Professional Documents

Culture Documents

Dol 450

Uploaded by

Chr. VestergaardOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dol 450

Uploaded by

Chr. VestergaardCopyright:

Available Formats

SECTION EIGHT: On-Line Description Creo Models

Important

Your on-line processor has a built in exhaust blower. Even if the main

switch is switched off, the blower will still be on. This is to prevent

chemical fumes in the conveyor/imagesetter. If a timer is connected in

series with the main power cable, the processor has to be modified, so

that the exhaust blower is always running.

Creo Hope / Carnfeldt

Dolev 450 EG 751

8.1 General

This section contains the processor’s basic install the imagesetter first. The imagesetter

operating instructions for working on-line with should be “levelled” and be put in its final

an imagesetter. position before the processor is connected.

Install the processor as described in section

SECTION 8

Before operating the processor on-line, the three. Level the processor in to its final position

procedures in section three Installation must before chemistry is added.

be performed. Read this entire section and

section four (Operation) before attempting to Connect the 9 pin interface cable to the conveyor.

operate the processor. Turn the power on and test the installation.

8.2 Installation of On-Line Section

Special care should be taken when the processor

is connected to imagesetter. Is advisable to

8-89 EG Manual, English Dolev 450

SECTION EIGHT: On-Line Description Creo Models

Contents

8.1 General................................................................................................................................... 89

8.2 Installation of On-Line Section.............................................................................................. 89

8.3 Conveyor Operation ............................................................................................................... 91

Conveyor Timer Settings............................................................................................................... 91

Communication Signals ................................................................................................................ 91

8.4 On-Line Drawings and Settings............................................................................................. 92

Interface PCB for Dolev, Drawing 4080105................................................................................. 92

Interface PCB for Dolev Layout, Drawing 890718 ...................................................................... 92

Cable - Conveyor / Imagesetter, Drawing 317748........................................................................ 93

Dolev Interface Timing Description ............................................................................................. 94

Conveyor Dolev 450, Drawing 317310 ........................................................................................ 95

Dev. / Fix. / Wash Rack 75 cm R43 1 7/8, Drawing 5974 .................................................... 96

Rack Side l.w. Gears R43 1 7/8, Drawing 117815 ....................................................................... 97

Rack Side r. w. Gears R43 1 7/8, Drawing 117825 ...................................................................... 98

Dry Rack R60 HTD drive EG 901, Drawing 320108a ................................................................ 99

Dry Rack R60 HTD Drive EG 901, Drawing 320108b .............................................................. 100

Installationsview 6332 ................................................................................................................ 101

Technical Specifications.............................................................................................................. 102

SECTION 8

Edition: 26 Mar 2002

Product numbers:

317925

EG Manual, English Dolev 450 8-90

SECTION EIGHT: On-Line Description Creo Models

8.3 Conveyor Operation Communication Signals

To display the signals from the imagesetter use

The operation of the conveyor is displayed the information screen shown below. To access

on the left icon. Please observe the conveyor from the main menu push .

icons: For more information see section four Opera-

tion.

Empty conveyor, ready.

Film is being transported in to the

conveyor.

CON1 CON2 CON3 CON4

1 0 0 0

Film is being cut.

PH01 PH02 PH03 PH04

Film is in the conveyor. 1 1 1 1

Film has entered the processor.

Off-line feed. CONX - Status conveyor switches.

PHOX - Status signals from imagesetter.

CON1 - Conveyor sensor right or left

activated ( 1).

Settings of timer and conveyor speed

are adjusted in the service menu. To CON2-3 Not used on Dolev imagesetters.

access the service menu please see section

5.7 CON4 - Load/Feed/Cut signal. (See state

diagram)

PHO1 - PH04 - Not used on Dolev

Conveyor Timer Settings

Number Settings Units Description

Conv. Timer 1 10 0,1 Sec Ready delay: The time from activation of

conveyor sensor wait is sent to imagesetter.

Conv. Timer 2 0 0,1 Sec Not used on Dolev 450.

Conv. Timer 3 40 0,1 Sec No-Feed delay: The time activation of the

SECTION 8

inlet sensor to conveyor motor stop.

Conv. Timer 4 0 0,1 Sec Not used on Dolev.

Conv. Timer 5 60 1 Sec Conveyor: Time out, error time out.

