Professional Documents

Culture Documents

Q Itp 002 Structural Concrete Grouting Rev 0 01-08-19

Q Itp 002 Structural Concrete Grouting Rev 0 01-08-19

Uploaded by

boumalek ahmedOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Q Itp 002 Structural Concrete Grouting Rev 0 01-08-19

Q Itp 002 Structural Concrete Grouting Rev 0 01-08-19

Uploaded by

boumalek ahmedCopyright:

Available Formats

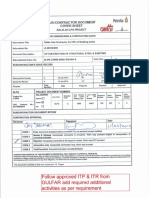

JESA INSPECTION AND TEST PLAN Doc N° JEJ-QXXXX-XX-IV/Q.

XXX/XXXXX Rev 0

Copy No. :

CONTROLLED COPY

INSPECTION & TEST PLAN (ITP)

Function: STRUCTURAL CONCRETE & GROUTING

Form: Q-ITP-002 Rev 0

1. Description : [Reference Document(s)] [Attributed Work Package(s)]

1. Receiving Inspection Report

1

2. Table of Contents 2. Batching Plant Calibration Certificate

1) Before Work Begins 3. Survey report

2) During Installation 4. Compaction report

3) After Installation 5. IFC Drawing

4) Review for the Final Quality Dossier 6. Signed Permit

7. Laboratory Test Reports

3. Scope 8. Site Work Instruction

This Inspection and Test Plan covers the inspection and testing requirements

9. From Work Inspection Report

for the following :

1. Formwork 10. Project Field QC System

2. Rebar 11. Pre Pour Inspection Report

3. Concrete pour 12. Grout Inspection Reports

4. Vibration 13. From Work Inspection Report

5. Finishing 14. MOS Quality Document

15. Punch List

Contr QM Contr CM/PM JESA QM JESA CM JESA PM OCP

Name:

Signature:

Date:

Rev Description Date Contr QM Contr CM JESA QM JESA CM JESA PM OCP

QC Document 1 of 7 Inspection Type:

Form: Q-ITP-002 Rev 0

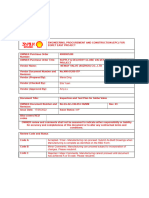

INSPECTION AND TEST PLAN

For Doc N° JEJ-QXXXX-XX-IV/Q.XXX/XXXXX Rev 0

STRUCTURAL CONCRETE &

GROUTING

Project Title: Contract No. :

OWNER: OFFICE CHERIFIEN DES PHOSPHATES (OCP) Contractor:

INSPECTION INVOLVEMENT

Item Controlling Document, Spec a/o Procedure Compliance/ Verifying

No.

Quality Control Activity

Acceptance Criteria Document REMARKS

Contr JESA Third Party OCP

BEFORE FIELD WORK BEGINS:

1 Equipment Calibrations Project Specs (Guidance Standards) Calibration Certificates DR DR H As applicable

2 Applicable quality plan & procedures Project Quality Plan ITP & Procedures Approved W DR Contr Quality Assuarance and Quality Control Plan, and ITPs

Drawings

3 Review Report IFC Drawings W S

4 Bench marks check 56500S IFC Drawing , Survey W W

Report

5 Work Permit Confirmation Project HSE System Signed Permit H H

6 Authorized personal documentation Project Specification Org Chart DR DR

Concrete batching plant certificates:

7 Water/ Cement/ Aggregate’s/ Admixture ratio and 56500S Batching Plant Calibration H H H

properties are determined as per project specification. Certificate

Laboratory Test Reports

8 Suitability tests for Concrete and Grout 56500S W W W

Material Certificates,

Material Receiving and Certificate (embedded and Laboratory Test Reports, Reinforcement bars: Tensile strength, bending test, elongation

9 reinforcement, Products) Insert Plates 56500S, (IFC drw. General notes for concrete works) MRM, RIR. DR DR test per spec

Welding procedures, and welder qualification for

10 welding jobs (embedded and reinforcement, Products) M-ITP- Welding Document Review Report W S If possible, the welding on site shall be avoided.

