Professional Documents

Culture Documents

HSE Risk Assessment (Contractor)

Uploaded by

Saim AliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSE Risk Assessment (Contractor)

Uploaded by

Saim AliCopyright:

Available Formats

HSE Risk Assessment (Contractor)

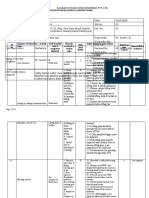

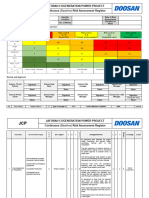

Company Name Hydrojet Facility Management LLC

Account / Project /

Department Name RA Ref No. RA/00067/09/HSE/23 Revision

Scope of Work

Sump pit cleaning at Innovation SOP/MS Ref

(Task / Equipment /

No.

WMS/00067/09/HSE/23

Facility) Hub & Huawei building-DIC

Assessment By

Saim ali Date 19/09/2023 Signature

(HSE Specialist)

Assessment By

Bishal Date 19/09/2023 Signature

(Operations Executive)

Reviewed & Approved By

Signature and

(Account Manager / Jhabindra Neupane Date 19/09/2023

Stamp

Department Head)

ESM5-Mod3-P007-F4 CLASSIFICATION: RESTRICTED Release Date: 19-sept-2023

Rev 0 UNCONTROLLED WHEN PRINTED Page 1 of 8

HSE Risk Assessment (Contractor)

Persons/Ass Inherent Residual

Conseque

Hazard ets/ Existing Control Risk Additional Responsible Risk Rating

Activity / Task nces

Identified Environment/ Measures Rating Control Party

(Risk

Exposed Measures

/ Impact) L S R L S R

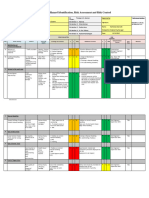

Ergonomic – Training on how to

Repetitive avoid ergonomic Site

Motion risks, Ability to vary Engineer

PTW, craft Training,

Engineering Engineering and Injuries, workers position i.e. Foreman

System inplace for

Services staff associated working from chair height, work 2 2 4 2 1 2

Sump PitCleaning disposal of HSE Personnel.

with this work a fixed surfaces angles etc.

contaminated earth.

position for Ability to take breaks

prolonged as needed to alleviate

periods of stress

time

Workers and Toolbox talks to be Area shall be well Site

Offloading of drivers conducted regarding barricade to make Engineer

material and Lack of proper methods of sure that is easily

other tools, road sign lifting operation. seen by other road Foreman

Site equipment post. Proper use of PPEs 3 3 9 users. 2 1 2

Preparation which will be Area like caped safety Sign boards and other HSE Personnel.

Sump Pit Cleaning used in the isolation for shoes, reflector warning shall be

course of the safely jackets, helmet, implemented as an

work. managing of masks among additional awareness on

work. others. the active operation.

Workers and TBT (toolbox talk) All personnel to be

nearby should be fully briefed on task & Site Engineer

Use of power Equipment operatives. conducting prior to Risk Assessment

tools like setting Damage to start the task & 3 4 12 Proper use of electrical Foreman 1 2 2

Sump Pit Cleaning exhaust fan the property, must cover tools and to only

Injury to emergency qualified personnel. Supervisor

work preparedness.

personnel. IMS

induction to be

given to all staff

ESM5-Mod3-P007-F4 CLASSIFICATION: RESTRICTED Release Date: 19-sept-2023

Rev 0 UNCONTROLLED WHEN PRINTED Page 2 of 8

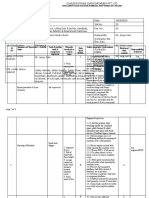

Manual Slip and trip Minor / Proper use of Action to be taken on

Handling falling with tools personal PPEs. 3 3 9 failure for PPEs Active Site Engineer 2 1 2

Sump Pit Cleaning / equipment. injuries. TBTs to be monitoring from all task Foreman

conducted before leaders.

start of task. First aid kits to be in

ESM5-Mod3-P007-F4 CLASSIFICATION: RESTRICTED Release Date: 19-sept-2023

Rev 0 UNCONTROLLED WHEN PRINTED Page 3 of 8

HSE Risk Assessment (Contractor)

place.

