Professional Documents

Culture Documents

Module # 8: 1. Design and Construction Features of Column Internals

Module # 8: 1. Design and Construction Features of Column Internals

Uploaded by

Ethio Face Event Organizer & EntertainmentOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Module # 8: 1. Design and Construction Features of Column Internals

Module # 8: 1. Design and Construction Features of Column Internals

Uploaded by

Ethio Face Event Organizer & EntertainmentCopyright:

Available Formats

NPTEL – Chemical Engineering – Chemical Engineering Design - II

Module # 8

MECHANICAL DESIGN OF MASS TRANSFER COLUMN: DESIGN OF

DISTILLATION AND ABSORPTION COLUMN

1. Design and construction features of column internals

1.1. Plate construction

1.2. Downcomer details

1.3. Feed inlets and side stream draws

1.4 Tray drainage

1.5 Tray manways

2. Column design specifications

3. Stresses developed in column

3.1 Axial and circumferential stresses

3.2. Compressive stresses caused by dead loads

3.3. Axial stresses due to wind loads

3.4. Analysis of stresses

Joint initiative of IITs and IISc – Funded by MHRD Page 1 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

Lecture 1: Column Construction and Internals

1. Design and construction features of column internals

1.1. Plate construction

Two types of plate constructions are practiced depending on the diameter of the column:

Sectional construction: The trays, downcomer segments and other tray components are

usually constructed in sections for column diameter of 1 m and above. The plate sections

are designed in such that it can be removed through the column manholes, preferably

detachable from both above tray and tray below. The plate sections are installedusually

starting from one side on a peripheral supported ring welded to inside shell wall. The

support ring is not normally extended into the downcomer area and tray perforations

needs to be avoided over the support ring area. Support ring width is usually between 40

to 90 mm. Trays are either clamped or bolted to the support ring.

The support beamsprevent tray deflection under load for larger diameter column. One or

more major beams are required for large diameter column (usually >3 m). Trays can be

supported by support rings and minor beams for small diametercolumn (usually <3 m)

i.e. omitting the major beams. The beams are commonly placed at about 0.6 m apart and

should able to hold on the necessary weight during column operation as well as

installation.The maximum plate deflection under the operating conditions should be less

than 3 mm for tower diameter more than 2.5 m ([1] page 564). The number of plate

sections installed under an apron and across accumulator trays is kept as minimum as

possible. Clearance should be provided between the bottom of the beams and the tray

below for the perpendicular installation of the beams to the liquid flow direction on the

tray below (Figure 8.1) i.e. in case of cross flow.

Joint initiative of IITs and IISc – Funded by MHRD Page 2 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

Figure 8.1. Common sectional construction of plate ([1] page 561).

Cartridge construction:

The cartridge or stacked type plate construction is used for column diameter smaller than

1 mas in such small diameter columns man entry to the column for the installation and

necessary maintenance work is difficult. Cartridge constructions are employed for sieve,

valve and bubble cap trays. The cartridge assemblies of 10 plates or so, are formed with

the help of screwed rods and plate spacer bars. The tall column is divided into numbers of

flanged sections and the prefabricated cartridge tray assemblies are installed in each

flanged sections with suitable downcomer clearance. The plates are not fixed to the shell

wall and leakage may occur.Avertical metal seal is frequently used around each tray to

decrease leakagearound the tray edge (Figure 8.2).

Joint initiative of IITs and IISc – Funded by MHRD Page 3 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

Figure 8.2.Common plate cartridge construction ([1] page 562).

Joint initiative of IITs and IISc – Funded by MHRD Page 4 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

1.2. Downcomer details

The liquid from the top tray is directed to the tray below through a downcomer or

downspout. The downcomer liquid flow passage is normally formed by a vertical plate

starting from the weir outlet, called an apron. The adequate residence time needs to be

ensured in the downcomers for the disengagement of vapor/gas from liquid. The

downcomer residence time of more than 3 s is desirable to get only clear liquid on the

tray. The different types of segmental downcomers constructions are shown in Figure

8.3. The bottom downcomer area is normally more than 50% of the top downcomer area

for sloped downcomers.

Figure 8.3. Design of segmental downcomers: (a) vertical apron, (b) inclined apron, (c) inlet weir and, (d) recessed well

([1] page 563).

Joint initiative of IITs and IISc – Funded by MHRD Page 5 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

1.3. Feed inlets and side stream draws

The feed liquid iscommonly introduced vertically downward into the downcomer of the

tray above the feed point through an open pipe. A slotted branch distributor is used for of

flashing feed (liquid)to avoid early flooding (Figure 8.4).The vapor is generally entered

the column tangentially through anopen inlet nozzle placed almost at right angles to the

liquid flow on the above tray.The clearance between the feed pipe end and feed plate

below is normallykept morethan 0.4 m when the feed liquid is flashed in active tray area.

