Professional Documents

Culture Documents

DN02 00BZL 137010 001 0

Uploaded by

taharOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

DN02 00BZL 137010 001 0

Uploaded by

taharCopyright:

Available Formats

0 29.07.2006 P.Balamurugan B.

Delprat Issued for construction

A 04.04.2006 P.Balamurugan B. Delprat Issued for review

Indice

Date Suivi Vérifié

Rev. Modifications apportées / Details of Revision

Date Coord. Checked

Nom Du Projet / Project Title:

CENTRALE TURBINE À GAZ DE BERROUAGHIA

PUISSANCE TOTALE DE 2 X 271 MW (ISO)

Maître de l’Ouvrage / Client:

SHARIKET KAHRABA BERROUAGHIA

Zone industrielle, Route Nationale No 18 Berrouaghia, willaya de Médéa

Constructeur / Contractor :

CONSORTIUM SIEMENS AG / SAIPEM SA /

SIEMENS ALGÉRIE / SAIPEM CONTRACTING ALGÉRIE

Membre du Groupement / Consortium Partner:

SIEMENS

Power Generation

Classement des documents SKB :

BRG-GG-740-069

Original / Original: NO Original / Original-No.: Code Projet Original :

Orig.-PC :

Projet / Project: Code Projet / PC:

Centrale Turbine à Gaz de Berrouaghia ALG298

Echelle Type Doc. / Dec:

Date Nom

Scale

Date Name Type of Doc.: DN02

Dessiné Titre / Title: Code Objet :

Drawn 04.04.2006 P.Balamurugan

Suivi

Contents Code :

Coord. 04.04.2006 B. Delprat Lighting System Commissioning 00BZL

Verifié

Checked F. Glaisner Procedure

Service

Dept.

COMMISSIONING Procédure d’essais des systèmes

Ref.:

Reg. 137010

d’éclairage No:

Unité / Dept.: UNID Indice / Rev.: Version

Saipem 0 EN

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :2 / 23

ALG298-DN02-00BZL-137010

Var. Offre / Offer – Var. / Opt.: N° Feuille / Page – No.:

ALG298-DN02-00BZL-137010 Var.: Page 1 OF 23

Fait avec / designed with: Remplace:

MS WORD Supersedes:

CHANGE RECORD PAGE

REV. N° Status Description of Revision

A IDA Issued for Review

0 IFC Issued for construction

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :3 / 23

ALG298-DN02-00BZL-137010

TABLE OF CONTENTS

1. INTRODUCTION AND OBJECTIVE.........................................................................................................4

OBJECTIVE..............................................................................................................................................................4

SYSTEM OVERVIEW................................................................................................................................................4

DESIGN DATA.........................................................................................................................................................5

SYSTEM CONTROL PHILOSOPHY.............................................................................................................................6

2. SCOPE AND MEASUREMENTS.................................................................................................................7

COMMISSIONING PHILOSOPHY AND SCOPE.............................................................................................................7

TYPE OF MEASUREMENTS.......................................................................................................................................7

SPECIAL TOOLS AND TEST EQUIPMENT..................................................................................................................7

3. PREREQUISITES...........................................................................................................................................8

COMPLETED PRE-COMMISSIONING ACTIVITIES......................................................................................................8

SYSTEM PREREQUISITES FOR COMMISSIONING.......................................................................................................8

4. PRECAUTIONS............................................................................................................................................11

HEALTH, SAFETY AND ENVIRONMENT.................................................................................................................11

5. PERFORMANCE..........................................................................................................................................11

COLD COMMISSIONING PREPARATORY CHECKS...................................................................................................11

5.1.1 Piping Preparatory Checks...............................................................................................................11

5.1.2 Mechanical Preparatory Checks.......................................................................................................11

5.1.3 Instrumentation Preparatory Checks................................................................................................12

5.1.4 Electrical Preparatory Checks..........................................................................................................12

5.1.5 Logics Checks....................................................................................................................................14

DYNAMIC COMMISSIONING...................................................................................................................................14

5.1.6 Preparation for Dynamic Commissioning........................................................................................14

5.1.7 Dynamic Commissioning Procedure.................................................................................................15

5.1.8 Operational Test................................................................................................................................15

6. ASSESSMENT AND POST-COMMISSIONING STATUS.....................................................................15

7. APPENDICES................................................................................................................................................17

ANNEX 1 – LIST OF REFERENCE DOCUMENTS......................................................................................................17

ANNEX 2 – GLOSSARY OF TERMS.........................................................................................................................18

