Professional Documents

Culture Documents

Baxter - Kifayat Hussain-1

Uploaded by

Kifaýať HuśśaiňOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Baxter - Kifayat Hussain-1

Uploaded by

Kifaýať HuśśaiňCopyright:

Available Formats

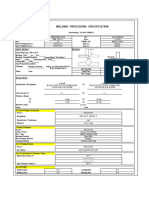

Write detailed responses to the following questions

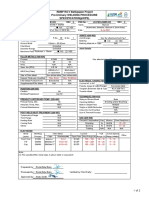

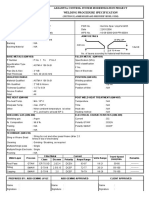

2. Transfer the information from the Procedure Qualification Record to the

Welding Procedure Specification.

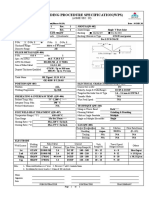

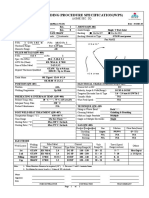

WELDING PROCEDURE SPECIFICATION

Material specification/grade 300 to 400

Fabricator SGA Engineering WPS #

Standard AS/NZS 1554.8:2014 Date

Process GMAW PQR

# 11024

Edge preparation oxy fuel gas Page

Welding direction 4G-PE Revision Date

Range qualification 4G-PE

Preheat temperature Ambient PWHT

Method and check method. Laser Hold

Inter-run temperature (max) 250 Other

Joint tolerance

Pre-qualified

To table

Root gap

Root face

Included angle

Backing

Welding consumables

Specification- Flux

Root E4916AUH10 Remainder Same

Classification-

Root AS/NZS4855:2007 Remainder Same

Shielding gas Flow rate n/a

Purge gas Flow rate n/a

Weld run details Welding parameters

Pass # Side Position Diam Tradename Amperage Voltage Current Travel Heat

mm range range and speed input

polarity mm/min kj/mm

1. 1 4G-PE 3.2 WIA 16TC 105 25 DC+ 310 .508

2. 1 "" "" "" 105 25 "" 295 .53

3. 1 "" "" "" 95 25 "" 330 .43

4. 1 "" "" "" 95 25 "" 330 .43

5. 2 1G "" "" 120 25 "" 320 .562

Technique FOREHAND Stringer/weave Stringer

Single-run or Multi-run Multi Electrical Stick out 20MM

Initial cleaning Grind/Wire brush Back gouge grind

Inter-run clean Grind\ire Gouge check visual mm

Notes/revisions

Standard for visual testing:

Approved by:

You might also like

- Pwps Jo Wps Asme 016 Rev.001Document2 pagesPwps Jo Wps Asme 016 Rev.001Bagandi ManurungNo ratings yet

- Welding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONDocument3 pagesWelding Procedure Specification (WPS) : As Per Asme Sec - Ix 2004 EDITIONJennifer French100% (2)

- WPS-ASME-009-1 Rev1Document1 pageWPS-ASME-009-1 Rev1Ahmed LepdaNo ratings yet

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Water Spray Hydraulic CalculationsDocument5 pagesWater Spray Hydraulic CalculationsVigneshwaran Santharam100% (1)

- MX Spark Detectors FUX 3001 DL FUX 3001 DL Ex PDFDocument2 pagesMX Spark Detectors FUX 3001 DL FUX 3001 DL Ex PDFNarendra Reddy BhumaNo ratings yet

- Preliminary Welding Procedure Specification (PWPS)Document2 pagesPreliminary Welding Procedure Specification (PWPS)Maneesh0% (1)

- Piping WpsDocument37 pagesPiping WpsZulfokar FahdawiNo ratings yet

- Pre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectDocument2 pagesPre-Liminary WELDING PROCEDURE Specification (PWPS) : RDMP RU-V Balikpapan ProjectBagandi ManurungNo ratings yet

- Welding Procecure SpecificationDocument9 pagesWelding Procecure SpecificationNwoha PeterNo ratings yet

- GMCo - WPSDocument8 pagesGMCo - WPSMohamed AtefNo ratings yet

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 pagesProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- GTAW Welding Procedure for ASTM A53 PipeDocument2 pagesGTAW Welding Procedure for ASTM A53 PipeS. K. M. ShujonNo ratings yet

- WPS Welding Performance SpecialistDocument2 pagesWPS Welding Performance SpecialistGobinath GovindarajNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document1 pageWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed LepdaNo ratings yet

- WPS-2 InchDocument2 pagesWPS-2 InchKarthikeyan MpNo ratings yet

- PQR For 32 MM PlateDocument1 pagePQR For 32 MM PlateMuhammed MubeenNo ratings yet

