Professional Documents

Culture Documents

18.aph Gude Bearing B-Min-Min

Uploaded by

Abhishek KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

18.aph Gude Bearing B-Min-Min

Uploaded by

Abhishek KumarCopyright:

Available Formats

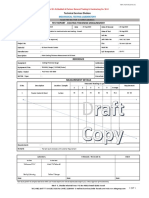

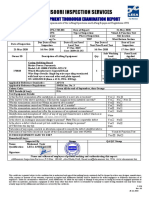

MVS ACMEI Technologies Pvt Ltd

LAB REPORT ON IN-SERVICE LUBE CM ANALYSIS

Client's Name : DAMODAR VALLEY CORPORATION BTPS Client's Plant Location : BOKARO JHARKHAND

MACHINE

Job Details Related to Client Equipment Information CONDITION

Department/Equipment

Name of Equipment APH GUDE BEARING B

Location

Type of Job Equipment Code of Client

Sample Sl.No 18 Function of Equipment

Sample Date May 10, 2023 Oil Sample Taken from

Sample Received at Lab May 17, 2023 Oil/Grease Operating Temp

Lab Sent Report May 31, 2023 Last Date of Major Failure

LUBRICANT

Additional Information for proper Analysis & Recommendation CONDITION

Type of Oil/Grease BEARING OIL Type of Gear

Oil Viscosity Grade SERVO CYL C680 Type of Bearing

Grease Grade Filter Mesh Size

Top-Up Last Date Oil Pr. Across Filter

Replacement Date Motor KW Rating

Heat Exchanger Motor RPM

Sump/Tank/MOT

35 LTR

Capacity (Litres)

SNAP-SHOT - IN-SERVICE LUBE CONDITION MONITORING STATUS (CURRENT + PREVIOUS THREE) :

Current

Previous Three Samples

Test Method/ Sample

Testing Parameters Type of Analysis & (UOM)

ASTM Ref. Sample Dated Sample Dated Sample Dated Sample Dated

May 10, 2023 Feb 08, 2023 Nov 10, 2022

Quantitative Analysis Cleanliness Level

NAS 1638 Class 10 N 10 N 12 A

ISO 4406 Level

Qualitative Analysis Wear Debris Analysis ASTM D7690

Machine Condition

Analytical Ferrography 7.00 N 13.00 N 20.00 C

Index

Abbrevations : N-Normal C-Caution A-Alert

CREATING VALUE WITH INTEGRATED RELIABILITY MAINTENANCE SERVICES

MVS ACMEI TECHNOLOGIES PVT.LTD., Mail: oilcm@acmeirm.com, Web: www.mvsgroup.co.in

Regd Office : #31, Leeven Heights, Jubilee Enclave, Madhapur Hyderabad-500081,Telangana

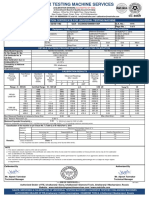

MVS ACMEI Technologies Pvt Ltd

LAB REPORT ON IN-SERVICE LUBE CM ANALYSIS

PROGNOSTIC EXPERTS IN FLUID TECHNOLOGIES

Name of Equipment Equipment Code of Client Lab Sample Code Oil Viscosity/Grease Grade