Conveyor/Photoset 4. CreoScitex Dol 450

Conv. motor speed 255

8-91 EG Manual, English Dolev 450

SECTION EIGHT: On-Line Description Creo Models

8.4 On-Line Drawings and Settings

Interface PCB for Dolev, Drawing 4080105

Interface PCB for Dolev Layout, Drawing 890718

The interface PCB is placed on the

conveyor sensor plug !

SECTION 8

You can test the ready signal by

manually activating it via the DC

motor 1. For more information see

section 5.9 in the output part in the

service manual.

EG Manual, English Dolev 450 8-92

SECTION EIGHT: On-Line Description Creo Models

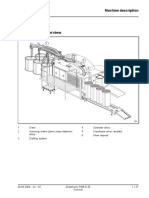

Imagesetter / Dolev

Conveyor

SECTION 8

Interface PCB

Cable - Conveyor / Imagesetter, Drawing 317748

8-93 EG Manual, English Dolev 450

SECTION EIGHT: On-Line Description Creo Models

Dolev Interface Timing Description

High

Low

1 2 3 4

1. Start of plot. This signal will be ignored by the processor.

2. Feeding time. The film is fed out of the Dolev. When the film reaches the inlet

sensor in the conveyor, the conveyor and processor start. The LOAD indicator

on the control panel is on.

3. Cutting Time. The film is cut inside the Dolev. When this is done, the conveyor is

stopped. When the signal goes high again, the conveyor starts again and transports the

film to the processor. The CUT indicator on the control panel is on.

4. The film is transported to the processor. The conveyor stops approx. 1 sec. after the inlet

sensor of the processor is activated. One way bearings on the rollers of the conveyor

allow the processor to pull the film out of the conveyor .

Dolev

SECTION 8

Inlet switch

Processor

Guide mounted

on Dolev NOTE:

Maximum 2mm gap

between Dolev and bottom

of conveyor

EG Manual, English Dolev 450 8-94

SECTION EIGHT: On-Line Description Creo Models

SECTION 8

Conveyor Dolev 450, Drawing 317310

8-95 EG Manual, English Dolev 450

SECTION EIGHT: On-Line Description Creo Models

Roller 50-000 and 55-000

Remmoved if Wet X-over

SECTION 8

Dev. / Fix. / Wash Rack 75 cm R43 1 7/8, Drawing 5974

EG Manual, English Dolev 450 8-96

SECTION EIGHT: On-Line Description Creo Models

SECTION 8

Rack Side l.w. Gears R43 1 7/8, Drawing 117815

8-97 EG Manual, English Dolev 450

SECTION 8

SECTION EIGHT: On-Line Description Creo Models

Rack Side r. w. Gears R43 1 7/8, Drawing 117825

EG Manual, English Dolev 450 8-98

SECTION EIGHT: On-Line Description Creo Models

SECTION 8

Dry Rack R60 HTD drive EG 901, Drawing 320108a

8-99 EG Manual, English Dolev 450

SECTION 8

SECTION EIGHT: On-Line Description Creo Models

Dry Rack R60 HTD Drive EG 901, Drawing 320108b

EG Manual, English Dolev 450 8-100

SECTION EIGHT: On-Line Description Creo Models

†††††††††††††††

SECTION 8

Installationsview 6332

8-101 EG Manual, English Dolev 450

SECTION EIGHT: On-Line Description Creo Models

Hope / Carnfeldt On-Line Processors for Creo Imagesetters:

EG 750 EG 751 EG 752

Dolev 450 Dolev 450 Dolev 450

Dimensions of on-line system

Length 228 cm / 89.8” 252 cm / 99.2” 252 cm / 99.2”

Width 115 cm / 45.3” 115 cm / 45.3” 115 cm / 45.3”

Height 110 cm / 43.3” 110 cm / 43.3” 110 cm / 43.3”

Shipping dimensions

Length 156 cm / 61.4” 156 cm / 61.4” 156 cm / 61.4”

Width 115 cm / 45.3” 115 cm / 45.3” 115 cm / 45.3”

Height 129 cm / 50.8” 129 cm / 50.8” 129 cm / 50.8”

Weight

Net 233 kg / 514 lb. 345 kg / 761 lb. 345 kg / 761 lb.

