Professional Documents

Culture Documents

Trench Calc

Uploaded by

Muhammad HassanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Trench Calc

Uploaded by

Muhammad HassanCopyright:

Available Formats

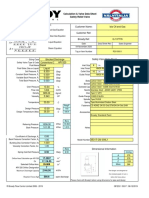

Pipeline Engineering

Pipeline Lowering and Roping Design ver 0.1

https://pipeeng.com/pipe_roping.html

Project Hasilpur line lowering Developer PipeEng

Mp37 to Mp38

Date 2022-08-25 Approver

Revision 0 Reviewer

This calculation was developed for the design of a pipeline lowering or roping operation. The calculations in this

tool are based on API RP 1117 methods developed from elastic free deflection theory to determine induced

stresses and deflection profiles.

Design Parameters

Pipe Outside Diameter, OD inch 12.750

Pipe Wall Thickness inch 0.219

Pipe Grade API Grade X70 / CSA Grade 483

Specified Minimum Yield Strength, SMYS psi 70,000

Maximum Allowable Operation Pressure, MAOP psi 1,100

Installation Temperature °F 70.0

Operating Temperature °F 90.0

Desired Vertical Deflection, Δ ft 5.0

Design Factor - 0.90

Poisson's Ratio, μ - 0.30

Linear Coefficient of Thermal Expansion of Steel, α in/in.°F 6.50e-6

Modulus of Elasticity , E psi 29000000

Longitudinal Flexural Stress Due to Existing Elastic psi 0.0

Curvature , Sc

Targeted Horizontal Length, Lh ft 1350.00

Result

Pipe Inner Diamter, d inch 12.31

Longitudinal Tensile Stress Due to Internal Pressure, Sp psi 9606

Longitudinal Tensile Stress Due to Thermal Change, Sr psi -3770

The Existing Longitudinal Stress, SE psi 5836

Minimum Trench Length, Lmin ft 277.5

Longitudinal Stress Due to Elongation, Ss psi 25137

Longitudinal Stress Available for bending, SA psi 32027

Maximum Free Span Between Supports, Ls ft 90.4

Downloaded on 25/08/2022, 09:46:04 from pipeeng.com Page 1 of 2

Pipeline Engineering

Preferred Trench Profile

Downloaded on 25/08/2022, 09:46:04 from pipeeng.com Page 2 of 2

You might also like

- HDD Calc SteelDocument4 pagesHDD Calc SteelRahamathulla Nizam mohideenNo ratings yet

- Pipeline CrossingDocument2 pagesPipeline CrossingRobby TriNo ratings yet

- API RP 1102 Pipeline Crossing Calculations: Input DataDocument2 pagesAPI RP 1102 Pipeline Crossing Calculations: Input DataCHANADAS50% (4)

- PipeDocument1 pagePipeRAMSNo ratings yet

- Api 1102, 2PLG 5 MTSDocument2 pagesApi 1102, 2PLG 5 MTSFabianArmazaNo ratings yet

- Hydrostatic Test Pressure Calculation: Pipe DataDocument2 pagesHydrostatic Test Pressure Calculation: Pipe DataAkram AlhaddadNo ratings yet

- API RP 1102 Pipeline Crossing Calculations: Input DataDocument2 pagesAPI RP 1102 Pipeline Crossing Calculations: Input Datapatrick6364No ratings yet

- Calculation Sheet of Main Pipes - Rev DDocument5 pagesCalculation Sheet of Main Pipes - Rev DAnonymous uXdS9Y7No ratings yet

- Down BlowDocument1 pageDown BlowRAMSNo ratings yet

- DataSheet 2 More 300# BV - FB - BW - NT-77 PDFDocument1 pageDataSheet 2 More 300# BV - FB - BW - NT-77 PDFSachin KumarNo ratings yet

- Electric Heater EH-2113101/201/301/401: Train No. 2 Train No. 3 Train No. 4Document1 pageElectric Heater EH-2113101/201/301/401: Train No. 2 Train No. 3 Train No. 4Manuel SerranoNo ratings yet

- Data Sheet Válvula de Seguridad y AlivioDocument4 pagesData Sheet Válvula de Seguridad y Aliviorenzo condeNo ratings yet

- Pipeline Strainer - SpecsDocument6 pagesPipeline Strainer - SpecsCristhian AyanomeNo ratings yet

- Caudalimetro Tubo Pitot Kobold AnuDocument9 pagesCaudalimetro Tubo Pitot Kobold AnuBase SistemasNo ratings yet

- Approval Foundation Pengganti Screw Pile To Footing Type C (Pematang GS) - SignDocument26 pagesApproval Foundation Pengganti Screw Pile To Footing Type C (Pematang GS) - SignDo ChannelNo ratings yet

- HYDRO 2019 Curnis-Bronzetti-Sayah PaperDocument24 pagesHYDRO 2019 Curnis-Bronzetti-Sayah PaperFrancisco GurzovNo ratings yet

- Cálculo de La Silleta ParcialDocument3 pagesCálculo de La Silleta ParcialALBERTO COCOM CELAYANo ratings yet