APH GUDE BEARING B CC215S18V3 SERVO CYL C680

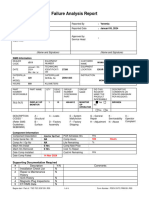

Analytical Ferrography / Wear Debris Analysis

MACHINE CONDITION INDEX : 7.00 Range & Limit : 16.00 - 23.00 Normal

TYPE OF WEAR

SLNO N N-F F F-M M M-H H FERROGRAM - 500X

PARTICLES

1 Normal Rubbing Wear ✔

2 Fatigue Wear ✔

3 Spheres ✔

4 Laminar Particles ✔

5 Severe Sliding Wear ✔

6 Catastrophic Wear ✔

7 Cutting Wear Particles ✔

8 Red Oxide ✔

9 Dark Metal Oxide ✔

10 Black Oxide ✔

11 Non-Ferrous Metallic ✔

12 Non-Metallic Crystals ✔

Non-Metallic

13

Amorphous ✔

14 Friction Polymers ✔

15 Fibers ✔

16 Copper Wear Debris ✔

Legend: N=NONE (0); N-F=NON to FEW (0.5); F=FEW (1); F-M=FEW to MODERATE (1.5); M=MODERATE (2); M-H=MODERATE to HEAVY (2.5); H=HEAVY (3)

Qualitative Observations

Normal rubbing wear particles are observed was rated in Few concentrations.

Non-metallic crystal (sand/dirt) particles are observed was rated in Few concentrations.

Laminar wear particles are measured to 38 microns in size as the particles observed was rated Few.

Investigative Observations

Wear Pattern Study indicates normal behavior.

CREATING VALUE WITH INTEGRATED RELIABILITY MAINTENANCE SERVICES

MVS ACMEI TECHNOLOGIES PVT.LTD., Mail: oilcm@acmeirm.com, Web: www.mvsgroup.co.in

Regd Office : #31, Leeven Heights, Jubilee Enclave, Madhapur Hyderabad-500081,Telangana

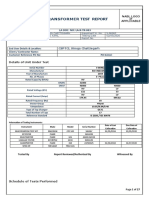

MVS ACMEI Technologies Pvt Ltd

LAB REPORT ON IN-SERVICE LUBE CM ANALYSIS

PROGNOSTIC EXPERTS IN FLUID TECHNOLOGIES

Name of Equipment Equipment Code of Client Lab Sample Code Oil Viscosity/Grease Grade

APH GUDE BEARING B CC215S18V3 SERVO CYL C680

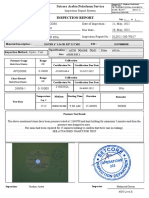

In-Service Lube Oil Contamination Level Analysis

Particle Count NAS 1638 System Standard

Contamination Status Normal

Particle Size Range No. of Particles/100ml

2-5 Microns

5-15 Microns 135206

15-25 Microns 10147

25-50 Microns 3620

50-100 Microns 510

>100 Microns 75

System NAS Level Class : 10

In-Service Lube Oil Contamination Level Quantitative Observations

Contamination status (NAS) found Normal.

Investigative Observations

Prescribed all Test Results are within limits.

RECOMMENDATION:

To Continue Normal Operation.

CREATING VALUE WITH INTEGRATED RELIABILITY MAINTENANCE SERVICES

MVS ACMEI TECHNOLOGIES PVT.LTD., Mail: oilcm@acmeirm.com, Web: www.mvsgroup.co.in

Regd Office : #31, Leeven Heights, Jubilee Enclave, Madhapur Hyderabad-500081,Telangana

MVS ACMEI Technologies Pvt Ltd

LAB REPORT ON IN-SERVICE LUBE CM ANALYSIS

PROGNOSTIC EXPERTS IN FLUID TECHNOLOGIES

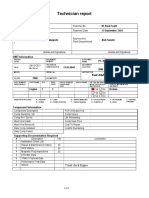

Analytical Ferrography Trends

Note :

Our in-Service Lube Condition Monitoring Report Observations and Recommendations are limited to Scope of Analysis offered in the Client prescribed AMC

Contract/Service Call W.O., Sample Collection Scope, extent of Oil & Equipment Data/Information furnished by Client as desired in our Report Format and/also

corrective action taken as per our earlier Reports (as the case may be).