ANNEX 3 – PERMIT TO WORK FORMAT................................................................................................................19

ANNEX 4 – PRE-COMMISSIONING INSPECTION TEST REPORT FORMATS..............................................................20

ANNEX 5 – COMMISSIONING INSPECTION TEST REPORT FORMATS.....................................................................21

ANNEX 6 – COMMISSIONING PUNCH-LIST FORMAT.............................................................................................22

Annex 7 – System Commissioning Handover Certificate Format.......................................................................23

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :4 / 23

ALG298-DN02-00BZL-137010

1. INTRODUCTION AND OBJECTIVE

Objective

The objective of this document is to detail the various preparatory checks, actual

preparation for commissioning and dynamic commissioning procedure including the post

commissioning operational tests procedure for lighting system.

System Overview

In respect of the function, lighting levels, quality and reliability of electric supply system,

the lighting system shall be divided and classified as follows:

Normal AC lighting

DC Escape lighting fed from 125 V DC Distribution board.

Normal lighting is the lighting set up and sized so as to enable normal operating

activities. Normal lighting is fed from the normal power supply system and is available as

long as the normal AC power supply exists. During 220 kV / GT blackout, the emergency

operation initiated by DCS will start the EDG and within 10 seconds the EDG will come

into full operation with a part of lighting fixtures connected to the normal AC switchgear.

The plant lighting will not be disrupted during the blackout.

The DC Escape lighting is provided in places of emergency exits, access to the control

room and other strategic points essential for personnel movement. This lighting system is

fed from DC Lighting sub-distribution boards which will be in turn fed from Station

125V DC Distribution board. This lighting system is sized so as to provide minimum

suitable conditions of escape or survival and enable communication activities, immediate

aid, evacuation of people or remedy actions to safeguard the power plant.

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :5 / 23

ALG298-DN02-00BZL-137010

Design Data

The lighting system is designed to give minimum illumination levels as given in the table

below.

The table furnished below gives the type of lighting fixtures provided for each area and

the level of lighting expressed in average lux when measured on an useful horizontal

plane at 80cm above the floor.

Area Type of lighting fixture Normal lighting (lux)

Machine rooms

HPSV lamps & Fluorescent 50

Path Way

lamps 200

Work Spot

Exterior lighting HPSV lamps & Projectors

10

Path Way

70/100

Work Zone

Control room Fluorescent lamps 500

Power building Fluorescent tubes 250

Workshop HPSV lamps & Fluorescent

250

tubes

Stores and racks Fluorescent tubes 100

Offices Fluorescent tubes 400

Corridors - stair case Fluorescent tubes 50

Cable gallery Fluorescent tubes 50

Lighting of primary HPSV lamps

50

roads

Lighting of secondary HPSV lamps

20

roads

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :6 / 23

ALG298-DN02-00BZL-137010

System Control Philosophy

Normal AC Lighting

For external lighting, HPSV Floodlights installed on 15m column are used. High pressure

sodium vapour lamps installed on 9m poles are used for road lighting with photocell

control. A photocell is located at the substation to control automatic lighting system.

Indoor lighting is generally provided by fluorescent luminaire type. For high ceilings,

high pressure mercury vapour lamps are used.

Supply

The source of power supply is from 400V – 230 V Main Lighting Distribution board

which is fed from two (2) Lighting Transformers, each of rating 200 KVA. This Main

Lighting Distribution board feeds respective area lighting sub-distribution boards from

which lighting fixtures are fed. Road lighting fixtures and 32 A & 63 A power socket

outlets are fed with 400 V AC – 3 phase power supply. Lighting and power socket

distribution is done from the same lighting sub-distribution board located in any

particular area.

DC Escape Lighting

Escape lights are provided in critical points for the safety of the people. Escape lighting is

also be provided in the proximity of communication points with control rooms and or/aid

centre (telephones, interphones etc.) Escape light points are provided along all passage

routes, escape routes guaranteeing sufficient light for the movement of personnel.

Supply

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :7 / 23

ALG298-DN02-00BZL-137010

This lighting system is fed from DC Lighting sub distribution boards which is in turn fed

from Station 125V DC Distribution board. The lamps are of incandescent type with 25W

power.

The switching on or switching off of exterior lighting is done either automatically using a

photo electric cell, or manually from the guardhouse.

2. SCOPE AND MEASUREMENTS

Commissioning Philosophy and Scope

The Lighting system can be commissioned after the commissioning of LV Distribution

system(BFA & BFB) and Earthing system (BAW).

