigenvector problem and is referenced in some mathematical texts.

The Natural Frequency for the Silo (Empty.) is 17.534 Hz.

The Natural Frequency for the Silo (Ope...) is 17.534 Hz.

Input Values:

Wind Analysis Results

Static Gust-Effect Factor, Operating Case [G]:

This is classified as a rigid structure. Static analysis performed.

Sample Calculation for the First Element

The ASCE code performs all calculations in Imperial Units

only. The wind pressure is therefore computed in these units.

Value of [Alpha] and [Zg]:

Design of SILO 4M X9M 13

ENG.AHMED SAAD

23-05-23

Effective Height [z]:

Velocity Pressure coefficient evaluated at height z [Kz]:

Type of Hill: No Hill

Wind Directionality Factor [Kd]:

As there is No Hill Present: [Kzt]:

Topographical Factor [Kzt]:

Velocity Pressure evaluated at height z, Imperial Units [qz]:

Force on the first element [F]:

Wind Vibration Calculations

This evaluation is based on work by Kanti Mahajan and Ed Zorilla

Nomenclature

Design of SILO 4M X9M 14

ENG.AHMED SAAD

23-05-23

Check other Conditions and Basic Assumptions:

Compute the vibration possibility. If Vp > 0.400E-06 no chance. [Vp]:

Compute the damping factor Df which is a measure of instability [Df]:

Compute the critical wind velocity [Vc]:

Compute the velocity at the top of the tower [Vw]:

Compute the maximum gust velocity using the gust response factor Gh [Vg]:

Since Vc is greater than Vg the dynamic deflection Z, does not

need to be computed.

The Natural Frequency for the Silo (Ope...) is 17.534 Hz.

Wind Load Calculation:

Design of SILO 4M X9M 15

ENG.AHMED SAAD

23-05-23

Note:

The Wind Loads calculated and printed in the Wind Load

calculation report have been factored by the input

scalar/load reduction factor of: 0.600.

Be sure the wind speed is in accordance with the specified

wind design code.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2019

The following table is for the Operating Case.

Wind/Earthquake Shear, Bending:

Note:

The Wind Shears/Moments and the Earthquake Shears/Moments calculated

and printed in the Wind/Earthquake Shear and Bending report have

been factored by the input Scalar/Load reductions factors of;

Wind: 0.600; Earthquake: 0.700.

Note:

Review the Silo Design Summary for the cumulative shear force

and bending moment on the support.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2019

Earthquake Load Calculation:

Input Values:

Design of SILO 4M X9M 16

ENG.AHMED SAAD

23-05-23

Seismic Analysis Results:

Check Approximate Fundamental Period from 12.8-7 [Ta]:

The Coefficient Cu from Table 12.8-1 is : 1.400

Fundamental Period (1/Frequency) [T]:

Check the Value of T which is the smaller of Cu*Ta and T:

As the time period is < 0.06 second, use section 15.4.2.

Compute the Base Shear per equation 15.4-5, [V]:

Distribute the Base shear force to each element according to the equations

Fx = Cvx * V (eqn. 12.8-11 ) and the vertical distribution factor

Cvx = Wx*hx^(k)/( Sum of Wi*hi^(k) ) and k is an exponent which is related

to the period of Vibration.

In this case, the value of k was 1.0

The Natural Frequency for the Silo (Ope...) is 17.534 Hz.

Earthquake Load Calculation:

Design of SILO 4M X9M 17

ENG.AHMED SAAD

23-05-23

Note:

The Earthquake Loads calculated and printed in the Earthquake

Load calculation report have been factored by the input

scalar/load reduction factor of: 0.700.

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2019

Wind Deflection Calculations:

The following table is for the Operating Case.

