Professional Documents

Culture Documents

Helukabel m32560 en GB

Uploaded by

elio negreteOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Helukabel m32560 en GB

Uploaded by

elio negreteCopyright:

Available Formats

N2XS(F)2Y

6/10 kV, 12/20 kV, 18/30 kV, Copper conductor, XLPE insulated, PE sheath, longitudinally water-

proof

TECHNICAL DATA PROPERTIES

n

Medium voltage cable acc. to DIN VDE 0276-620, HD 620 S2, • for outdoor use

IEC 60502 • direct burial

• the materials used during manufacturing are cadmium-free, con-

Temperature range during installation -20°C tain no silicone and are free from substances harmful to the wetting

Permissible operating temperature of the conductor properties of lacquers

+90°C

Short circuit temperature at the conductor

+250°C (Short circuit tempera- APPLICATION

n

ture max. 5 s) Suitable for indoor installation and in cable ducts, outdoors, under-

Nominal voltage see table ground and in water as well as for installation on cable trays for

Operating voltage see table industries, switch-boards and power stations. The PE-outer sheath

Test voltage see table is resistant to high mechanical stress for laying the cables. The inner

conducting layer between the conductor and the XLPE insulation

Minimum bending radius 15x Outer-Ø

and the firmly bonded outer conducting layer on the XLPE insulation

assures a construction free of partial discharges with high operational

CABLE STRUCTURE

n reliability.

• Copper conductor bare, stranded acc. to DIN VDE 0295 Class 2 /

IEC 60228 Class 2

• Inner conductive layer NOTES

n

• Core insulation: XLPE acc. to HD 620 S2 (compound type DIX8) • rm = round, stranded conductor

• Outer conductive layer • the conductor is metrically (mm²) constructed, AWG numbers are

• Longitudinally waterproof, conductive wrapping approximated, and are for reference only

• Screen: braiding of copper wires with one or two counter helix • the PE outer sheath is not flame retardant acc. to DIN EN 60332-1-

conductors 2

• Longitudinally waterproof wrapping • for maximum operational reliability, the core insulation and the ou-

• Outer sheath: PE acc. to HD 620 S2 (compound type DMP2) ter conductive layer are simultaneously extruded and permanently

• Sheath colour: black welded together. For installation, a peeling tool is recommended.

04.08.2021 / We reserve the right to make technical changes; the imprint in the image is purely exemplary

6/10 kV

Part no. No. cores x AWG, approx. Operating Test voltage Outer Ø mm, Cu-weight kg/km Weight kg/km,

cross-sec. voltage1) kV approx. approx.

mm² max. kV

32560 1 x 35 rm / 16 2 12 21 26.0 518.0 1050.0

32561 1 x 50 rm / 16 1 12 21 28.0 662.0 1150.0

32562 1 x 70 rm / 16 2/0 12 21 30.0 854.0 1460.0

32563 1 x 95 rm / 16 3/0 12 21 31.0 1094.0 1700.0

32564 1 x 120 rm / 16 4/0 12 21 32.0 1334.0 2030.0

32565 1 x 150 rm / 25 300 kcmil 12 21 34.0 1723.0 2350.0

32566 1 x 185 rm / 25 350 kcmil 12 21 36.0 2059.0 2700.0

32567 1 x 240 rm / 25 500 kcmil 12 21 38.0 2587.0 3300.0

32568 1 x 300 rm / 25 600 kcmil 12 21 40.0 3163.0 3900.0

32569 1 x 400 rm / 35 750 kcmil 12 21 44.0 4234.0 4850.0

32570 1 x 500 rm / 35 1000 kcmil 12 21 47.0 5194.0 6000.0

79954 1 x 630 rm / 35 1250 kcmil 12 21 49.0 6442.0 7020.0

12/20 kV

Part no. No. cores x AWG, approx. Operating Test voltage Outer Ø mm, Cu-weight kg/km Weight kg/km,

cross-sec. voltage1) kV approx. approx.