Mid-day breaks to Drink plenty of warm

be obtained just as water and energy

Heat stress the UAE labor law boosting foods.

for site says during summer TBT on heat stress Site Engineer

Severe worker, season. TBT on 4 3 12 subjects shall be 2 1 2

weathers. Employees and dehydration, heat stress subject delivered to all site Foreman

Sump Pit Cleaning supervisors, skin burning to be introduced to operatives.

visitors. and general all taskforce. Use of sign boards shall

body Multiple water be implemented.

weakness stations and other Use of approved PPE HSE personnel

resting facilities to shall be followed while

be in place. the operation is taking

place.

Full time monitoring

shall be maintained

while the work is taking

place.

Only Confined space Gas detector shall be

trainee shall be used to access if the

Body

allowed to access the space has no negative

Hazardous weakness. Site Engineer

space. Confined implementation.

gasses Loss of sight

space permits shall be

explosions focus. Foreman

provided as way of All entry shall be

and Sloping in the Explosion, 5 4 20 2 2 4

Sump Pit Cleaning controlling the entry controlled by a permit

environment. space to handle suffocation,

and shall be given by to work system

Lack of with task. fatality,

authorized personnel specifying the

oxygen severe injury HSE personnel

only. description of work and

to body, death

hazard and should be

clearly understood and

followed and well

signed.

Use of appropriate

Breathing Apparatus

and full SCBA will be

provided.

ESM5-Mod3-P007-F4 CLASSIFICATION: RESTRICTED Release Date: 19-sept-2023

Rev 0 UNCONTROLLED WHEN PRINTED Page 4 of 8

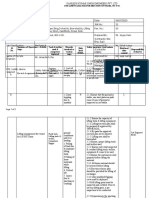

HSE Risk Assessment (Contractor)

High collapsing Multiple tests shall be

Hazardous Suffocation. Confined space

rate from carried out during the

environment, permit system

workers trying to Internal 5 3 15 task as permit is said. Site Engineer 3 2 6

lack of shall be

Sump Pit Cleaning conduct the task injuries Proper PPEs shall be Foreman

oxygen less implemented and

from confined laid in place of work. supervisor

than 19.5% followed.

space.

and above

TBT to be given

23.5%

before start of work.

Workers,

Ensure that H2S

other involved

Less than 10ppm

personnel Space must be adequately Site

permissible

Working from shall be led to well ventilated tested and Engineer

Harmful exposure level

Sump Pit Cleaning heights on explosion, 5 4 20 certified for toxic Foreman 2 2 4

gasses (H2S, 8hrs,Ventilation

completing the suffocation, allowable limits, HSE Personnel

CO) reducing Fans to be

task. fatality, injury flammable atmosphere or

oxygen level. positioned such

to body oxygen levelin the air.

that they are

burnings,

effective.

coma,

Supervisor to check if

ventilationis up to

standard

Workers and Oxygen readings Gas test at atmosphere

Sump Pit Cleaning supervisors tobe taken on a shall be done before Site

High humidity Loss of salts continuous basis. and during progress of Engineer

Changing levels. Close

through high 3 3 9 work by trained gas Foreman 2 1 2

conditions. inspection

sweetings tester ensure that HSE Personnel

gases all allowable

Suffocation Pretest every 30

limitO2 level, Toxic

min

gas level, LEL,

monitor 8hrs once

Every day.

Anyone entering

Not being Other Use of validated

Involved confined space must

able to employees

taskforce tripods and wear safety Site

remove exposing harness to all

during the harness/safety belt Engineer

worker from themselves

course of the space entry. 2 3 6 with life line. 1 2 2

Sump Pit Cleaning hazardous in attempt todo

task. Top watchers shall be Foreman HSE

working area so Use of permits and well trained on

in time. Serious to follow its emergency plan and Personnel

injuries. procedures without

confined space

failure. language.

ESM5-Mod3-P007-F4 CLASSIFICATION: RESTRICTED Release Date: 19-sept-2023

Rev 0 UNCONTROLLED WHEN PRINTED Page 5 of 8

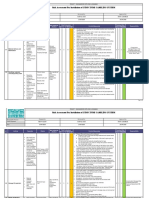

HSE Risk Assessment (Contractor)

Maintaining the Workers,

Before any vehicle Separate routes shall be

place of work by drivers,

Vehicles and is given a site pass introduces ie

proper visitors. Site

other cars at shall be under pedestrian’s way and

housekeeping, Fractures 3 4 12 Engineer 2 2 4

Sump Pit Cleaning site leak taken into multiple vehicle way.