The document describes the various steps required to successfully commission the

Lighting System. This document serves as a basic guideline however deviation from the

procedures may be necessary based on actual site conditions and vendor.

specific requirements. The document incorporates vendor information and engineering

data that is available at the time of operation.

Type of Measurements

The Lux Level of the lighting system to be measured and recorded each building and

plant area.

Special Tools and Test Equipment

As far as Lighting system concern there is no any such special tools are required.

However necessary arrangements to be made based on site conditions.

The minimum requirements testing equipments are,

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :8 / 23

ALG298-DN02-00BZL-137010

1. Multimeter

2. Lux Meter

3. Megger (500V)

3. PREREQUISITES

Completed Pre-Commissioning Activities

The following systems are expected to be commissioned before commissioning of the

Lighting system.

KKS Code System name

BFA LV Switchgear Substation 1

BFB LV Distribution Substation 2

BZL Lighting Transformers & Distribution

BV DC Supply UPS

BAW Earthing

system Prerequisites for Commissioning

General preparation check – GP

Task N° Definition Done / Date

GP-LG01 Check all the SLDs, Key OLDs and ensure all aspects related to

commissioning of lighting have been resolved.

GP-LG02 Ensure the lighting distribution transformers (TS11 & TS12) are

energised.

GP-LG03 Make sure that all lighting fixtures are connected with proper

earthing.

GP-LG04 Ensure the Main Lighting distribution boards are commissioned.

GP-LG05 Ensure that the Escape lightings from DC lighting sub

distribution boards are energised.

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :9 / 23

ALG298-DN02-00BZL-137010

GP-LG06 All punch-listed points in the open category should be properly

listed down and corrective action shall be taken.

GP-LG07 Ensure that all the systems as detailed in the section 3 will be

commissioned and operating satisfactorily.

GP-LG08 Ensure the necessary work permits has been taken to energise

the lighting system in Substation 1 & 2.

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :10 / 23

ALG298-DN02-00BZL-137010

Construction

achievement of

BZL

Visual inspection

& Static pre

commissioning

tests

Mechanical

Completion of

BZL

Prerequisites for

commissioning

of BZL System

Dynamic Tests

Commissioning

Completion of sys

BZL

BZL System

Handover to

operations

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :11 / 23

ALG298-DN02-00BZL-137010

4. PRECAUTIONS

Health, Safety and Environment

1. Ensure the work area is clean and all the pre-commissioning debris has been

removed.

2. The working Engineer requires to be certified by the senior Electrical Engineer.

3. Ensure there should not be any supports hanging over the Lighting fixtures and

Distribution boards.

4. Ensure the CO2 hand held type fire extinguishers are provided in appropriate places.

5. Ensure all necessary permits to work have been raised and outstanding permits have

been closed.

6. Commissioning work Team, in advance of the Pre-Com/Com activities taking place

shall issue a Livening-Up Notice (LUN). The LUN form is issued by

Commissioning to notify Construction and all contractors of the Pre-Com/Com

activities on specific equipment, lines, devices, systems or areas.

7. Personnel involved in the pertinent Pre-Com/Com activities shall not leave the work

area unattended when equipment is in operation or dynamic/pressure operations are

taking place.

8. Conduct daily Tool Box meeting at the work place before starting the work.

9. Brief the commissioning team regarding the escape routes and necessary preventive

action.

5. PERFORMANCE

Cold Commissioning Preparatory Checks

5.1.1 Piping Preparatory Checks

Not applicable for commissioning the Lighting system.

5.1.2 Mechanical Preparatory Checks

Not applicable for commissioning the Lighting system.

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :12 / 23

ALG298-DN02-00BZL-137010

5.1.3 Instrumentation Preparatory Checks

Not applicable for commissioning the Lighting system.

5.1.4 Electrical Preparatory Checks

Ready for commissioning/Mechanical completion certificate stating that the system is

ready for commissioning should be available and also the following should be verified.

Make sure all electrical construction / commissioning ITR’s (ITR-A & B) should be

completed without any A category punch list.

Distribution Boards

Task Remarks Signature

Ensure all electrical isolation is in place.

Ensure the installation is mechanically complete and free

from debris.

Carry out random checks on 10% of terminations to

ensure they are torqued to correct value. If any is not meet

the value then 100% check should be initiated.

Ensure all Incoming and outgoing MCCB’s are racked in

properly.

Carry out 500V DC insulation test on each section of the

LV Distribution board Bus.

