Professional Documents

Culture Documents

FP PDW 001 - 02

Uploaded by

oris0 ratings0% found this document useful (0 votes)

6 views2 pagesThe document provides inspection procedures for a wheeled dry chemical fire extinguisher to be performed monthly. The inspection includes checking that the extinguisher is properly installed and accessible, examining it for damage or leaks, and ensuring pressure gauges and weight are within normal ranges. Any extinguishers failing inspection should be removed from service and replaced. Repair work is to be initiated if needed, with a work order raised.

Original Description:

Original Title

FP-PDW-001_02

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides inspection procedures for a wheeled dry chemical fire extinguisher to be performed monthly. The inspection includes checking that the extinguisher is properly installed and accessible, examining it for damage or leaks, and ensuring pressure gauges and weight are within normal ranges. Any extinguishers failing inspection should be removed from service and replaced. Repair work is to be initiated if needed, with a work order raised.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views2 pagesFP PDW 001 - 02

Uploaded by

orisThe document provides inspection procedures for a wheeled dry chemical fire extinguisher to be performed monthly. The inspection includes checking that the extinguisher is properly installed and accessible, examining it for damage or leaks, and ensuring pressure gauges and weight are within normal ranges. Any extinguishers failing inspection should be removed from service and replaced. Repair work is to be initiated if needed, with a work order raised.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 2

INSPECTION & TEST PROCEDURE NO. OS-FP-PDW-001-IT REV.

02 DATE: 16-06-01

EQUIPMENT TYPE WHEELED DRY CHEMICAL EXTINGUISHER

INTERVAL 1 MONTHLY

PRECAUTIONS

Note: Tick boxes to indicate completion.

1. Obtain an approved Work Permit before commencing activities.

PREPARATION/ISOLATION

2. Check that the equipment tags are as detailed on work order sheet/work permit.

INSPECTION ACTIVITY

3. Check the extinguisher is installed in its designated location.

4. Check the extinguisher is clearly visible and that access to it is not obstructed.

5. Check the operating instructions on the extinguisher nameplate are legible and facing outwards.

6. Check the extinguisher safety seals and/or tamper indicators are not broken or missing.

7. Check hose and nozzle of the extinguisher are not damaged or obstructed.

8. Check the extinguisher for physical damage, corrosion, leakage or clogging of the nozzle.

9. Check the condition of the wheels, tyres and carriage of the unit.

10. Check the nitrogen cylinder pressure gauge reading is within the ‘operable’ range.

11. Check the fullness of the extinguisher by checking the weight as stated on the nameplate.

12. Sign off Work Permit.

Note: If an extinguisher fails any part of this inspection it should be removed from service

immediately and replaced with spare one of the same specification.

REPAIR WORK

13. Is repair work or corrective action required?

YES NO

14. Has a Work Order been raised?

YES NO

REFERENCE INFORMATION

Dry Chemical Extinguisher Service and Maintenance Instructions

Doc. No. 5-93102-902806-A-012

You might also like

- 8 Part Eye Exam RevisedDocument17 pages8 Part Eye Exam RevisedpasambalyrradjohndarNo ratings yet

- Sex Quotes and SayingsDocument11 pagesSex Quotes and SayingsXuxuLanchau100% (1)

- Vdocuments - MX Mechanicalmechanical Pe Study Guidestudy Guide As A Professional Engineer You WillDocument90 pagesVdocuments - MX Mechanicalmechanical Pe Study Guidestudy Guide As A Professional Engineer You WillorisNo ratings yet

- Biblical MeditationDocument33 pagesBiblical Meditationoris100% (1)

- Jimmy Kwik - Morning Routine PDFDocument3 pagesJimmy Kwik - Morning Routine PDFLuiza MartaNo ratings yet

- Blinding GuidelineDocument13 pagesBlinding GuidelinekishorsinghNo ratings yet

- Meat Consumption and Animal Sacrifice in Valmiki RamayanDocument90 pagesMeat Consumption and Animal Sacrifice in Valmiki Ramayanparvez saifiNo ratings yet