Slip and trip Foreman

aging. Serious checks.

falling. Proper TBT shall be HSE Personnel

injuries.

Only cars with valid given to workers and

third party shall be better skills on how to

allowed at site. keep area clean.

PPE shall be

implemented.

Sump Pit Cleaning Failure of Drivers and Introduction of driver

Moving Only authorized

control involved 3 5 15 and vehicle check list Site 2 2 4

vehicles. Property workers drivers with valid Full documentation Engineer

driving license shall foreman

damage. checking and color

Serious be allowed at site. coding system for fit

injuries. equipment at site.

Serious Competent

Unfamiliar with injuries. workers are only Regular monitoring Site

Working at to carry out the shall be emphasized

condition of Engineer

Sump Pit Cleaning night. Body task. from the start of work

work. 4 3 12 2 1 2

Feeling sleepy weakness. till the closer time. Foreman

Appropriate PPEs TBT shall be given before

hence fall of Male nurse

tools. the start of work.

High spread of

Workers and TBT about Isolation campaign

COVID-19 from Site

Sump Pit Cleaning staff shall be COVID-19 and social distance

the exchange of 5 4 20 Engineer 3 1 3

COVID-19 affected by awareness. keeping shall be

working tools.

Failure to read the high action taken.

Symptoms like dry Foreman

the symptoms of spread of First aid kits to be in place

cough, runny nose, Supervisor

COVID-19. COVID-19 and a ready stand

dizziness, among

others to be given. by team to handle

emergency cases.

Lack of Involved task

Emergency equipment like TBT to be Monthly equipment

force Site

response on conducted on inspection shall be

fire extinguishers visitors are in 4 4 16 Site 2 2 4

fire. to stop any fire proper use of implemented.

edges of Engineer

Sump Pit Cleaning equipment and TBT and other up to

start. Minor/major

similar uniform date fire warden

injuries Foreman

tools working. techniques to be Supervisor

Property displayed.

Cable looping shall

ESM5-Mod3-P007-F4 CLASSIFICATION: RESTRICTED Release Date: 19-sept-2023

Rev 0 UNCONTROLLED WHEN PRINTED Page 6 of 8

HSE Risk Assessment (Contractor)

damage. be prohibited due to

its live hazards.

PTW and Full tight inspection to be

Working for too Workers follow done by all the multi

long and task is WMS & RA senior staff. Site

not completed. Slip, trip, to brief to all staff. Area to be well Engineer

Fallin All pipe lines to barricaded.

Sump Pit Cleaning Workers tend to water. blocked and plug 5 3 15 Proper PPE to be Foreman 2 1 2

Working near work from and Major the wall and delivered to all task

miss place or position injuries ensureclose force. Supervisor

just to reach the properly.

task done. Fractures Check the TBT to be conducted by

conditionof the HSE personnel and give

ladder if require out all the dangers of

before use and fix working near miss.

properly inside the

tank and make sure

that ladder is

reaching

Adequate

Workers and Temporary

supervisors accessto be TBT on proper

arranged housekeeping and leaving Site

Slip, trip properly, the workplace in good Engineer

&falls Inspect the manners.

Equipment’s Foreman

Sump Pit Cleaning Minor / Major

During closer beforeall 3 2 6 2 1 2

Loading the injuries. deployed term is

time Close monitoring by the Supervisor

Equipment gone

End of task supervisor

and Materials Use of dust bin and

other

collection pits for

all the unwanted.

Improper Taskforce Introduction of Hot work

Mishandling

means of involved and Isolate the power system to be implemented

of electrical

handling other nearby supply priorto start Looping of electrical

Sump Pit Cleaning equipment

Lack of safe workers the task Wear cable should be action

like LED

guards. Major appropriate PPEs taken.

lights

Taskforce and injuries and use of Use of sign boards to

nearby workers. face shields, 4 3 12 be implemented. Site 2 2 4

Electrical masks among Active monitoring to be Engineer

ESM5-Mod3-P007-F4 CLASSIFICATION: RESTRICTED Release Date: 19-sept-2023

Rev 0 UNCONTROLLED WHEN PRINTED Page 7 of 8

HSE Risk Assessment (Contractor)

shock. others. maintained from the Foreman

Non-electrical start of work until the

tools to be used closing time.

inside the tank.