Check the main Lighting Distribution Board outgoing

MCB’s operation and Neutral link connections are

properly connected at Substation 1 & 2.

Carry out 500V DC insulation test on anti-condensation

heater wiring.

Check the ON / OFF operation of MCCB’s from local

panel.

Finally keep all MCCB’s and MCB’s in OFF position.

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :13 / 23

ALG298-DN02-00BZL-137010

Protection

CT’s

Task Remarks Signature

Check the polarity flick test on each CT

Check the primary injection of each CT at rated CT

current and ensure correct reading and phase on the

Kilowatt Hour Meter and Ammeter.

Lighting Power cabling

Task Remarks Signature

Ensure all cables are installed and properly terminated.

Check the continuity test on all cables to ensure that there

is no cross phasing.

Check the IR value with Megger for 1 minute on

power/control cables at the following voltage.

220V/400V – 500V DC

Lighting Transformers (TS11 & TS12)

Task Remarks Signature

Ensure all electrical isolation are in place.

Ensure the mechanical installations are complete and free

from debris.

Check the winding resistance of the transformer.

Check the Insulation Resistance test using a 500V DC

voltage for 1 minute.

Check the Tripping from the transformer incomer breaker.

Check the operation of Off circuit Tap Changer operation

in the Transformer.

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :14 / 23

ALG298-DN02-00BZL-137010

General

Task Remarks Signature

Ensure Lighting system has been installed in line with

project earthing philosophy and drawings.

Check if there are any outstanding site quires/instructions

or electrical drawing mark ups that effect commissioning.

Ensure the Electrical livening up notice is raised for

Lighting system at the time of commissioning.

Check the temporary straps based on the Temporary strap

register.

5.1.5 Logics Checks

The following logic checks should be under taken as part of the pre-commissioning

sequence.

1. All trips from transformer protective devices to switchgear Panel.

Dynamic Commissioning

5.1.6 Preparation for Dynamic Commissioning

No. TASK DESCRIPTION INITIALS

1 Ensure that all the control power for the panel are powered up and

the alarms are cleared.

2 Ensure that the transformer pre-commissioning checks are

completed and ITR’s are completed.

3 Ensure that all the alarms are cleared in the Transformer control

panel.

4 Ensure that the 125V DC distribution board are energised by UPS

power for commission the DC lighting.

5 Check the earthing system of the transformer is properly connected.

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :15 / 23

ALG298-DN02-00BZL-137010

5.1.7 Dynamic Commissioning Procedure

No. TASK DESCRIPTION INITIALS

1 Close the LV Breaker at 00BHA/BHB bus.

2 Check the voltage in the control Panel.

3 Check the transformer if any noise.

4 Close the MCCB in the Lighting distribution board.

5 Check the incoming voltage.

6 Energise the outgoing circuit MCCB’s one by one and check the

lighting illumination.

7 Energise the DC distribution board thro UPS and check the 125V

DC lighting.

8 Ensure the Lux levels are as per design by measuring in different

places.

5.1.8 Operational Test

1. Verify the satisfactory operation of lighting system.

2. Verify the satisfactory operation of Lighting Transformer.

6. ASSESSMENT AND POST-COMMISSIONING STATUS

System status

The Lighting system distribution system is commissioned and can be safely fed with LV

supply.

Preservation status

The Lighting system is always kept in live condition, so no preservation is applicable for

this system.

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :16 / 23

ALG298-DN02-00BZL-137010

Reinstatement status

Restore any temporary arrangements made to simulate the trip commands in the Lighting

system while doing the pre-commissioning activities.

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :17 / 23

ALG298-DN02-00BZL-137010

7. APPENDICES

Annex 1 – List of Reference Documents

Engineering Documents

00 TBD 132101 Electrical Design Basis Memorandum

00 TBD 132115 Design Calculation for protection relay setting

00 TBD 132142 Electrical Load list and Power Balance

00 BZL 132112 Design Calculation for Lighting Design

00 TBD 132415 Specification for Lighting system and Equipments

YD01 00TBD 935019 Lighting - Products Data Sheets

List of Drawings

00 TBD 132161 Key One Line Diagram

00 BZL 132168 One line diagram for Lighting

00 UYC 132258 Lighting Layout for Substation 1

00 UAA 132286 Lighting Layout for Substation 2

Installation and Maintenance Documents

00 TBD 935018 General Installation and Maintenance Manual

Spare Parts List for Commissioning

XF00 00TBD 935005 List of Spare parts for Commissioning / Start-up

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :18 / 23

ALG298-DN02-00BZL-137010

Annex 2 – Glossary of Terms

Abbreviation or Term Description

MCCB Moulded case Circuit Breaker

LV Low Voltage

MCB Miniature Circuit Breaker

UPS Uninterruptible Power Supply

DC Direct Current

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :19 / 23

ALG298-DN02-00BZL-137010

Annex 3 – Permit to Work Format

Before starting the commissioning activity of the Lighting system the work permit format

must be filled and approved by the Commissioning Manager with counter signing by Site

HSE manager.