mm² max. kV

32571 1 x 35 rm / 16 2 24 42 31.0 518.0 1210.0

32572 1 x 50 rm / 16 1 24 42 33.0 662.0 1400.0

32573 1 x 70 rm / 16 2/0 24 42 34.0 854.0 1550.0

Continued on next page 1/2

N2XS(F)2Y

6/10 kV, 12/20 kV, 18/30 kV, Copper conductor, XLPE insulated, PE sheath, longitudinally water-

proof

12/20 kV

Part no. No. cores x AWG, approx. Operating Test voltage Outer Ø mm, Cu-weight kg/km Weight kg/km,

cross-sec. voltage1) kV approx. approx.

mm² max. kV

32574 1 x 95 rm / 16 3/0 24 42 36.0 1094.0 1800.0

32575 1 x 120 rm / 16 4/0 24 42 37.0 1334.0 2150.0

32576 1 x 150 rm / 25 300 kcmil 24 42 39.0 1723.0 2400.0

32577 1 x 185 rm / 25 350 kcmil 24 42 41.0 2059.0 2850.0

32578 1 x 240 rm / 25 500 kcmil 24 42 43.0 2587.0 3250.0

32579 1 x 300 rm / 25 600 kcmil 24 42 45.0 3163.0 3850.0

32580 1 x 400 rm / 35 750 kcmil 24 42 48.0 4234.0 4900.0

32581 1 x 500 rm / 35 1000 kcmil 24 42 52.0 5194.0 6100.0

33092 1 x 630 rm / 35 1250 kcmil 24 42 54.0 6442.0 7340.0

18/30 kV

Part no. No. cores x AWG, approx. Operating Test voltage Outer Ø mm, Cu-weight kg/km Weight kg/km,

cross-sec. voltage1) kV approx. approx.

mm² max. kV

32582 1 x 50 rm / 16 1 36 63 37.0 662.0 1700.0

32583 1 x 70 rm / 16 2/0 36 63 38.0 854.0 1950.0

32584 1 x 95 rm / 16 3/0 36 63 40.0 1094.0 2300.0

32585 1 x 120 rm / 16 4/0 36 63 42.0 1334.0 2600.0

32586 1 x 150 rm / 25 300 kcmil 36 63 43.0 1723.0 3000.0

32587 1 x 185 rm / 25 350 kcmil 36 63 45.0 2059.0 3350.0

32588 1 x 240 rm / 25 500 kcmil 36 63 47.0 2587.0 4100.0

32589 1 x 300 rm / 25 600 kcmil 36 63 50.0 3163.0 4800.0

32590 1 x 400 rm / 35 750 kcmil 36 63 53.0 4234.0 5750.0

32591 1 x 500 rm / 35 1000 kcmil 36 63 56.0 5194.0 6700.0

708487 1 x 630 rm / 35 1250 kcmil 36 63 59.0 6442.0 7760.0

1) max. permissible operating voltage three-phase alternating current (AC) conductor/conductor

04.08.2021 / We reserve the right to make technical changes; the imprint in the image is purely exemplary

2/2

You might also like

- 35kv Xlpe Phelps DodgeDocument2 pages35kv Xlpe Phelps DodgeCommercial One100% (2)

- Proposed Four-Storey Residential BuildingDocument4 pagesProposed Four-Storey Residential BuildingChrispin Barnigo100% (1)

- HT Cable Termination Kit 14.3.22Document8 pagesHT Cable Termination Kit 14.3.22JIGSNo ratings yet

- ARP 107-6001 Mitsubishi Torque SpecsDocument1 pageARP 107-6001 Mitsubishi Torque SpecsJohnTexeiraNo ratings yet

- 08.COSHH RegisterDocument38 pages08.COSHH RegisterRichu Pali100% (1)

- 35kv Xlpe Phelps Dodge PDFDocument2 pages35kv Xlpe Phelps Dodge PDFRodney LanagNo ratings yet

- Terminaiton Kit SpecificaitonDocument5 pagesTerminaiton Kit SpecificaitonVaibhav ShahNo ratings yet

- Stainless Steel Technical HandbookDocument27 pagesStainless Steel Technical Handbookravikumarang100% (1)

- Norma Parte 1Document100 pagesNorma Parte 1Alejandra López100% (1)

- Bond Strength of Mortar To Masonry Units: Standard Test Method ForDocument8 pagesBond Strength of Mortar To Masonry Units: Standard Test Method Foranon_694321072100% (1)