Insert Plates

App’d Cert. NDE /

11 Certification of NDE Personnel 56500S Personnel List DR DR

Carry outReview of NDE test reports for welding jobs App’d Cert. NDE /

12 (embedded and reinforcement, Products) Insert Plates 56500S Personnel List DR DR

(if applicable)

13 Cleaned area check Project specification Visual in place S S

Area must be clean prior to work start

DURING INSTALLATION

QC Document 2 of 7 Inspection Type:

INSPECTION AND TEST PLAN

For Doc N° JEJ-QXXXX-XX-IV/Q.XXX/XXXXX Rev 0

STRUCTURAL CONCRETE &

GROUTING

Project Title: Contract No. :

OWNER: OFFICE CHERIFIEN DES PHOSPHATES (OCP) Contractor:

INSPECTION INVOLVEMENT

Item Controlling Document, Spec a/o Procedure Compliance/ Verifying

No.

Quality Control Activity

Acceptance Criteria Document REMARKS

Contr JESA Third Party OCP

1 Cover concrete reinforcement: 56500S (IFC drw). Pre Pour Inspection Report W W NOTE: Required concrete reinforcement is specified in drawings.

Pre Pour Inspection

2 Concrete Formwork Layout and Elevation 56500S (IFC drw). Report / Visual & W W

dimensional survey Report

Visual & dimensional

3 Concrete Formwork Dimensions 56500S (IFC drw). survey Report W W

4 Placement of Reinforcement and Embeds per design and 56500S (IFC drw). Visual & dimensional W W

Drawings, Cleaned from Rust, and any foreran objects. survey Report

5 Dimensional Inspection of Reinforcement 56500S (IFC drw). Pre Pour Inspection Report W W

6 Anchor Bolts/ Sleeves Location, Spacing and Projection 56500S (IFC drw). Pre Pour Inspection Report W W

(measurement report "as-built")

Material Certificates,

7 Anchor bolts certificates check 56500S (IFC drw). Laboratory Test Reports, W W

MRM, RIR.

Release to pour concrete + Complete Concrete Approval Approval checklist / Visual

8 Checklist 56500S (IFC drw). inspection/Pre Pour W W

Inspection Report

9 Pre-pour inspection of grounding/earthing system IFC Drawings Grounding Inspection W W

installation Report

QC Document 3 of 7 Inspection Type:

INSPECTION AND TEST PLAN

For Doc N° JEJ-QXXXX-XX-IV/Q.XXX/XXXXX Rev 0

STRUCTURAL CONCRETE &

GROUTING

Project Title: Contract No. :

OWNER: OFFICE CHERIFIEN DES PHOSPHATES (OCP) Contractor:

INSPECTION INVOLVEMENT

Item Controlling Document, Spec a/o Procedure Compliance/ Verifying

No.

Quality Control Activity

Acceptance Criteria Document REMARKS

Contr JESA Third Party OCP

10 Surface inspection 56500S Pre Pour Inspection Report W W

(&): Log book to be maintained for daily recording details of total

structural concrete poured and items related traceability.

11 Slump test 56500S Laboratory Test Reports W W

12 Water stops 56500S Pre Pour Inspection Report W W

The concrete shall be always vibrated. The vibrators must have

dimensions available to penetrate in the formwork and between

13 Vibration to be followed during pouring 56500S Pre Pour Inspection Report W S the reinforcements without moving them. The thickness of the

layers to be vibrated shall not exceed SPEC. The max height of

free fall of the concrete will not exceed SPEC.

Formworks. Water on half hour before concrete

14 installation. In hot weather 56500S Pre Pour Inspection Report W W

15 Tests of conformity control (compressive strength of the 56500S Laboratory Test Reports W W H

structural concrete & grout)

56500S

16 Control joints Grout Inspection Reports W W

17 Grouting 56500S, (IFC drw. General notes for concrete works) Grout Inspection Reports W W

Laitenance Removal (Bushing) + Issue Release for Visual inspection / Release

18 Grouting 56500S, (IFC drw. General notes for Grouting works) Report W W

56500S compliance to standard

19 Grout Materials Testing Review Report W W

20 Grout Placement 56500S, (IFC drw. General notes for Grouting works) Visual inspection Report W W

QC Document 4 of 7 Inspection Type:

INSPECTION AND TEST PLAN

For Doc N° JEJ-QXXXX-XX-IV/Q.XXX/XXXXX Rev 0

STRUCTURAL CONCRETE &

GROUTING

Project Title: Contract No. :

OWNER: OFFICE CHERIFIEN DES PHOSPHATES (OCP) Contractor:

INSPECTION INVOLVEMENT

Item Controlling Document, Spec a/o Procedure Compliance/ Verifying

No.