CREATING VALUE WITH INTEGRATED RELIABILITY MAINTENANCE SERVICES

MVS ACMEI TECHNOLOGIES PVT.LTD., Mail: oilcm@acmeirm.com, Web: www.mvsgroup.co.in

Regd Office : #31, Leeven Heights, Jubilee Enclave, Madhapur Hyderabad-500081,Telangana

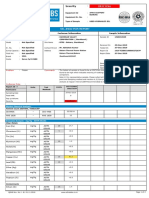

DAMODAR VALLEY CORPORATION BTPS

ELEMENTAL ANALYSIS TEST REPORT

EQUIPMEMT DETAILS SAMPLE DETAILS

EQUIPMEMT NAME APH GUIDE BEARING B REPORT NO 18

COMPONENT BEARING SAMPLE DATE 10.05.2023

MFR -- RECIEVED DATE 17.05.2023

AREA MILL AREA REPORT DATE 31.05.2023

LUBRICANT NAME SERVO CYL C680 LAB SAMPLE ID CC215S18V3

SUMP CAPACITY 35 LTR SAMPLE POINT NA

TEST REPORT

RECOMMENDATION : wear metal analysis shows the normal machine condition.

RESULTS

TEST PARAMETERS UOM LIMITS Current result Previous results TEST METHOD

10.05.2023 08.02.2023 10.11.2022

WEAR METALS

IRON, Fe PPM 150 50.8 53.1 41.9 ASTM D 5185

CHROMIUM, Cr PPM 10 <1 <1 <1 ASTM D 5185

TIN, Sn PPM -- <1 <1 <1 ASTM D 5185

SILVER,Ag PPM -- <1 <1 <1 ASTM D 5185

ALUMINIUM, Al PPM 20 <1 <1 <1 ASTM D 5185

NICKEL, Ni PPM -- <1 <1 <1 ASTM D 5185

COPPER, Cu PPM 50 5.1 5.9 7.3 ASTM D 5185

LEAD, Pb PPM 50 <1 <1 <1 ASTM D 5185

TITANIUM,Ti PPM -- <1 <1 <1 ASTM D 5185

CADMIUM,Cd PPM -- <1 <1 <1 ASTM D 5185

MANGANESE,Mn PPM -- <1 <1 <1 ASTM D 5185

MOLYBDENUM, Mo PPM -- <1 <1 <1 ASTM D 5185

CONTAMINATION

VANADIUM,V PPM 30 <1 <1 <1 ASTM D 5185

SILICON, Si PPM 30 10.2 11.4 9.2 ASTM D 5185

SODIUM, Na PPM 50 <1 <1 <1 ASTM D 5185

ADDITIVES

CALCIUM, Ca PPM -- 21.3 20.5 22 ASTM D 5185

MAGNESIUM, Mg PPM -- <1 <1 <1 ASTM D 5185

BORON, B PPM -- <1 <1 <1 ASTM D 5185

ZINC, Zn PPM -- 90.5 96.3 84.6 ASTM D 5185

PHOSPHOROUS, P PPM -- 86.3 80.2 71.7 ASTM D 5185

BARIUM, Ba PPM -- <1 <1 <1 ASTM D 5185

**********End Report**********

MVS ACMEI TECHNOLOGIES PVT.LTD., Mail: oilcm@acmeirm.com, Web: www.mvsgroup.co.in,Regd Office : #31, Leeven Heights, Jubilee Enclave, Madhapur Hyderabad-

500081,Telangana

You might also like

- Hydraulic System For Bucket Wheel-MinDocument4 pagesHydraulic System For Bucket Wheel-Minsivasakti chp2No ratings yet

- Oil Analysis Report: Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil NaduDocument11 pagesOil Analysis Report: Power Mech Projects LTD Site: 2x600 MW CEPL-Tuticorin-Tamil Nadudevi JammanaNo ratings yet

- Vendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefDocument3 pagesVendor Inspection Results Aal Inspection Results: Sample Description (Please Tick) For Aal RefAmit KumarNo ratings yet

- Omega Laboratory Test ReportDocument7 pagesOmega Laboratory Test ReportSumit JainNo ratings yet