- Non-Ferrous Metal SmeltingDocument47 pagesNon-Ferrous Metal SmeltinggtdomboNo ratings yet

- NA2XS FL 2Y RM 18 30 KV PDFDocument2 pagesNA2XS FL 2Y RM 18 30 KV PDFSid Ali RABEHINo ratings yet

- WI-NG-6460-002-041 Commissioning of XLPE Power Cables (13.8kV and 33kV) Rev01Document10 pagesWI-NG-6460-002-041 Commissioning of XLPE Power Cables (13.8kV and 33kV) Rev01Makesh IndhuNo ratings yet

- Bob Engnath On QsteelqDocument6 pagesBob Engnath On QsteelqJason BowmanNo ratings yet

- Technical User Guide for 127 - 500 kV High Voltage XLPE Cable SystemsDocument12 pagesTechnical User Guide for 127 - 500 kV High Voltage XLPE Cable Systemsmani_208eeNo ratings yet

- Helukabel M32480 en GBDocument2 pagesHelukabel M32480 en GBAshish bhattNo ratings yet

- Helukabel 1DB 33054 enDocument2 pagesHelukabel 1DB 33054 enLaurentiu CatalinNo ratings yet

- 1DB 38062 enDocument2 pages1DB 38062 enIkhuosho AbodeNo ratings yet

- Cabble Data SheetDocument6 pagesCabble Data Sheetabd asaadNo ratings yet

- Pg032 - o Power LV (N) YyryDocument1 pagePg032 - o Power LV (N) YyryDolyNo ratings yet

- Cable - Datasheet - (Eng) S07RC4N8-F, Pirelli - 2002-04-01 - Screened-Submersible-SensorcableDocument2 pagesCable - Datasheet - (Eng) S07RC4N8-F, Pirelli - 2002-04-01 - Screened-Submersible-SensorcableA. Muhsin Pamungkas100% (1)

- U-1000 R2V (Industrial Unarmoured) : DescriptionDocument5 pagesU-1000 R2V (Industrial Unarmoured) : DescriptionJayagurunathanNo ratings yet

- Data Sheet YCP EN 0420Document1 pageData Sheet YCP EN 0420Fareed KhanNo ratings yet

- MV Power Cables for Utilities Distribution & BuildingsDocument2 pagesMV Power Cables for Utilities Distribution & BuildingsJoseph Poplinger0% (1)

- N2Xsy: Technical Data ConstructionDocument2 pagesN2Xsy: Technical Data ConstructionAthanasios AntonopoulosNo ratings yet

- 4x2.5GV+Sch and 7x2.5GV+SchDocument1 page4x2.5GV+Sch and 7x2.5GV+SchalaNo ratings yet

- Topflex - EMV-3-PLUS-2YSLCY-J: ® Double Screened, EMC-preferred TypeDocument2 pagesTopflex - EMV-3-PLUS-2YSLCY-J: ® Double Screened, EMC-preferred TypesrushtiNo ratings yet

- Vs 3c10ev07t m3Document6 pagesVs 3c10ev07t m3matheuzalexsanderNo ratings yet

- TerraweldDocument1 pageTerraweldMANUEL CASTRONo ratings yet

- R04350BDocument1 pageR04350BEduardo OlivaresNo ratings yet

- Technical Information PDFDocument24 pagesTechnical Information PDFroyclhorNo ratings yet

- Description: Generated 4/18/06 - HTTP://WWW - Nexans.fr/e-Service/ Page 1 / 2Document2 pagesDescription: Generated 4/18/06 - HTTP://WWW - Nexans.fr/e-Service/ Page 1 / 2vairam_eee01No ratings yet

- 1DB 10881 enDocument1 page1DB 10881 enFreddy MormontoyNo ratings yet

- YMvK Dca-S2 0.6 - 1 KVDocument10 pagesYMvK Dca-S2 0.6 - 1 KVstefanopadovan235No ratings yet

- BL 1040 CTDocument5 pagesBL 1040 CTasdrubal hernandezNo ratings yet

- TEFELEN Technical Product CatalogueDocument16 pagesTEFELEN Technical Product CatalogueDiego MantillaNo ratings yet

- MEDIUM VOLTAGE POWER CABLES 25kVDocument2 pagesMEDIUM VOLTAGE POWER CABLES 25kVButch BuciaNo ratings yet