Gross 315 kg / 695 lb. 450 kg / 992 lb. 450 kg / 992 lb.

Specifications

Inlet width 75 cm / 29" 75 cm / 29” 75 cm / 29”

Tank capacity 25 l / 6.6 US gal. 26.5 l / 7 US gal. 35 l / 9.3 US gal.

Rack length dev. 32 cm / 12.6” 44 cm / 17.3” 67 cm / 26.4”

Developing time min.-max. 20-80 sec. 15-90 sec. 15-90 sec

Speed at 30 sec. dev. time 64 cm/min. 88 cm/min. 134 cm/min.

25.2”/min. 34.6”/min 52.8”/min

Max. film length off-line 5 m / 16.4 ft 10 m / 32.8 ft 10 m / 32.8 ft

Min. film size off-line 18x10 cm / 7 x 4” 18x10 cm / 7 x 4” 18x10 cm / 7 x 4”

Max. format (set by imagesetter) 66x54 cm / 26x21” 66x54 cm / 26x21” 66x54 cm / 26x21”

Dev./fix./wash temperature range 20-45°C/68-113°F 20-45°C/68-113°F 20-45°C/68-113°F

Exhaust blower Built in Built in Built in

Exhaust connection Ø 10 cm/4" Ø 10 cm/4” Ø 10 cm/4”

Circulation rate dev., fix. 10 l/min./2.7 US gal. 22 l/min./5.8 US gal. 22 l/min./5.8 US gal

Water consumption (operate) 3.5 l/min./0.9 US gal. 3.5 l/min./0.9 US gal. 3.5 l/min./0.9 US gal.

Emission of heat to room (operate) 2000 W/586 BTU/hr 2300W/674BTU/hr 2300W/674 BTU/hr

Water connection 3⁄4” MPT 3⁄4” MPT 3⁄4” MPT

Drain connection 6 x 1" hose nipple 3x1” hose nipple 3x1” hose nipple

Replenishment containers Dev/fix 30 l/8 US gal. Dev/fix 30l/8 US gal. Dev/fix 30l/8 US gal.

Max. power consumption 3700 VA 5900VA 5900VA

Average power consumption:

Operate 3100 W 5000W 5000W

Power save 600 W 1000W 2000W

Night mode 550 W 600W 600W

Power supply:

1x230ACV+/-10% / 50/60Hz 20 amp 30 amp 30 amp

3x230ACV+/-10% / 50/60Hz - 3 x 16 amp 3x16 amp

SECTION 8

Technical Specifications

EG Manual, English Dolev 450 8-102

You might also like

- Audio Board Schematic OverviewDocument28 pagesAudio Board Schematic OverviewVicente FernandezNo ratings yet

- Micro Controller Washing Machine TimerDocument40 pagesMicro Controller Washing Machine TimerArjun Pratap Singh85% (20)

- Manual de Referencia PlanmecaDocument288 pagesManual de Referencia PlanmecaJorge Escalona Hernandez100% (2)

- 3 DOF Helicopter - User ManualDocument23 pages3 DOF Helicopter - User ManualMurilloMaganNo ratings yet

- Manual NIMBUS VTOLDocument23 pagesManual NIMBUS VTOLEwfa RamenNo ratings yet

- PLC Programming from Novice to Professional: Learn PLC Programming with Training VideosFrom EverandPLC Programming from Novice to Professional: Learn PLC Programming with Training VideosRating: 5 out of 5 stars5/5 (1)

- Main Products IntroductionDocument99 pagesMain Products Introductionmliugong100% (1)

- LF20 LF30 Desktop Type User's Manual - Kuntai (Tracy)Document30 pagesLF20 LF30 Desktop Type User's Manual - Kuntai (Tracy)Denis Bender0% (1)

- Drawing CombingDocument29 pagesDrawing CombingShoaib ArifNo ratings yet

- Dol8 - 0 317996 317997Document23 pagesDol8 - 0 317996 317997Chr. VestergaardNo ratings yet

- Dol4P 1Document20 pagesDol4P 1Chr. VestergaardNo ratings yet

- Estun ProNet Series Users Manual V2.02Document182 pagesEstun ProNet Series Users Manual V2.02Valeriy KobaNo ratings yet