- MT Inspection Record Form For Compressor Rotor: 05-TR-RCDDocument3 pagesMT Inspection Record Form For Compressor Rotor: 05-TR-RCDHimanyu RafiqNo ratings yet

- Preventive Maintenance-Cooling TowerDocument9 pagesPreventive Maintenance-Cooling TowerMuhammed Raqib Mohamed RazaliNo ratings yet

- Client:: Olectra Greentech LTDDocument1 pageClient:: Olectra Greentech LTDnareshNo ratings yet

- Sae 1035Document2 pagesSae 1035Maintenance Plant 1 & 2No ratings yet

- Technical Services Division: Mechanical Testing LaboratoryDocument1 pageTechnical Services Division: Mechanical Testing Laboratorym.aliNo ratings yet

- Testing Protocol for Steel Seamless PipesDocument7 pagesTesting Protocol for Steel Seamless Pipesqc deNo ratings yet

- Lube Oil PresentationDocument19 pagesLube Oil Presentationasirul_meNo ratings yet

- TRDR 300204825BDocument2 pagesTRDR 300204825BVidya SheeshNo ratings yet

- Sae 1010Document2 pagesSae 1010Maintenance Plant 1 & 2No ratings yet

- Saic Q 1001Document2 pagesSaic Q 1001Hussain Nasser Al- NowiesserNo ratings yet

- Inspection Report: 150 MW Dhamangaon Solar Project, MaharashtraDocument6 pagesInspection Report: 150 MW Dhamangaon Solar Project, Maharashtrakaushik21185No ratings yet

- Updated Standard Manufacturing Quality Plan For Battery ChargersDocument4 pagesUpdated Standard Manufacturing Quality Plan For Battery ChargersAbhilash KumarNo ratings yet

- Qap TataDocument5 pagesQap TataDesign VardhNo ratings yet

- Ultrasonic Testing Procedure Qualification Record for Gas Pipeline WeldsDocument10 pagesUltrasonic Testing Procedure Qualification Record for Gas Pipeline WeldsArvind Sahani100% (1)

- Raw Material Incoming Inspection Report: 0.23 - 0.28 0.30 Max 0.90 - 1.30 0.03 Max 0.03 Max 0.10 - 0.20 0.0005 - 0.003Document2 pagesRaw Material Incoming Inspection Report: 0.23 - 0.28 0.30 Max 0.90 - 1.30 0.03 Max 0.03 Max 0.10 - 0.20 0.0005 - 0.003Maintenance Plant 1 & 2No ratings yet

- Saudi Aramco Pre-Commissioning Form: Instrument TransformersDocument4 pagesSaudi Aramco Pre-Commissioning Form: Instrument TransformersJithuRaj0% (1)

- Omega: ServicesDocument7 pagesOmega: ServicesSumit JainNo ratings yet

- Oil Analysis Evaluation BasicsDocument10 pagesOil Analysis Evaluation BasicsJuan Carlos Espinoza FloresNo ratings yet

- Magnetic Particle Testing ReportDocument3 pagesMagnetic Particle Testing ReportRonel John Rodriguez CustodioNo ratings yet

- 10CDCF LM-1600406 (PFGD)Document2 pages10CDCF LM-1600406 (PFGD)Sohaib AhmadNo ratings yet

- Toyota PickupDocument11 pagesToyota Pickupalexberhane3No ratings yet

- Satr A 2001Document7 pagesSatr A 2001Naveed ShahNo ratings yet

- 1114-1182 Vij Engineers & Consultants PVT LTD UTE - 40-1156Document1 page1114-1182 Vij Engineers & Consultants PVT LTD UTE - 40-1156VikasNo ratings yet

- Transformer Test Report: LA DOC. NO: LA-R-TR-003Document27 pagesTransformer Test Report: LA DOC. NO: LA-R-TR-003mayur dhandeNo ratings yet

- Omega: ServicesDocument7 pagesOmega: ServicesSumit JainNo ratings yet

- Man Rider Winch VisualDocument6 pagesMan Rider Winch VisualRanjithNo ratings yet