Wind Deflection:

Critical Wind Velocity for Tower Vibration:

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2019

Design of SILO 4M X9M 18

ENG.AHMED SAAD

23-05-23

Longitudinal Stress Constants:

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2019

Longitudinal Allowable Stresses:

Longitudinal Stress Report

Note: Longitudinal Operating and Empty Stresses are computed in the

corroded condition. Since there was no hydrotest requested,

stresses pertaining to that case type have not been calculated.

Longitudinal Pressure Stresses due to:

Design of SILO 4M X9M 19

ENG.AHMED SAAD

23-05-23

Longitudinal Stresses due to Weight Loads for these Conditions:

Longitudinal Stresses due to Weight Loads and Bending for these Conditions:

Longitudinal Stresses due to these Conditions:

Longitudinal Stresses due to Applied Axial Forces:

Design of SILO 4M X9M 20

ENG.AHMED SAAD

23-05-23

Longitudinal Stresses due to User Forces and Moments:

Stress Combination Load Cases for Vertical Silos:

Load Case Definition Key

General Notes:

Case types HI and HE are in the Un-Corroded condition.

Case types WE, WF, and CW are in the Un-Corroded condition.

A blank stress and stress ratio indicates that the corresponding

stress comprising those components that did not contribute to that

type of stress.

An asterisk (*) in the final column denotes overstress.

Analysis of Load Case 1 : NP+EW+WI+FW+BW

Design of SILO 4M X9M 21

ENG.AHMED SAAD

23-05-23

Analysis of Load Case 2 : NP+EW+EE+FS+BS

Analysis of Load Case 3 : NP+OW+WI+FW+BW

Analysis of Load Case 4 : NP+OW+EQ+FS+BS

Analysis of Load Case 5 : NP+HW+HI

Analysis of Load Case 6 : NP+HW+HE

Design of SILO 4M X9M 22

ENG.AHMED SAAD

23-05-23

Analysis of Load Case 7 : IP+OW+WI+FW+BW

Analysis of Load Case 8 : IP+OW+EQ+FS+BS

Analysis of Load Case 9 : EP+OW+WI+FW+BW

Analysis of Load Case 10 : EP+OW+EQ+FS+BS

Analysis of Load Case 11 : HP+HW+HI

Analysis of Load Case 12 : HP+HW+HE

Design of SILO 4M X9M 23

ENG.AHMED SAAD

23-05-23

Analysis of Load Case 13 : IP+WE+EW

Analysis of Load Case 14 : IP+WF+CW

Analysis of Load Case 15 : IP+VO+OW

Analysis of Load Case 16 : IP+VE+EW

Analysis of Load Case 17 : NP+VO+OW

Design of SILO 4M X9M 24

ENG.AHMED SAAD

23-05-23

Analysis of Load Case 18 : FS+BS+IP+OW

Analysis of Load Case 19 : FS+BS+EP+OW

Element From : 20 to : 30

Governing Load Case 7 : IP+OW+WI+FW+BW

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2019

ASME Code, Section VIII Division 1, 2017

Design of SILO 4M X9M 25

ENG.AHMED SAAD

23-05-23

Materials of Construction:

Normalized is determined based on the UCS-66 material curve selection and Figure UCS-66.

Impact Tested is based on material selection and material data properties.

Element Pressures and MAWP (KPa. & mm.):

Element Types and Properties:

Loads for Foundation/Support Design:

Factored Loads:

Un-Factored Loads:

Design of SILO 4M X9M 26

ENG.AHMED SAAD

23-05-23

Note:

Wind and Earthquake moments include the effects of user defined

forces and moments if any exist in the job and were specified

to act (compute loads and stresses) during these cases. Also

included are moment effects due to eccentric weights if any are

present in the input.