All the safety actions to be followed before starting the commissioning activity.

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :20 / 23

ALG298-DN02-00BZL-137010

Annex 4 – Pre-Commissioning Inspection Test Report Formats

E-008A – Earthing

E-012A – Control or Relay panel Cubicle

E-013A – Control station / Junction box

E-016A – Distribution Board

E-017A – Lighting and Small power

E-028A – Ex Enclosures

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :21 / 23

ALG298-DN02-00BZL-137010

Annex 5 – Commissioning Inspection Test Report Formats

E-004B – Current Transformer

E-006B – Protection Relay

E-009B – LV Starter / Contactor

E-010B – LV Fuse switch / Isolator / MCB

E-012B – Control or Relay panel Cubicle

E-016B – Distribution Board

E-017B – Lighting and Small power

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :22 / 23

ALG298-DN02-00BZL-137010

Annex 6 – Commissioning Punch-List Format

Diffusion non restreinte

CENTRALE TURBINES À GAZ DE BERROUAGHIA 2x271 MW 29/07/06

REVISION : 0

LIGHTING SYSTEM COMMISSIONING PROCEDURE

PAGE :23 / 23

ALG298-DN02-00BZL-137010

Annex 7 – System Commissioning Handover Certificate Format

Diffusion non restreinte

You might also like

- D.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualFrom EverandD.C. Powered Timing Light Model 161.2158 for 12 Volt Ignition Systems Sears Owners ManualNo ratings yet

- P Qac Pro 240 39467 CDocument24 pagesP Qac Pro 240 39467 Ccsc EXPERTISENo ratings yet

- NPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00Document6 pagesNPT10111-PE-V-DS-621101-030 - Instrument Datasheet - Level Gauge F & B Rev-00kkumar_717405No ratings yet

- BPX-G-G-WE-029 Specification For Pipeline, Flowlines, WellpDocument38 pagesBPX-G-G-WE-029 Specification For Pipeline, Flowlines, WellpdonaldoguerreroNo ratings yet

- Pre-Commissioning & CommissioningDocument31 pagesPre-Commissioning & CommissioningKAABECHE SlimaneNo ratings yet

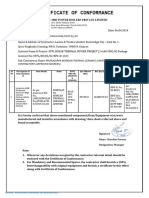

- Certificate of Conformance: 12/4, Delhi Mathura Road Near Sarai Khawaja Chowk Delhi NCR 121003 Haryana INDIADocument2 pagesCertificate of Conformance: 12/4, Delhi Mathura Road Near Sarai Khawaja Chowk Delhi NCR 121003 Haryana INDIAchandanNo ratings yet

- Spreader Beam Calculation ReportDocument15 pagesSpreader Beam Calculation ReportGurhan Atalay100% (1)

- NPT10111-PE-V-DS-621101-033 - R1 - Dial Type Level GaugeDocument5 pagesNPT10111-PE-V-DS-621101-033 - R1 - Dial Type Level Gaugekkumar_717405No ratings yet

- Handbook of Nitride Semiconductors and Devices, GaN-based Optical and Electronic DevicesFrom EverandHandbook of Nitride Semiconductors and Devices, GaN-based Optical and Electronic DevicesNo ratings yet

- Procédure MTDocument11 pagesProcédure MTAslaouiNo ratings yet

- QAP-UEPL-BHOPAL-54-9550-01 Rev.03Document6 pagesQAP-UEPL-BHOPAL-54-9550-01 Rev.03udayakarnaNo ratings yet

- Binded Hook Up & InstallationDocument44 pagesBinded Hook Up & InstallationrajNo ratings yet

- 8 Commissioning ManualDocument9 pages8 Commissioning ManualtaharNo ratings yet

- NAV-10-GM-BR-IEM-035 Rev1Document10 pagesNAV-10-GM-BR-IEM-035 Rev1Korcan ÜnalNo ratings yet

