Professional Documents

Culture Documents

SOP For Bunker Fire

SOP For Bunker Fire

Uploaded by

BPOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SOP For Bunker Fire

SOP For Bunker Fire

Uploaded by

BPCopyright:

Available Formats

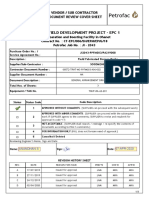

DB POWER LIMITED, RAIGARH

2 X 600 MW Power Plant

DB / SOP / BF

SOP for BUNKER FIRE

Issue No: Issue Date: Revision: Revision Date: File no: Page 1 of 4

WORK INSTRUCTIONS

FOR

BUNKER FIRE

[DB / SOP / BF]

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

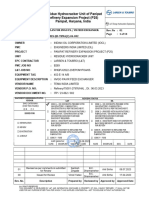

DB POWER LIMITED, RAIGARH

2 X 600 MW Power Plant

DB / SOP / BF

SOP for BUNKER FIRE

Issue No: Issue Date: Revision: Revision Date: File no: Page 2 of 4

Amendment Record

Amendment Amendment Nature of Change ACK No.

Date

Rev Page

No. No.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

DB POWER LIMITED, RAIGARH

2 X 600 MW Power Plant

DB / SOP / BF

SOP for BUNKER FIRE

Issue No: Issue Date: Revision: Revision Date: File no: Page 3 of 4

1.0 Purpose:

This Procedure is intended to provide guidance and instructions for carrying out for Bunker Fire.

2.0 Responsibility:

1. All the personnel involved in carrying out /supervising the above activities are required to ensure

implementation of this procedure.

2. In the event of any changes required in the procedure such changes may be requested with Site

in charge, who would take appropriate action with approval from respective departmental heads.

3.0 BUNKER FIRE:

The coal stored in the Bunkers can catch fire due to various reasons and if it is not attended

immediately it can cause major fire hazards. The hot coal falling on the belt feeder can easily

damage the feeder belt. It is therefore necessary to keep a close watch of the coal in the

bunker.

The first action to be taken in case of fire is noticed in the Bunker is to close the gate above the

feeder and stop the mill. Call the fire service, stop feeding coal to the Bunker’s under fire. Since

there is no provision in the Bunker to evacuate the burning coal, the only alternative to is to flood

the Bunker with fire water and wait for the fire to be completely quenched. After ascertaining

that the fire has been completely quenched, the feeder gate can be opened gradually. Open the

feeder end cover and run the feeder and remove the wet coal through the open end. By this

method, the entire wet coal is to be removed from the bunker.

Prevention of fire in the bunkers,

1. No unauthorized welding works should be allowed in the Bunker floor.

2. Any maintenance work at the bunker floor that requires welding works should be carried out

only with a valid Special Permit to Work in which it is clearly mentioned about the requirement of

welding work. While issuing the permit, all the necessary precautions to be taken for fire

protection, have to be clearly mentioned in the permit. Copies of the permit has to be sent to the

Fire & Safety department for their concurrence, before the permit is finally issued. Both Fire &

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

DB POWER LIMITED, RAIGARH

2 X 600 MW Power Plant

DB / SOP / BF

SOP for BUNKER FIRE

Issue No: Issue Date: Revision: Revision Date: File no: Page 4 of 4

Safety departments personnel must be available at the work spot for any violation of the permit

conditions and take immediate action to prevent any hot metal falling in to the Bunker.

3. The work permit issued has to be cancelled by the end of the day and a new permit taken again

the next day if the work involves more than one day. No permit can be issued for a certain

periods of days for any work in the bunker floor involved in welding works. The permit has to be

issued on day to day basis only.

4. Use of yard coal can also sometimes causes fire if the yard coal has not been properly compacted

and sprayed by fire water.

5. Keeping the coal in the Bunker’s unused for a long period can also cause the coal to catch fire.

Hence it is necessary that whenever a planned shutdown is taken for the unit for a period more

than 7 days the coal in all the Bunker’s should be emptied.

Prepared by: Reviewed by: Approved by:

Signature: Signature: Signature:

Name: Name: Name:

Designation: Designation: Designation:

You might also like

- Urs Incinerator 200 KG Rev.02Document8 pagesUrs Incinerator 200 KG Rev.02Sugiarto SudarsonoNo ratings yet

- HW Elem TRD Skills Test Answers JGHDocument3 pagesHW Elem TRD Skills Test Answers JGHjust english100% (1)

- 41 SOP For Fire Fighting SystemDocument13 pages41 SOP For Fire Fighting SystemBPNo ratings yet

- SAS FDC PDFDocument105 pagesSAS FDC PDFDevas Shukla100% (1)

