Professional Documents

Culture Documents

Setp by Step Design of Transformer

Uploaded by

blaagicaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Setp by Step Design of Transformer

Uploaded by

blaagicaCopyright:

Available Formats

Setp by step design of transformer

1. 1 Inductor and Transformer Design Design Problem # 1 Design a (250 VA) 250 Watt isolation

transformer with the following specifications using core geometry 𝑲 𝒈 approach. Input voltage, 𝑽𝒊 =

230 V Output voltage, 𝑽 𝒐 = 230 V Output Power, 𝑷 𝒐 = 250 Watts Frequency, 𝒇 = 50 Hz Efficiency, 𝜼

= 95 % Regulation, 𝜶 = 5 % Flux density, 𝑩 𝒂𝒄 = 1.6 T Design Steps: - Various steps involved in

designing this transformer are: Step # 1: Calculation of total power Total power, 𝑃𝑡 = 𝐼𝑛𝑝𝑢𝑡 𝑝𝑜𝑤𝑒𝑟 +

𝑂𝑢𝑡𝑝𝑢𝑡 𝑃𝑜𝑤𝑒𝑟 = 𝑃𝑂 𝜂 + 𝑃𝑂 = 250 0.95 + 250 = 513.16 𝑤𝑎𝑡𝑡𝑠. Step # 2: Calculation of electrical

condition Electrical conditions, 𝐾𝑒 = 0.145𝐾𝑓 2 𝑓2 𝐵 𝑚 2 × 10−4 = 0.145 × 4.44 × 502 × 1.62 × 10−4 =

1.83 Step # 3: Calculation of core geometry Core geometry, 𝐾𝑔 = 𝑃𝑡 2𝐾 𝑒 𝛼 = 513.16 2×1.83×5 = 𝟏𝟖.

𝟎𝟒 cm5 Step # 4: Selection of transformer core For the core geometry calculated in step # 3, the closest

lamination number is 𝑬𝑰 − 𝟏𝟓𝟎. For 𝑬𝑰 − 𝟏𝟓𝟎 lamination, Magnetic path length (MPL) = 22.9 cm Core

weight =2.334 Kg

2. 2 Copper weight = 853 gm Mean length turn (MLT) = 22 cm Iron area, 𝐴 𝑐 = 13.8 cm2 Window area,

𝑊𝑎 = 10.89 cm2 Area product, 𝐴 𝑝 = 𝐴 𝑐 × 𝑊𝑎 = 150 cm2 Core geometry, 𝐾𝑔 = 28.04 cm5 Surface

area, 𝐴 𝑡 = 479 cm2 Step # 5: Calculation of primary number of turns Primary number of turns, 𝑁𝑝 =

𝑉𝑖×104 𝐾 𝑓 𝐵 𝑎𝑐 𝑓𝐴 𝑐 = 513.16×104 4.44×1.6×50×13.8 = 𝟒𝟕𝟎 turns Step # 6: Calculation of current

density Current density, 𝐽 = 𝑃𝑡×104 𝐾 𝑓×𝐾 𝑢×𝐵 𝑎𝑐×𝑓×𝐴 𝑝 = 513.16×104 4.44×0.4×1.6×50×150 =

240.78 A/cm2 Step # 7: Calculation of input current Input current, 𝐼𝑖 = 𝑖𝑛𝑝𝑢𝑡 𝑝𝑜𝑤𝑒𝑟 𝑖𝑛𝑝𝑢𝑡 𝑣𝑜𝑙𝑡𝑎𝑔𝑒 =

𝑃𝑜/𝜂 𝑉𝑖 = ( 250 0.95 ) 230 = 1.144 A Step # 8: Calculation of cross-sectional area (bare) of conductor

for primary winding Bare conductor cross-sectional area, 𝐴 𝑤𝑝(𝐵) = 𝐼 𝑖 𝐽 = 1.144 240.78 = 0.00475 cm2

Step # 9: Selection of wire from wire table The closest Standard Wire Gauge (SWG) corresponding to

the bare conductor area calculated in step # 8 is 21 SWG. For 21 SWG conductor, 𝐴 𝑤𝑝(𝐵) = 0.00519

cm2 i.e. 0.519 mm2 Resistance for 21 SWG conductor is 33.2 Ω Km = 332 𝜇Ω 𝑐𝑚 Step # 10:

Calculation of primary winding resistance Resistance of primary winding, 𝑅 𝑝 = 𝑀𝐿𝑇 × 𝑁𝑝 × 332 ×