- Ductile Iron Pipe vs. HDPE Pipe: Strength and ForDocument15 pagesDuctile Iron Pipe vs. HDPE Pipe: Strength and ForZahid JiwaNo ratings yet

- TechnipFMC - Pipeline StrainersDocument6 pagesTechnipFMC - Pipeline StrainersYadir SánchezNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument29 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Anexo 4 - Dimensionamiento PSV-7004 1Document2 pagesAnexo 4 - Dimensionamiento PSV-7004 1JairoVidalNo ratings yet

- Data Sheet 2 Less 800# PV - SW - NT-77Document1 pageData Sheet 2 Less 800# PV - SW - NT-77Sachin KumarNo ratings yet

- D9 Ppag-100-Et-C-025-3 PDFDocument5 pagesD9 Ppag-100-Et-C-025-3 PDFSantiago GarciaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument31 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Mawt 31.3Document21 pagesMawt 31.3Yehia HassanNo ratings yet

- G7 Ppag-100-Et-C-036-3 PDFDocument7 pagesG7 Ppag-100-Et-C-036-3 PDFSantiago GarciaNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument30 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument66 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Site G - BD Calculations For Balustrade - 20220211 - PART 1Document77 pagesSite G - BD Calculations For Balustrade - 20220211 - PART 1Ronald RoblesNo ratings yet

- Calculation Pipe Header For CompressorDocument4 pagesCalculation Pipe Header For CompressorsyaifullintechNo ratings yet

- Intercambiador Agua AguaDocument19 pagesIntercambiador Agua Agualimarali1705No ratings yet

- Piping SpecificationDocument77 pagesPiping SpecificationVignesh Panchabakesan67% (3)

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument37 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- 26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002Document33 pages26071-100-V1A-MCAG-00315 - Isometric Drawing With BOM For Common Facilities SS-3 341-SS-114 - 002ogyrisky100% (1)

- A51L-6438-250-PNID - Rev 5Document1 pageA51L-6438-250-PNID - Rev 5Manuel SerranoNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument38 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Data Sheet 2 Less 800# PV - SW - LT-76Document1 pageData Sheet 2 Less 800# PV - SW - LT-76Sachin KumarNo ratings yet

- Final TestDocument15 pagesFinal TestSeptian FirdausNo ratings yet

- Max-Allowable-Pressure-of-Pipes-and-Pipellines-CER-04022013-1 (V. S. Kumar-Unprotected)Document74 pagesMax-Allowable-Pressure-of-Pipes-and-Pipellines-CER-04022013-1 (V. S. Kumar-Unprotected)chemical509No ratings yet

- Max Allowable Pressure of Pipes and PipellinesDocument73 pagesMax Allowable Pressure of Pipes and PipellinesRamzi BEN AHMEDNo ratings yet

- Product CatalogueDocument92 pagesProduct CatalogueZakaria ChouliNo ratings yet

- 1441793840reactor Datasheet 10kl ss316Document3 pages1441793840reactor Datasheet 10kl ss316Adrian StoicescuNo ratings yet

- TECHNIO COMMERCIAL PROPOSAL FOR WELL TEST Trailer PACKAGE R2-AWK Option1 DASDocument2 pagesTECHNIO COMMERCIAL PROPOSAL FOR WELL TEST Trailer PACKAGE R2-AWK Option1 DASslbclqrkNo ratings yet

- Gas Ultrasonic Meter Sizing ReportDocument4 pagesGas Ultrasonic Meter Sizing ReportWUMINGNo ratings yet

- HFY-PIP-SP-00005 X Specification For Piping Materials - A-CommentedDocument77 pagesHFY-PIP-SP-00005 X Specification For Piping Materials - A-CommentedVignesh Panchabakesan100% (1)

- Sales and Marketing Presentation - 2019 - Rev1Document36 pagesSales and Marketing Presentation - 2019 - Rev1HANIF AKBARNo ratings yet

- Max Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Document74 pagesMax Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)velan73No ratings yet

- 1 TPH For 10.54P Boiler IBR Design Calculations - R2-6-2-13Document21 pages1 TPH For 10.54P Boiler IBR Design Calculations - R2-6-2-13Vishal KandNo ratings yet

- Data Sheet-Ball ValveDocument2 pagesData Sheet-Ball ValveJatin Vadhera VCSP100% (1)

- Calculation Cover Sheet: ClientDocument9 pagesCalculation Cover Sheet: Clientanamaria ursuNo ratings yet

- Boiler Design Concept, Operation and Maintenance.Document126 pagesBoiler Design Concept, Operation and Maintenance.Trisha Mae BelmonteNo ratings yet

- API-650 Water Storage Tank TK-2Document27 pagesAPI-650 Water Storage Tank TK-2Athira ZahraNo ratings yet

- Max Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Document74 pagesMax Allowable Pressure of Pipes and Pipellines CER 04022013 1 (V. S. Kumar Unprotected)Esapermana RiyanNo ratings yet

- Aspen Exchanger Design and Rating Shell & Tube V10: DescriptionDocument37 pagesAspen Exchanger Design and Rating Shell & Tube V10: DescriptionCHELSEE VALENTINA SANCHEZ MUÑOZNo ratings yet