Wider tray spacing is needed where the feed pipe and the side stream takeoff pipe to

provide a liquid seal are installed.

Figure 8.4. (a) Takeoff nozzles (draw off) and, (b) Feed ([1] page 564).

1.4 Tray drainage

Some amount of liquid is usually remains trapped on a bubble cap (positive seal tray) and

on certain valve trays when the column is shut down. This liquid is normally drains

through weep holes located near the outlet weirs. Weep hole diameter usually ranges

from 3 to 15 mm. The recommended weep hole area is 4 inch2per 100ft2 of tray area with

50 bubble caps and 4 inch weir to drain in about 8 h[3].

Joint initiative of IITs and IISc – Funded by MHRD Page 6 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

1.5 Tray manways

The maintenance workers travel from one tray to another through tray manways (Figure

8.1). The size of the manways should be such that a person can safely travel through a

tray manway segment and also it is removable through the column manholes. Manways

are usually rectangular and the recommended size is 40 cm×50 cm. Tray manways should

be removable from top and as well as from the tray below.

2. Column design specifications

The column specifications and operating conditions appended below are continued from

the process design calculations of sieve plate tower given in module #7.

Shell ID(𝐷𝑖 ):2403mm (𝐷𝑖 is denoted as 𝐷𝑇 in module #7)

Number of trays: 14

Tray spacing (𝑇𝑡 ): 600 mm

Hole diameter (𝑑 ):12 mm

Plate thickness (𝑡𝑡 ): 12 mm

Weir height (𝑊 ): 40 mm

Material for trays, down comers and weirs: Stainless steel SS304L

Shell material: Stainless steel (SS304L), double welded bolt joints

Allowable stress for shell material: 108×106Pa (108 MPa)

Density of shell material (𝜌𝑠 ) =7800 kg/m3

Skirt height:2 m

Operating pressure = 118825 Pa (bottom tray pressure)

Design pressure (𝑝) = 1.1×operating pressure = 130708 Pa

Operating temperature =56.3 to 105 °C

Design temperature= 1.1×maximum operating temperature = 116°C

Top disengaging space: 600 mm (same as the tray spacing taken)

Bottom separator space:1000mm

Insulation material taken: Asbestos

Insulation thickness considered: 50 mm

Density of insulation (𝜌ins ): 270 kg/m3(asbestos)

Joint initiative of IITs and IISc – Funded by MHRD Page 7 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

Minimum shell thickness (𝒕𝒔 ):

𝑝𝐷 𝑖 130708 ×2.403

𝑡𝑠 = 2𝑓𝐽 −𝑝 = 2×(108×10 6 )×0.8−130708 ; 𝐽 = 0.8

(8.1)

=1.81 ≈2 mm

Use 𝑡𝑠 =8 mm thickness including corrosion allowance of 6 mm. This value is in

accordance to IS 2844-1964.

𝐦𝐚𝐣𝐨𝐫 𝐚𝐱𝐢𝐬

Standard ellipsoidal head with𝐦𝐢𝐧𝐨𝐫 𝐚𝐱𝐢𝐬= 2:

𝑖 𝑝𝐷 130708 ×2.403

The minimum thickness required, 𝑡 = 2𝑓𝑗 −0.2𝑝 = 2× 108×10 6 ×0.8−0.2×130708

(8.1)

=1.81 mm ≈ 2 mm

The head thickness of 8 mm is selected with corrosion allowance of 6 mm for uniformity.

Column height (𝑯) ≈ 𝑇𝑡 + 𝑇𝑡 × 13 + 𝑡𝑡 × 14 + 1000

≈ 600 + 600 × 13 + 12 × 14 + 1000 ≈9.6 m

[Head height from the cylindrical portion of the column is neglected)

Joint initiative of IITs and IISc – Funded by MHRD Page 8 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

Lecture 2: Stresses Developed in Column

3. Stresses developed in column

3.1 Axial and circumferential stresses

The axial stress (𝒇𝒂𝒔 ) resulting from the internal pressure in a closed cylindrical shell is

given by ([2] page 155):

𝑝𝐷

𝑓𝑎𝑠 = 4𝑗 𝑡𝑜 [Pa]

𝑠

(8.2)

𝑝 =Internal column pressure (usually the design pressure is 5-10% higher than the

operating pressure), Pa

𝐷𝑜 =Column outside diameter (=𝐷𝑖 + 2 × 8 =2419 mm=2.419 m), m

𝑡𝑠 = Thickness of the column shell, m

𝑐 =Corossion allowance, m

𝑗=Joint efficiency

𝟏𝟑𝟎𝟕𝟎𝟖×𝟐.𝟒𝟏𝟗

𝒇𝒂𝒔 = 𝟒×𝟎.𝟖×(𝟖×𝟏𝟎−𝟑 ) = 12.4×106 Pa

(8.2)