10−6 = 22 × 470 × 332 × 10−6 = 3.433 Ω

3. 3 Step # 11: Calculation of copper loss in primary winding Primary winding copper loss 𝑃𝑝 = 𝐼 𝑝 2 × 𝑅

𝑝 = 1.1442 × 3.433 = 4.493 Watts Step # 12: Calculation of secondary winding turns Number of turns in

the secondary winding 𝑁𝑠 = 𝑁 𝑝×𝑉𝑠 𝑉𝑖 [1 + 𝛼 100 ] = 469×230 230 [1 + 5 100 ] = 493 Step # 13:

Calculation of bare conductor area for secondary winding Cross-sectional area of bare conductor for

secondary winding 𝐴 𝑤𝑠(𝐵) = 𝐼 𝑖 𝐽 = 1.087 240.78 = 0.00451 cm2 = 0.451 mm2 Step # 14: Selection of

conductor size required for secondary winding From the wire table, the closest cross-sectional area (i.e.

next to) is found by choosing the conductor size as 21 SWG. For 21 SWG wire, bare conductor area is

0.519 mm2 , for which resistance/cm is 332 𝜇Ω/𝑐𝑚. Step # 15: Calculation of secondary winding

resistance Secondary winding resistance 𝑅 𝑠 = 𝑀𝐿𝑇 × 𝑁𝑠 × 332 × 10−6 = 22 × 493 × 332 × 10−6 =

3.601 Ω Step # 16: Calculation of copper in secondary winding Copper loss in secondary winding, 𝑃𝑠 =

𝐼 𝑜 2 × 𝑅 𝑠 = 1.0872 × 3.601 = 4.255 Watts Step # 17: Calculation of total copper loss Total copper loss,

𝑃𝑐𝑢 = 𝑃𝑝 + 𝑃𝑠 = 4.493 + 4.255 = 8.747 Watts Step # 18: Calculation of voltage regulation Voltage

regulation, 𝛼 = 𝑃𝑐𝑢 𝑃𝑜 = 8.747 250 = 0.035 = 3.5 % Step # 19: Calculation of Watts per Kg (W/K)

Watts/Kg, 𝑊 𝐾 = 0.000557𝑓1.68 𝐵𝑎𝑐 1.86 = 0.000557 × 501.68 × 1.61.86 = 0.9545

4. 4 Step # 20: Calculation of core loss Core loss, 𝑃𝑓𝑒 = 𝑊 𝐾 × 𝑊𝑡𝑓𝑒 × 10−3 = 0.9545 × 2334 × 10−3 =

2.23 Watts Step # 21: Calculation of total loss Total loss in the transformer, 𝑃Σ = 𝑃𝑐𝑢 + 𝑃𝑓𝑒 = 8.748 +

2.23 = 10.978 Watts Step # 22: Calculation of Watts/unit area Watts/unit area, 𝜓 = 𝑃Σ 𝐴 𝑡 = 10.978 479

= 0.023 Watts/cm2 Step # 23: Calculation of temperature rise Temperature rise, 𝑇𝑟 = 450𝜓0.826 = 450

× 0.0230.826 = 19.95 0 C Step # 24: Calculation of window utilization factor Window utilization factor,

𝐾 𝑢 = 𝐾 𝑢𝑝 + 𝐾 𝑢𝑠 = 𝑁 𝑝×𝐴 𝑤𝑝(𝐵) 𝑊𝑎 + 𝑁 𝑠×𝐴 𝑤𝑠(𝐵) 𝑊𝑎 = 470×0.00519+493×0.00519 10.89 = 0.46

You might also like

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Magnetics Calculations For Transformer DesignsDocument7 pagesMagnetics Calculations For Transformer DesignsFabian HarteryNo ratings yet

- Design of TransformerDocument47 pagesDesign of TransformerhamzaNo ratings yet

- Section - 1 (Power Transformer) A. Purpose: The Purpose of This Document Is To Design (Sizing Calculation) MainDocument2 pagesSection - 1 (Power Transformer) A. Purpose: The Purpose of This Document Is To Design (Sizing Calculation) Mainsrikanta100% (1)

- How To Calculate AC Choke For Mains Supply and DC Choke For DC BusDocument2 pagesHow To Calculate AC Choke For Mains Supply and DC Choke For DC BusNanda KumarNo ratings yet

- Transformer Manufacturer EnquiryDocument26 pagesTransformer Manufacturer EnquiryblaagicaNo ratings yet