Quality Control Activity

Acceptance Criteria Document REMARKS

Contr JESA Third Party OCP

21 Grout Curing 56500S, (IFC drw. General notes for Grouting works) Visual inspection Report W W

56500S compliance to standard

22 Grout Void Testing Review Report W W

23 Complete Installation checklist Grouting Log 56500S, (IFC drw. General notes for Grouting works) Approval checklist W W

24 Concrete Masonry Materials Testing 56500S, (IFC drw. General notes for concrete works) compliance to standard W W

25 Concrete Masonry Placement 56500S, (IFC drw. General notes for concrete works) compliance to standard W W

26 Concrete Masonry Testing 56500S, (IFC drw. General notes for concrete works) compliance to standard W W

AFTER INSTALLATION

Curing

1 Immediately concrete installation 56500S Inspection Report W W

2 Removal of form work. 56500S From Work Inspection W W

Report

Formed surfaces finish

3 Rough form, smooth form, architecture form 56500S Inspection Report W W

Repair work

4 For small holes 20x20mm filled with mortar 56500S MOS Quality Document W W

5 As built drawing and report 56500S Revised Drawings Report DR DR

6 Finishing inspection 56500S Final Inspection Repot W W

Site Work Instruction

7 Structure Release for Installation Works Site Work Instruction, 56500S Release inspection report / H H

Punch List

QC Document 5 of 7 Inspection Type:

INSPECTION AND TEST PLAN

For Doc N° JEJ-QXXXX-XX-IV/Q.XXX/XXXXX Rev 0

STRUCTURAL CONCRETE &

GROUTING

Project Title: Contract No. :

OWNER: OFFICE CHERIFIEN DES PHOSPHATES (OCP) Contractor:

INSPECTION INVOLVEMENT

Item Controlling Document, Spec a/o Procedure Compliance/ Verifying

No.

Quality Control Activity

Acceptance Criteria Document REMARKS

Contr JESA Third Party OCP

Final Quality Dossier

8 (Post Fab and Install): Review for the Final Quality Site Work Instruction MC General Review Report DR DR

Dossier

QC Document 6 of 7 Inspection Type:

INSPECTION AND TEST PLAN

For Doc N° JEJ-QXXXX-XX-IV/Q.XXX/XXXXX Rev 0

STRUCTURAL CONCRETE &

GROUTING

Project Title: Contract No. :

OWNER: OFFICE CHERIFIEN DES PHOSPHATES (OCP) Contractor:

INSPECTION INVOLVEMENT

Item Controlling Document, Spec a/o Procedure Compliance/ Verifying

No.

Quality Control Activity

Acceptance Criteria Document REMARKS

Contr JESA Third Party OCP

Description of Inspection degrees

Hold Point (H):

A point at which organization is required to notify the quality inspector prior to undertaking subsequent work. The party has to perform this check and it needs to be successful in order to proceed to the next stage of

the construction, attendance at the site is mandatory and signature is required on the check sheet of Inspection, Work shall not proceed without approval of Quality Control.

Witness Point (W):

This point is used to designate an operation in which the quality inspector requires to be notified about in due time before performance, Attendance at the site is expected, the signature is required on check sheet and

Checklist, but if the signatory is not present at the time, follow on work may proceed and the document(s) to be signed later.

Surveillance (S):

Observing or monitoring the work, inspection or test, random attendance at site, no signature required on the Inspection Request (ITN) or its accompanying documentation.

Review Point (DR):

Examination of records, document & test results to ensure compliance or to verify certain characteristics are met and that the check has been done and it passed.

QC Document 7 of 7 Inspection Type:

You might also like

- Inspection and Test PlanDocument58 pagesInspection and Test PlanTouil Houssem100% (1)

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- Itp For Piping Fabrication and Erection CorrectionDocument4 pagesItp For Piping Fabrication and Erection CorrectionAnand Ramachandran67% (3)

- Catalog PDFDocument92 pagesCatalog PDFSolomon Ndugwa BalemeziNo ratings yet

- Inspection and Test Plan (ITP) WeldingDocument3 pagesInspection and Test Plan (ITP) WeldingMuhammed Abo-Fandood100% (5)

- Water Tank ItpDocument5 pagesWater Tank Itptuan mai vanNo ratings yet

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Img 0004Document3 pagesImg 0004Shruti BhatiaNo ratings yet