Circumferential stress (𝒇𝒄𝒔 )=𝟐 × 𝒇𝒂𝒔

(8.3)

= 𝟐𝟒. 𝟖 × 𝟏𝟎𝟔 Pa

3.2. Compressive stressescaused by dead loads

Stress induced by shell (𝑓dead wt . shell ) and insulation (𝑓dead wt . insulation ) at any

distance, 𝑋, from the top of a vessel having a constant shell thickness ([2] page

156):

𝜋

𝑊𝑠𝑒𝑙𝑙 = 𝑚shell 𝑔 = [ 4 𝐷𝑜 2 − 𝐷𝑖 2 𝜌𝑠 𝑥]𝑔

(8.4)

Where, 𝑊 = Weight of shell above point 𝑥 from column top, kg.m/s2

𝐷𝑜 and 𝐷𝑖 = Outside and inside diameter of shell, m

𝑥 = Distance measured from the top of the vessel, m

s = Density of shell material, kg/m3

𝑔 =Gravity of the earth, m/s2

Joint initiative of IITs and IISc – Funded by MHRD Page 9 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

𝑚shell =Shell mass, kg

𝜋

𝑚shell = 𝐷𝑜 2 − 𝐷𝑖 2 𝜌𝑠 𝐻 × 1.2

4

(8.5)

𝜋

= 2.4192 − 2.4032 × 7800 × 9.6 × 1.2

4

≈5446 kg including 20% extra weight for head covers, flanges, bolting etc.

Shell weight stress ignoring corrosion allowance:

𝒎𝐬𝐡𝐞𝐥𝐥 𝒈

𝒇𝐝𝐞𝐚𝐝 𝐰𝐭. 𝐬𝐡𝐞𝐥𝐥 =𝝅

𝑫𝒐 𝟐 −𝑫𝒊 𝟐

𝟒

(8.6)

𝟓𝟒𝟒𝟔×𝟗.𝟖𝟏

=𝝅 ≈ 𝟏 × 𝟏𝟎𝟔 Pa

𝟐.𝟒𝟏𝟗𝟐 −𝟐.𝟒𝟎𝟑𝟐

𝟒

Weight of insulation, 𝑊ins = 𝑚ins 𝑔 = 𝜋𝐷𝑖𝑛𝑠 𝜌𝑖𝑛𝑠 𝑥𝑡𝑖𝑛𝑠 𝑔 [kg.m/s2]

(8.7)

Where, 𝐷𝑖𝑛𝑠 = mean insulation diameter, m

𝑡𝑖𝑛𝑠 = thickness of insulation, m

𝜌𝑖𝑛𝑠 = density of insulation, kg/m3

Mass of column insulation: 𝑚ins = 𝜋𝐷𝑖𝑛𝑠 𝜌𝑖𝑛𝑠 𝐻𝑡𝑖𝑛𝑠

= 𝜋 × 2.419 × 270 × 9.6 × 0.05 = 985 [kg]

Insulation weight stress:

𝑾𝐢𝐧𝐬

𝒇𝐝𝐞𝐚𝐝 𝐰𝐭. 𝐢𝐧𝐬𝐮𝐥𝐚𝐭𝐢𝐨𝐧 = 𝝅𝑫

𝒎 (𝒕𝒔 −𝒄)

(8.8)

𝟗𝟖𝟓×𝟗.𝟖𝟏

= 𝝅× 𝟐.𝟒𝟏𝟗+𝟐×𝟎.𝟎𝟓 [(𝟖−𝟔)×𝟏𝟎−𝟑 ] ≈ 𝟎. 𝟔 × 𝟏𝟎𝟔 Pa

𝐷𝑚 =mean shell diameter (≈ 𝐷𝑖𝑛𝑠 = 𝐷𝑜 + 2 × insulation thickness), m

Total liquid contents in the column depend on total number of trays, tray liquid

holdup, liquid in down comer etc. Stress resulted from liquid retained tower in vessel

is given by following equation ([2] page 157):

𝑊 liquid

𝑓dead wt . liquid = 𝜋𝐷 [Pa]

𝑚 (𝑡 𝑠 −𝑐)

(8.9)

Joint initiative of IITs and IISc – Funded by MHRD Page 10 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

Mass of liquid in the column:

Liquid depth on trays≈40+27.2≈68 mm [maximum of (𝑤 + 𝑤𝑐 ) in both sections]

Active area per tray (𝐴𝐴 )=3.616 m2 (please refer to module #7)

Liquid density= 955 kg/m3 [maximum liquid density one could get in both sections:

module #7]

Mass of liquid=(3.616×14×0.068×955)×1.3≈4274 kg

(This includes 30% additional liquid held in downcomers)