- Power Cables & Wires Technical ManualDocument163 pagesPower Cables & Wires Technical Manualbharatsehgal00@gmail.comNo ratings yet

- DESIGNDocument7 pagesDESIGNjaythakar8887No ratings yet

- unit-II TransformersDocument19 pagesunit-II Transformersc.naresh9727100% (1)

- Transformer Design NotesDocument15 pagesTransformer Design Notesrishabh100% (2)

- Design of TransformersDocument26 pagesDesign of TransformersSagun KatuwalNo ratings yet

- Design of Single and Three Phase Transformer Using MATLABDocument6 pagesDesign of Single and Three Phase Transformer Using MATLABDevesh JayaswalNo ratings yet

- CM OLTC Operating Instruction-HM0.460.301-EN PDFDocument52 pagesCM OLTC Operating Instruction-HM0.460.301-EN PDFDeegii DeegiiNo ratings yet

- Substation Design Guidelines 1636703821Document40 pagesSubstation Design Guidelines 1636703821Hasan AlmatroodNo ratings yet

- Calculations For Design Parameters of Transformer - Engineer ExperiencesDocument40 pagesCalculations For Design Parameters of Transformer - Engineer ExperiencesSamit DasNo ratings yet

- Module 4: Substation Equipment's Details and Operations: July 2021Document14 pagesModule 4: Substation Equipment's Details and Operations: July 2021Gundeboyina GopiNo ratings yet

- I S 2099Document38 pagesI S 2099Hariprasad gantyalaNo ratings yet

- What Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPDocument5 pagesWhat Is The Difference Between MCB, MCCB, ELCB, and RCCB - EEPcurazaq100% (1)

- Transformer DesigneDocument6 pagesTransformer Designemhm770077100% (1)

- Important NumericalsDocument1 pageImportant NumericalscheshankarNo ratings yet

- Current Transformer Design GuideDocument3 pagesCurrent Transformer Design Guidedeepthik27No ratings yet

- How To Design A Transformer - Size and Selection - Technical ArticlesDocument7 pagesHow To Design A Transformer - Size and Selection - Technical ArticlesVamshi LavooriNo ratings yet

- 220kv GSSDocument46 pages220kv GSSAnkit KumarNo ratings yet

- Transformer Design ParametersDocument6 pagesTransformer Design ParametersPravat SatpathyNo ratings yet

- CT For Protection: Prof.O.V.Gnana SwathikaDocument24 pagesCT For Protection: Prof.O.V.Gnana SwathikaSarthak VatsNo ratings yet

- Dual Ratio Transformer MonographDocument7 pagesDual Ratio Transformer MonographGhanshyam Lalwani0% (1)

- Psabits WithanswersDocument12 pagesPsabits WithanswersChinnareddy KarriNo ratings yet

- Short Circuit Calculations With Transformer and Source Impedance - Arc Flash & Electrical Power Training - BrainfillerDocument5 pagesShort Circuit Calculations With Transformer and Source Impedance - Arc Flash & Electrical Power Training - BrainfillerJairo RamosNo ratings yet

- Transformer ProtectionDocument21 pagesTransformer ProtectioncalecaleNo ratings yet

- Earth Fault Protection of TransformerDocument2 pagesEarth Fault Protection of TransformerHARIHARANNo ratings yet

- Transformer Design ParametersDocument6 pagesTransformer Design ParametersArif Shah100% (1)

- Is 900-Code of Practice For Installation and Maintenance of Induction MotorDocument37 pagesIs 900-Code of Practice For Installation and Maintenance of Induction MotormailbkraoNo ratings yet

- Study of KV Switch YardDocument35 pagesStudy of KV Switch YardRamana ParavastuNo ratings yet

- Interview Questions: Collected by Asif AhmedDocument15 pagesInterview Questions: Collected by Asif Ahmedashish sahaNo ratings yet

- Reactive Power ImprovementDocument55 pagesReactive Power ImprovementKira Chakuri100% (1)

- Calculate IDMT Over Current Relay Setting (50 - 51)Document7 pagesCalculate IDMT Over Current Relay Setting (50 - 51)Woei Song OoiNo ratings yet

- IS 3716-1978 Ins Cood Application Guide PDFDocument96 pagesIS 3716-1978 Ins Cood Application Guide PDFRohit Dera0% (1)

- EEC Unit VIDocument8 pagesEEC Unit VITushar Shinde100% (2)

- Rating of The Circuit BreakersDocument19 pagesRating of The Circuit BreakersRoopa ReddyNo ratings yet