- PERSONALITY DEVELOPMENT CHAPTER 1 MaemaeDocument11 pagesPERSONALITY DEVELOPMENT CHAPTER 1 MaemaeFreshDianne Mhilkie Silvosa100% (1)

- The Greater Heaven Meditation - Meridian Qigong - Energy Gates QigongDocument9 pagesThe Greater Heaven Meditation - Meridian Qigong - Energy Gates Qigongspiraldao100% (1)

- AC260Document64 pagesAC260Elvis Lizarazo100% (1)

- Sullair 900 1150 ControllerDocument52 pagesSullair 900 1150 ControllerRich_78No ratings yet

- Portable Abrasive Blasting UnitDocument19 pagesPortable Abrasive Blasting UnitMoch. Nur Hidayat100% (1)

- Apeks - DS, US, TEK3 & Extrair 1st Stage - Issue 4 (2011!02!15)Document22 pagesApeks - DS, US, TEK3 & Extrair 1st Stage - Issue 4 (2011!02!15)RichNo ratings yet

- Selection of Separator With BootDocument2 pagesSelection of Separator With BootMaryJane Ayisha Sado-ObahNo ratings yet

- Apeks Dry+Suit+Valve+in+-+Issue+1+Maintenance (10!01!2006)Document13 pagesApeks Dry+Suit+Valve+in+-+Issue+1+Maintenance (10!01!2006)ReadnixNo ratings yet

- Technical Maintenance Manual: Legend First StageDocument18 pagesTechnical Maintenance Manual: Legend First StageValdrickNo ratings yet

- User Manual: Ompass OntrollerDocument58 pagesUser Manual: Ompass Ontrollerhendra suwandhie100% (5)

- Apeks Flight 2ndt Stage Maintenance Issue 9 (28-11-2011)Document21 pagesApeks Flight 2ndt Stage Maintenance Issue 9 (28-11-2011)ReadnixNo ratings yet

- Haramase Simulator Achievement GuideDocument3 pagesHaramase Simulator Achievement GuideRisdiansyah 08633% (9)

- Repairinstruction PDFDocument23 pagesRepairinstruction PDFAmal TharakaNo ratings yet

- Manual de Servei XTX200XTX100XTX50 (2011)Document23 pagesManual de Servei XTX200XTX100XTX50 (2011)Joan Pladeveya SelvasNo ratings yet

- Manual Bombas SandPiper S20Document24 pagesManual Bombas SandPiper S20Rodrigo F MNo ratings yet

- FP Pde 001 - 02Document2 pagesFP Pde 001 - 02orisNo ratings yet

- FP PCW 001 - 02Document2 pagesFP PCW 001 - 02orisNo ratings yet

- FP Pef 001 - 02Document2 pagesFP Pef 001 - 02orisNo ratings yet

- FP Pce 001 - 02Document2 pagesFP Pce 001 - 02orisNo ratings yet

- FP Pew 001 - 02Document2 pagesFP Pew 001 - 02orisNo ratings yet

- FP Pce 002 - 02Document2 pagesFP Pce 002 - 02orisNo ratings yet

- FP PDW 002 - 02Document2 pagesFP PDW 002 - 02orisNo ratings yet

- FG HSD 005Document2 pagesFG HSD 005orisNo ratings yet

- BC ABC: Strike First CorporationDocument4 pagesBC ABC: Strike First CorporationPriceNo ratings yet

- FP PCW 002 - 02Document2 pagesFP PCW 002 - 02orisNo ratings yet

- FP Pef 002 - 02Document2 pagesFP Pef 002 - 02orisNo ratings yet

- CGN BDF 001 - 02Document2 pagesCGN BDF 001 - 02orisNo ratings yet

- CGN BDF 003 - 02Document2 pagesCGN BDF 003 - 02orisNo ratings yet

- Repair Instruction: PrecautionDocument14 pagesRepair Instruction: PrecautionastaorNo ratings yet

- 1B Seal IomDocument4 pages1B Seal IomSulaiman Kadher KNo ratings yet

- Cartridge Dry Chemical Fire Extinguishers Model 10-20-30Document28 pagesCartridge Dry Chemical Fire Extinguishers Model 10-20-30Eric AdriansyahNo ratings yet