Conduct site specific

Removal of used Risk Assessment. All loads shall be divided

material Shifting Workers, Do not operate in to normal and single

Sump Pit Cleaning of cut off and visitors and pressure washer handled load. Site Engineer

other brokerages supervisors unless qualified Manual working tools 2 2 4

House Lack of andauthorized to and subjects shall be Foreman

keeping knowledge and Major do so given before the task of

3 3 9

skills. injuries. Read the work. HSE Personnel

Manufacturer Tight supervision shall

Instructions. be maintained all the

Wear all time while the operating.

requiredPPE.

All the working

yard shall be

barricaded and

signs shall be

put in place

Slip and trip Workers and Area shall be Only trained workers

Operation of falling Leakage visitors Major barricaded shall be allowed to Site Engineer

Pressure of oil and other injuries with warning operate the Jetting-

Washer’ liquids. tape. 3 4 12 machine. Foreman

High pressure Fractures Men at work Active monitoring 2 1 2

Sump Pit Cleaning sign post and should be maintained HSE personnel

many others while the activity is

shall be put in taking place.

place.

Slip and trip Workers and Area shall be Only trained workers

Operation of falling Leakage visitors Major barricaded shall be allowed to Site Engineer

Pressure of oil and other injuries with warning operate the Jetting-

Sump Pit Cleaning Washer’ liquids. tape. 3 4 12 machine. Foreman

Fractures

High pressure Men at work Active monitoring 2 1 2

sign post and should be maintained HSE personnel

many others while the activity is

shall be put taking place.

in place.

ESM5-Mod3-P007-F4 CLASSIFICATION: RESTRICTED Release Date: 19-sept-2023

Rev 0 UNCONTROLLED WHEN PRINTED Page 8 of 8

HSE Risk Assessment (Contractor)

ESM5-Mod3-P007-F4 CLASSIFICATION: RESTRICTED Release Date: 19-sept-2023

Rev 0 UNCONTROLLED WHEN PRINTED Page 9 of 8

You might also like

- Manage risks from air compressor workDocument2 pagesManage risks from air compressor workRafee Pie90% (10)

- Risk Assessment Form for Sand Blasting and PaintingDocument6 pagesRisk Assessment Form for Sand Blasting and PaintingRochdi Bahiri100% (10)

- 2 - Concrete MixerDocument2 pages2 - Concrete MixerRafee Pie100% (1)

- 27 Risk Assessment-Construction of Ecm Holding Tank and Silt TrapDocument5 pages27 Risk Assessment-Construction of Ecm Holding Tank and Silt TrapprabuNo ratings yet

- Scaffolding Erection and DismantlingDocument14 pagesScaffolding Erection and DismantlingDylan GreyNo ratings yet

- JSA Formet New Blasting & PaintingDocument5 pagesJSA Formet New Blasting & Paintingsakthi venkatNo ratings yet

- Kitacon generator hazard IDDocument2 pagesKitacon generator hazard IDRafee Pie100% (2)

- 01 Safety Operating Manual For Water Jetting WorkDocument16 pages01 Safety Operating Manual For Water Jetting WorkMohd Khaidir100% (1)

- JSA - Anti Termite Treatment WorkDocument5 pagesJSA - Anti Termite Treatment WorkRaju Khalifa67% (3)

- Risk Assessment New Warehouse Report Rev. 020124Document6 pagesRisk Assessment New Warehouse Report Rev. 020124Pyroclave Middle EastNo ratings yet

- Tools / Equipment:: Job Safety Analysis (Jsa)Document5 pagesTools / Equipment:: Job Safety Analysis (Jsa)Sameer AlmahboubNo ratings yet

- 31.HIRA - Boom Placer OperationDocument3 pages31.HIRA - Boom Placer OperationMMRDACA07 SAFETYNo ratings yet

- JSA Format Erection of Column 901-C-01Document9 pagesJSA Format Erection of Column 901-C-01sakthi venkatNo ratings yet