- Bolt Test Certificate for M12 1.75Px100 GalznDocument1 pageBolt Test Certificate for M12 1.75Px100 GalznBARKAT ALINo ratings yet

- Crs 000007Document2 pagesCrs 000007ahetesham marufNo ratings yet

- Far Report Can't Crank D6R SN TTT00894 Site Patratani Pt. DizamatraDocument5 pagesFar Report Can't Crank D6R SN TTT00894 Site Patratani Pt. Dizamatrasumarno ajaNo ratings yet

- Lab Report FormateDocument3 pagesLab Report FormateSrini VasanNo ratings yet

- Ved New Sep 320 Ok ReportDocument44 pagesVed New Sep 320 Ok ReportRaj YadavNo ratings yet

- Indian Oil Corporation Limited: ASTM/IP/IS1448)Document3 pagesIndian Oil Corporation Limited: ASTM/IP/IS1448)Arvind DhakaNo ratings yet

- Raw Material Incoming Inspection Report: 0.18 - 0.23 0.30 Max 0.80 - 1.10 0.03 Max 0.03 Max 0.10 - 0.20 0.0005 - 0.003Document1 pageRaw Material Incoming Inspection Report: 0.18 - 0.23 0.30 Max 0.80 - 1.10 0.03 Max 0.03 Max 0.10 - 0.20 0.0005 - 0.003Maintenance Plant 1 & 2No ratings yet

- Ultrasonic Testing Thickness Measurement Report: Component DescriptionDocument2 pagesUltrasonic Testing Thickness Measurement Report: Component DescriptionPand AemonaEon100% (4)

- LA Ravi Sir NC 7Document6 pagesLA Ravi Sir NC 7mangalamtestingbureaNo ratings yet

- Autran MBX-pds-EngDocument3 pagesAutran MBX-pds-EngVusal HasanovNo ratings yet

- Inspection Report: Setcore Arabia Petroleum ServiceDocument1 pageInspection Report: Setcore Arabia Petroleum ServiceMahmoud SalahNo ratings yet

- Sample Test Certificate (24.12.2022)Document1 pageSample Test Certificate (24.12.2022)PalaniyandiNo ratings yet

- Premiovin Solution 2021Document3 pagesPremiovin Solution 2021AMUDI EMEKANo ratings yet

- Report Genset TimbanganDocument4 pagesReport Genset TimbanganmahmudiNo ratings yet

- Casing Stabbing BoardDocument1 pageCasing Stabbing BoardRanjithNo ratings yet

- Galvanizing Coating Thickness ReportsDocument3 pagesGalvanizing Coating Thickness Reportsm.aliNo ratings yet

- Ut Report-1 PDFDocument1 pageUt Report-1 PDFsureshrathod2No ratings yet

- Magnetic Particle Inspection Report for Mask Fasteners Pvt LtdDocument2 pagesMagnetic Particle Inspection Report for Mask Fasteners Pvt LtdGauravNo ratings yet

- Phased Array Examination Report: Nexus Inspectorate Private LimitedDocument1 pagePhased Array Examination Report: Nexus Inspectorate Private LimitedNexus InspectorateNo ratings yet

- Saudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechDocument2 pagesSaudi Aramco Test Report: Calibration Test Report - Pressure Recorder SATR-A-2004 24-Mar-16 MechSajid ShaikhNo ratings yet

- ELV (ED Coating)Document2 pagesELV (ED Coating)Mohit SinghNo ratings yet

- Tesla Cybertruck Beast EpaDocument13 pagesTesla Cybertruck Beast EpaJoey Klender0% (1)

- FAR_ZBN41205Document4 pagesFAR_ZBN41205yeremia kristianNo ratings yet

- Setcore Arabia Petroleum Service Inspection ReportDocument1 pageSetcore Arabia Petroleum Service Inspection ReportMahmoud SalahNo ratings yet