- 21 07 Bidders ListDocument10 pages21 07 Bidders ListJAGUAR GAMINGNo ratings yet

- Vol III Design Basis ReportDocument97 pagesVol III Design Basis ReportTamilkumar D (Tamil)No ratings yet

- Itp For Stacker ReclaimerDocument77 pagesItp For Stacker ReclaimerAlif Rahmat Febrianto100% (2)

- Inspection & Test Plan (Itp)Document6 pagesInspection & Test Plan (Itp)Pahlevi MattasanNo ratings yet

- Itp For Field Erected Tank Rev A PDF FreeDocument9 pagesItp For Field Erected Tank Rev A PDF FreeMahmoud GaberNo ratings yet

- Plant Location Company Doc. No. NADocument8 pagesPlant Location Company Doc. No. NAsivaNo ratings yet

- Planning and Design Handbook On Precast Building StructuresDocument137 pagesPlanning and Design Handbook On Precast Building StructuresBashar Alshathir100% (1)

- ITP - Earth WorksDocument8 pagesITP - Earth WorksVasilica BArbarasaNo ratings yet

- Construction SpecificationsDocument12 pagesConstruction SpecificationsChristian VillenaNo ratings yet

- W QC A 009 Rev1 Written PracticeDocument17 pagesW QC A 009 Rev1 Written PracticeAlif Rahmat FebriantoNo ratings yet

- ITPDocument7 pagesITPSyed Mahmud Habibur Rahman83% (6)

- Field Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-018Document8 pagesField Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-018bernard100% (1)

- Field Quality Control PlanDocument59 pagesField Quality Control Plan1339979100% (2)

- Itp and Test Plan Rubber Fender Rev. 0Document5 pagesItp and Test Plan Rubber Fender Rev. 0Danu Sutanto100% (1)

- Heat Exchanger QAPDocument3 pagesHeat Exchanger QAPRajnikant PatelNo ratings yet

- Npe SD Sqe Pip Ax4303 0009 Pad Leak TestDocument7 pagesNpe SD Sqe Pip Ax4303 0009 Pad Leak TestYulian Adhriansyah100% (1)

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- Prosedur Plumbness MJKDocument9 pagesProsedur Plumbness MJKAnonymous xdBQM5VkYNo ratings yet

- P1066-CTD-QAC-ITP-001-Rev-C-ITP For Fabrication, Erection & Testing of Tank WorkDocument9 pagesP1066-CTD-QAC-ITP-001-Rev-C-ITP For Fabrication, Erection & Testing of Tank WorkEILA545 QAQCNo ratings yet

- ITP Fencing Rev - 00 PDFDocument3 pagesITP Fencing Rev - 00 PDFanon_987276020No ratings yet

- HTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRADocument10 pagesHTG365. QAC. Inspection and Test Plan REV 2. 2022 06 24 (2) MRAGreg Rabulan100% (1)

- P1066-CTD-QAC-ITP-002-B-Inspe... of Structural Steel WorkDocument4 pagesP1066-CTD-QAC-ITP-002-B-Inspe... of Structural Steel WorkEILA545 QAQCNo ratings yet

- 017-W005-2667 - ITP - PDA Test Rev C0Document3 pages017-W005-2667 - ITP - PDA Test Rev C0Mohammad Hadoumi SaldanNo ratings yet

- 20SRV002-NGL-QC-ITP-001 Rev C0Document11 pages20SRV002-NGL-QC-ITP-001 Rev C0mohd as shahiddin jafri100% (1)

- Field Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-006Document7 pagesField Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-006bernardNo ratings yet

- Field Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-016Document7 pagesField Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-016bernardNo ratings yet

- Field Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-017Document14 pagesField Inspection & Test Plan (F-Itp) : DOC. NO.: I-T3108-QAQC-017bernardNo ratings yet

- Title: Inspection & Test PlanDocument3 pagesTitle: Inspection & Test PlanNova CastyNo ratings yet

- Exw P023 0003 Ci Laj It 00001 - CCDocument16 pagesExw P023 0003 Ci Laj It 00001 - CCCesar DuriasNo ratings yet

- Inspection Check List: FV R E M I C L 0 4 5 0 0Document2 pagesInspection Check List: FV R E M I C L 0 4 5 0 0Samboy DionisioNo ratings yet