- HCN Sla 00 Bac Ec 00 260-A GCB Site Test ProcedureDocument17 pagesHCN Sla 00 Bac Ec 00 260-A GCB Site Test ProcedureBuồnNgủNo ratings yet

- DRP001 Ouf Gal Pro Q 000 064 S1Document26 pagesDRP001 Ouf Gal Pro Q 000 064 S1Rafat KhanNo ratings yet

- 2097-1-G-G0-034 COAL PREPARATION & FIRING SYSTEM - Rev 00Document15 pages2097-1-G-G0-034 COAL PREPARATION & FIRING SYSTEM - Rev 00lightsonsNo ratings yet

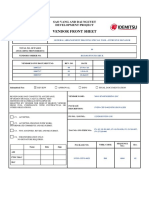

- Vendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectDocument4 pagesVendor Front Sheet: Sao Vang and Dai Nguyet Development ProjectjfdlksaNo ratings yet

- CMBA 00 D3 PRO 001 079 - RevB2 Pipe Stress Calculation Outlet Discharge ScrubberDocument30 pagesCMBA 00 D3 PRO 001 079 - RevB2 Pipe Stress Calculation Outlet Discharge ScrubberJona TegarNo ratings yet

- 0069 - DTCB - O&M ManualDocument115 pages0069 - DTCB - O&M ManualkwakerNo ratings yet

- A5d010002 - Ballast Heeling Process Flow DiagramDocument21 pagesA5d010002 - Ballast Heeling Process Flow DiagramMarin GotovinaNo ratings yet

- YS2-03-C10017-TL-DTS-M-003 Rev 0 (6 Inch Mobile Pig Launcher)Document4 pagesYS2-03-C10017-TL-DTS-M-003 Rev 0 (6 Inch Mobile Pig Launcher)Gajendra PatilNo ratings yet

- Gac 12 VX RMH Lah 008 - Rev 1 - Ipbd & GCBDocument3 pagesGac 12 VX RMH Lah 008 - Rev 1 - Ipbd & GCBDipayan DasNo ratings yet

- Instrument General SpecificationDocument7 pagesInstrument General SpecificationIwan TristiawanNo ratings yet

- SAIPEM MS Grounding & Lightning ProtectionDocument20 pagesSAIPEM MS Grounding & Lightning Protectionsyam prasad100% (1)

- Document DetailsDocument2 pagesDocument DetailsMohammed AbdallaNo ratings yet

- Bolt Torquing Reference - 2Document5 pagesBolt Torquing Reference - 2DILSHAD AHEMADNo ratings yet

- TBL 31 E 153b 001 SP 021 en 0 Commissioning ITPL Bypass Operation - 01!01!01Document12 pagesTBL 31 E 153b 001 SP 021 en 0 Commissioning ITPL Bypass Operation - 01!01!01DangolNo ratings yet

- PaintingDocument22 pagesPaintingAmit Kumar MilanNo ratings yet

- IMIRDocument10 pagesIMIRvizagnucalcuttaNo ratings yet

- DRP001 Ouf Gal Pro Q 000 063 S2Document66 pagesDRP001 Ouf Gal Pro Q 000 063 S2Rafat KhanNo ratings yet

- 2097-1-G-G0-027 LDO and HFO System - Rev 00Document12 pages2097-1-G-G0-027 LDO and HFO System - Rev 00lightsonsNo ratings yet

- VD 1233 330 Dig 001 1Document12 pagesVD 1233 330 Dig 001 1Reza AranNo ratings yet

- VMS GailDocument129 pagesVMS GailManjunatha VNo ratings yet

- TTP 2 KHO ED 8130 M 107 00 - Conv - InstManDocument52 pagesTTP 2 KHO ED 8130 M 107 00 - Conv - InstManArcanjoCicletaNo ratings yet

- Metering System Rev 1Document11 pagesMetering System Rev 1sswahyudi100% (1)

- HVAC Cause & Effect DiagramDocument6 pagesHVAC Cause & Effect DiagramAdrian IrawanNo ratings yet

- QAP-UEPL-BHOPAL-54-04 Rev.03Document6 pagesQAP-UEPL-BHOPAL-54-04 Rev.03udayakarnaNo ratings yet

- GRP Lining of Water TanksDocument7 pagesGRP Lining of Water Tanksben100% (1)

- TBL 31 E 153b 001 SP 008 en 0 Commissioning ITPL Steam Bypass System - 01Document16 pagesTBL 31 E 153b 001 SP 008 en 0 Commissioning ITPL Steam Bypass System - 01DangolNo ratings yet