Weights:

PV Elite is a trademark of Intergraph CADWorx & Analysis Solutions, Inc. 2019

Design of SILO 4M X9M 27

ENG.AHMED SAAD

23-05-23

Table of Contents

Description .......................................... 1

PV Elite Silo Analysis Program: Input Data ...... 3

Complete Listing of Silo Elements and Details: ................................................................... 4

XY Coordinate Calculations: ...................... 7

Element Thickness, Pressure, Diameter and Allowable Stress : ................................................ 7

Element and Detail Weights: ................... 10

Element and Detail Weights: ................... 12

Cumulative Silo Weight .............................................................................................. 12

Cumulative Silo Moment ............................................................................................. 12

Input Values: ...................................... 13

Earthquake Load Calculation: .................. 16

Wind Deflection Calculations: .................. 18

Longitudinal Stress Report ...................... 19

Stress Combination Load Cases for Vertical Silos: 21

Materials of Construction:....................... 26

Loads for Foundation/Support Design: ........ 26

Design of SILO 4M X9M 28

You might also like

- Sky Light - 1Document32 pagesSky Light - 1Nazar Bazaraa100% (1)

- Reducer SpoolDocument13 pagesReducer SpoolSAGARNo ratings yet

- SACD (RCDC) - Release Note - 23.00.00Document17 pagesSACD (RCDC) - Release Note - 23.00.00Abel MulugetaNo ratings yet

- 35M GRD Tower Design Report STCDocument10 pages35M GRD Tower Design Report STCEhtesham AliNo ratings yet

- Lead Construction Sweat Tea Design NewDocument14 pagesLead Construction Sweat Tea Design NewsobhiNo ratings yet

- Proper Bolt Axial Tightening ForceDocument1 pageProper Bolt Axial Tightening ForcePrabhu SelvaRajNo ratings yet

- DTS-214 Design Doc 400kV SC GantryDocument49 pagesDTS-214 Design Doc 400kV SC GantryanoginNo ratings yet

- Design Calculations For The Dome Structure-Type 1Document6 pagesDesign Calculations For The Dome Structure-Type 1msiddiq1100% (2)

- C ClampDocument26 pagesC Clamparulmurugu100% (4)

- Curtain Wall-Report REv 1-10-21Document11 pagesCurtain Wall-Report REv 1-10-21MuraleedharanNo ratings yet

- Proper Bolt Axial Tightening Force and Proper Tightening TorqueDocument1 pageProper Bolt Axial Tightening Force and Proper Tightening Torquecmms88No ratings yet

- Ashpower L-Ashoury For Power, Telecom, and Steel Industry Technical Design Calculation For 20M Stadium Mast PoleDocument14 pagesAshpower L-Ashoury For Power, Telecom, and Steel Industry Technical Design Calculation For 20M Stadium Mast PoleEhtesham AliNo ratings yet

- Structural Design Summary For 12X20Meter Steel Structure: ClientDocument9 pagesStructural Design Summary For 12X20Meter Steel Structure: ClientmanojNo ratings yet

- 2005 Datasheet Hot Induction BendDocument3 pages2005 Datasheet Hot Induction BendAqib Khan VCSPNo ratings yet

- Scaffolding Formwork Design CalculationsDocument17 pagesScaffolding Formwork Design Calculationsbhadrakmishra100% (3)

- Soğuk Kamara Basınçlı Dökümde Güncel Teknolojiler Ve Endüstri 4.0Document27 pagesSoğuk Kamara Basınçlı Dökümde Güncel Teknolojiler Ve Endüstri 4.0SüleymanŞentürkNo ratings yet

- Design of Special Purpose Hydraulic Press Machine Ijariie8769Document5 pagesDesign of Special Purpose Hydraulic Press Machine Ijariie8769Jack JohnNo ratings yet

- Structural Calculation for Glass BalustradeDocument47 pagesStructural Calculation for Glass Balustradewaweng22No ratings yet

- Burj Vista F1 12 Panel Design Rev0 22feb16Document71 pagesBurj Vista F1 12 Panel Design Rev0 22feb16Kilaru HareeshNo ratings yet

- Bolt Strength PDFDocument1 pageBolt Strength PDFSilambarasi MurugesanNo ratings yet