- ExcavationDocument73 pagesExcavationZien Mahmoud Ahmad0% (1)

- Hydrotesting Job Safety AnalysisDocument5 pagesHydrotesting Job Safety Analysissakthi venkatNo ratings yet

- JSA Format Erection of Exchanger 903-E-04Document6 pagesJSA Format Erection of Exchanger 903-E-04sakthi venkatNo ratings yet

- Block Work (Unit Masonary) RISK ASSESSMENTDocument8 pagesBlock Work (Unit Masonary) RISK ASSESSMENTVimal ViswanathNo ratings yet

- Activity-Based Risk Assessment For Asphalt Paving From PSA To Building 50-3 Inventory of Work ActivitiesDocument13 pagesActivity-Based Risk Assessment For Asphalt Paving From PSA To Building 50-3 Inventory of Work ActivitiesH.J KENo ratings yet

- Task Risk Assessment for Excavation, Backfilling, Leveling and CompactionDocument7 pagesTask Risk Assessment for Excavation, Backfilling, Leveling and CompactionBilal50% (2)

- Tra 002Document6 pagesTra 002Bilal0% (1)

- 2 - Concrete MixerDocument2 pages2 - Concrete MixerRafee Pie0% (1)

- Construction Risk AssessmentDocument21 pagesConstruction Risk AssessmentMuhammad Shahid Iqbal0% (1)

- Job Safety Analysis for Blasting and Painting WorkDocument11 pagesJob Safety Analysis for Blasting and Painting WorkRajuNo ratings yet

- 03 - Risk AssessmentDocument8 pages03 - Risk AssessmentSanu N100% (1)

- JSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformDocument6 pagesJSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformRaju KhalifaNo ratings yet

- Risk Assessment For MT Works in Port Road - DammamDocument4 pagesRisk Assessment For MT Works in Port Road - DammamRenatoNo ratings yet

- Risk Assessment 2A1Document10 pagesRisk Assessment 2A1Illias ShaikNo ratings yet

- Construction Risk AssessmentDocument19 pagesConstruction Risk AssessmentMuhammad Shahid Iqbal100% (3)

- Job Safety Analysis Work SheetDocument5 pagesJob Safety Analysis Work SheetMuhammad UsmanNo ratings yet

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- JRA-CDA-PL-049-REV-0 - Carousel General MaintenanceDocument4 pagesJRA-CDA-PL-049-REV-0 - Carousel General MaintenanceMiller DutraNo ratings yet

- JSA Format Internal ReactorDocument13 pagesJSA Format Internal Reactorsakthi venkatNo ratings yet

- Ra Fps-008-WeldingDocument11 pagesRa Fps-008-WeldinggrantNo ratings yet

- Risk AssessmentDocument7 pagesRisk AssessmentRenjith RaviNo ratings yet

- NEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalDocument15 pagesNEW Form JHA-Assembling & Dismatling of Crawler Crane-FinalKarthik babuNo ratings yet

- JSA Format Erection of Exchanger 903-E-01Document5 pagesJSA Format Erection of Exchanger 903-E-01sakthi venkatNo ratings yet

- ELEC/RA-001 Risk Assessment CCPP, MBPL: Pipe Rack and Bottom Ash AreaDocument12 pagesELEC/RA-001 Risk Assessment CCPP, MBPL: Pipe Rack and Bottom Ash AreaYuva samaj sewa TrustNo ratings yet

- Jsa For Pipe Fabrication ErrectionDocument8 pagesJsa For Pipe Fabrication Errectiondeepakkumaryadav841441No ratings yet

- 25 - ConcretingDocument1 page25 - ConcretingRafee Pie100% (1)

- Risk AssesmentDocument3 pagesRisk AssesmentShahd JaberNo ratings yet

- Job Safety Analysis For Civil WorkDocument9 pagesJob Safety Analysis For Civil Worksakthi venkatNo ratings yet

- Pipe Fabrication and Erection JSADocument8 pagesPipe Fabrication and Erection JSAjithin shankarNo ratings yet

- Risk AssesmentDocument4 pagesRisk AssesmentShahd JaberNo ratings yet

- JSA-Scaffolding Erection & Dismantling Works RV-00Document2 pagesJSA-Scaffolding Erection & Dismantling Works RV-00abou bakarNo ratings yet