- Pt. Amman Mineral Nusa Tenggara Batu Hijau Project Specifcation Fire Extinguiser and CabinetsDocument4 pagesPt. Amman Mineral Nusa Tenggara Batu Hijau Project Specifcation Fire Extinguiser and Cabinetselia nugraha adiNo ratings yet

- Power Generation Corporation 1 Thermal Power Project Management Board 3Document2 pagesPower Generation Corporation 1 Thermal Power Project Management Board 3mameniqNo ratings yet

- B713-DAC-BHM-1547-Fire Fightning System Design Basis Report (Alstom)Document8 pagesB713-DAC-BHM-1547-Fire Fightning System Design Basis Report (Alstom)Sabiha Mahafuza ZozoneeNo ratings yet

- 3n4 - RAM - Oman Concrete Mix Design ApprovalDocument2 pages3n4 - RAM - Oman Concrete Mix Design ApprovalMohammad AftabNo ratings yet

- DRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFDocument10 pagesDRP001-OUF-GAL-RAM-E-000-191 Rev-S! PDFMohammad AftabNo ratings yet

- SMP For Fluidizing Air BlowerDocument20 pagesSMP For Fluidizing Air BlowerSonrat100% (1)

- 08572-Trht-Ms-Ppfm003-A06-002 - D General Arrangement Drawing Diesel TankDocument3 pages08572-Trht-Ms-Ppfm003-A06-002 - D General Arrangement Drawing Diesel TankSamer ArousNo ratings yet

- PT Amman Mineral Nusa Tenggara Batu Hijau Project: Project Development Department Fire Water PumpsDocument14 pagesPT Amman Mineral Nusa Tenggara Batu Hijau Project: Project Development Department Fire Water Pumpselia nugraha adiNo ratings yet

- PM Work For Dry Ash UnloaderDocument4 pagesPM Work For Dry Ash UnloaderSonratNo ratings yet

- PM Work For Fly Ash Wet System-1Document15 pagesPM Work For Fly Ash Wet System-1Sonrat100% (1)

- 001-20160204 Boiler Efficiency PGT ProcedureDocument48 pages001-20160204 Boiler Efficiency PGT ProcedureK R Kumar RanjanNo ratings yet

- SMP For Supply Water PumpDocument13 pagesSMP For Supply Water PumpSonratNo ratings yet

- PT Amman Mineral Nusa Tenggara Batu Hijau Project Specification Fire Protection CriteriaDocument18 pagesPT Amman Mineral Nusa Tenggara Batu Hijau Project Specification Fire Protection Criteriaelia nugraha adiNo ratings yet

- 5479 VOIUME 4 (Recovered)Document320 pages5479 VOIUME 4 (Recovered)Kapil Mishra100% (1)

- TP-WMS-05940-SPC-A4-D1-L-Specification For ValvesDocument34 pagesTP-WMS-05940-SPC-A4-D1-L-Specification For Valvesbmanojkumar16100% (1)

- Nghi Son 2 BOT Thermal Power Plant Project Design Query SheetDocument4 pagesNghi Son 2 BOT Thermal Power Plant Project Design Query SheetMr NgocNo ratings yet

- Adobe Scan 09-Mar-2023Document3 pagesAdobe Scan 09-Mar-2023himanshu koleyNo ratings yet

- 08572-Trht-Ms-Ppfm003-A06-001 - D General Arrangement Drawing Fire Water Storage TankDocument3 pages08572-Trht-Ms-Ppfm003-A06-001 - D General Arrangement Drawing Fire Water Storage TankSamer ArousNo ratings yet

- SMP For Sealing Water Pump Multi Stage.Document13 pagesSMP For Sealing Water Pump Multi Stage.SonratNo ratings yet

- GB090 2614 299 El CL 0001 - 1Document19 pagesGB090 2614 299 El CL 0001 - 1tanujaayerNo ratings yet

- DN02 00BZL 137010 001 0Document23 pagesDN02 00BZL 137010 001 0taharNo ratings yet

- Titanium: Method Statement For Tower Pilecap ConstructionDocument5 pagesTitanium: Method Statement For Tower Pilecap ConstructionKelvin LauNo ratings yet

- Specification - Api 612 6 Edition - Steam Turbines, Special Purpose ApplicationsDocument18 pagesSpecification - Api 612 6 Edition - Steam Turbines, Special Purpose ApplicationsjaseelNo ratings yet

- PM WORK For Fluidizing Blower of Fly Ash SiloDocument4 pagesPM WORK For Fluidizing Blower of Fly Ash SiloSonratNo ratings yet

- Hav Ext DC FRM XXXXDocument3 pagesHav Ext DC FRM XXXXMehmet AtabayNo ratings yet

- TSE Treatment BOQDocument1 pageTSE Treatment BOQurssulthan44160% (1)

- PT Amman Mineral Nusa Tenggara Batu Hijau Project SpecificationDocument6 pagesPT Amman Mineral Nusa Tenggara Batu Hijau Project Specificationelia nugraha adiNo ratings yet