- 1659K01-DC-5950 - 01 Design Modification and Testing Fan ScreenDocument7 pages1659K01-DC-5950 - 01 Design Modification and Testing Fan ScreenBùi Văn TấnNo ratings yet

- Element Thickness 2Document20 pagesElement Thickness 2Vipul GandhiNo ratings yet

- Element Thickness 3Document24 pagesElement Thickness 3Vipul GandhiNo ratings yet

- Test ReportDocument18 pagesTest ReportBilel MahjoubNo ratings yet

- Weight & Bolting - Rev0Document32 pagesWeight & Bolting - Rev0Nasrul Adli100% (1)

- App5 EC2 DesignDocument70 pagesApp5 EC2 Designm_ganea268973No ratings yet

- Union Contracting - Car Parking Rev02Document47 pagesUnion Contracting - Car Parking Rev02krvprasadNo ratings yet

- PSC Design (Aashto-Lrfd Tyu07) TutorialDocument44 pagesPSC Design (Aashto-Lrfd Tyu07) TutorialMohammad Tawfiq WaraNo ratings yet

- Design Calculations of Chiller FoundationDocument15 pagesDesign Calculations of Chiller FoundationStressDyn Consultants100% (1)

- Basering calculations and weld sizes for operating caseDocument6 pagesBasering calculations and weld sizes for operating caseevrim77No ratings yet

- Structural Calculation For Steel Chassis of Cladding Between Floors (Part.5) Building-BDocument60 pagesStructural Calculation For Steel Chassis of Cladding Between Floors (Part.5) Building-Bنصر عبدالسلامNo ratings yet

- SKYLIGHT REPORT - Rev 01Document16 pagesSKYLIGHT REPORT - Rev 01Muraleedharan100% (1)

- Do It Yourself 1Document63 pagesDo It Yourself 1Nguyen Duc CuongNo ratings yet

- TK-02 Supported Roof - Calculo Soporte TechoDocument5 pagesTK-02 Supported Roof - Calculo Soporte Techojoaquin torrano veraNo ratings yet

- Report Roof StructureDocument44 pagesReport Roof Structuremsiddiq1No ratings yet

- RC Design EC2Document70 pagesRC Design EC2Picior Cristian100% (2)

- Design Pressure Vessel Using PV EliteDocument8 pagesDesign Pressure Vessel Using PV EliteVitor OlivettiNo ratings yet

- Notes in Machine Design: Insert The Title of Your Presentation HereDocument221 pagesNotes in Machine Design: Insert The Title of Your Presentation HerePatrick MarcaidaNo ratings yet

- Firefhting Tank 320M3Document26 pagesFirefhting Tank 320M3hgag selim100% (1)

- CSM Adac L&T 0h02 1 DesignDocument27 pagesCSM Adac L&T 0h02 1 Designtamim2014No ratings yet

- Design Calculations: For Steel StructureDocument46 pagesDesign Calculations: For Steel Structurethiện50% (2)

- Automated Home SystemDocument5 pagesAutomated Home SystemMohammed AlfazNo ratings yet

- MCC Bus Bar Sizing CalculationDocument12 pagesMCC Bus Bar Sizing Calculationerkamlakar223480% (5)

- Drillstring DesignDocument40 pagesDrillstring DesignOSama HeshamNo ratings yet

- RAWLPLUG EasyFix PRO Design ReportDocument4 pagesRAWLPLUG EasyFix PRO Design ReportQuangKhảiNo ratings yet

- Design Calculation of Louvers-1Document7 pagesDesign Calculation of Louvers-1vj8584No ratings yet

- m3 CalculationDocument45 pagesm3 CalculationHgagselim Selim100% (1)

- LCP709 TK 003Document41 pagesLCP709 TK 003hgag selimNo ratings yet

- Design and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS WorkbenchDocument27 pagesDesign and Analysis of PROTECTED FLANGE COUPLING Solidworks 2016 and ANSYS Workbenchamu100% (1)