- C03-001-Structural Steel CalculationsDocument86 pagesC03-001-Structural Steel CalculationsNguyễnBìnhPhươngNo ratings yet

- GS-266-MOS-Installation of Method Statement For Installation, Termination & Testing of LV MV, Cables &Wires-REV00Document13 pagesGS-266-MOS-Installation of Method Statement For Installation, Termination & Testing of LV MV, Cables &Wires-REV00Zubair Ahmed KhaskheliNo ratings yet

- YS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Document4 pagesYS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Gajendra PatilNo ratings yet

- C-051-080-DAT-0003 Rev. 0 Datasheet For Differential Pressure TransmitterDocument50 pagesC-051-080-DAT-0003 Rev. 0 Datasheet For Differential Pressure TransmitterMidha NeerNo ratings yet

- Design & Calculation Cathodic Protection Impressed Cureent SystemDocument13 pagesDesign & Calculation Cathodic Protection Impressed Cureent SystemLuthfiSiradj96% (27)

- C03-001-Structural Steel CalculationsDocument166 pagesC03-001-Structural Steel CalculationsNguyễnBìnhPhươngNo ratings yet

- G-4-1-Pipe Supports Foundations Civil Calculation Notes (ET0153-NC-GEC-80401-02)Document31 pagesG-4-1-Pipe Supports Foundations Civil Calculation Notes (ET0153-NC-GEC-80401-02)Walid AmdouniNo ratings yet

- CB MX71ZZ El Rep 0001 000Document56 pagesCB MX71ZZ El Rep 0001 000alemdar.muhendislik25No ratings yet

- Orifice Cal. Rev.2Document75 pagesOrifice Cal. Rev.2waheed2286No ratings yet

- 1N1LG02 0 Liquid Starter Interlocking CheckList 1N1R042Document23 pages1N1LG02 0 Liquid Starter Interlocking CheckList 1N1R042Spellcaster0% (1)

- KG - 008 Write Up For Steam Blowing Scheme For Khargone Units PDFDocument92 pagesKG - 008 Write Up For Steam Blowing Scheme For Khargone Units PDFHimanshu ChaturvediNo ratings yet

- Draft Work Order - BCF: (Mining Site Only) ) If Yes, Please Attach DBS Print Screen DSPSCMACDocument1 pageDraft Work Order - BCF: (Mining Site Only) ) If Yes, Please Attach DBS Print Screen DSPSCMACFajar WinarkoNo ratings yet

- Tske 002087 00 Doc Po 0001 08 ADocument16 pagesTske 002087 00 Doc Po 0001 08 ARaja VigneshNo ratings yet

- SICAM 8 ProfileDocument2 pagesSICAM 8 ProfiletaharNo ratings yet

- VARIATEURDocument2 pagesVARIATEURtaharNo ratings yet

- Bro Digitax HDDocument64 pagesBro Digitax HDtaharNo ratings yet

- Mmi Um013 - en PDocument148 pagesMmi Um013 - en PtaharNo ratings yet

- Unidrive M300 Sell SheetsDocument2 pagesUnidrive M300 Sell SheetstaharNo ratings yet

- Commander S Flyer USDocument2 pagesCommander S Flyer UStaharNo ratings yet

- Preventive TimerDocument1 pagePreventive TimertaharNo ratings yet

- Midea V6R Heat Recovery VRF Owner ManualDocument13 pagesMidea V6R Heat Recovery VRF Owner ManualtaharNo ratings yet

- KN Yb 1000Document13 pagesKN Yb 1000taharNo ratings yet

- OpsLogix Capacity Reports Data SheetDocument4 pagesOpsLogix Capacity Reports Data SheettaharNo ratings yet

- Ac7.2 - Synthetic Filter MediaDocument2 pagesAc7.2 - Synthetic Filter MediataharNo ratings yet

- Component S8BA DS EN 202012 U701I-E3-03Document39 pagesComponent S8BA DS EN 202012 U701I-E3-03taharNo ratings yet

- Service Manual: Four-Way CassetteDocument23 pagesService Manual: Four-Way CassettetaharNo ratings yet

- 3VT94003MG10 Datasheet enDocument3 pages3VT94003MG10 Datasheet entaharNo ratings yet

- VRF v4 Plus I SeriesDocument114 pagesVRF v4 Plus I SeriestaharNo ratings yet

- 6-6 Installation Guidelines of Power Quality Analyzer (公开)Document20 pages6-6 Installation Guidelines of Power Quality Analyzer (公开)taharNo ratings yet