- Emotron Syncoption Instruction 01-5828-01r1.enDocument28 pagesEmotron Syncoption Instruction 01-5828-01r1.enhadiNo ratings yet

- 0101 PDFDocument30 pages0101 PDFMuchamadAndiPutraNo ratings yet

- Posi-Stop ManualDocument16 pagesPosi-Stop Manualandres gonzalezNo ratings yet

- PKONV EC-IFSF Manual V1.3 ENDocument19 pagesPKONV EC-IFSF Manual V1.3 ENsavantzpcdmaNo ratings yet

- Service: Mammolux R2Document46 pagesService: Mammolux R2man12757No ratings yet

- Setup Manual: 3Urjudppdeoh7HuplqdovDocument108 pagesSetup Manual: 3Urjudppdeoh7HuplqdovBouain AnisNo ratings yet

- QNET VTOL User ManualDocument27 pagesQNET VTOL User ManualSuryabhan SinghNo ratings yet

- Qnet Rotpen User ManualDocument12 pagesQnet Rotpen User ManualJose Osbaldo Trejo OrtizNo ratings yet

- Tech-Tool_Release_News_2.8.230Document10 pagesTech-Tool_Release_News_2.8.230Reza AminiNo ratings yet

- v107 Nb-Series Setup Manual enDocument108 pagesv107 Nb-Series Setup Manual enNestor MarriagaNo ratings yet

- Flo-Tech™ Integrated Actuator and Throttle Body: Installation and Operation ManualDocument24 pagesFlo-Tech™ Integrated Actuator and Throttle Body: Installation and Operation ManualAbdulrehman Soomro100% (1)

- Comunicacion Omron S71200Document206 pagesComunicacion Omron S71200Jaime FernandezNo ratings yet

- Analogicas Opcionales Slot de Comunicaciones MAB221-ADB21-DAB21Document18 pagesAnalogicas Opcionales Slot de Comunicaciones MAB221-ADB21-DAB21RUBEN ELECTROMAINNo ratings yet

- Xrio Converter Manual Abb Ref615 v1.0 Enu Tu2.22 v1.000Document11 pagesXrio Converter Manual Abb Ref615 v1.0 Enu Tu2.22 v1.000m_dh87129No ratings yet

- Manual Programacao Bematech MP 4200 THDocument113 pagesManual Programacao Bematech MP 4200 THMichael FeijóNo ratings yet

- Startup Guide Manual: 3Urjudppdeoh7HuplqdovDocument126 pagesStartup Guide Manual: 3Urjudppdeoh7HuplqdovMashudSalehNo ratings yet

- ENG - Delta S4 Operator Manual V1.0Document13 pagesENG - Delta S4 Operator Manual V1.0rommel Cheugoua DjandjeuNo ratings yet

- ETS Series AC Servo User's Manual: Version V1.06Document144 pagesETS Series AC Servo User's Manual: Version V1.06Joimir PerezNo ratings yet

- NB HMI Comm ProtocolsDocument166 pagesNB HMI Comm ProtocolsFelix Yuksel ArisoyNo ratings yet

- UNIGEN en - Technical Documentation PDFDocument24 pagesUNIGEN en - Technical Documentation PDFMiroslav VasicNo ratings yet

- Owner'S Manual: Manual de Usuario Manual Do UsuárioDocument32 pagesOwner'S Manual: Manual de Usuario Manual Do UsuáriofelipizilNo ratings yet

- Owl RobotDocument32 pagesOwl RobotgerpemNo ratings yet

- Rotary Pendulum - Quick Start GuideDocument4 pagesRotary Pendulum - Quick Start GuidedanisthemannotNo ratings yet

- Intelilite 9: New Features ListDocument21 pagesIntelilite 9: New Features Listjessner mataNo ratings yet

- v108 Nb-Series Host Connection Setup Manual enDocument214 pagesv108 Nb-Series Host Connection Setup Manual enhaith2407No ratings yet

- cs50 Software Industrial Protocol ManualDocument236 pagescs50 Software Industrial Protocol ManualNhiBônNo ratings yet

- NB-Designer Operation Manual: Programmable TerminalsDocument558 pagesNB-Designer Operation Manual: Programmable TerminalsBouain AnisNo ratings yet

- User Manual: Manufactured by ItalyDocument66 pagesUser Manual: Manufactured by ItalyRaul Angel Perez AbadNo ratings yet