𝟒𝟐𝟕𝟒×𝟗.𝟖𝟏

𝒇𝐝𝐞𝐚𝐝 𝐰𝐭. 𝐥𝐢𝐪𝐮𝐢𝐝 = ≈2.6×106 Pa

𝝅× 𝟐.𝟒𝟏𝟗+𝟐×𝟎.𝟎𝟓 [(𝟖−𝟔)×𝟏𝟎−𝟑 ]

(8.9)

Stress induced by column attachments like trays, overhead condenser, instruments,

platform, ladders etc ([2] page 157):

𝑊 attachments

𝑓dead wt . attachments = [Pa]

𝜋𝐷𝑚 (𝑡 𝑠 −𝑐)

(8.10)

Mass of column attachments=5446 kg (Considering 100% of shell mass for column

attachments like trays, tray supports, overhead condenser etc.).

𝟓𝟒𝟒𝟔

𝒇𝐝𝐞𝐚𝐝 𝐰𝐭. 𝐚𝐭𝐭𝐚𝐜𝐡𝐦𝐞𝐧𝐭𝐬 = 𝝅× 𝟐.𝟒𝟏𝟗+𝟐×𝟎.𝟎𝟓 [(𝟖−𝟔)×𝟏𝟎−𝟑 ] ≈ 𝟑. 𝟒 × 𝟏𝟎𝟔 Pa

(8.10)

The total dead load stresses, 𝑓total acting along the longitudinal axis of the shell:

𝒇𝐝𝐞𝐚𝐝,𝐭𝐨𝐭𝐚𝐥 = 𝒇𝐝𝐞𝐚𝐝 𝐰𝐭. 𝐬𝐡𝐞𝐥𝐥 + 𝒇𝐝𝐞𝐚𝐝 𝐰𝐭. 𝐢𝐧𝐬𝐮𝐥𝐚𝐭𝐢𝐨𝐧 + 𝒇𝐝𝐞𝐚𝐝 𝐰𝐭. 𝐥𝐢𝐪𝐮𝐢𝐝 + 𝒇𝐝𝐞𝐚𝐝 𝐰𝐭. 𝐚𝐭𝐭𝐚𝐜𝐡𝐦𝐞𝐧𝐭𝐬

(8.11)

= 𝟕. 𝟔 × 𝟏𝟎𝟔 Pa<<allowable stress for the shell materials

Joint initiative of IITs and IISc – Funded by MHRD Page 11 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

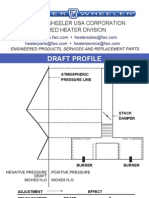

3.3. Axial stresses due to wind loads

The wind loading depends on wind velocity, air density and shape of the column ([2]

page 157). The maximum anticipated wind pressure of 2500 Pais used in this design. It is

considered that fours cables are equally placed for guyed column subtending an angle of

45° with vertical wall. The wind loading acting on a vertical vessel is given by:

1

𝑃𝑤 = 2 𝐶𝐷 𝜌air 𝑉𝑤 2 𝐴

(8.12)

Where,𝐶𝐷 = drag coefficient

𝜌air = density of air, kg/m3

𝑉𝑤 = wind velocity, m/s

𝐴 = projected area of the column normal to the direction of wind, m2

Above the guy ring: The column is designed like an unguyed vessel and the bending

moment is given byfollowing equation ([2] page 159), where 𝐻 = 𝑥.

1

𝑀𝑤 ,𝐻 = 2 𝑃𝑤 𝑥 2 𝐷eff

(8.13)

1

= 2 × 2500 × 9.62 × 2.419 + 2 × 0.05 =290kN

𝐷eff =Effective column diameter considering the insulation thickness, m

The bending stress due to wind load:

𝟒𝑴𝒘,𝑯

𝒇𝐰𝐢𝐧𝐝,𝑯,𝐚𝐛𝐨𝐯𝐞 𝐠𝐮𝐲 = (8.14)

𝝅𝑫𝒎 𝟐 𝒕𝒔 −𝒄

𝟒×𝟐𝟗𝟎×𝟏𝟎𝟑

= 𝝅×𝟐.𝟒𝟏𝟗𝟐 [(𝟖−𝟔)×𝟏𝟎−𝟑 ] = 𝟑𝟏. 𝟔 × 𝟏𝟎𝟔 Pa

Below the guy ring:The maximum bending moment caused by wind load from guyed

𝐻 3

wire to column located at above the base (𝑋 = 4 𝐻) is given by ([2] page 162):

4

𝑃𝑤 𝐻2𝐷 eff 𝑀𝑤 ,𝐻

𝑀𝑤 ,𝐻,guy (max ) = = =18.12kN

32 16

(8.15)

Corresponding bending stress:

𝟒𝑴𝒘,𝑯,𝒈 𝐦𝐚𝐱 𝒇𝐰𝐢𝐧𝐝,𝑯,𝐚𝐛𝐨𝐯𝐞 𝐠𝐮𝐲

𝒇𝐰𝐢𝐧𝐝,𝑯,𝐛𝐞𝐥𝐨𝐰 𝐠𝐮𝐲 = =

𝝅𝑫𝒎 𝟐 𝒕𝒔 −𝒄 𝟏𝟔

(8.16)

Joint initiative of IITs and IISc – Funded by MHRD Page 12 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

≈ 𝟐 × 𝟏𝟎𝟔 Pa

The compressive stress in column induced by guy wire tension, where angle 𝜃(45°) is

making by the guy wires with the vertical wall ([2] page 162):

0.04𝑃𝑤 𝐻𝐷eff

𝑓com ,guy = tan 𝜃 𝑡 𝑠 −𝑐 𝐷𝑜

(8.17)

0.04×2500 ×9.6× 2.419+2×0.05

= =0.5×106 Pa

1 ×[ 8−6 ×10 −3 ]×2.419

3.4. Analysis of stresses

For upwind side

Total stress = Bending stress 𝑓wind ,𝐻,above guy

+ Circumfarential 𝑓𝑎𝑠

−Radial stress 𝑓dead ,total (8.18)

= 31.6 + 12.4 − 7.6 ≈ 𝟑𝟕 𝐌𝐏𝐚

For downwind side

Total stress = Bending stress 𝑓wind ,𝐻,above guy

+ Axial stress 𝑓𝑐𝑠

+Compressive stress due to guy wires reaction(𝑓com ,guy )

−Radial stress 𝑓dead ,total (8.19)

= 31.6 + 24.8 + 0.25 − 7.6 ≈ 𝟒𝟗 MPa

The maximum stress of 49 MPa is much below the allowable design of stress of 108

MPa and the design is acceptable.

Note: Influence of seismic load is not considered in this lesson. The detailed stress

calculations and the underlying theories are discussed in module #6.

Joint initiative of IITs and IISc – Funded by MHRD Page 13 of 14

NPTEL – Chemical Engineering – Chemical Engineering Design - II

Practice problem: Perform the mechanical design of a bubble cap absorption column for

the removal of NH3 from a cracking operation using water as the scrubbing liquid. Refer

to module #7 (practice problem) for the details.

References

[1]. R. K. Sinnott, Coulson & Richardson’s Chemical Engineering: Chemical

Engineering Design (vol. 6), Butterworth-Heinemann, 3rd ed. 1999.

[2]. Brownell L.E. and E.H. Young, Process Equipment Design, John Wiley and Sons,

Inc. 1959. New York.

[3]. KisterH.Z. Distillation design, McGraw-Hill Inc., 1992, New York.

Joint initiative of IITs and IISc – Funded by MHRD Page 14 of 14

You might also like

- A Primer On Rectangular TanksDocument7 pagesA Primer On Rectangular Tanksfawmer61No ratings yet

- Astm F714Document10 pagesAstm F714santiago barrionuevoNo ratings yet

- Design of Overhead Water Tank 29Document28 pagesDesign of Overhead Water Tank 29rashmi bhailaNo ratings yet

- Process Equipment Design Chapter 4 - Storage VesselDocument53 pagesProcess Equipment Design Chapter 4 - Storage Vesselhugo100% (2)

- Rectangular Tank Engineering PracticeDocument7 pagesRectangular Tank Engineering PracticeJessicalba Lou100% (1)

- Tube Bending ProcedureDocument5 pagesTube Bending ProcedureJaime Zea67% (3)

- Adigrat University: College of Engineering and Technology Department of Chemical EnginneringDocument39 pagesAdigrat University: College of Engineering and Technology Department of Chemical EnginneringSeid Aragaw100% (1)

- Mechanical Design For Pressure VesselDocument26 pagesMechanical Design For Pressure VesselibicengNo ratings yet

- Thaioil WOOD High Pressure Heat Exchangers - Conventional 'D' Type Channel V Breech LockDocument29 pagesThaioil WOOD High Pressure Heat Exchangers - Conventional 'D' Type Channel V Breech LockPranpath NarupantawartNo ratings yet

- HTFS Presentation 2Document57 pagesHTFS Presentation 2Divyesh Patel100% (1)

- NTIW Tube Sheet PaperDocument10 pagesNTIW Tube Sheet PaperPankaj SinglaNo ratings yet

- Chapter One: Introdution To ProjectDocument21 pagesChapter One: Introdution To Projectabiy balkewNo ratings yet

- 882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDocument6 pages882design of Helical Baffle in Shell and Tube Heat Exchanger and Comparing With Segmental Baffle Using Kern Method PDFDavid Alemán Sánchez100% (1)