- FXZ1 (FRT, ZH) : Halogen FreeDocument4 pagesFXZ1 (FRT, ZH) : Halogen FreeMario LuvineriNo ratings yet

- Nexans - N2XSY 8 7 15 KV DNC ET 031b 3Document1 pageNexans - N2XSY 8 7 15 KV DNC ET 031b 3Joel Carhuancho NanaNo ratings yet

- Controls, Inc.: BD FE 180/E 30 Bis E 90 Orange) Halogen-FreeDocument1 pageControls, Inc.: BD FE 180/E 30 Bis E 90 Orange) Halogen-FreeShoaib-Ur -RehmanNo ratings yet

- 550220271-Terminal Block Sakdu 4n X 26Document14 pages550220271-Terminal Block Sakdu 4n X 26Ismuliono IisNo ratings yet

- Spec 55: High Performance Wire and CableDocument11 pagesSpec 55: High Performance Wire and Cabledemos70No ratings yet

- TopCable FR N20XA8E AR ENG 900009012204Document1 pageTopCable FR N20XA8E AR ENG 900009012204ISGENo ratings yet

- Catalog Cable GlandsDocument2 pagesCatalog Cable GlandsAlejandro JoseNo ratings yet

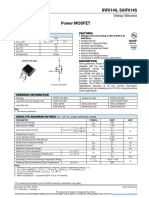

- Vishay Power MOSFET D2PAK Surface MountDocument10 pagesVishay Power MOSFET D2PAK Surface MountРинат ИвановNo ratings yet

- Revitex VAC40: Sleevings For Thermal, Electrical, Mechanical & Emi ApplicationsDocument2 pagesRevitex VAC40: Sleevings For Thermal, Electrical, Mechanical & Emi ApplicationsJesus VerduzcoNo ratings yet

- Opgw: Optical Cables Optical Ground WireDocument3 pagesOpgw: Optical Cables Optical Ground WireMilagros Mercedes Olmos CervantesNo ratings yet

- A2XS FL 2Y RE 64 110 123 KV SolidDocument2 pagesA2XS FL 2Y RE 64 110 123 KV Soliddorinmircea1959No ratings yet

- 8BK30 Catalog PDFDocument22 pages8BK30 Catalog PDFRafael SilvaNo ratings yet

- Nkt-06086 Katalog HochspannungsgarniturenDocument20 pagesNkt-06086 Katalog Hochspannungsgarniturenrjk941-1No ratings yet

- Tds New 1c Cu 35kvDocument2 pagesTds New 1c Cu 35kvButch BuciaNo ratings yet

- Wall Bushings: STB Series: 40.5 252 KV Combined Wall Bushings With Current Transformer: STB-L Series: 40.5 252kVDocument4 pagesWall Bushings: STB Series: 40.5 252 KV Combined Wall Bushings With Current Transformer: STB-L Series: 40.5 252kVRamesh PatelNo ratings yet

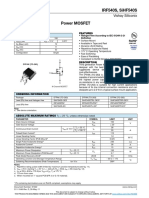

- Sihf540s 1761631Document10 pagesSihf540s 1761631Campuran CHANNELNo ratings yet

- N2XSH RM 6/10 KV: DescriptionDocument2 pagesN2XSH RM 6/10 KV: DescriptionasssasasNo ratings yet

- Gas Tube Surge Arrestor Type N Male Female, Bulkhead: Product Data Sheet N-UC230-01Document2 pagesGas Tube Surge Arrestor Type N Male Female, Bulkhead: Product Data Sheet N-UC230-01João Carlos OliveiraNo ratings yet

- 1X240 - AL - XLPE - ATA - PVC - 18 - 30 (36) KVDocument1 page1X240 - AL - XLPE - ATA - PVC - 18 - 30 (36) KVShadi BadawyNo ratings yet

- Internationally Approved Explosive Atmosphere Cable GlandDocument1 pageInternationally Approved Explosive Atmosphere Cable GlandHazzim Abu HanipahNo ratings yet

- The Right Molded Case Circuit Breaker for Your ApplicationDocument56 pagesThe Right Molded Case Circuit Breaker for Your Applicationwil alfNo ratings yet