- PDF Created With Pdffactory Pro Trial Version: Wed Jul 19 10:32:37 2006Document96 pagesPDF Created With Pdffactory Pro Trial Version: Wed Jul 19 10:32:37 2006Abrakain69No ratings yet

- Control Transformer DesignDocument3 pagesControl Transformer DesignParag RekhiNo ratings yet

- Power Electronics SeminarDocument25 pagesPower Electronics Seminarsreemukhi100% (3)

- Transformer Solved Examples of Basic Electrical Eng by Nagrath and KothariDocument4 pagesTransformer Solved Examples of Basic Electrical Eng by Nagrath and KothariAnurag ZwNo ratings yet

- MVA Method Short Circuit CalculationDocument7 pagesMVA Method Short Circuit Calculationdskymaximus100% (1)

- Current Carrying Capacities & Other Technical TablesDocument7 pagesCurrent Carrying Capacities & Other Technical TablesImran_firdousiNo ratings yet

- Circle Diagram and Motor SimulationDocument4 pagesCircle Diagram and Motor SimulationShri KulkarniNo ratings yet

- Upptcl Training (Ee)Document27 pagesUpptcl Training (Ee)AakashNo ratings yet

- Current Transformer: Profile No.: 273 NIC Code: 27102Document14 pagesCurrent Transformer: Profile No.: 273 NIC Code: 27102Rama SubrahmanyamNo ratings yet

- Calculation of Positive Sequence ImpedanceDocument14 pagesCalculation of Positive Sequence ImpedancesathiyaseelanNo ratings yet

- Influence of Instrument Transformers On Power System ProtectionDocument142 pagesInfluence of Instrument Transformers On Power System Protection1453hNo ratings yet

- Ip 16 12 1Document12 pagesIp 16 12 1DhanushNo ratings yet

- Circuit BreakerDocument70 pagesCircuit BreakerBADAL CHOUDHARYNo ratings yet

- Available Fault Current Calculation: E I kVA X 1000 Trans. FLADocument7 pagesAvailable Fault Current Calculation: E I kVA X 1000 Trans. FLAAdil AberkanNo ratings yet

- Battery Sizing: From Open ElectricalDocument11 pagesBattery Sizing: From Open ElectricalBADRI VENKATESHNo ratings yet

- Transposition in Transformer WindingsDocument29 pagesTransposition in Transformer WindingsM V Ravindra Mutyala100% (1)

- Chapter 6: Stray Loss Terminology For The Power Transformer and It'S Perspective Analysis For Design OptimizationDocument17 pagesChapter 6: Stray Loss Terminology For The Power Transformer and It'S Perspective Analysis For Design OptimizationxiaomiNo ratings yet

- Rating 3Document1 pageRating 3blaagicaNo ratings yet

- PSM and TMS Settings Calculation of A RelayDocument20 pagesPSM and TMS Settings Calculation of A RelayblaagicaNo ratings yet

- Fault CalculationDocument3 pagesFault CalculationblaagicaNo ratings yet

- Synchronous CondenserDocument2 pagesSynchronous CondenserblaagicaNo ratings yet

- 132kV Power TransformerDocument7 pages132kV Power TransformerblaagicaNo ratings yet

- Generator Protection XZCDocument25 pagesGenerator Protection XZCblaagica100% (1)

- Short Circuit CalculationDocument8 pagesShort Circuit CalculationblaagicaNo ratings yet

- 3Ftr-Three Phase Transformers: General Technical SpecificationsDocument2 pages3Ftr-Three Phase Transformers: General Technical SpecificationsblaagicaNo ratings yet

- Etoolslit PDFDocument2 pagesEtoolslit PDFblaagicaNo ratings yet

- Transformer Manufacturer EnquiryDocument26 pagesTransformer Manufacturer EnquiryblaagicaNo ratings yet

- Global Voltage Stability Analysis of A Power System Using Network Equivalencing Technique in The Presence of TCSCDocument18 pagesGlobal Voltage Stability Analysis of A Power System Using Network Equivalencing Technique in The Presence of TCSCblaagicaNo ratings yet

- 4 Izdelek - Projektna Naloga - OdtDocument70 pages4 Izdelek - Projektna Naloga - OdtblaagicaNo ratings yet

- Optimal Power FlowDocument2 pagesOptimal Power FlowblaagicaNo ratings yet

- Cable Impedance Calculations Open Electrical PDFDocument4 pagesCable Impedance Calculations Open Electrical PDFblaagicaNo ratings yet