- Sizing CalcDocument1 pageSizing CalcHilary AbaratuNo ratings yet

- API 650-Water SS Tank-060914Document84 pagesAPI 650-Water SS Tank-060914A.K.M Shafiq MondolNo ratings yet

- Valves & Controls: FCT Trunnion Mounted Split Body Ball ValvesDocument16 pagesValves & Controls: FCT Trunnion Mounted Split Body Ball ValvesadrianioantomaNo ratings yet

- Storage Tank Design Calculation - Api 650: Close Floating RoofDocument32 pagesStorage Tank Design Calculation - Api 650: Close Floating RoofhgagNo ratings yet

- Sabic Hdpe B5429: High Density PolyethyleneDocument2 pagesSabic Hdpe B5429: High Density Polyethylenegetasew altasebNo ratings yet

- Unit-II (A) - Solid State WeldingDocument68 pagesUnit-II (A) - Solid State WeldingEmad Raza KhanNo ratings yet

- RCD ObjectivesDocument3 pagesRCD ObjectivesiamcerbzjrNo ratings yet

- ACEE2011-4CER WalentynskiR CybulskiK KozielDocument11 pagesACEE2011-4CER WalentynskiR CybulskiK KozielGaurav PawarNo ratings yet

- 107 RCDDocument170 pages107 RCDseth alexis pancipaneNo ratings yet

- Automotive Parts - Unscreened Low-Voltage Cables: Japanese Automobile Standard JASO D611:2009Document25 pagesAutomotive Parts - Unscreened Low-Voltage Cables: Japanese Automobile Standard JASO D611:2009Chung Le100% (1)

- Base Plate Verification ExampleDocument10 pagesBase Plate Verification ExampleKarthikeyan VediNo ratings yet

- CSA S16-01 Example 001Document7 pagesCSA S16-01 Example 001Bùi Văn HợpNo ratings yet

- Cracking Control On Early Age Concrete Through Internal Curing ShenDocument348 pagesCracking Control On Early Age Concrete Through Internal Curing Shenmirvahid HOSSiNiNo ratings yet

- Design Guide 5 For Concrete Filled Hollow Section Columns Under Static and Seismic LoadingDocument70 pagesDesign Guide 5 For Concrete Filled Hollow Section Columns Under Static and Seismic LoadingAlejandroNo ratings yet

- Aluminium Kyanite Composite NewDocument64 pagesAluminium Kyanite Composite NewneikarrakeshNo ratings yet

- Chapter 4 - Bolted Connections: A Beginner's Guide To The Steel Construction Manual, 13 Ed. (Old)Document3 pagesChapter 4 - Bolted Connections: A Beginner's Guide To The Steel Construction Manual, 13 Ed. (Old)perdhana2000No ratings yet

- 4000A Bus DuctDocument9 pages4000A Bus DuctRan Vijaysingh100% (1)

- Mechanical Analysis On Locally ProducedDocument91 pagesMechanical Analysis On Locally ProducedtitiNo ratings yet

- Loctite 648: Technical Data SheetDocument3 pagesLoctite 648: Technical Data SheetRuiNo ratings yet

- Local Specifications LRTDocument193 pagesLocal Specifications LRTTimothy Ryan WangNo ratings yet

- Use of BS 5950Document3 pagesUse of BS 5950Smr Only100% (1)

- Barc RT Level - 2Document160 pagesBarc RT Level - 2NavnitNo ratings yet

- Modulus of Elasticity ApplicationsDocument8 pagesModulus of Elasticity ApplicationsNag RazzNo ratings yet

- AISI S214-07 Standard and Commentary (1st Printing) PDFDocument54 pagesAISI S214-07 Standard and Commentary (1st Printing) PDFthjozsefNo ratings yet

- Materials Science and Engineering Properties 1st Edition Charles Gilmore Solutions ManualDocument18 pagesMaterials Science and Engineering Properties 1st Edition Charles Gilmore Solutions Manualedithclara2jb100% (29)

- Astm d6218-00Document19 pagesAstm d6218-00Francisco DelgadoNo ratings yet

- SC 1.5 Mechanical NDT, Issue 2, 30 April 2020edDocument27 pagesSC 1.5 Mechanical NDT, Issue 2, 30 April 2020edMuhammadFaizalNo ratings yet

- CEN - TC 229 m100 AnnexDocument42 pagesCEN - TC 229 m100 AnnexÓscar LópezNo ratings yet

- Saipem Pres2Document45 pagesSaipem Pres2alexrodriguezabcNo ratings yet

- Glulam HandbookDocument360 pagesGlulam HandbookchechumenendezNo ratings yet

- Chap. 7 - Pressure VesselsDocument37 pagesChap. 7 - Pressure VesselsGritz Kay Labucay MarforiNo ratings yet

- 17tooling by Design - Definning Acceptable Burr HeightDocument3 pages17tooling by Design - Definning Acceptable Burr HeightSIMONENo ratings yet

- Flexural Strength of PCSDocument6 pagesFlexural Strength of PCSClaira CaloNo ratings yet

- Answer KeyDocument13 pagesAnswer KeyLəonardo SasingNo ratings yet