- Solving Heat Exchanger ProblemsDocument3 pagesSolving Heat Exchanger ProblemsThirukkumaranBalasubramanianNo ratings yet

- BreechLock HEDocument1 pageBreechLock HEibrahim1961No ratings yet

- Heat ExchangersDocument7 pagesHeat ExchangersAgustin Gago LopezNo ratings yet

- Working Principle of Shell and Tube Heat ExchangerDocument8 pagesWorking Principle of Shell and Tube Heat ExchangersanjayNo ratings yet

- Breech LockDocument12 pagesBreech LockPramod Dixit100% (1)

- CFD Analysis of Shell and Tube Heat Exchanger A ReviewDocument5 pagesCFD Analysis of Shell and Tube Heat Exchanger A Reviewteguh hady aNo ratings yet

- Pressure VesselprojectDocument26 pagesPressure VesselprojectMuhammadAli100% (1)

- Process Equipment DesignDocument27 pagesProcess Equipment DesignVivek NairNo ratings yet

- TEMA SelectionDocument15 pagesTEMA SelectionmaruthigabbitaNo ratings yet

- Pap 2Document68 pagesPap 2Aziz SyahrizalNo ratings yet

- Design CalculationDocument3 pagesDesign CalculationRavi AgarwalNo ratings yet

- Tube Roller ExpansionDocument12 pagesTube Roller ExpansionTejaswiNo ratings yet

- eBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeDocument18 pageseBroc-Shell and Tube Heat Exchangers Model Series and Customer Oriented Solutions, FunkeMoly69xNo ratings yet

- Applied Thermal Engineering: Farhad Nemati Taher, Sirous Zeyninejad Movassag, Kazem Razmi, Reza Tasouji AzarDocument7 pagesApplied Thermal Engineering: Farhad Nemati Taher, Sirous Zeyninejad Movassag, Kazem Razmi, Reza Tasouji AzarememNo ratings yet

- Fem For Inclined Pressure VesselDocument5 pagesFem For Inclined Pressure VesselPrayas SubediNo ratings yet

- Basics of Double Pipe Heat Exchanger (Heat Transfer Slides)Document38 pagesBasics of Double Pipe Heat Exchanger (Heat Transfer Slides)Asad Imran Munawwar100% (2)

- Heat Exchanger Checklist As Per TEMADocument6 pagesHeat Exchanger Checklist As Per TEMAMONANo ratings yet

- Equipment Design Group 12 ChE 4201 NewDocument26 pagesEquipment Design Group 12 ChE 4201 NewJazer Mari CantosNo ratings yet

- Bolted Flange Design According To ASME Section VIII Division 1Document18 pagesBolted Flange Design According To ASME Section VIII Division 1LORENA REISNo ratings yet

- Heat Exchanger DesignDocument41 pagesHeat Exchanger Designishita.brahmbhatt100% (1)

- TEMA Type Heat Exchangers PDFDocument4 pagesTEMA Type Heat Exchangers PDFkinjalpatel123450% (1)

- Bellows For Shell and Tube Heat ExchangersDocument32 pagesBellows For Shell and Tube Heat ExchangersRahul Mishra100% (1)

- Comparative Study EN 13445 / ASME Section VIII Div. 1 & 2Document48 pagesComparative Study EN 13445 / ASME Section VIII Div. 1 & 2Anand PatelNo ratings yet

- Packed Column InternalsDocument36 pagesPacked Column InternalsdinakaranpatelNo ratings yet

- Heat ExchangersDocument62 pagesHeat ExchangersMahmoud Abdelaal100% (2)

- Air Cooled Exchangers PDFDocument18 pagesAir Cooled Exchangers PDFRaghav SharmaNo ratings yet

- Menghitung TangkiDocument43 pagesMenghitung TangkiMuhammad TaqiyuddinNo ratings yet

- 17 ShellTubeExchangerDocument4 pages17 ShellTubeExchangermich0pNo ratings yet

- BN-DS-T29 Collar Bolts For Removable Bundle Heat ExchangerDocument1 pageBN-DS-T29 Collar Bolts For Removable Bundle Heat ExchangerAlexDdd123No ratings yet

- Design of Pressure VesselDocument137 pagesDesign of Pressure VesselAnand Bhandarkar75% (4)

- Process Equipment Design - I (ChE 553)Document32 pagesProcess Equipment Design - I (ChE 553)Debjyoti DasNo ratings yet

- Shell and Tube Heat Exchanger Design Using CFD ToolsDocument4 pagesShell and Tube Heat Exchanger Design Using CFD ToolsChockalingam AthilingamNo ratings yet

- PWHTDocument75 pagesPWHTAhmed Shaban Kotb100% (1)