- Kuwait Lab Tests Zinc Coating ThicknessDocument3 pagesKuwait Lab Tests Zinc Coating Thicknessm.aliNo ratings yet

- Component Condition Report DM007Document9 pagesComponent Condition Report DM007ahmat ramadaniNo ratings yet

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisFrom EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisRating: 4 out of 5 stars4/5 (2)

- Aph#a Support BearingDocument4 pagesAph#a Support BearingAbhishek KumarNo ratings yet

- Specific Energy Consumption & Throughput of Coal Mill BTPS-A (Mar-23)Document1 pageSpecific Energy Consumption & Throughput of Coal Mill BTPS-A (Mar-23)Abhishek KumarNo ratings yet

- pressureProcedTest PDFDocument7 pagespressureProcedTest PDFfaizal azizNo ratings yet

- TD-022 Air Preheater Support Bearing - Insllatation CareDocument1 pageTD-022 Air Preheater Support Bearing - Insllatation CareAbhishek KumarNo ratings yet

- Taper Roller BearingDocument130 pagesTaper Roller BearingAbhishek KumarNo ratings yet

- pressureProcedTest PDFDocument7 pagespressureProcedTest PDFfaizal azizNo ratings yet

- Modified OM On Revised TA, DA & LTA EntitlementDocument1 pageModified OM On Revised TA, DA & LTA EntitlementAbhishek KumarNo ratings yet

- ICICI Bank Credit Card Fees and ChargesDocument11 pagesICICI Bank Credit Card Fees and ChargesAbhishek KumarNo ratings yet

- 1319 3 Guidelines For WeldingDocument64 pages1319 3 Guidelines For Weldingg_sanchetiNo ratings yet

- 5556 Setting Techniques For Timken Tapered Roller BearingsDocument20 pages5556 Setting Techniques For Timken Tapered Roller BearingsAnonymous Clyy9NNo ratings yet

- NSK CAT E728g 6 PDFDocument11 pagesNSK CAT E728g 6 PDFScarduelliNo ratings yet

- Thermal Insulation Application GuideDocument7 pagesThermal Insulation Application GuideAbhishek KumarNo ratings yet

- Safety ValveDocument56 pagesSafety ValveAbhishek KumarNo ratings yet

- Nkeksnj ?KKVH Fuxe Cksdkjks Rki Fo - QR Dsunz: / Damodar Valley Corporation / Bokaro Thermal Power StationDocument7 pagesNkeksnj ?KKVH Fuxe Cksdkjks Rki Fo - QR Dsunz: / Damodar Valley Corporation / Bokaro Thermal Power StationAbhishek KumarNo ratings yet

- Chemistry in Power PlantDocument25 pagesChemistry in Power PlantAbhishek KumarNo ratings yet

- Vedic Maths SutrasDocument1 pageVedic Maths SutrasramdpcNo ratings yet

- Developing An Effective Safety Culture PDFDocument25 pagesDeveloping An Effective Safety Culture PDFAbhishek KumarNo ratings yet

- Power House ChemistryDocument136 pagesPower House ChemistryAbhishek KumarNo ratings yet

- Final Project On Power PlantDocument58 pagesFinal Project On Power PlantAbhishek KumarNo ratings yet

- Developing An Effective Safety Culture PDFDocument25 pagesDeveloping An Effective Safety Culture PDFAbhishek KumarNo ratings yet

- RECN 2058 Zed 10 and Zed 10 FX Improve Digital NoiseDocument2 pagesRECN 2058 Zed 10 and Zed 10 FX Improve Digital NoiseLalo JonerNo ratings yet

- Rond À BétonDocument1 pageRond À Bétonayoube mecaNo ratings yet

- 5.2. Operation Manual - Starter-EngDocument26 pages5.2. Operation Manual - Starter-EngBelal Ameen100% (1)