- pg033 - O POWER LV (N) 2XY PDFDocument1 pagepg033 - O POWER LV (N) 2XY PDFDolyNo ratings yet

- MC33290Document12 pagesMC33290Harris RaoNo ratings yet

- Siemens CLS 200Document16 pagesSiemens CLS 200Stenio LanzaNo ratings yet

- Nexans XT Medium Voltage Single Core...Document15 pagesNexans XT Medium Voltage Single Core...Mathias CanalesNo ratings yet

- Le Plasma Range EngDocument12 pagesLe Plasma Range EngBertho Quisoccala LlampiNo ratings yet

- Amphenol - Epower ConnectorsDocument8 pagesAmphenol - Epower ConnectorsMaike SongNo ratings yet

- Nexans - TXXI 1kV CuDocument2 pagesNexans - TXXI 1kV CuchenshivaNo ratings yet

- Flexi PlywoodDocument11 pagesFlexi Plywoodkkinfra005No ratings yet

- Transparent Level GaugesDocument4 pagesTransparent Level GaugesAlfonso BlancoNo ratings yet

- Evaluation of The Bulk Specific Gravity For Granular MaterialsDocument1 pageEvaluation of The Bulk Specific Gravity For Granular MaterialsProf. Prithvi Singh KandhalNo ratings yet

- SHRH DMW FailuresDocument1 pageSHRH DMW FailuresNandaNo ratings yet

- Posorja Multipurpose Terminal Terminal Works: Pump House ConstructionDocument9 pagesPosorja Multipurpose Terminal Terminal Works: Pump House Constructionhz135874No ratings yet

- Alkali Aggregate Reaction, Alkali Carbonate Reaction and Pyrite AttackDocument3 pagesAlkali Aggregate Reaction, Alkali Carbonate Reaction and Pyrite AttackVasanthapragash NadarajhaNo ratings yet

- Etchant Selection GuideDocument6 pagesEtchant Selection GuideSantosh KumarNo ratings yet

- First Balfour Silo 2 Proposed CostingDocument6 pagesFirst Balfour Silo 2 Proposed CostingMark Roger II HuberitNo ratings yet

- L4-Steel Work Part 1a - Connection and Fire ProtectionDocument33 pagesL4-Steel Work Part 1a - Connection and Fire ProtectionTjia TjieNo ratings yet

- Procedure Development For Brazing Inconel 718 Honeycomb Sandwich StructuresDocument8 pagesProcedure Development For Brazing Inconel 718 Honeycomb Sandwich StructuresAchmad Arifudin HidayatullohNo ratings yet

- 6 BrickworkDocument42 pages6 BrickworkSiti Nurul SyakinahNo ratings yet

- ADS Product CatalogDocument58 pagesADS Product Catalogvipequi50No ratings yet

- BW FOX+EV+Pipe EN 2019 GL 232 PreviewDocument2 pagesBW FOX+EV+Pipe EN 2019 GL 232 Previewtan yahyaNo ratings yet

- OneSteel Reinforcing Area CalculatorDocument12 pagesOneSteel Reinforcing Area CalculatormingmingminglesNo ratings yet

- 50-ACI 318 ChangesDocument2 pages50-ACI 318 ChangesAnis ShatnawiNo ratings yet

- Al Chris BoqDocument35 pagesAl Chris BoqYhan SaludoNo ratings yet

- On Bubble Deck SlabDocument16 pagesOn Bubble Deck SlabDaman100% (1)

- UL Listing July 2011Document2 pagesUL Listing July 2011Imran Mughle AzamNo ratings yet

- Comparative Study of Epoxy and Polyester Resin-Based Polymer ConcreteDocument7 pagesComparative Study of Epoxy and Polyester Resin-Based Polymer Concretemohamadi42No ratings yet

- Occidental Mindoro State College: Punch List Report No. 7Document3 pagesOccidental Mindoro State College: Punch List Report No. 7Mark Stephen FelipeNo ratings yet

- Practical Application of Intensive Quenching Process for Steel PartsDocument8 pagesPractical Application of Intensive Quenching Process for Steel PartsDouglas RodriguesNo ratings yet

- DPWH PRICE MATRIX 1st QuarterDocument264 pagesDPWH PRICE MATRIX 1st QuarterLauro LagoNo ratings yet