- Manual For Hand Portable Halon 1211 ExtinguishersDocument8 pagesManual For Hand Portable Halon 1211 ExtinguishersSerge aswadNo ratings yet

- HDS 35 30 Eb 15755090 Operator's ManualDocument42 pagesHDS 35 30 Eb 15755090 Operator's ManualGer DclNo ratings yet

- Sta Filter 1M ProdDocument2 pagesSta Filter 1M ProdMeng Kiat SawNo ratings yet

- Inflator Powerline: Technical Maintenance ManualDocument20 pagesInflator Powerline: Technical Maintenance ManualRossNo ratings yet

- Instructions: Rotary Lobe BlowersDocument15 pagesInstructions: Rotary Lobe BlowersKumarNo ratings yet

- Manual Hd20fnmdl1smDocument23 pagesManual Hd20fnmdl1smFelipe BrainNo ratings yet

- s1fnmdl3sm PDFDocument27 pagess1fnmdl3sm PDFMaintenanceNo ratings yet

- Metal Bellows Seal Assembly: ForewordDocument4 pagesMetal Bellows Seal Assembly: ForewordMahmoud Abo ElnasrNo ratings yet

- Speeflo Powrliner 850: Owner'S ManualDocument56 pagesSpeeflo Powrliner 850: Owner'S Manualmartha garciaNo ratings yet

- John Craine Manual 3710 - IOMDocument8 pagesJohn Craine Manual 3710 - IOMJason Salas FloresNo ratings yet

- John Crane IOM-5610-5610Q-8PG-BW-OCT2015Document8 pagesJohn Crane IOM-5610-5610Q-8PG-BW-OCT2015Marco CruzNo ratings yet

- 049b Pump ChecklistDocument13 pages049b Pump ChecklistRamy AdelNo ratings yet

- Repair Instruction: PrecautionDocument18 pagesRepair Instruction: PrecautionJosemar AgostinhoNo ratings yet

- Iom 2 4PG BW Oct2015Document4 pagesIom 2 4PG BW Oct2015Victor Flores ResendizNo ratings yet

- Installation, Operation and Maintenance Instructions: Model 3410Document56 pagesInstallation, Operation and Maintenance Instructions: Model 3410RUBEN ACOSTANo ratings yet

- John Crane Type 5611 and 5611Q Elastomer Bellows Cartridge Seal Assembly and Installation InstructionsDocument6 pagesJohn Crane Type 5611 and 5611Q Elastomer Bellows Cartridge Seal Assembly and Installation InstructionsAan Sarkasi AmdNo ratings yet

- Dual Metal Bellows Cartridge Seal: ForewordDocument8 pagesDual Metal Bellows Cartridge Seal: ForewordnguyennhatbaoNo ratings yet

- S 1 FNMDL 3 SMDocument26 pagesS 1 FNMDL 3 SMspattacutNo ratings yet

- Energy IsolationDocument17 pagesEnergy IsolationAnggara BudiantoNo ratings yet

- Elastomer Bellows Cartridge Seal: ForewordDocument8 pagesElastomer Bellows Cartridge Seal: ForewordMahmoud Abo ElnasrNo ratings yet

- Mnaual de Instrucciones Instalacion y Operacion 12661RWGVOperManRevDocument12 pagesMnaual de Instrucciones Instalacion y Operacion 12661RWGVOperManRevБехар ТиагоNo ratings yet

- Installation, Operation and Maintenance InstructionsDocument56 pagesInstallation, Operation and Maintenance InstructionsleoNo ratings yet

- Intro To NDT Module 2 TranscriptDocument14 pagesIntro To NDT Module 2 TranscriptCARLOS SUNTAXINo ratings yet

- CGN BDF 002 - 02Document2 pagesCGN BDF 002 - 02orisNo ratings yet

- Ak TrainingDocument2 pagesAk TrainingX'mix ĐreamerNo ratings yet

- RD Series 100 ManualDocument8 pagesRD Series 100 ManualquentinNo ratings yet

- SF6 Leak Detector TIF XP-1A ManualDocument20 pagesSF6 Leak Detector TIF XP-1A ManualwubinhappydayNo ratings yet