- PSC Design (EC2) Tutorial PDFDocument49 pagesPSC Design (EC2) Tutorial PDFGeorge LazarNo ratings yet

- ContentDocument23 pagesContentajay katrojNo ratings yet

- Tank Design OutDocument26 pagesTank Design OutEyasin ArafatNo ratings yet

- DC S3-1301 REV.0 OriginalDocument93 pagesDC S3-1301 REV.0 OriginalPeja JusohNo ratings yet

- STAADxETABSxRCDC-Residential-Building-Manual-v2.0Document60 pagesSTAADxETABSxRCDC-Residential-Building-Manual-v2.0Jaymark SorianoNo ratings yet

- 325 Series Coupling FlangeDocument9 pages325 Series Coupling FlangeRajendra PraharajNo ratings yet

- Wake Frequency CalcDocument4 pagesWake Frequency Calcteban09No ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- 5 Pdfsam SingleDocument1 page5 Pdfsam Singleahmed aboyosefNo ratings yet

- Complete Listing of Silo Elements and Details:: Eng - Ahmed Saad 23-05-23Document1 pageComplete Listing of Silo Elements and Details:: Eng - Ahmed Saad 23-05-23ahmed aboyosefNo ratings yet

- Extracted Pages From 3601709 - Fabrication Drawings1Document1 pageExtracted Pages From 3601709 - Fabrication Drawings1ahmed aboyosefNo ratings yet

- Eng - Ahmed Saad 23-05-23: Density Height Pressure On WallDocument1 pageEng - Ahmed Saad 23-05-23: Density Height Pressure On Wallahmed aboyosefNo ratings yet

- 5 Pdfsam SingleDocument1 page5 Pdfsam Singleahmed aboyosefNo ratings yet

- 5 Pdfsam SingleDocument1 page5 Pdfsam Singleahmed aboyosefNo ratings yet

- 5 Pdfsam SingleDocument1 page5 Pdfsam Singleahmed aboyosefNo ratings yet

- 5 Pdfsam SingleDocument1 page5 Pdfsam Singleahmed aboyosefNo ratings yet

- 5 Pdfsam SingleDocument1 page5 Pdfsam Singleahmed aboyosefNo ratings yet

- AssemDocument4 pagesAssemahmed aboyosefNo ratings yet

- 5 Pdfsam SingleDocument1 page5 Pdfsam Singleahmed aboyosefNo ratings yet

- 5 Pdfsam SingleDocument1 page5 Pdfsam Singleahmed aboyosefNo ratings yet

- 5 Pdfsam SingleDocument1 page5 Pdfsam Singleahmed aboyosefNo ratings yet

- 5 Pdfsam SingleDocument1 page5 Pdfsam Singleahmed aboyosefNo ratings yet

- Grid BDocument4 pagesGrid Bahmed aboyosefNo ratings yet

- StairDocument4 pagesStairahmed aboyosefNo ratings yet

- SingleDocument14 pagesSingleahmed aboyosefNo ratings yet

- Tk100-Parts - PDocument46 pagesTk100-Parts - Pahmed aboyosefNo ratings yet

- Savola: - FCV 260-40 FT 260-40Document1 pageSavola: - FCV 260-40 FT 260-40ahmed aboyosefNo ratings yet

- Volume Design Final 2Document1 pageVolume Design Final 2ahmed aboyosefNo ratings yet

- TK100 - ASSEM - SkidDocument14 pagesTK100 - ASSEM - Skidahmed aboyosefNo ratings yet

- OMR Sheet Has Been Attached at The End: EST Erial ODocument8 pagesOMR Sheet Has Been Attached at The End: EST Erial OSangeeta BansalNo ratings yet