- Heat Exchangers DesignDocument28 pagesHeat Exchangers Designagarwalashwin320% (1)

- Pressure Vessel DesignDocument68 pagesPressure Vessel DesignAchuat Deo0% (1)

- Shell and Tube Heat Exchanger DesignDocument3 pagesShell and Tube Heat Exchanger Design1AdityaPathania1No ratings yet

- Ideas To Achieve Optimal Combination of Axial & Cross FlowDocument28 pagesIdeas To Achieve Optimal Combination of Axial & Cross FlowAmirah SufianNo ratings yet

- B.16.5 Interpretation PDFDocument68 pagesB.16.5 Interpretation PDFmohdluthfiNo ratings yet

- Heat Exchangers SeminarDocument15 pagesHeat Exchangers SeminarShivang Gupta100% (1)

- Shell and Tube Heat ExchangerDocument7 pagesShell and Tube Heat ExchangerGaurav SharmaNo ratings yet

- Training Manual For PVelite Basic LevelDocument41 pagesTraining Manual For PVelite Basic LevelsudokuNo ratings yet

- The Plant Cell Wall: A Topical Study of Architecture, Dynamics, Comparative Chemistry and Technology in a Biological SystemFrom EverandThe Plant Cell Wall: A Topical Study of Architecture, Dynamics, Comparative Chemistry and Technology in a Biological SystemNo ratings yet

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988From EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNo ratings yet

- Column DesignDocument6 pagesColumn DesignVarun MalhotraNo ratings yet

- MDPE Final TutorialDocument4 pagesMDPE Final Tutoriallata sinsinwarNo ratings yet

- Design & Detailing of Water Retaining Structures & Pre Cast Water Tank Floor SystemDocument69 pagesDesign & Detailing of Water Retaining Structures & Pre Cast Water Tank Floor SystemAnonymous ciKyr0t94% (18)

- Chapter One: 1.1) Introduction of Pressure VesselDocument55 pagesChapter One: 1.1) Introduction of Pressure VesselAbenezer BirhanuNo ratings yet

- Pressure Vessel Training ModuleDocument40 pagesPressure Vessel Training ModuleIdil Fitri100% (1)

- Chapter (8) Design of Water TankDocument9 pagesChapter (8) Design of Water TankEng Hala Aboalfahem100% (1)

- ABSA News 008-V13-Iss1Document4 pagesABSA News 008-V13-Iss1Mas Arman TewoNo ratings yet

- BS 7910Document12 pagesBS 7910Mas Arman Tewo50% (2)

- ABSA Failure Alert IB06-003Document1 pageABSA Failure Alert IB06-003Mas Arman TewoNo ratings yet

- Torque of Stainless Steel, Non Ferrous TorqueDocument1 pageTorque of Stainless Steel, Non Ferrous TorqueMas Arman TewoNo ratings yet

- Engineering Critical Analyses To BS 7910Document15 pagesEngineering Critical Analyses To BS 7910Mas Arman TewoNo ratings yet

- FEA 107 Validation ExperimentDocument7 pagesFEA 107 Validation ExperimentMas Arman TewoNo ratings yet

- Ethylene Heat Flux John ZinkDocument4 pagesEthylene Heat Flux John ZinkMas Arman Tewo100% (1)

- 1386 - FM Front Page Industrial Burner HandbookDocument14 pages1386 - FM Front Page Industrial Burner HandbookMas Arman Tewo0% (1)

- Earthquake Loading Specified in GDocument3 pagesEarthquake Loading Specified in GMas Arman TewoNo ratings yet

- Causal Factor Chart and Fault Tree TemplateDocument7 pagesCausal Factor Chart and Fault Tree TemplateMas Arman TewoNo ratings yet

- Tall Vertical ColumnsDocument2 pagesTall Vertical ColumnsMas Arman TewoNo ratings yet

- Causal Factor Chart and Fault Tree TemplateDocument7 pagesCausal Factor Chart and Fault Tree TemplateMas Arman TewoNo ratings yet

- Fired Heater Checklist FW PDFDocument2 pagesFired Heater Checklist FW PDFMas Arman Tewo100% (2)

- Origin of Damascus Steel PDFDocument9 pagesOrigin of Damascus Steel PDFMas Arman TewoNo ratings yet

- Decline of Islamic Science PDFDocument21 pagesDecline of Islamic Science PDFMas Arman Tewo0% (1)

- Part 1 ISLAMIC TECHNOLOGY Transfer TO THE WEST PDFDocument14 pagesPart 1 ISLAMIC TECHNOLOGY Transfer TO THE WEST PDFMas Arman TewoNo ratings yet

- Goodyear Heat Exchanger Rupture PDFDocument10 pagesGoodyear Heat Exchanger Rupture PDFMas Arman TewoNo ratings yet