- TT Release News 2.8.170Document14 pagesTT Release News 2.8.170Quispe EfrainNo ratings yet

- "Synchronization and Load Sharing ": Technical DocumentationDocument41 pages"Synchronization and Load Sharing ": Technical DocumentationduaNo ratings yet

- ME Electives 4 Experiment 6 Conveyor Belt ControlDocument9 pagesME Electives 4 Experiment 6 Conveyor Belt Controlmon patrick pradoNo ratings yet

- Introduction To Manufacturing: Automation and RoboticsDocument202 pagesIntroduction To Manufacturing: Automation and RoboticsCesar GeronimoNo ratings yet

- Technician's Facility For Westlock: User ManualDocument224 pagesTechnician's Facility For Westlock: User Manualm rioNo ratings yet

- XRIO Converter Manual Siemens 7SD610 V4.6 TU2.22 ENU V1.000Document9 pagesXRIO Converter Manual Siemens 7SD610 V4.6 TU2.22 ENU V1.000Sakthi MuruganNo ratings yet

- Industrialprotocolmanual enDocument310 pagesIndustrialprotocolmanual endinhquang19991No ratings yet

- Image System CD100 Technical Man - Code 50 80 004Document129 pagesImage System CD100 Technical Man - Code 50 80 004Anthony RichardNo ratings yet

- Hands-On Guide To OVSV610R103 C&C08 Switch: Huawei Technologies Co., LTDDocument29 pagesHands-On Guide To OVSV610R103 C&C08 Switch: Huawei Technologies Co., LTDAbdullatifNo ratings yet

- Manual NBDocument214 pagesManual NBRiichArd GutiieRrezNo ratings yet

- ESA Update AnnouncementDocument5 pagesESA Update Announcementedin cabreraNo ratings yet

- PJ1000C-LCD: User ManualDocument30 pagesPJ1000C-LCD: User ManualQuive CarlosNo ratings yet

- Selec Atsel VFD User Manual - 2020Document44 pagesSelec Atsel VFD User Manual - 2020pampankgNo ratings yet

- ProntoPro OG 5230814614 - Edn 1 PDFDocument21 pagesProntoPro OG 5230814614 - Edn 1 PDFroshan mungurNo ratings yet

- Siemens PLC With TIA Portal V12 Prof SP1 enDocument52 pagesSiemens PLC With TIA Portal V12 Prof SP1 enernesto antonioNo ratings yet

- Electro-Hydraulic Actuator Type PVEP / PVEP-F TechDocument16 pagesElectro-Hydraulic Actuator Type PVEP / PVEP-F TechHYDRAULICGURUNo ratings yet

- ComAp InteliPro Comprehensive Guide 1 5Document110 pagesComAp InteliPro Comprehensive Guide 1 5manuel enrique reyes duarteNo ratings yet

- FLUXGATE NETCOURSE Detector-CP102B Installation&Operation ManualDocument16 pagesFLUXGATE NETCOURSE Detector-CP102B Installation&Operation ManualWilmer J Zambrano DNo ratings yet

- Ci RL4 MBMCDocument23 pagesCi RL4 MBMCktriantafillidis5No ratings yet

- User Manual For Teraranger Tower Evo: Hardware Revision 1.0 Firmware Revision 1.1.1Document27 pagesUser Manual For Teraranger Tower Evo: Hardware Revision 1.0 Firmware Revision 1.1.1Victor CuadraNo ratings yet

- CA751 IM E GeorgiaDocument56 pagesCA751 IM E GeorgiaGiorgi KurtsikidzeNo ratings yet

- Ventilation Control: For Suprabox Comfort 800 To 5000Document51 pagesVentilation Control: For Suprabox Comfort 800 To 5000Tempo BrasilNo ratings yet

- FC Series Add-On Instruction For VLT® EtherNetIP MCA 121 MG92M102Document14 pagesFC Series Add-On Instruction For VLT® EtherNetIP MCA 121 MG92M102Lisias MouraNo ratings yet

- Polaroid LCD FLM1511Document30 pagesPolaroid LCD FLM1511videosonNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- HHP engine fault codesDocument41 pagesHHP engine fault codesWhite Tiger100% (1)