- Short Circuit Force For Equipment PDFDocument17 pagesShort Circuit Force For Equipment PDFblaagica100% (1)

- Fault Current CalculationDocument8 pagesFault Current CalculationPramod B.Wankhade100% (3)

- Considerations When Restraining Molecularly Oriented PVC PipeDocument10 pagesConsiderations When Restraining Molecularly Oriented PVC Pipeanupma vermaNo ratings yet

- Bangalore Metallurgy in AIM BrochureDocument7 pagesBangalore Metallurgy in AIM Brochurebhavesh solankiNo ratings yet

- En 1 4057 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67No ratings yet

- 2D Problems of ElasticityDocument14 pages2D Problems of ElasticityRishan Joshua DsilvaNo ratings yet

- Clarky TutorialDocument8 pagesClarky Tutorialmano121No ratings yet

- Lampiran Spek AlatDocument17 pagesLampiran Spek AlatBunga Rajhana Ragil GayatriNo ratings yet

- Slide Geogrid For EmbankmentDocument5 pagesSlide Geogrid For EmbankmentShazrin ZakariaNo ratings yet

- NTU Method - Wikipedia, The Free EncyclopediaDocument3 pagesNTU Method - Wikipedia, The Free EncyclopedianeondustNo ratings yet

- Chapter 7 PDFDocument42 pagesChapter 7 PDFSoufiane MoussamineNo ratings yet

- Elastic Analysis - Limit Analysis (Plastic Analysis)Document42 pagesElastic Analysis - Limit Analysis (Plastic Analysis)Abhijeet Singh Jamwal100% (1)

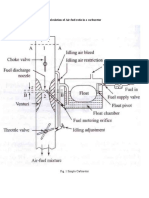

- Air-Fuel-Ratio-Calculation For CarburettorDocument10 pagesAir-Fuel-Ratio-Calculation For Carburettorsumeetsharma27No ratings yet

- Venturimeter, OrificemeterDocument13 pagesVenturimeter, OrificemetersantaNo ratings yet

- Sinker EdmDocument23 pagesSinker Edmdario larrosaNo ratings yet

- 322 11 Patran Exercise 11 Rubber SealDocument18 pages322 11 Patran Exercise 11 Rubber SealstaedtlerpNo ratings yet

- Intermolecular Forces of Attraction 1. Dipole-Dipole ForceDocument2 pagesIntermolecular Forces of Attraction 1. Dipole-Dipole ForceNica GamesNo ratings yet

- Material Science: Cast IronDocument40 pagesMaterial Science: Cast IronNagaraj ThakkannavarNo ratings yet

- 3 s2.0 B9780128166628000151 MainDocument23 pages3 s2.0 B9780128166628000151 MainMaria Monica Hernandez OrozcoNo ratings yet

- Composites: Part A: Ping Zhang, Qiang Li, Yimin XuanDocument7 pagesComposites: Part A: Ping Zhang, Qiang Li, Yimin Xuaneid elsayedNo ratings yet

- PDC - TR 06 02 PDFDocument227 pagesPDC - TR 06 02 PDFHelenNo ratings yet

- 2014 Entropy Tutorial With Solution For StudentsDocument6 pages2014 Entropy Tutorial With Solution For StudentsChen ZhihaoNo ratings yet

- Nyse MMM 2005Document108 pagesNyse MMM 2005gaja babaNo ratings yet

- Capacitance Test-1Document4 pagesCapacitance Test-1vinayakNo ratings yet

- Jooned Hendrarsakti, PH.D, IPM: Internal Flow - IntroductionDocument10 pagesJooned Hendrarsakti, PH.D, IPM: Internal Flow - IntroductionHafidzNo ratings yet

- s2 1 PDFDocument3 pagess2 1 PDFkrishnaNo ratings yet

- IC FabricationDocument78 pagesIC FabricationSayandip KarNo ratings yet

- Identification of Patterns in Blood of Vaccinated People, CrystallizedDocument14 pagesIdentification of Patterns in Blood of Vaccinated People, Crystallizedpln up2ksulselNo ratings yet

- Momentum TransferDocument2 pagesMomentum TransferrahulNo ratings yet

- Structure of Atom Chemistry Mind MapDocument2 pagesStructure of Atom Chemistry Mind MapPratibha GadheNo ratings yet

- EP3511172B1Document88 pagesEP3511172B1Thanh Hậu TrầnNo ratings yet

- Engineering Theory ET Culvert PDFDocument30 pagesEngineering Theory ET Culvert PDFSmart KhanNo ratings yet