- Sample3 Drawing PDFDocument2 pagesSample3 Drawing PDFMas Arman TewoNo ratings yet

- Lifting LugDocument24 pagesLifting LugMas Arman Tewo100% (6)

- Onetuv Cheklist Design HTTPDocument3 pagesOnetuv Cheklist Design HTTPMas Arman TewoNo ratings yet

- SM 5 Units 2 MarksDocument25 pagesSM 5 Units 2 MarksSuriya DevNo ratings yet

- Strength of Materials - II Question Bank PDFDocument11 pagesStrength of Materials - II Question Bank PDFpavanNo ratings yet

- Thin Cylinder Experiment: Apparatus We Have Used A Thin Cylinder SM1007Document8 pagesThin Cylinder Experiment: Apparatus We Have Used A Thin Cylinder SM1007Rohan Kumar0% (1)

- Hoop Stress For Circular Pipes and Tanks: Ce123 - Lecture 2Document21 pagesHoop Stress For Circular Pipes and Tanks: Ce123 - Lecture 2Gray Fiore FullbusterNo ratings yet

- EMG 4103 SOLID AND STRUCTURAL MECHANICS III EXAM (Revised) - PrintreadyDocument4 pagesEMG 4103 SOLID AND STRUCTURAL MECHANICS III EXAM (Revised) - PrintreadyDuncoh DunNo ratings yet

- Download pdf Autofrettage Processes Technology And Modelling 1St Edition Uday S Dixit Author ebook full chapterDocument53 pagesDownload pdf Autofrettage Processes Technology And Modelling 1St Edition Uday S Dixit Author ebook full chapterfannie.wise916100% (2)

- Brittle Coat Test: Davalsab.M.LDocument14 pagesBrittle Coat Test: Davalsab.M.LKiran KumarNo ratings yet

- Anh - Anh Huong Cua Ap Suat Toi Ung Suat Cua Nong SungDocument6 pagesAnh - Anh Huong Cua Ap Suat Toi Ung Suat Cua Nong SungNguyen TuanNo ratings yet

- 4 Thick CylindersDocument66 pages4 Thick CylindersEswaran Parameswaran100% (4)

- Structural Strength Assessment For Unlined Steel Stack Using Finite Element Analysis Cst-1017Document8 pagesStructural Strength Assessment For Unlined Steel Stack Using Finite Element Analysis Cst-1017Srinivasa Rao VenkumahanthiNo ratings yet

- SOM 2 MarksDocument8 pagesSOM 2 MarksSiva ShanmugamNo ratings yet

- Reformer Furnaces - Material, Damage Mechanism and AssessmentDocument21 pagesReformer Furnaces - Material, Damage Mechanism and AssessmentMuhammad Noor FadhliNo ratings yet

- 06 Asme B31G 2009Document58 pages06 Asme B31G 2009JamesNo ratings yet

- Stress QuizDocument8 pagesStress QuizNagarjuna SeellaNo ratings yet

- ReporthuehuehueheuhuhuheeDocument14 pagesReporthuehuehueheuhuhuheeAnonymous GV18teQO8ONo ratings yet

- Design Calculation-Print A4Document51 pagesDesign Calculation-Print A4jne100% (1)

- DNV GL-ST-F101 Combined Loading CriterionDocument8 pagesDNV GL-ST-F101 Combined Loading Criterionandixmen2021No ratings yet

- 6.57 Onshore Pipeline Mechanical Design ReportDocument17 pages6.57 Onshore Pipeline Mechanical Design ReportSanjay Kumar100% (2)

- 2010 Fracture Control Strategy For Conversion of O&G Pipelines To CO2Document12 pages2010 Fracture Control Strategy For Conversion of O&G Pipelines To CO2hefflingerNo ratings yet

- 9A01401 Strength of Materials - IIDocument4 pages9A01401 Strength of Materials - IIsivabharathamurthyNo ratings yet

- Project Report On Piping StressDocument68 pagesProject Report On Piping StressAkshay GeraNo ratings yet

- Integrated Structural Health MonitoringDocument251 pagesIntegrated Structural Health Monitoringipali4christ_5308248No ratings yet

- Under Re - Attachment (Elastic Bend)Document4 pagesUnder Re - Attachment (Elastic Bend)ISRAEL PORTILLONo ratings yet

- Indian Standard: Criteria For Structural Design of PenstocksDocument14 pagesIndian Standard: Criteria For Structural Design of Penstocksanil basnetNo ratings yet

- Bearing & Thin WalledDocument17 pagesBearing & Thin WalledEmjay SevillaNo ratings yet

- CE6306-Strength of Materials Part-A EditDocument15 pagesCE6306-Strength of Materials Part-A EditgoldencometNo ratings yet

- Sickle PlateDocument26 pagesSickle PlateSambhav Poddar100% (1)