- Shop ItpDocument4 pagesShop ItpRanu JanuarNo ratings yet

- 25045-A1000-18-ITP-E-003r003 - ITP Works For Conduit Underground and DuctbanksDocument12 pages25045-A1000-18-ITP-E-003r003 - ITP Works For Conduit Underground and DuctbanksmsmkhanNo ratings yet

- Carpet LayingDocument7 pagesCarpet Layingparesh.ahirNo ratings yet

- Asorc-Qcp 1652 ModifiedDocument22 pagesAsorc-Qcp 1652 ModifiedalkhiatNo ratings yet

- Performance Qualification For Rotary PressDocument51 pagesPerformance Qualification For Rotary Pressua2848580No ratings yet

- 14A. 2082-PM-ITP-7016 Rev.0 - SITE ITP InsulationDocument8 pages14A. 2082-PM-ITP-7016 Rev.0 - SITE ITP InsulationAmarKumarNo ratings yet

- Weekly Report For Control Valve - REV 0 15 January 2023Document12 pagesWeekly Report For Control Valve - REV 0 15 January 2023Andy ArdianNo ratings yet

- FM-NPD-12 (IPP Handover Check List)Document1 pageFM-NPD-12 (IPP Handover Check List)akash.vd.1603No ratings yet

- AGP-22050-ITP-PIP-Q01-0002 00 - ITP For Piping Erection and AssemblyDocument46 pagesAGP-22050-ITP-PIP-Q01-0002 00 - ITP For Piping Erection and Assemblyangelito bernalNo ratings yet

- 0000100324/17-Civil Inspection and Test Plan: 0000100324/17 03-100000-0000100324 - FTC-CIV-ITP-xxxxxxDocument1 page0000100324/17-Civil Inspection and Test Plan: 0000100324/17 03-100000-0000100324 - FTC-CIV-ITP-xxxxxxMeshaal ALBalharithNo ratings yet

- QP06-Appendix 2 - ITP Form PDFDocument2 pagesQP06-Appendix 2 - ITP Form PDFryan christian TaccadNo ratings yet

- 25045-A1000-18-ITP-E-004r004 - ITP For Underfloor RacewayDocument8 pages25045-A1000-18-ITP-E-004r004 - ITP For Underfloor RacewaymsmkhanNo ratings yet

- Mobis Isir ManualDocument17 pagesMobis Isir ManualGabriel MolinaNo ratings yet

- AGP-22050-ITP-SPC-Q01-0001 00 REV 0 ITP For Surface Preparation and CoatingDocument18 pagesAGP-22050-ITP-SPC-Q01-0001 00 REV 0 ITP For Surface Preparation and Coatingangelito bernalNo ratings yet

- IQWQ-CE1091-VPNDT-00-2566 - A PT ProcedureDocument23 pagesIQWQ-CE1091-VPNDT-00-2566 - A PT Procedurejacksonbello34No ratings yet

- EG.02.J.96.053.102NM 03 1 PublicationDocument6 pagesEG.02.J.96.053.102NM 03 1 Publicationfhairuz.wahidNo ratings yet

- QAR-QD#419-2 Single PartsDocument2 pagesQAR-QD#419-2 Single PartsIrwanto ManafNo ratings yet

- Itp Pi 001 Piping Work RevDocument8 pagesItp Pi 001 Piping Work Revcrusher28No ratings yet

- H1006400MKF51 Sa12qt 01Document4 pagesH1006400MKF51 Sa12qt 01MarcoNo ratings yet

- NPK-SGS-PFC - Sir - 13R00 - Sir 16062017Document7 pagesNPK-SGS-PFC - Sir - 13R00 - Sir 16062017dang2172014No ratings yet

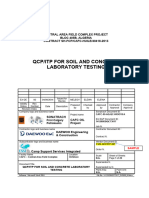

- QCP - ITP For Soil & Concrete Laboratory Testing - CSSIDocument29 pagesQCP - ITP For Soil & Concrete Laboratory Testing - CSSIM'HAMED BENKREIRANo ratings yet

- Embankment - Fill: Inspection & Test PlanDocument4 pagesEmbankment - Fill: Inspection & Test PlanJeff AlinayaNo ratings yet

- Qa-R-01 List of Measuring Equipment and Calib. DueDocument2 pagesQa-R-01 List of Measuring Equipment and Calib. DuevinothNo ratings yet

- Inspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationDocument3 pagesInspection and Test Plan (ITP) : REFERENCE AWS D1.1 Ed.2015 & Client SpecificationKhaled GamalNo ratings yet