- Galambos 1986Document18 pagesGalambos 1986gcoNo ratings yet

- GastrectomyDocument19 pagesGastrectomyCyrus GarciaNo ratings yet

- Monster Visual Discrimination CardsDocument9 pagesMonster Visual Discrimination CardsLanaNo ratings yet

- Grace Lipsini1 2 3Document4 pagesGrace Lipsini1 2 3api-548923370No ratings yet

- Siga-Cc1 12-22-2010Document6 pagesSiga-Cc1 12-22-2010Felipe LozanoNo ratings yet

- 96 Amazing Social Media Statistics and FactsDocument19 pages96 Amazing Social Media Statistics and FactsKatie O'BrienNo ratings yet

- Types of Speech StylesDocument31 pagesTypes of Speech StylesRomnick BistayanNo ratings yet

- A ULTIMA ReleaseNotesAxiomV PDFDocument38 pagesA ULTIMA ReleaseNotesAxiomV PDFIVANALTAMARNo ratings yet

- Cell Selection ReselectionDocument35 pagesCell Selection ReselectionThiaguNo ratings yet

- Smoktech Vmax User ManualDocument9 pagesSmoktech Vmax User ManualStella PapaNo ratings yet

- Airs-Lms - Math-10 - q3 - Week 3-4 Module 3 Rhonavi MasangkayDocument19 pagesAirs-Lms - Math-10 - q3 - Week 3-4 Module 3 Rhonavi MasangkayRamil J. Merculio100% (1)

- Chanel SWOT AnalysisDocument5 pagesChanel SWOT AnalysisJeish KimNo ratings yet

- 41 PDFsam Redis CookbookDocument5 pages41 PDFsam Redis CookbookHữu Hưởng NguyễnNo ratings yet

- Philippine Police Report Suicide InvestigationDocument2 pagesPhilippine Police Report Suicide InvestigationPAUL ALDANA82% (34)

- List of household items for relocationDocument4 pagesList of household items for relocationMADDYNo ratings yet

- I Button Proper TDocument4 pagesI Button Proper TmariammariaNo ratings yet

- Business EnvironmentDocument12 pagesBusiness EnvironmentAbhinav GuptaNo ratings yet

- District Wise List of Colleges Under The Juridiction of MRSPTU BathindaDocument13 pagesDistrict Wise List of Colleges Under The Juridiction of MRSPTU BathindaGurpreet SandhuNo ratings yet

- Design ThinkingDocument16 pagesDesign ThinkingbhattanitanNo ratings yet

- NSX 100-630 User ManualDocument152 pagesNSX 100-630 User Manualagra04100% (1)

- Starting A Business Candle Making 2009Document2 pagesStarting A Business Candle Making 2009Carlo Fabros Junio100% (4)

- 3.1 C 4.5 Algorithm-19Document10 pages3.1 C 4.5 Algorithm-19nayan jainNo ratings yet

- Lecture 29: Curl, Divergence and FluxDocument2 pagesLecture 29: Curl, Divergence and FluxKen LimoNo ratings yet

- Klein & Kulick Scandolous ActsDocument20 pagesKlein & Kulick Scandolous ActsClaudia Costa GarcíaNo ratings yet

- Guillermo Estrella TolentinoDocument15 pagesGuillermo Estrella TolentinoJessale JoieNo ratings yet

- InteliLite AMF20-25Document2 pagesInteliLite AMF20-25albertooliveira100% (2)

- Project Wise CSR Expenditure FY202223Document15 pagesProject Wise CSR Expenditure FY202223gowowor677No ratings yet

- SCJP 1.6 Mock Exam Questions (60 QuestionsDocument32 pagesSCJP 1.6 Mock Exam Questions (60 QuestionsManas GhoshNo ratings yet

- Analysis and Design of Multi Storey Building by Using STAAD ProDocument5 pagesAnalysis and Design of Multi Storey Building by Using STAAD Prolikith rockNo ratings yet