- Mobile Phone Charger ReferencesDocument13 pagesMobile Phone Charger ReferencesMohd Amirul AkmalNo ratings yet

- (Power Electronics and Power Systems) Slobodan N. Vukosavic - Grid-Side Converters Control and Design (2018, Springer International Publishing)Document288 pages(Power Electronics and Power Systems) Slobodan N. Vukosavic - Grid-Side Converters Control and Design (2018, Springer International Publishing)Isabella Bianchin100% (2)

- EV Charging ReportDocument28 pagesEV Charging ReportQuang Linh Lê100% (1)

- Excitation CourseDocument31 pagesExcitation Coursevenkat8eNo ratings yet

- Toshiba VF As1 230v 460vDocument326 pagesToshiba VF As1 230v 460vVisan GabrielNo ratings yet

- Installation Operation Manual: Growatt 7000UEDocument45 pagesInstallation Operation Manual: Growatt 7000UEsoti9No ratings yet

- Canon IR2200 Trouble Error CodesDocument29 pagesCanon IR2200 Trouble Error CodesnafeesNo ratings yet

- Driller's Console Chapter 4Document41 pagesDriller's Console Chapter 4Mihai MateiNo ratings yet

- Solar Inverter TRIO-5.8/7.5/8.5-TL-OUTD: From 5.8 To 8.5 KWDocument4 pagesSolar Inverter TRIO-5.8/7.5/8.5-TL-OUTD: From 5.8 To 8.5 KWhmm.hugo7845No ratings yet

- Power Quality Improvement in Transmission Line Using DPFCDocument7 pagesPower Quality Improvement in Transmission Line Using DPFCVIVA-TECH IJRINo ratings yet

- Deep Sea Electronics PLC: DSE7110 MKII & DSE7120 MKII Operator ManualDocument100 pagesDeep Sea Electronics PLC: DSE7110 MKII & DSE7120 MKII Operator ManualKelvinNo ratings yet

- Experiment 10Document3 pagesExperiment 10toshi12No ratings yet

- Circuits MidtermDocument208 pagesCircuits MidtermJohnjoseph Vera100% (1)

- Drts 34: Automatic Relay Test System Automatic Relay Test SystemDocument8 pagesDrts 34: Automatic Relay Test System Automatic Relay Test SystemRanabir DebNo ratings yet

- Caa-Vaa 1Document5 pagesCaa-Vaa 1EMD NSPCLNo ratings yet

- Refresher Day 18Document3 pagesRefresher Day 18Jevan A. CalaqueNo ratings yet

- Brake Failure Indicator Design: Bachelor of TechnologyDocument19 pagesBrake Failure Indicator Design: Bachelor of TechnologyAniket KarmakarNo ratings yet

- Dc-Ac Inverters: Owner's ManualDocument32 pagesDc-Ac Inverters: Owner's Manualalex castroNo ratings yet

- GE Power ManagemenDocument21 pagesGE Power ManagemeningguedezandresNo ratings yet

- M.SC - in Electrical and Comp Control EngDocument36 pagesM.SC - in Electrical and Comp Control EngIslam FattouhNo ratings yet

- A PWM Circuit Using Operational AmplifiersDocument7 pagesA PWM Circuit Using Operational Amplifiershamza abdo mohamoud100% (1)

- Simbol Pneumatik - From NorgrenDocument174 pagesSimbol Pneumatik - From NorgrenArief Wahyu PurwitoNo ratings yet

- SHARP LED TV Lc32le260m SERVICE MANUALDocument36 pagesSHARP LED TV Lc32le260m SERVICE MANUALJustin Ng71% (7)

- Alternating Current and Direct Current PDFDocument5 pagesAlternating Current and Direct Current PDFHafiz HamzaNo ratings yet

- Mini - Power - Station-Report TemplatesDocument31 pagesMini - Power - Station-Report Templatesمحمد الرمالي100% (1)

- Panelview Plus and Panelview Plus Compact 400 and 600 TerminalsDocument30 pagesPanelview Plus and Panelview Plus Compact 400 and 600 TerminalsIyapparaj PazhaniNo ratings yet

- FMDS0514Document30 pagesFMDS0514NozibolNo ratings yet

- Technical - GLD - INDUCTION FURNACEDocument2 pagesTechnical - GLD - INDUCTION FURNACEAkash Sharma100% (3)

- Variable Speed Drive Fundamentals Clarence A PhippsDocument380 pagesVariable Speed Drive Fundamentals Clarence A Phippss12original100% (2)