- CME-Plus: Kit AssemblyDocument8 pagesCME-Plus: Kit AssemblyZOKANo ratings yet

- Action To Be Done Potential Hazards Location ActivitiesDocument28 pagesAction To Be Done Potential Hazards Location ActivitiesReda MashalNo ratings yet

- Permit To Work Checklist 11 - Isolation Permit - WATER INGRESS SENSOR CH 6Document2 pagesPermit To Work Checklist 11 - Isolation Permit - WATER INGRESS SENSOR CH 6Reg GulfoNo ratings yet

- 02250202-728 (R00) 300HH, 375, 375H, 375HH, 425 and 425H JD IT4 Standard and AFDocument78 pages02250202-728 (R00) 300HH, 375, 375H, 375HH, 425 and 425H JD IT4 Standard and AFjavierNo ratings yet

- Fire Protection Parameters - Proposed CPU CateringDocument1 pageFire Protection Parameters - Proposed CPU CateringorisNo ratings yet

- FF 20 Ur 00Document1 pageFF 20 Ur 00orisNo ratings yet

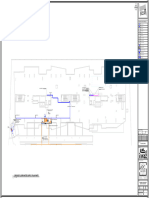

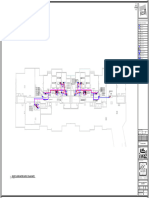

- Ground Floor HVAC-Drain Part 3: Issue StatusDocument1 pageGround Floor HVAC-Drain Part 3: Issue StatusorisNo ratings yet

- GWP Expected Sewage FlowsDocument3 pagesGWP Expected Sewage FlowsorisNo ratings yet

- Ar-001 02Document2 pagesAr-001 02orisNo ratings yet

- DS 40 Ur 00Document1 pageDS 40 Ur 00orisNo ratings yet

- Ground Floor Water Supply Plan-Part1 1: Issue StatusDocument1 pageGround Floor Water Supply Plan-Part1 1: Issue StatusorisNo ratings yet

- FF 20 RF 01Document1 pageFF 20 RF 01orisNo ratings yet

- WS 30 RF 01Document1 pageWS 30 RF 01orisNo ratings yet

- Ground Floor Water Supply Plan-Part3 1: Issue StatusDocument1 pageGround Floor Water Supply Plan-Part3 1: Issue StatusorisNo ratings yet

- FP PCW 002 - 02Document2 pagesFP PCW 002 - 02orisNo ratings yet

- WS 30 RF 02Document1 pageWS 30 RF 02orisNo ratings yet

- DiDocument1 pageDiorisNo ratings yet

- CGN BDF 001 - 02Document2 pagesCGN BDF 001 - 02orisNo ratings yet

- LT-23 - SPL - (G-1) - MED-Home Work - States of Matter - 09-09-21Document5 pagesLT-23 - SPL - (G-1) - MED-Home Work - States of Matter - 09-09-21orisNo ratings yet

- UntitledDocument1 pageUntitledorisNo ratings yet

- LT-23 SPL (G-1) Morphology of Animals - 04-09-21Document6 pagesLT-23 SPL (G-1) Morphology of Animals - 04-09-21orisNo ratings yet

- LT-23 - SPL - (G-1) - MED-Home Work - Work Energy Power-16-09-21Document7 pagesLT-23 - SPL - (G-1) - MED-Home Work - Work Energy Power-16-09-21orisNo ratings yet

- CGN BDF 002 - 02Document2 pagesCGN BDF 002 - 02orisNo ratings yet

- 5 Building Envelope: Table 5.5-0 Building Envelope Requirements For Climate Zone 0 (A, B)Document1 page5 Building Envelope: Table 5.5-0 Building Envelope Requirements For Climate Zone 0 (A, B)orisNo ratings yet