- 8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9503-00001 - 00 - ItpDocument5 pages8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9503-00001 - 00 - ItpRami KsidaNo ratings yet

- Inspection Task Report No. - 1 - : Rev.01 1 Inspection Activity Hydrotest of FlowlineDocument17 pagesInspection Task Report No. - 1 - : Rev.01 1 Inspection Activity Hydrotest of FlowlinehilalNo ratings yet

- Set - 1 - Excon - SP-22.pmd - Excon - ShowPReview - FInal - 290422 - Ebook1Document348 pagesSet - 1 - Excon - SP-22.pmd - Excon - ShowPReview - FInal - 290422 - Ebook1Chandra SekaranNo ratings yet

- 3.5. Liability of The Civil Engineer and The Client: Breach of Duty of Care Break of Client's DutyDocument2 pages3.5. Liability of The Civil Engineer and The Client: Breach of Duty of Care Break of Client's DutyCharlie OnlyNo ratings yet

- ERA Menteinance SpecificationDocument149 pagesERA Menteinance SpecificationGizachew belayNo ratings yet

- Machine For Concretepropo-2Document18 pagesMachine For Concretepropo-2birhanu morkaNo ratings yet

- Maharastra Nhai Report PDFDocument33 pagesMaharastra Nhai Report PDFASHWINEENo ratings yet

- Mechanical Permit: Office of The Building OfficialDocument2 pagesMechanical Permit: Office of The Building OfficialCrystal TutorNo ratings yet

- Neopolitan 90 (NP90) : Wood-Gas Fired OvensDocument2 pagesNeopolitan 90 (NP90) : Wood-Gas Fired OvensjhonathanNo ratings yet

- Bulkhaul Standard NewDocument4 pagesBulkhaul Standard NewAntónio TrindadeNo ratings yet

- Item Description QTY Unit Price /unit (PHP) Price (PHP) Remarks Bill of MaterialsDocument1 pageItem Description QTY Unit Price /unit (PHP) Price (PHP) Remarks Bill of MaterialsEdciel EbuenNo ratings yet

- Details Sample 4 Roof Eve PDFDocument1 pageDetails Sample 4 Roof Eve PDFNg TzewayNo ratings yet

- A05 Elevations 1 & 2Document1 pageA05 Elevations 1 & 2Daniel EvansNo ratings yet

- HV Cable Installation ChecklistDocument2 pagesHV Cable Installation ChecklistbabanNo ratings yet

- Part Number 6311-Z-NR-C3, Deep Groove Ball Bearings (6000, 6200, 6300, 6400)Document3 pagesPart Number 6311-Z-NR-C3, Deep Groove Ball Bearings (6000, 6200, 6300, 6400)Travis DavisNo ratings yet

- B1 SampleDocument3 pagesB1 SampleƏlihəsən TəhməzliNo ratings yet

- 29 - Bechtel r2 Project Execution Plan - Ac Submission PDFDocument53 pages29 - Bechtel r2 Project Execution Plan - Ac Submission PDFtarek.abbas8598No ratings yet

- Eccentric Details CLR For Yadaw 06-01-2020Document1 pageEccentric Details CLR For Yadaw 06-01-2020Husen GhoriNo ratings yet

- OK - LVT Interface PDFDocument19 pagesOK - LVT Interface PDFJavier Molina DelgadoNo ratings yet

- Cementitious WaterproofingDocument5 pagesCementitious WaterproofingLong An ĐỗNo ratings yet

- MOMENT Grout CouplersDocument15 pagesMOMENT Grout CouplersDio DikaNo ratings yet

- Standar Operational Procedure (Civil)Document7 pagesStandar Operational Procedure (Civil)sefinaNo ratings yet

- Preinstallation VerificationDocument5 pagesPreinstallation VerificationbalamuruganNo ratings yet

- NZTA P11E N Draft v4 30 Sep 21Document6 pagesNZTA P11E N Draft v4 30 Sep 21Ramy HusseinNo ratings yet

- Abb Weather ProofDocument58 pagesAbb Weather ProofEhsan ShaukatNo ratings yet

- RCC A3 Size ChartDocument1 pageRCC A3 Size ChartRam TqrNo ratings yet

- Sushant School of Art and ArchitectureDocument6 pagesSushant School of Art and Architectureankushsingla.barch21No ratings yet