- Material Approval Submission: Jazz City KulimDocument13 pagesMaterial Approval Submission: Jazz City KulimMuhamad Yazid Bin Md YatinNo ratings yet

- 402-E-14 Ab B269-Rhcu-Lt-402-Mes-Qd-Tema (2) - 04-002Document14 pages402-E-14 Ab B269-Rhcu-Lt-402-Mes-Qd-Tema (2) - 04-002tarun gotiNo ratings yet

- Flood Test SOPDocument6 pagesFlood Test SOPSonratNo ratings yet

- QAP-UEPL-BHOPAL-54-9550-01 Rev.03Document6 pagesQAP-UEPL-BHOPAL-54-9550-01 Rev.03udayakarnaNo ratings yet

- Itp HavacDocument12 pagesItp Havac1965karanfil6No ratings yet

- f16 Schedule of Subvendors List-LatestDocument7 pagesf16 Schedule of Subvendors List-LatestariyaNo ratings yet

- Nuclear Power Corporation of India LTDDocument35 pagesNuclear Power Corporation of India LTDsanthosh100% (1)

- SMP For Dry Ash UnloaderDocument8 pagesSMP For Dry Ash UnloaderSonratNo ratings yet

- Materials Approval For Thermal Insulation BoardDocument34 pagesMaterials Approval For Thermal Insulation BoardsabbirNo ratings yet

- 08572-Trht-Ms-Ppfm003-A06-004 - D General Arrangement Drawing Lean Amine Surge TankDocument3 pages08572-Trht-Ms-Ppfm003-A06-004 - D General Arrangement Drawing Lean Amine Surge TankSamer ArousNo ratings yet

- Fat - MSB Pmu JinjangDocument6 pagesFat - MSB Pmu JinjangFirdaus Muhammad100% (1)

- 402-E-09 B269-Rhcu-Lt-402-Mes-Qd-Tema (2) - 04-001Document14 pages402-E-09 B269-Rhcu-Lt-402-Mes-Qd-Tema (2) - 04-001tarun gotiNo ratings yet

- QAP-UEPL-BHOPAL-54-04 Rev.03Document6 pagesQAP-UEPL-BHOPAL-54-04 Rev.03udayakarnaNo ratings yet

- 5083 CVC WSS Ed 0011 - R8Document326 pages5083 CVC WSS Ed 0011 - R8Nitin SakpalNo ratings yet

- Sirri Island Gas Gathering & NGL Recovery Project: Active Fire Fighting Safety Equipment SpecificationDocument12 pagesSirri Island Gas Gathering & NGL Recovery Project: Active Fire Fighting Safety Equipment SpecificationRIMEL ASMANo ratings yet

- Maamoura and Baraka Development ProjectDocument11 pagesMaamoura and Baraka Development ProjectAHMED AMIRANo ratings yet

- 141 000 Pi SPC 0004Document28 pages141 000 Pi SPC 0004Mehmet AtabayNo ratings yet

- Eil Job No.: A545: Owner:-Dangote Oil Refining CompanyDocument19 pagesEil Job No.: A545: Owner:-Dangote Oil Refining CompanySandip Sur100% (1)

- Maamoura and Baraka Development Project 3314.02.DACC.15059Document18 pagesMaamoura and Baraka Development Project 3314.02.DACC.15059AHMED AMIRANo ratings yet

- HAV-EXT-HS-PLN-0143: Emergency Action PlanDocument7 pagesHAV-EXT-HS-PLN-0143: Emergency Action Planum erNo ratings yet

- CH BB SLD El 04 04Document2 pagesCH BB SLD El 04 04Ahmed MarzokNo ratings yet

- Sop LRSB BlowerDocument6 pagesSop LRSB BlowerApnrl maincontrolroom100% (1)

- P4 Forwarding NoteDocument1 pageP4 Forwarding NoteIlayaraja MKNo ratings yet

- BRS1-SP-E-BRS-0014.RD1 Cathodic Protection SpecificationDocument31 pagesBRS1-SP-E-BRS-0014.RD1 Cathodic Protection SpecificationABDELKADERNo ratings yet

- Design of MCRDocument159 pagesDesign of MCRRajat MarvalNo ratings yet

- S-900-1242-022 - 6a - 002 - A1 (Excavation Permit)Document3 pagesS-900-1242-022 - 6a - 002 - A1 (Excavation Permit)Umar SaidNo ratings yet

- 230828AR-A Emergency Light Replacement From MS Body To Fiber BodyDocument4 pages230828AR-A Emergency Light Replacement From MS Body To Fiber BodywasimNo ratings yet

- HRSG Drum End Enclosure: Caithness HRSG Reference Design Equipment Scope: HRSGDocument10 pagesHRSG Drum End Enclosure: Caithness HRSG Reference Design Equipment Scope: HRSGgk80823No ratings yet