- JSA PANEL SULLAYILDocument6 pagesJSA PANEL SULLAYILthennarasuNo ratings yet

- RA INSTALLATION Electrical PannelDocument7 pagesRA INSTALLATION Electrical PannelAmrou Ben RjebNo ratings yet

- RA Excavation For ExcavationDocument13 pagesRA Excavation For ExcavationSasi KumarNo ratings yet

- RA 13 (Water Proofing Membrane Application)Document4 pagesRA 13 (Water Proofing Membrane Application)abdulthahseen007No ratings yet

- JSA Risk Assessment Form for Pile Cutting JobDocument13 pagesJSA Risk Assessment Form for Pile Cutting JobYusuf HeryanaNo ratings yet

- Risk AssessmentDocument6 pagesRisk AssessmentRenjith RaviNo ratings yet

- JSA - Non-Destructive Testing (NDT) - Liquid Penetrant TestDocument5 pagesJSA - Non-Destructive Testing (NDT) - Liquid Penetrant TestRajuNo ratings yet

- Rse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerDocument2 pagesRse Iii Project - 5555 Risk Assessment: Piping Engineer, Supervisor, Foremen, Safety OfficerOws Anish100% (1)

- HEI JHA Leakage RectificationDocument7 pagesHEI JHA Leakage RectificationJavid AaqibNo ratings yet

- HIRARC Raised Floor SystemDocument6 pagesHIRARC Raised Floor Systemmohd zulhafizNo ratings yet

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- JSA Site Office Prep & Fabrication WHDocument9 pagesJSA Site Office Prep & Fabrication WHArib RahmanNo ratings yet

- RA Excavation For Trial TrenchDocument9 pagesRA Excavation For Trial TrenchSasi KumarNo ratings yet

- JRA 10-005 Insttalation of New Dodo GateDocument9 pagesJRA 10-005 Insttalation of New Dodo GateAijaz AhmedNo ratings yet

- Job Hazard Analysis: Format For JHA WorksheetDocument9 pagesJob Hazard Analysis: Format For JHA WorksheetWaseem AhmadNo ratings yet

- Naf 2020 Ra 012 00Document12 pagesNaf 2020 Ra 012 00vinayNo ratings yet

- Slab Coring Risk AssessmentDocument5 pagesSlab Coring Risk Assessmentadeniyi abiolaNo ratings yet

- 05-Division 2-Section 02200 GRP Pipelines MateriaDocument3 pages05-Division 2-Section 02200 GRP Pipelines MateriaSaim AliNo ratings yet

- Method Statement For PPR Pipes and Fittings InstallationDocument9 pagesMethod Statement For PPR Pipes and Fittings InstallationAnandu AshokanNo ratings yet

- Method Statement For Conduit Condition Evaluation (CCTV and Man Entry Survey)Document10 pagesMethod Statement For Conduit Condition Evaluation (CCTV and Man Entry Survey)Saim AliNo ratings yet

- Risk / Impact Assessment Control Sheet: MatrixDocument4 pagesRisk / Impact Assessment Control Sheet: MatrixSaim AliNo ratings yet

- Saim Ali Abbasi (Sep 2022) (1)Document1 pageSaim Ali Abbasi (Sep 2022) (1)Saim AliNo ratings yet

- Adult CPR GuidelinesDocument1 pageAdult CPR GuidelinesMarta Hrynyovska100% (2)

- ABG Answers Sheet - 2Document1 pageABG Answers Sheet - 2khryss100% (1)

- Bahasa Inggris Bu FanniDocument5 pagesBahasa Inggris Bu Fanninina purbaNo ratings yet

- The Best Care: Proposal for COVID-19 Home Testing KitDocument7 pagesThe Best Care: Proposal for COVID-19 Home Testing KitAin NatashaNo ratings yet

- Case Study An Older COVID-19 Patient in A Turkish IntensiveDocument7 pagesCase Study An Older COVID-19 Patient in A Turkish IntensiveAJENGNo ratings yet

- Oropharyngeal and Nasopharyngeal Suctioning (Rationale)Document3 pagesOropharyngeal and Nasopharyngeal Suctioning (Rationale)Jemina Rafanan Racadio100% (2)