- LT-23 - SPL - GP1-MED-Home Work - Structure of Atom 29-07-21Document7 pagesLT-23 - SPL - GP1-MED-Home Work - Structure of Atom 29-07-21orisNo ratings yet

- LT-23 SPL G 1&2 - MED-Home Work-Biological Classification - 22-07-21Document7 pagesLT-23 SPL G 1&2 - MED-Home Work-Biological Classification - 22-07-21orisNo ratings yet

- LT-23 SPL G-1 - NEET - Motion in A Straight Line - 19-06-21Document8 pagesLT-23 SPL G-1 - NEET - Motion in A Straight Line - 19-06-21orisNo ratings yet

- LT-23 SPL (G-1) - States of Matter-11-09-21Document8 pagesLT-23 SPL (G-1) - States of Matter-11-09-21orisNo ratings yet

- External Wall DetailDocument1 pageExternal Wall DetailorisNo ratings yet

- Vdocuments - MX Commercial Air Conditioning Industrial VentilationDocument38 pagesVdocuments - MX Commercial Air Conditioning Industrial VentilationorisNo ratings yet

- Prevention of Infection in The Hospital SettingDocument100 pagesPrevention of Infection in The Hospital SettingShantie Harun Al RosyidNo ratings yet

- Nightmares COVID-19Document6 pagesNightmares COVID-19stephyates1No ratings yet

- Convergent Plate BoundariesDocument45 pagesConvergent Plate Boundariesjherwinperez2007No ratings yet

- Answers For Practice Problems in Lesson 5: Practice Problem #1: Specific Gravity Calculation For Coarse AggregateDocument2 pagesAnswers For Practice Problems in Lesson 5: Practice Problem #1: Specific Gravity Calculation For Coarse AggregateDjonraeNarioGalvezNo ratings yet

- Catl Exp 2018 LR PDFDocument276 pagesCatl Exp 2018 LR PDFChera IlieNo ratings yet

- Bid SheetDocument10 pagesBid SheetVi KraNo ratings yet

- Karnataka Prohibition On Beggary ActDocument14 pagesKarnataka Prohibition On Beggary Actusha242004No ratings yet

- Chap 37Document13 pagesChap 37buatadekNo ratings yet

- CHN Rabe: Tsaang Gubat (Carmona Retusa)Document3 pagesCHN Rabe: Tsaang Gubat (Carmona Retusa)Sheila May Teope SantosNo ratings yet

- MSDS ProkleenDocument6 pagesMSDS ProkleenDesta Eka PrasetyaNo ratings yet

- Jeffrey Ansloos - Indigenous Peoples and Professional Training in Psychology in CanadaDocument17 pagesJeffrey Ansloos - Indigenous Peoples and Professional Training in Psychology in CanadaleoNo ratings yet

- SCM Domino S Pizza Final B7Document17 pagesSCM Domino S Pizza Final B7radhika guptaNo ratings yet

- Acupuntura - GráficosDocument41 pagesAcupuntura - GráficosHeribertoNo ratings yet

- Ap Psychology Important Vocab TermsDocument1 pageAp Psychology Important Vocab Termsapi-238155503No ratings yet

- Starters: Please Ask Our Waiting Staff For Our Today'S Special MenuDocument2 pagesStarters: Please Ask Our Waiting Staff For Our Today'S Special MenuAdrian HartantoNo ratings yet

- Mineral Resources and Food ResourcesDocument31 pagesMineral Resources and Food Resourcesvaishali TMU studentNo ratings yet

- Carvera Manual EngDocument30 pagesCarvera Manual EngBilly DipperNo ratings yet

- NGOs and Their Impact On EducationDocument10 pagesNGOs and Their Impact On EducationNelson GuillenNo ratings yet

- 419E1BDocument3 pages419E1Bvidhyapmgrpsy2020No ratings yet

- United States Court of Appeals, Tenth CircuitDocument6 pagesUnited States Court of Appeals, Tenth CircuitScribd Government DocsNo ratings yet

- Xyr 5000 Wt530Document9 pagesXyr 5000 Wt530murali52100% (1)

- Chapter 13Document9 pagesChapter 13Michael KemifieldNo ratings yet