- Amc For Ahp Operation and Maintenance For Nabha Power LimitedDocument96 pagesAmc For Ahp Operation and Maintenance For Nabha Power LimitedLaxmi Laxmi dNo ratings yet

- RHA - Open Cut Piping & Manhole Iinstallation (Page 4)Document5 pagesRHA - Open Cut Piping & Manhole Iinstallation (Page 4)tanaNo ratings yet

- 1nlrwmtqn4ac0etxquill3q3 3 4Document2 pages1nlrwmtqn4ac0etxquill3q3 3 4anmol kumarNo ratings yet

- Lessons Learned 04 21Document17 pagesLessons Learned 04 21vasu_suvaNo ratings yet

- WOB Solar Power Product Solutions Guide BrochureDocument21 pagesWOB Solar Power Product Solutions Guide Brochurevineets058No ratings yet

- An Elementary School Classroom in A Slum: Stanza 1Document2 pagesAn Elementary School Classroom in A Slum: Stanza 1Pooja RajeshNo ratings yet

- SRC Annual Report 2021 Low-ResDocument95 pagesSRC Annual Report 2021 Low-ResJohn ParkerNo ratings yet

- Guidelines On RDF Usage PDFDocument153 pagesGuidelines On RDF Usage PDFpavnitkiran02100% (1)

- 3.1 Project Description ACSDocument12 pages3.1 Project Description ACSgilang mrNo ratings yet

- IMRAD Bahay PagbabagoDocument27 pagesIMRAD Bahay PagbabagoMG Lumidao SalvadorNo ratings yet

- Office of The Sangguniang Bayan: Municipality of Delfin AlbanoDocument17 pagesOffice of The Sangguniang Bayan: Municipality of Delfin AlbanoGrace Managuelod GabuyoNo ratings yet

- Health City Novena Masterplan 2030Document34 pagesHealth City Novena Masterplan 2030Tan Tock Seng Hospital100% (2)

- NCP Pharyngitis 4 NoviDocument1 pageNCP Pharyngitis 4 NoviCharina AubreyNo ratings yet

- Cadbury Dairy Milk's Advertising Campaigns in IndiaDocument35 pagesCadbury Dairy Milk's Advertising Campaigns in IndiaRohit GomesNo ratings yet

- Acca F6 Uk Taxation FA 2017: Course Notes For Exams From June 2018 To March 2019Document100 pagesAcca F6 Uk Taxation FA 2017: Course Notes For Exams From June 2018 To March 2019AliRazaSattarNo ratings yet

- Servovalve Andritz HydroDocument4 pagesServovalve Andritz HydroYhony Gamarra VargasNo ratings yet

- Mettler Toledo Ti-Note Easyplus Titrators Ap015: Chloride in Beverages by Precipitation TitrationDocument1 pageMettler Toledo Ti-Note Easyplus Titrators Ap015: Chloride in Beverages by Precipitation TitrationVILMA CAROLINA PORTILLO CHAVEZNo ratings yet

- GE 24inch Front Load Washer: ModelsDocument99 pagesGE 24inch Front Load Washer: Modelsdan themanNo ratings yet

- Sensitive Periods: Sensitivity To OrderDocument3 pagesSensitive Periods: Sensitivity To OrderSindhuNo ratings yet

- Ranbaxy Laboratories LimitedDocument9 pagesRanbaxy Laboratories LimitedMaroof BaigNo ratings yet

- 1610130042Document2 pages1610130042Kuldeep ShrivastavaNo ratings yet

- CaMaNaVaTon 201Document12 pagesCaMaNaVaTon 201guaporicNo ratings yet

- Rotork JordanDocument28 pagesRotork JordanTrie WahyudiNo ratings yet

- KSSM Bio F5 C2Document84 pagesKSSM Bio F5 C2Jia XuanNo ratings yet

- Mat 152-Test 1 Review Spring 2020Document14 pagesMat 152-Test 1 Review Spring 2020Alejandra TexidorNo ratings yet

- Types of Mental Health Issues and Illnesses: Anxiety DisordersDocument3 pagesTypes of Mental Health Issues and Illnesses: Anxiety DisordersRáche SolonNo ratings yet

- Magnetic Properties of Co Ordination CompoundsDocument14 pagesMagnetic Properties of Co Ordination CompoundsbnkjayaNo ratings yet

- Operator Manual of Xray GeneratorDocument43 pagesOperator Manual of Xray GeneratorMohamed belhasanNo ratings yet

- 11 Laminar FlowDocument48 pages11 Laminar FlowBrahim LetaiefNo ratings yet

- 2020 Ritter Essentials Catalogue E2 PDFDocument20 pages2020 Ritter Essentials Catalogue E2 PDFchimedbatorNo ratings yet