- Test Bank For Nursing A Concept Based Approach To Learning Volume 2 1 Edition NcclebDocument36 pagesTest Bank For Nursing A Concept Based Approach To Learning Volume 2 1 Edition Ncclebmono.haiduck6htcr8100% (42)

- Saf06 Check List For Entry & Work in Enclosed Spaces PTWDocument5 pagesSaf06 Check List For Entry & Work in Enclosed Spaces PTWDmytroNo ratings yet

- Parainfluenza Viral DiseaseDocument4 pagesParainfluenza Viral DiseaseJulian Camilo Oviedo NaranjoNo ratings yet

- DPI PPE For Schools COVID VersionDocument43 pagesDPI PPE For Schools COVID VersionJitesh ThakurNo ratings yet

- Management of Cyanide PoisoningDocument3 pagesManagement of Cyanide PoisoningnadiaramadaniNo ratings yet

- HbA1c test results for two analyzersDocument9 pagesHbA1c test results for two analyzerstechlabNo ratings yet

- Asthma in AdultsDocument25 pagesAsthma in AdultsAnam MirNo ratings yet

- Epithelioid Hemangioendothelioma of The Superior Vena 2022 Archivos de BroncDocument1 pageEpithelioid Hemangioendothelioma of The Superior Vena 2022 Archivos de Broncguidance mtisiNo ratings yet

- The Heart Is A Muscular Pump That Moves The Blood Through Two PathwaysDocument3 pagesThe Heart Is A Muscular Pump That Moves The Blood Through Two Pathwaysdaija paulNo ratings yet

- Safety in The TheatreDocument13 pagesSafety in The Theatregiana 4eNo ratings yet

- Respi 2008 (Soal-Jawab)Document24 pagesRespi 2008 (Soal-Jawab)Debbi YuniseraniNo ratings yet

- Material Safety Data Sheet: Omyacarb 1T / 2T / 3T / 4T - SJDocument3 pagesMaterial Safety Data Sheet: Omyacarb 1T / 2T / 3T / 4T - SJHeri SetiyantoNo ratings yet

- Olahan Data Spps AmandaDocument47 pagesOlahan Data Spps AmandaRiyan NurdiansyahNo ratings yet

- Safety Data Sheet for Hydraulic OilDocument6 pagesSafety Data Sheet for Hydraulic OilaminNo ratings yet

- INSTRUMENTS For UGDocument22 pagesINSTRUMENTS For UGPugazhenthi CNo ratings yet

- MCN 2-Pedia-Clinical Scenario 6-RLE-PlanDocument3 pagesMCN 2-Pedia-Clinical Scenario 6-RLE-PlanMark oliver GonzalesNo ratings yet

- IN English: This Is Not For SaleDocument19 pagesIN English: This Is Not For SaleArianne B. CabañezNo ratings yet

- (Advances in Delivery Science and Technology) Kevin P. O'Donnell, Hugh D. C. Smyth (Auth.), Hugh D.C. Smyth, Anthony J. Hickey (Eds.) - Controlled Pulmonary Drug Delivery - Springer-Verlag NeDocument572 pages(Advances in Delivery Science and Technology) Kevin P. O'Donnell, Hugh D. C. Smyth (Auth.), Hugh D.C. Smyth, Anthony J. Hickey (Eds.) - Controlled Pulmonary Drug Delivery - Springer-Verlag NeEnrique Dirzo MartinezNo ratings yet

- NSTP 1 PrefinalsDocument22 pagesNSTP 1 PrefinalsSairah Camille ArandiaNo ratings yet

- AMC BLS Training TeamDocument6 pagesAMC BLS Training TeamRajasekhar BandiNo ratings yet

- Prevent COVID-19 Spread AwarenessDocument2 pagesPrevent COVID-19 Spread AwarenessIrish S. DelacruzNo ratings yet

- Material Safety Data Sheet Nag Champa: Emergency Phone Number Chemtrec: (24 Hours)Document3 pagesMaterial Safety Data Sheet Nag Champa: Emergency Phone Number Chemtrec: (24 Hours)Sudhit SethiNo ratings yet

- Contingency Plan For Face-to-Face Classes S.Y. 2022-2023Document21 pagesContingency Plan For Face-to-Face Classes S.Y. 2022-2023Mark Jayson Gonzaga100% (1)