- DEE-920-11 - Rev 0Document3 pagesDEE-920-11 - Rev 0Karim ZahranNo ratings yet

- GMAW welding parameters for SS400 pipeDocument2 pagesGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- WELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTDocument1 pageWELDING PROCEDURE SPECIFICATION FOR SOUTH PARS GAS FIELD DEVELOPMENTAhmed LepdaNo ratings yet

- PRESSURE SWITCH DATA SHEET R1 - ApprovedDocument7 pagesPRESSURE SWITCH DATA SHEET R1 - ApprovedArvnd VckyNo ratings yet

- Welding Procedure Specification (AutoRecovered)Document2 pagesWelding Procedure Specification (AutoRecovered)virnmontalesNo ratings yet

- Field Welding Procedure (HOIST CYLINDER BALL AND LIFT ARM BALL)Document33 pagesField Welding Procedure (HOIST CYLINDER BALL AND LIFT ARM BALL)Aamir AshinNo ratings yet

- Prequalified Qualified by TestingDocument5 pagesPrequalified Qualified by Testingcarlosoliveros1967No ratings yet

- WPS-PQR Pengelasan (AA)Document12 pagesWPS-PQR Pengelasan (AA)Abrianto AkuanNo ratings yet

- Techtop 5 HPDocument3 pagesTechtop 5 HPJOKO WIKARNANo ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- Salt Pumps Data Sheet Xi'An Space Huawei Chemical & Biological Engineering Co - LTDDocument3 pagesSalt Pumps Data Sheet Xi'An Space Huawei Chemical & Biological Engineering Co - LTDkayaltharanNo ratings yet

- PQR No TECH-PS01 Rev.2 SMAW - NORMALDocument4 pagesPQR No TECH-PS01 Rev.2 SMAW - NORMALcfranciaNo ratings yet

- Welding Procedure Specification (WPS) : (Asme Sec. Ix)Document3 pagesWelding Procedure Specification (WPS) : (Asme Sec. Ix)Ahmed Lepda100% (1)

- Procedure Qualification Record (PQR) Khewari Development ProjectDocument2 pagesProcedure Qualification Record (PQR) Khewari Development Projectsar sarNo ratings yet

- WPS & PQRDocument13 pagesWPS & PQRValentin RadulescuNo ratings yet

- Asme IxDocument1 pageAsme IxAxel Navarro AlbinesNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument1 pageWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- 00 WPS STR 10-12-2018Document35 pages00 WPS STR 10-12-2018alok987No ratings yet

- Form Wps JBL09-2011Document2 pagesForm Wps JBL09-2011fawad aliNo ratings yet

- WPS for Gas Field Development WeldingDocument2 pagesWPS for Gas Field Development WeldingAhmed LepdaNo ratings yet

- WPS 03 2014Document2 pagesWPS 03 2014vinuNo ratings yet

- JOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCDocument5 pagesJOINTS (QW-402) : in Accordance With QW-200.1, Section IX, ASME BPVCmkhalil1148No ratings yet

- Pessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CDocument1 pagePessing Libya INC: Fill: SMAW Sfa. No: 5.28&5.5 Post Weld Heat Treatment: 620-650 Deg CMahmoud HaggagNo ratings yet

- PQR FLow LineDocument2 pagesPQR FLow Linesar sarNo ratings yet

- Welding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeDocument2 pagesWelding Procedure Specification (WPS) : Asme Sec Ix, 2017 Boiler and Pressure Vessel CodeNuwan RanaweeraNo ratings yet

- Wimpey - Wacg-22-222-5Document6 pagesWimpey - Wacg-22-222-5jaas jawadNo ratings yet

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Draft WPSDocument32 pagesDraft WPSAnilkumar G NairNo ratings yet

- DEE-920-12 - Rev 0Document3 pagesDEE-920-12 - Rev 0Karim ZahranNo ratings yet

- Request welding procedure approvalDocument18 pagesRequest welding procedure approvalecsuperal100% (1)

- FW0007Document5 pagesFW0007alefeli26No ratings yet

- AECOM ASME PQR for SA-516 Pipe WeldsDocument3 pagesAECOM ASME PQR for SA-516 Pipe Weldscorey jacobsNo ratings yet

- Reliance Engineering Associates (P) Limited Welding Procedure SpecificationDocument1 pageReliance Engineering Associates (P) Limited Welding Procedure SpecificationdeepakNo ratings yet

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 pagesIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanNo ratings yet

- SILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Document2 pagesSILVER-WPS-GESA-01 5mm To 32 MM SMAW LW P1 TO P1 - PQR-0063-W-18Abdulmecit YetisNo ratings yet