- Energy Balance CalculationsDocument43 pagesEnergy Balance CalculationsSasmilah KandsamyNo ratings yet

- Experimental Stress Analysis-Chapter 5 PDFDocument6 pagesExperimental Stress Analysis-Chapter 5 PDFSiva SriNo ratings yet

- FormulasDocument5 pagesFormulasPremNo ratings yet

- +2 Unit 6 Combo emDocument28 pages+2 Unit 6 Combo emBaskar RNo ratings yet

- Chapter 7 Pure SubstanceDocument22 pagesChapter 7 Pure SubstanceMUHAMMED FAISALNo ratings yet

- Electron Beam WeldingDocument19 pagesElectron Beam WeldingSahil DhimanNo ratings yet

- Light Dependent Resistance Project Report PhysicsDocument23 pagesLight Dependent Resistance Project Report Physicsapi-342687563100% (1)

- WWW - Manaresults.co - In: Board Diploma Examination, (C-16) JUNE-2019 Dme-Third Semester ExaminationDocument3 pagesWWW - Manaresults.co - In: Board Diploma Examination, (C-16) JUNE-2019 Dme-Third Semester ExaminationTanniru AnjibabuNo ratings yet

- ME2404 Computer Aided Simulation and Analysis Laboratory Lab PlanDocument1 pageME2404 Computer Aided Simulation and Analysis Laboratory Lab PlanaadhanNo ratings yet

- Solution For 1.4 and 1Document4 pagesSolution For 1.4 and 1lieu_hyacinth0% (1)

- Pergamon: Int. J. Rock Mech. Min. Sci. & Geomech. AbstrDocument8 pagesPergamon: Int. J. Rock Mech. Min. Sci. & Geomech. AbstrDavid Almanza PerezNo ratings yet

- Nonlinear Finite Element Modelling and Thermal Stress AnalysisDocument22 pagesNonlinear Finite Element Modelling and Thermal Stress AnalysisBib GmzNo ratings yet

- Mechanical Properties of Tempered EN19 SteelDocument17 pagesMechanical Properties of Tempered EN19 Steelmpaka felliNo ratings yet

- Slab Design Calculation: f (5* f A /8 A βDocument1 pageSlab Design Calculation: f (5* f A /8 A βchannajayamangala100% (1)

- Basis of Design Case Study BuildingDocument49 pagesBasis of Design Case Study BuildingAnonymous AV90SAXa5V0% (1)

- Glass SpecificationDocument36 pagesGlass SpecificationSayed Abdul Hafiz100% (1)

- Earthquake Engineering & Structural DynamicsDocument98 pagesEarthquake Engineering & Structural DynamicsSugumar SNo ratings yet

- ANSI 117-2020 Standard Specification For Structural Glued Laminated Timber of Softwood Species PDFDocument75 pagesANSI 117-2020 Standard Specification For Structural Glued Laminated Timber of Softwood Species PDFAbdurrahman CinarNo ratings yet

- Cs533b Slides Mar2Document6 pagesCs533b Slides Mar2Nikhil NambissanNo ratings yet

- 2022 YIJC Prelims H2Phy 9749 03Document24 pages2022 YIJC Prelims H2Phy 9749 03RanNo ratings yet

- Viscosity Problems and SolutionsDocument6 pagesViscosity Problems and SolutionsCairo WaliidNo ratings yet

- Review Article: Review of Sand Production Prediction ModelsDocument17 pagesReview Article: Review of Sand Production Prediction ModelsaliNo ratings yet

- ps-1 Model Paper 2Document3 pagesps-1 Model Paper 2Kunal Dev KaushalNo ratings yet

- Assignment 4 EOS SRK EOSDocument2 pagesAssignment 4 EOS SRK EOSHozefa DaginawalaNo ratings yet

- Ten So MeterDocument6 pagesTen So MeterSohaib AhmadNo ratings yet

- Def Stan 01-8Document33 pagesDef Stan 01-8pradellesNo ratings yet