- DELL Optiplex 390 Tech GuideDocument38 pagesDELL Optiplex 390 Tech Guidesearching1_2No ratings yet

- A Universal Programming Cable For RadiosDocument39 pagesA Universal Programming Cable For RadiosANSELMO LIMANo ratings yet

- Protection Coordination Back UpDocument35 pagesProtection Coordination Back UpJohn Paul Inovero JavierNo ratings yet

- Instrumentation and ControlDocument13 pagesInstrumentation and ControlEvans HopeNo ratings yet

- Tranquility 27 (TT) Series Tranquility 20 (TS) Series Tranquility 16 (TC) Series Tranquility (TR) SeriesDocument84 pagesTranquility 27 (TT) Series Tranquility 20 (TS) Series Tranquility 16 (TC) Series Tranquility (TR) SeriesMichael MartinNo ratings yet

- 4 Quarter: Technical Drafting 9Document18 pages4 Quarter: Technical Drafting 9severiano pamplonaNo ratings yet

- Computer Organization Unit-1Document147 pagesComputer Organization Unit-1Akula Lakshmi SreenivasuluNo ratings yet

- ELECTRIC MOTOR CONTROLS TOPICSDocument24 pagesELECTRIC MOTOR CONTROLS TOPICSKim KeatNo ratings yet

- Continuous Level Measurement - Ultrasonic ControllersDocument8 pagesContinuous Level Measurement - Ultrasonic ControllersSaipavan ChanduNo ratings yet

- Service Manual PGN511 (Allure A9+) : SPA Condor ElectronicsDocument15 pagesService Manual PGN511 (Allure A9+) : SPA Condor ElectronicsLife PowerNo ratings yet

- ABS HIRA For Store ConstructionDocument6 pagesABS HIRA For Store Constructionsyed khaja misbhuddinNo ratings yet

- Motion Sensors: by Elva S. Agbon Ics 30 BDocument10 pagesMotion Sensors: by Elva S. Agbon Ics 30 BMukul KumarNo ratings yet

- Dimensions: Size Li - SsDocument3 pagesDimensions: Size Li - SsShubh BhawsarNo ratings yet

- 42LC3D ManualDocument68 pages42LC3D ManualKeith ConradNo ratings yet

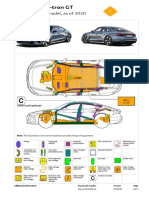

- Audi Rescue Data Sheets (E-Tron GT - Sportback - 2020 - 5d - Electric - EN)Document4 pagesAudi Rescue Data Sheets (E-Tron GT - Sportback - 2020 - 5d - Electric - EN)caragan1970No ratings yet

- Rizal Technological University College of Engineering and Industrial Technology Boni Avenue, City of MandaluyongDocument4 pagesRizal Technological University College of Engineering and Industrial Technology Boni Avenue, City of MandaluyongTech ProfessorNo ratings yet

- Emp-168 Analizador Bioquimico PDFDocument2 pagesEmp-168 Analizador Bioquimico PDFAlberto Ybañez CastañedaNo ratings yet

- STI WS100SG2 Instruction ManualDocument24 pagesSTI WS100SG2 Instruction ManualJMAC Supply100% (1)

- EEE 1: Essentials of Electrical and Electronics Engineering: Lecture 0: Lab FamiliarizationDocument18 pagesEEE 1: Essentials of Electrical and Electronics Engineering: Lecture 0: Lab FamiliarizationAverly Jerryl EscotoNo ratings yet

- Choosing Between Semi-Bridgeless or Interleaved PFC Pre-RegulatorsDocument4 pagesChoosing Between Semi-Bridgeless or Interleaved PFC Pre-RegulatorsJean-Yves LAPORTENo ratings yet

- Aeg L82470bi PDFDocument72 pagesAeg L82470bi PDFCecília PerdigãoNo ratings yet

- 2 Link Belt MG434 Service Manual EnglishDocument80 pages2 Link Belt MG434 Service Manual EnglishraulNo ratings yet

- 50 Years of Crane Component ExcellenceDocument32 pages50 Years of Crane Component ExcellenceMahnooshNo ratings yet

- OM 532-06435-En-Collahuasi Rev000Document112 pagesOM 532-06435-En-Collahuasi Rev000Marcos Matias MedinaNo ratings yet