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Document2 pagesASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- WPS 84281 R06Document1 pageWPS 84281 R06Ritesh kumarNo ratings yet

- WPS-ASME-007-1 Rev0Document1 pageWPS-ASME-007-1 Rev0Ahmed LepdaNo ratings yet

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyFrom EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyRating: 4 out of 5 stars4/5 (1)

- Gear Durability and Failure Analysis Case StudiesDocument2 pagesGear Durability and Failure Analysis Case StudiesLilian RoseNo ratings yet

- Concrete PropertiesDocument32 pagesConcrete PropertiesEldho CaNo ratings yet

- Texapon SFA (OPP)Document1 pageTexapon SFA (OPP)paromanikNo ratings yet

- Module 3 - Flexural Strength in Beams (WSD & Cracked Sections - Tansformed Section Method)Document5 pagesModule 3 - Flexural Strength in Beams (WSD & Cracked Sections - Tansformed Section Method)Mika Vernadeth SingNo ratings yet

- 1 Modeling of Shear Walls For Non Linear and Pushover Analysis of Tall BuildingsDocument12 pages1 Modeling of Shear Walls For Non Linear and Pushover Analysis of Tall BuildingsHareen CherukuruNo ratings yet

- Term-II Examination 2022-23 Class 11 ChemistryDocument5 pagesTerm-II Examination 2022-23 Class 11 ChemistryGEETA JUNAWANo ratings yet

- GR9677 SolutionsDocument132 pagesGR9677 SolutionsDavid Latchman0% (1)

- Hampson Linde CycleDocument2 pagesHampson Linde CyclerkibNo ratings yet

- Rupture Disk - Application and InspectionDocument33 pagesRupture Disk - Application and InspectionLudi D. LunarNo ratings yet

- FMP Series: High Pressure Fi LtersDocument14 pagesFMP Series: High Pressure Fi LtersДаниіл ЩигельськийNo ratings yet

- ECLYPSE TECH File ENG Rev 0.5Document18 pagesECLYPSE TECH File ENG Rev 0.5hassaniNo ratings yet

- Chapter 10: Particle Size Reduction and SeparationDocument4 pagesChapter 10: Particle Size Reduction and SeparationYsabel Salvador DychincoNo ratings yet

- Exxon Mobil Matls Lab A105N Vs A350LF2 GrainSize PDFDocument5 pagesExxon Mobil Matls Lab A105N Vs A350LF2 GrainSize PDFAnonymous nw5AXJqjdNo ratings yet

- SuperconductorsDocument11 pagesSuperconductorspranavabaascaran100% (1)

- Mathcad - Crane CalculationsDocument9 pagesMathcad - Crane Calculationsapi-232034744No ratings yet

- 9800 XRF XRD - ArtigoDocument8 pages9800 XRF XRD - Artigocelestino biasottoNo ratings yet

- Names of Reg Water Company in PakistanDocument1 pageNames of Reg Water Company in PakistannaeemakhtaracmaNo ratings yet

- NOK 'Packings 2021 enDocument304 pagesNOK 'Packings 2021 enJa RoyNo ratings yet

- MSS SP-65 (1999)Document11 pagesMSS SP-65 (1999)Islam SolimanNo ratings yet

- AIAA EbooksDocument9 pagesAIAA Ebookssarah86304325No ratings yet

- Modeling and CFD Analysis of Air FlowDocument15 pagesModeling and CFD Analysis of Air FlowTarik Hassan ElsonniNo ratings yet

- Bend Terhadap Efektifitas Desain Horizontal Directional Drilling (HDD) Secara Teknis Dan EkonomisDocument6 pagesBend Terhadap Efektifitas Desain Horizontal Directional Drilling (HDD) Secara Teknis Dan EkonomisFattah WidodoNo ratings yet

- Upstream ProcessingDocument30 pagesUpstream ProcessingsamsolidNo ratings yet

- ME 101-Lecture 22-25-Kinematics of A Particle PDFDocument67 pagesME 101-Lecture 22-25-Kinematics of A Particle PDFRohan MittalNo ratings yet

- Concrete-Filled Stainless Steel Tubular Columns (2019)Document149 pagesConcrete-Filled Stainless Steel Tubular Columns (2019)cuongibst2012No ratings yet

- API-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFDocument3 pagesAPI-1000-11 - Rev - 0WPSAPI5L x42-x52 PDFSailesh SharmaNo ratings yet

- CATALOGO DE CONECTORES BC-LOK - CompressedDocument71 pagesCATALOGO DE CONECTORES BC-LOK - Compressedleopoldo cobosNo ratings yet

- KV650C2 diesel generator specificationsDocument4 pagesKV650C2 diesel generator specificationsAnonymous DuwQk4iNo ratings yet